TRADEDOR TD55DM User manual

Tradedor TD55DM & TD55SEL Installation Guide

TD55DM & TD55SEL

Installation Guide

Tradedor TD55DM & TD55SEL Installation Guide

1

Installation Guide

Finished door

Tradedor TD55DM & TD55SEL Installation Guide

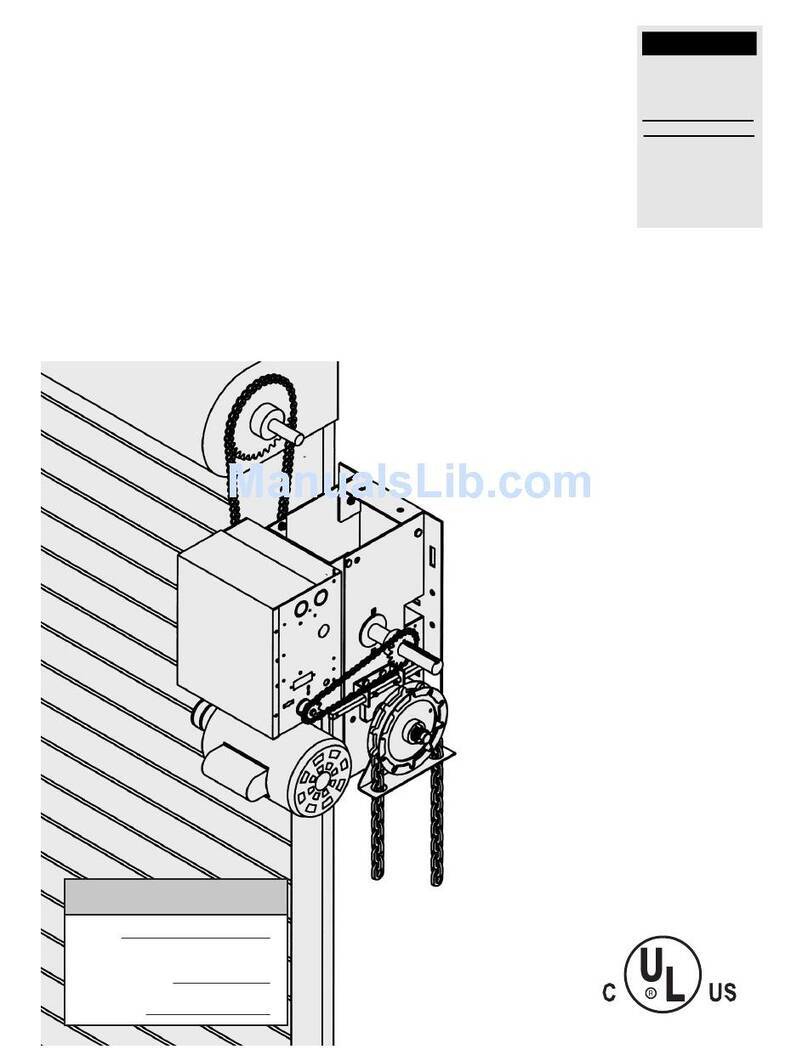

10 11 12 13 7 15 14

21 3 4 5 6 7 8 9 1

Diagram 1

Door Overview

Please check all components for

any visible damage, if there is

any please contact your supplier.

1 Head Plate

2 Guides

3 Full Box

4 Tube End

5 Barrel

6 Security Straps

7 Curtain

8 Motor

9 Motor Plate

10 Guide Rail

11 Plastics Caps

12 End Lock

13 Base Rail

14 Remote Control Fob

15 Switches (if any)

2

Equipment Required

• 2 x Step ladders or hop ups

• Spirit level

• Tape measure

• Power drill

• 10mm A/F Spanner

• 2 x Pozi-screwdrivers

• 7mm Metal drill bit

• 10mm Metal drill bit

• 7mm Masonry drill bit

• Hacksaw

• Small electrical screwdriver

• 4mm A/F Allen key

Tradedor Component Checklist

• Door Curtain.

• Barrel Assembly (Barrel, Tube End, Security Springs,

Security Collars).

• Head Plate with Motor Attached.

• Head Plate.

• One Pair of Guide Runners.

• Control System with Two Remote Fobs.

