M131

6

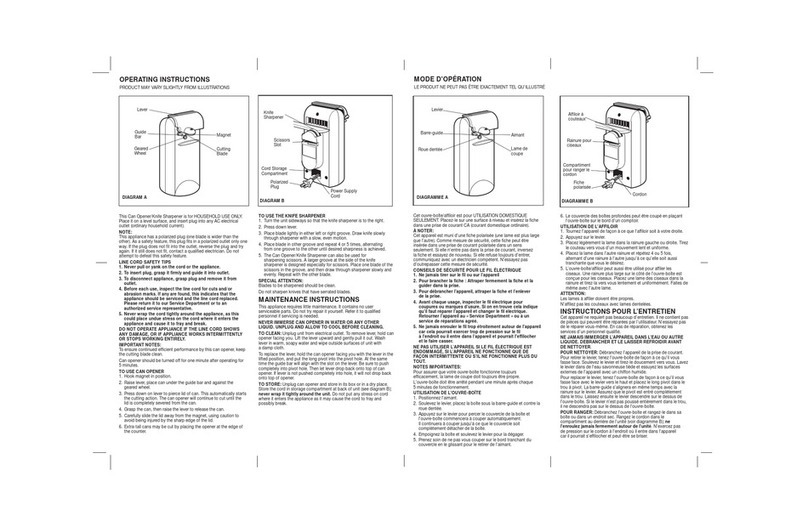

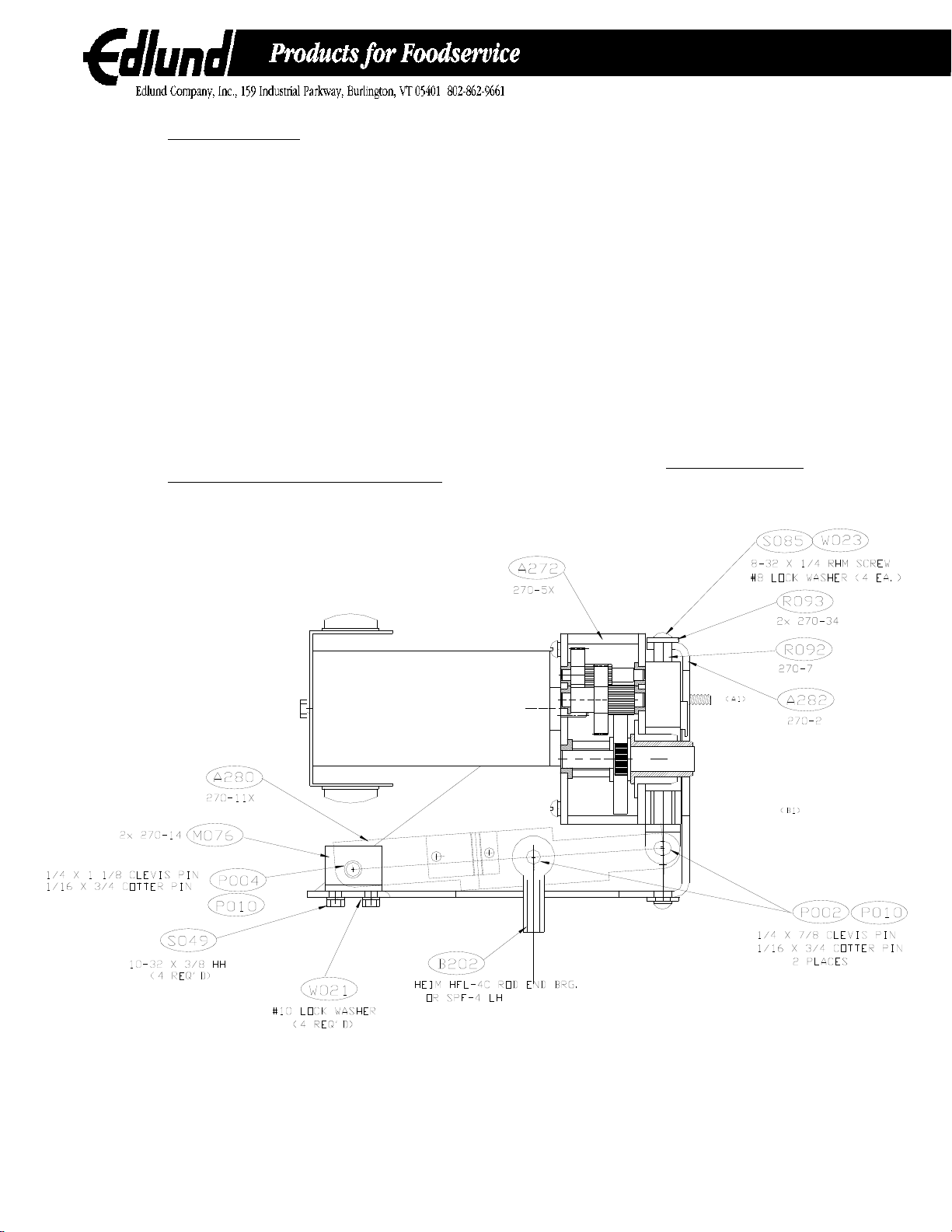

IV. Assembly of Model 270 & 270C Frame Assembly into Housing Assembly (Fig. 1-Fig. 4)

1. With the top of the motor facing the rear of the housing, install the frame assembly into the bottom opening of the housing and

slide the frame assembly up against the rear of the housing faceplate. Secure the frame assembly in place from the bottom of the

housing using two screws (S049) and washer (W021) and Loctite No. 242. The socket head screws must be installed using a ball type

Allen wrench. Do not tighten screws tight.

2. Install the right shoulder screw (S316) and the left shoulder screw (S317) on to the two studs on the front of the housing using

Loctite No. 242. Turn the housing over and securely tighten the two screws (S042) that secure the bottom of the frame.

3. Install the shield assembly (A279) over the output shaft and check to make sure it latches by pressing on the shield where the metal

insert is located. If the shield will not latch remove the frame assembly and place shims behind the shoulder screws (S309) that retain

the gear latch. Replace the frame assembly and try latching the shield again. Repeat shimming procedure until the shield