• Fixings Kit (Qty 10: 5 x 50 screws 7mm brown rawl

plugs, plastic caps and Qty 1 plastic adjustment wand).

Please note: xings supplied work on the majority of

materials but if you know that you require specialised

xing please replace with these.

Checklist & Components

Tradedor TD55DM & TD55SEL Installation Guide

These tting instructions are for guidance only, you should always assess your garage construction

for installation as each garage & opening has its own specic needs. Please read these instructions

carefully and in full before commencing the installation of the roller garage door.

3

IMPORTANT SAFETY

INSTRUCTIONS

The RD55 Econ must be installed

and operated in accordance with the

instructions supplied; failure to do

so could result in damage to your

door and compromise your safety.

WARNING AND GUIDANCE NOTES

1 At least TWO people are required to install this product.

2 Prior to installing please remove all rings, watches and

sharp objects to avoid any possibility of damage.

3 Prior to installing please remove any items of loose

clothing to avoid any risk of entanglement or injury.

4 Your door comes complete with a 3 pin plug as

standard (this is supplied and must be fitted with

a 13amp fuse) which should be plugged straight

into a 13amp 3 pin switched socket in the vicinity

of your door, should you need any extra electrical

work. This must be carried out by a suitably qualied

person, if you have any doubts please consult an

electrician.

5 Your receiver box should be installed in a location that

is at a comfortable height to operate the push buttons,

but out of the easy reach of children.

6 Please do not allow children to operate the push

buttons or remote control fobs, as serious injury can

occur from misuse.

7 Warning: you must have a clear line of sight of the

whole of your roller garage door when the door is

in operation. Failure to do so may result in harm to

persons or damage to your roller garage door.

Warning & Guidance

Tradedor TD55DM & TD55SEL Installation Guide

g.1.1

g.1.2

4

1 Check all the measurements of your new

garage door against your order conrmation

and double check your opening size to make

sure everything is correct (g.1.1) & (g.1.2).

2 Carefully remove your old garage door

and frame if applicable.

3 Sweep down the sides and lintel with a stiff

brush and clear all debris.

4 Make sure the opening is free from any

raised metal or brick work.

1. Preparing Site For Installation

Tradedor TD55DM & TD55SEL Installation Guide

5

A Top xing between 50mm to 100mm

down from the top of the guide rail.

B Bottom xing 50mm to 100mm up

from the oor.

C Marking at least one other xing,

spread these evenly between the

two already marked points on the

guide runners so that you have

a secure xing.

D Drill a 7mm hole all the way through

each of the marks on the guide

runners and then drill a 10mm hole

to countersink through the first

layer only so you can get the screw

head through.

1 Both guide runners will be marked

with the letter ‘F’ to indicate the front.

This has the flat face when looking

in the rear box section of the guide

runner (g.2.1). It will t against the

wall for a behind fixing or face out

of the garage for a between fixing.

2 Measure from oor to lintel and refer to

diagram 2, checking the lintel is level.

Cut the guide runners to size as needed

using a hack saw, for best results cut the

end which will be the bottom (g.2.2).

3 Offer both cut guide runners up against

the walls they will be xed to and mark

the xing points, either on the at face

for a behind xing (g.2.3) or for a between

xing in the opening (g.2.4). For best

results these should be as follows; g.2.1 Please be aware that guide rails may vary in prole from picture

g.2.2

g.2.4

g.2.3

Front Face

2. Preparing Guide Runners

For Installation

Tradedor TD55DM & TD55SEL Installation Guide

Fixing Options

Below Lintel Fixing:

Cut guide runners to measured height less 210mm.

Limited Opening Fixing:

Measure from oor to highest point, deduct 210mm and cut guide runners to size.

Behind Lintel Fixing:

Cut guide runners to measured height.

LINTEL

ROOF OR

JOISTS

GUIDE

RUNNER GUIDE

RUNNER GUIDE

RUNNER

TOP

ROLL

TOP

ROLL

TOP

ROLL

LINTEL LINTEL

ROOF OR

JOISTS

Behind lintel fixing’ 3Limited opening fixing 2Below lintel fixing 1

205

MM

< >

205

MM

< >

205

MM

< >

ROOF OR

JOISTS

123

Diagram 2

6

Tradedor TD55DM & TD55SEL Installation Guide

1 Place your hop ups / step ladders and one

guide runner each side of the opening.

2 If you have a safety edge system on your

door then you will need to remove the

securing screw.

3 With one person each end, lift the header

assembly by the header plate up and into

place, then guide the locating stem at each

end into the hollow section of guide runners

(this can be made easier by slightly angling

the header if there is not enough room to

simply drop the locating stem in) (g.3.1).

4 Lift the whole unit ush into place and check

that the top box and guide runners are plumb

level and square (g.3.2 & g.3.3).

5 Drill a 7mm xing through the top hole in

the guide runners and secure into place

(g.3.4).

6 Check the case and guide runners are

still level and square, then proceed to drill

a 7mm xing through the remaining holes,

remembering to check the guide runners

are square and plumb after each xing.

7 Check to make sure all xings have not

caused the front fascia to be pulled in,

as this will rub against the slats causing

damage and scratching to the face.

8 Making sure 1 person is holding the back

case in place remove any screws from

each end and keep safe for later, then lift

the backcase up so it can be removed to

expose the curtain of the door.

9 (For Internal Manual Override system)

Remove winding stem from your winding

handle where it has been taped securely.

10 (For External Manual Override system)

remove metal shaft via the plastic circlet

(p.34, g.15.1, number 4 ).

g.3.1

g.3.3

g.3.2

g.3.4

11 Remove screw from end of stem and keep

safe for later.

12 Cut cable ties and release curtain, and place

available curtain into guide rails through the

mouth of the guides.

13 Insert winding stem through pre-drilled hole

in header plate. Turn to release more curtain

into guides, roughly 4 slats in total, remove

winding stem and keep safe for later.

7

3. Installing Header Assembly

Tradedor TD55DM & TD55SEL Installation Guide

Finished door from inside

8

Tradedor TD55DM & TD55SEL Installation Guide

1 Carefully remove the cover by sliding it upwards

from the enclosure, there is a membrane ribbon

from the buttons on the box to the internal pcb

board, please remove this from the pcb board

by pulling carefully upwards.

2 Drill a 5mm hole in the wall roughly the centre

of where you would like to x the receiver box,

then using the supplied xings insert one of the

6mm wall plugs into the hole and screw one

of the screws into this leaving approximately

10mm of screw head and thread showing.

3 Slide the rear of the receiver box at against

the wall and over the screw to hold in place

and make sure it is level and square while you

mark the remaining two xings located at the

bottom of the receiver box.

4 Remove receiver box from wall and drill 5mm

holes into these two marks then place the

remaining 6mm wall plugs into the holes.

5 Slide the receiver box back over the top screw

and using xing provided secure the bottom

two lugs in place.

6 Remove the green 4 terminal motor connector

from the board (g.4.1) and you will see the

letters on the board underneath.

7 Wiring as follows;

Pre wired Mains Power:

N– Neutral / Blue power cable

L– Live / Brown power cable

E – Earth / Green/Yellow

power cable

g.4.1

Motor:

E– Green/Yellow motor cable

N– Blue motor cable (4 core)

L– Brown motor cable (4 core)

L– Black motor cable (4 core)

9

4. Installing Receiver Box

(HOLD TO RUN) - TYPE 1

Tradedor TD55DM & TD55SEL Installation Guide

Direction Of Rotation (HOLD TO RUN)

1 Press and hold the right ( ) button on the handset and the door should start moving in the downward

direction. Should the barrel be turning in the upwards direction press the stop button ( ).

2 Swap the black and brown motor wires round in the green motor connection block.

3 Re-attach the membrane ribbon to the pcb board on to the 4 pins on the top right (g.5.2).

4 Press and hold the down button and the door should start to close. Should the barrel be turning

in the upwards direction press the stop button. Reverse the membrane ribbon on the pins.

5 Press and release the down button ( ). If the door closes, press the stop button and in the top

left corner is a bank of 5 dip switches (g 5.2) ick the second from top dip switch to the right.

You should now have to press and hold the down button for the door to close.

1 Slide the black cover down on the remote control

handset and you will reveal four buttons (g 5.1).

2 Press and hold the left button ( ), then press and

hold the right button ( ) if the door moves then

the handset is already programmed in, please repeat

with all other handsets if they are all programmed

please proceed to 'Direction of rotation Section',

if not then carry on to step 3.

3 With the handset in hand, located the red learn

button on the top right hand side of the board next

to the digital display (g.5.2) and press and hold till

the digital display comes up S.T.U then release.

4 Press and release the top button on the handset twice.

5 The S.T.U display will ash quickly to indicate success.

6 Repeat for all handsets.

g.5.1

g.5.2

10

5. Programming Remote Control

Handsets (HOLD TO RUN) - TYPE 1

Tradedor TD55DM & TD55SEL Installation Guide

11

1 Remove the lid of the receiver box by

unscrewing small screw at bottom (g 5.1 A)

and then sliding the lid up, being careful to

remove plug-in cable from board (g 5.1 C).

2 Place the Receiver box on the wall with the

cable pointing downwards at a comfortable

height to operate the push buttons, but out of

the easy reach of children. Between 1500mm

up from the oor and 300mm down from the

roof/ceiling is recommended.

3 Making sure the box is square, mark

the two xings (one top and one bottom),

then drill and secure with xings (g 5.1 B).

4 For ease of installation, undo the terminal

clamp at the bottom (g.5.1D).

5 Wiring as follows (fig.5.2 & fig.5.3);

Pre wired Mains Power:

N– Neutral / Blue power cable

L– Live / Brown power cable

Earth – Earth power cable

Motor:

L– Brown motor cable (4 core)

R– Black motor cable (4 core)

Earth – Earth connection motor

cable (4 core)

N– Blue motor cable (4 core)

SPECIAL ATTENTION: red link wire

from Gto Uand Gto SMUST STAY IN

g.5.2

g.5.3

230v TUBE MO-

TOR CONNECTION

Connect tube motor

where shown

Note: This connection will

supply 230v AC and is

specically for tube motor

operation

Tube Motor 230v AC 50Hz

Mains Supply

230v AC 50Hz

Stop

Gn/Yl

Brown

Blue

Mains Supply Connection

AC IN

N L

Connect mains

power supply

where shown

Recommended

Power Supply

Protection:-

13A fused Spur or

Single Pole

connected

protected by MCB

Type 'A'

Ext Key-Switch Connection

Close

Open

Com

Ext Push Button Connection

Open

Close

L

R

N

Motor Direction

Motor Earth

Motor Common

Motor Direction

Terminal Connections

U D G VU S

MANUAL PHOTOCELL

24v dc

Reflective

Photocell

0v

U D G V U S

MANUAL PHOTOCELL

24v DC Photocell Connection

+24v

N/C

com

UD G VUS

MANUA PHOTOCELL

N

LMains Power 230v AC (Live)

Mains Power 230v AC (Neutral)

Mains Power (Earth)

UExternal connection - Open

D External connection - Close

V +24v dc

G 0V / Switch Common / Photocell Common

Photocell connection - N/C contact

External connection - Stop

Mains Supply

Motor

Manual

Photocell

Basic Remote Control Operation

UDGVUS

MANUAL PHOTOCELL

External

Push Button

Connection

Safety Brake Connection

U D GVU S

MANUAL PHOTOCELL

Safety Brake

(N/C) Switch

Connection

MOTOR

L R N

230v Tube Motor Connection

Gn/Yl

Black

Brown

Blue

Connect tube

motor where

shown

Note:

This connection

will supply 230v

AC and is

specifically

for tube motor

operation

Tube Motor

230v AC 50Hz

MOTOR

L R

Volt free Switching Connection

N

Connection to

provide a 'volt

free' switching

operation

Com

Close

Open

To add an additional external

push button station

Connect where shown leaving link

fitted between G + U

To add an additional external

key-switch

Connect where shown leaving link

fitted between G + U + S

To add an additional photocell for

safety

Connect where shown leaving

links fitted between G + S

Activating the photocell will stop

and re-open a closing door

External

Key switch

Connection

Date

Drawn by

Chk'd by

Drg #

Title

Ellard House

Floats Road

Roundthorn Industrial Estate

Wythenshawe, Manchester

M23 9WB

Tel: 0161 945 4561

Fax: 0161 945 4566

This drawing is the property of ELLARD LTD, it may not be reproduced without the written authorisation of Ellard Ltimited. All interlecual property rights are expressly reserved Revision / Notes:

04/07/2018

D. England

J. Monks

This is a special connection that

does not provide a voltage output

The unit must be factory modified

to give this function and will be

marked 'Volt Free' as such

For Basic remote Control

Operation

Leave links fitted between

G + U + S

Connect safety brake where

shown

Leave link fitted between

U + S

Connection Detail For

ATHENA 2nd GEN

(White Enclosure/White Transmitter)

elec-ATHENA2-001A

Com

MAINS SUPPLY

CONNECTION

Connect mains power supply

where shown

Recommended Power Supply

Protection:- 13A fused Spur

or Single Pole connected

protected by MCB Type 'A'

Mains Supply 230v AC

50Hz

Mains Supply

230v AC 50Hz

Stop

Gn/Yl

Brown

Blue

Mains Supply Connection

AC IN

N L

Connect mains

power supply

where shown

Recommended

Power Supply

Protection:-

13A fused Spur or

Single Pole

connected

protected by MCB

Type 'A'

Ext Key-Switch Connection

Close

Open

Com

Ext Push Button Connection

Open

Close

L

R

N

Motor Direction

Motor Earth

Motor Common

Motor Direction

Terminal Connections

U D G VU S

MANUAL PHOTOCELL

24v dc

Reflective

Photocell

0v

U D G V U S

MANUAL PHOTOCELL

24v DC Photocell Connection

+24v

N/C

com

UD G VUS

MANUA PHOTOCELL

N

LMains Power 230v AC (Live)

Mains Power 230v AC (Neutral)

Mains Power (Earth)

UExternal connection - Open

D External connection - Close

V +24v dc

G 0V / Switch Common / Photocell Common

Photocell connection - N/C contact

External connection - Stop

Mains Supply

Motor

Manual

Photocell

Basic Remote Control Operation

UDGVUS

MANUAL PHOTOCELL

External

Push Button

Connection

Safety Brake Connection

U D GVU S

MANUAL PHOTOCELL

Safety Brake

(N/C) Switch

Connection

MOTOR

L R N

230v Tube Motor Connection

Gn/Yl

Black

Brown

Blue

Connect tube

motor where

shown

Note:

This connection

will supply 230v

AC and is

specifically

for tube motor

operation

Tube Motor

230v AC 50Hz

MOTOR

L R

Volt free Switching Connection

N

Connection to

provide a 'volt

free' switching

operation

Com

Close

Open

To add an additional external

push button station

Connect where shown leaving link

fitted between G + U

To add an additional external

key-switch

Connect where shown leaving link

fitted between G + U + S

To add an additional photocell for

safety

Connect where shown leaving

links fitted between G + S

Activating the photocell will stop

and re-open a closing door

External

Key switch

Connection

Date

Drawn by

Chk'd by

Drg #

Title

Ellard House

Floats Road

Roundthorn Industrial Estate

Wythenshawe, Manchester

M23 9WB

Tel: 0161 945 4561

Fax: 0161 945 4566

This drawing is the property of ELLARD LTD, it may not be reproduced without the written authorisation of Ellard Ltimited. All interlecual property rights are expressly reserved Revision / Notes:

04/07/2018

D. England

J. Monks

This is a special connection that

does not provide a voltage output

The unit must be factory modified

to give this function and will be

marked 'Volt Free' as such

For Basic remote Control

Operation

Leave links fitted between

G + U + S

Connect safety brake where

shown

Leave link fitted between

U + S

Connection Detail For

ATHENA 2nd GEN

(White Enclosure/White Transmitter)

elec-ATHENA2-001A

Com

SAFETY BREAK

CONNECTION

Connect safety brake

where shown

Safety Break (N/C) Switch

Connection

Mains Supply

230v AC 50Hz

Stop

Gn/Yl

Brown

Blue

Mains Supply Connection

AC IN

N L

Connect mains

power supply

where shown

Recommended

Power Supply

Protection:-

13A fused Spur or

Single Pole

connected

protected by MCB

Type 'A'

Ext Key-Switch Connection

Close

Open

Com

Ext Push Button Connection

Open

Close

L

R

N

Motor Direction

Motor Earth

Motor Common

Motor Direction

Terminal Connections

U D G VU S

MANUAL PHOTOCELL

24v dc

Reflective

Photocell

0v

U D G V U S

MANUAL PHOTOCELL

24v DC Photocell Connection

+24v

N/C

com

UD G VUS

MANUA PHOTOCELL

N

LMains Power 230v AC (Live)

Mains Power 230v AC (Neutral)

Mains Power (Earth)

UExternal connection - Open

D External connection - Close

V +24v dc

G 0V / Switch Common / Photocell Common

Photocell connection - N/C contact

External connection - Stop

Mains Supply

Motor

Manual

Photocell

Basic Remote Control Operation

UDGVUS

MANUAL PHOTOCELL

External

Push Button

Connection

Safety Brake Connection

U D GVU S

MANUAL PHOTOCELL

Safety Brake

(N/C) Switch

Connection

MOTOR

L R N

230v Tube Motor Connection

Gn/Yl

Black

Brown

Blue

Connect tube

motor where

shown

Note:

This connection

will supply 230v

AC and is

specifically

for tube motor

operation

Tube Motor

230v AC 50Hz

MOTOR

L R

Volt free Switching Connection

N

Connection to

provide a 'volt

free' switching

operation

Com

Close

Open

To add an additional external

push button station

Connect where shown leaving link

fitted between G + U

To add an additional external

key-switch

Connect where shown leaving link

fitted between G + U + S

To add an additional photocell for

safety

Connect where shown leaving

links fitted between G + S

Activating the photocell will stop

and re-open a closing door

External

Key switch

Connection

Date

Drawn by

Chk'd by

Drg #

Title

Ellard House

Floats Road

Roundthorn Industrial Estate

Wythenshawe, Manchester

M23 9WB

Tel: 0161 945 4561

Fax: 0161 945 4566

This drawing is the property of ELLARD LTD, it may not be reproduced without the written authorisation of Ellard Ltimited. All interlecual property rights are expressly reserved Revision / Notes:

04/07/2018

D. England

J. Monks

This is a special connection that

does not provide a voltage output

The unit must be factory modified

to give this function and will be

marked 'Volt Free' as such

For Basic remote Control

Operation

Leave links fitted between

G + U + S

Connect safety brake where

shown

Leave link fitted between

U + S

Connection Detail For

ATHENA 2nd GEN

(White Enclosure/White Transmitter)

elec-ATHENA2-001A

Com

B

B

D

C

A

g.5.1

6. Installing Reciever Box

(HOLD TO RUN) - TYPE 2

Tradedor TD55DM & TD55SEL Installation Guide

Direction Of Rotation (Hold To Run)

1 Press and hold the bottom button ( ) on the handset and the barrel should start turning in the

downwards direction. Should the barrel be turning in the up direction, press the middle stop button

( ) so the barrel stops and then move the left of the three dip switches up (g.6.2 A).

2 Press and hold the bottom button ( ) on the handset, and the barrel should start turning in the

downwards direction.

3 Press and hold the right-hand button ( ) on the front of the receiver box and the barrel should start

turning in the downwards direction. Should the barrel be turning in the up direction, press the middle

button ( ) on the front of the receiver box so the barrel stops and then move the right of the three

dip switches up (g.6.2 C).

4 Press and release the down button ( ). If the door closes, press the stop button and ick the middle

dip switch up (g.6.2 B). You should now have to press and hold the down button for the door to close.

Deleting Remote Control Handset’s Memory

1 Press and hold the black programming button for roughly 3 seconds. The green LED will

ash three times, go solid, then rapidly ash. Keep hold until ashing stops.

2 Test to see if remote operates door.

1 Re-attach the front box cable to the board.

2 Press and hold the bottom button ( ), if the door

moves then the handset is already programmed in.

Repeat with all other handsets.

3 If not programmed then press and release the black

programming button located at the top of the receiver

box (g.6.2). The green LED on the front cover will

start ashing.

4 Press and hold the top button on the handset ( ).

The green LED will ash faster and go out.

5 Test handset by pressing either direction, the barrel

should move. Repeat with all other handsets that

need programming.

g.6.1

g.6.2

A B C

12

7. Programming Remote Control

Handsets & Push Button

(HOLD TO RUN) - TYPE 2

Tradedor TD55DM & TD55SEL Installation Guide

13

1 Open the lid of the receiver box by unscrewing the

four screws (one in each corner) (g.8.1).

2 Remove the two screws from the bottom of the box

(these can be found behind the glands) and the wall

mounting plate can be removed from the back

(g.8.2 & g.8.3).

3 Making sure the xing plate is square with the screw

fixings at the bottom, mark the four fixings points.

This should be at a comfortable height to operate the

push buttons but out of the easy reach of children

- between 1500mm from the oor and 300mm down

from the roof/ceiling is recommended. Drill and then

secure in place (g.8.4).

4 Hook the top of the receiver box on to the wall xing

plate with the cable glands pointing downwards and

secure with the two screws.

5 Remove the green 5 terminal block in the bottom left

corner (g.8.5) and you will see letters printed on the

circuit board.

6 Wiring as follows:

Mains Power:

N– Neutral / Blue 3 core cable (power)

L – Live / Brown 3 core cable (power)

Earth – connect power cable directly to earth from

motor in plastic connector.

Motor:

U– Brown 4 core cable (motor)

V– Black 4 core cable (motor)

Earth - connect motor cable directly to earth from

motor in plastic connector.

W(c) – Blue motor cable (4 core)

g.8.1

g.8.2

g.8.3

8. Installing Receiver Box

(SAFETY EDGE) - TYPE 1

Tradedor TD55DM & TD55SEL Installation Guide

Direction Of Rotation (SAFETY EDGE)

1 Press and hold the top open button on the receiver board (g.8.5). This is located at the bottom

right corner of the yellow transformer and the barrel should start turning in the upwards direction.

Should the barrel be turning in the down direction, swap motor wires black to U and brown to V.

2 Press and hold the top open button on the receiver board to check.

g.8.5

g.8.4

7 Before plugging in, check to make sure that there

are no bare cables touching and all wires are

securely xed.

8 There is a four dipswitch block at the bottom

middle of the receiver board (usually blue or red).

Slide dipswitch 2 into the up position (g.8.5).

14

Tradedor TD55DM & TD55SEL Installation Guide

15

Somfy Rollixo RTS Control Panel

No Description

1Up Button

2Stop Button

3Down Button

4Prog Button

5Prog LED

6Motor & safety brake LED

7Safety Edge LED

8Battery LED

9Photocell LED

1

2

34

56 7 8 9

Mounting The Rollixo Rts

Remove the

courtesy light

cover.

1 2 Unscrew and

remove the

panel cover.

3Mark the

wall drilling

positions.

4Secure the

Rollixo RTS

in place.

Motor Wiring

L1 N2 L

M

12 34

Bleu

Marron

Noir

Green/Yellow

Brown

Blue

Black

Connect the motor wires into terminals 1, 2, 3 & 4

as illustrated above.

Note: The motor direction can be reversed during

the commissioning procedure.

1Secure the motor supply cable

in place with the cable clamp.

2

Tradedor TD55DM & TD55SEL Installation Guide

16

Safety Brake Wiring

Sec

Safety EdgeStop

K

56 78 9 1

Sec

Safety Edg eStop

K

56 78 9 1

Connect the

safety brake into

terminals 5 & 6.

1Connect link provided to

connect terminals 5 & 6 if

no safety brake is required.

2

Powering Up The Rollixo RTS

Unfold the aerial so

that it points vertically

downwards.

1Screw the bulb

supplied into

the light tting.

2Ret the panel

cover and secure

with the screw.

3Ret the

courtesy

light cover.

4

All the LED's

come on briey

and then out.

If the motor LED comes on, check the safety

brake or link connection.

If the safety edge LED comes on, the safety

edge transmitter has not been recognised.

(This is normal if the safety edge transmitter

has not been paired to the Rollixo RTS yet).

3 421

Prog

STOP

1

2

3 421

Prog

STOP

Plug in the supply cable and

connect the mains supply.

5

Tradedor TD55DM & TD55SEL Installation Guide

1 Press and hold the down button on receiver box so the curtain starts to roll down to 300mm (roughly

6 slats) from top of the guide runners.

2 Place the plastic wand in to the limit nearest the curtain of the door (g.9.1) and turn 10 times in

the negative direction (this is marked on the head of the motor near the limits) (g.9.2).

3 Press and hold the up button and the door will travel to the top and should stop on its own, if the

door gets to 100mm from the top of guide runners (roughly 2 slats) and hasn’t stopped, then stop

the door and take it back down to 300mm from top of guides (roughly 6 slats) turn again 15 times

in the negative direction, take the door up and repeat until the door does stop before it gets to

100mm from top.

4 Whilst holding the up button turn the wand in the positive direction and the door will start to judder

up, keep going until there is only the last slat in the guides, take the door down a little and back up

to make sure you are happy.

5 Move the plastic wand in to the limit nearest you inside the garage (g.9.1) and turn 10 times in the

negative direction.

6 Press and hold the down button so the door closes, it should stop before it touches the oor if this

is not the case take the door back up 300mm off the oor and turn again 15 times in the negative

direction, take the door back down and repeat until the door does stop before it reaches the oor.

7 Whilst holding the down button turn the wand in the positive direction and the door will start to

judder down, keep going until the door slats are fully compressed and a little pressure is applied

from the top (don’t apply to much pressure as this will damage the door and straps), take the door

up a little and back down to make sure you are happy.

8 Once the guide runners are xed you will need to secure the top box, with the curtain to the closed

position you will have access to the whole top box. This is best done through the end anges of the

header plate, either forward or sideways through the header plate itself if a between xing (g.9.3).

9 Close the door down to make sure the curtain doesn't catch anywhere and the front case is not

bowed in so as to rub on the curtain during operation, then seal down the sides and along the top

case if needed (silicon sealant is recommended).

10 Take winding stem and screw. Insert winding stem into the motor through pre-drilled hole in header

plate, then secure in place with screw on top.

PLEASE NOTE! You will see there are optional xing positions on the straps

for them to be screwed to the barrel, these are not needed but if you would

like to do this PLEASE BE WARNED that no screws can be secured 650mm

from the head of the motor as you will damage it!

17

9. Setting Motor Limits

Tradedor TD55DM & TD55SEL Installation Guide

g.9.1

g.9.2

g.9.3

18

Tradedor TD55DM & TD55SEL Installation Guide

Programming Base Rail Unit

(SAFETY EDGE)

1 Once installation is complete and before

powering up, slide back down dip switch ‘2’ in

the control panel, this can be found on the four

dipswitch block at the bottom middle of the

receiver board (usually blue or red) (g.10.1).

2 For access to the base rail unit on the right side

(where the writing is), push at the end of the

grey cover and slide to the left. This will give

access to the board (g.10.2).

3 Remove the plastic tab from the batteries and

the LEDs will blink on the safety edge unit.

4 Inside the receiver box press and hold the

“PROG” button on the receiver card (this is the

card plugged onto the board) until you hear

a single beep (g.10.4), then press and hold the

“PROG” button on the wireless safety edge

(g.10.3) and you will hear another beep from

the receiver box.

5 Wait several seconds until you hear 2 beeps

from the receiver box and pairing is complete.

g.10.1

PUSH

GREY

SECTION

g.10.2

19

10. Setting Up Wireless Safety

Edge Kit (OPTICAL EDGE) - TYPE 1

This manual suits for next models

1

Table of contents

Other TRADEDOR Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

SOMFY

SOMFY Dexxo Pro io installation manual

Amazing Roller Shutters

Amazing Roller Shutters SE14.21 CP 970 installation instructions

SEA

SEA LEPUS 600 manual

Wayne-Dalton

Wayne-Dalton 9800 Installation instructions and owner's manual

CAME

CAME V6000P installation manual

Genie

Genie QuietLift 2040L Operation and maintenance manual

BFT

BFT ULISSE C Installation and user manual

Motorline professional

Motorline professional RAP100S User& installer's manual

vds

vds AT PLUS-2500 Manual for installation and maintenance

Clare Controls

Clare Controls GD00Z-5 Integration Release Notes

Raynor

Raynor Safety signal 3220RGD owner's manual

Chamberlain

Chamberlain H owner's manual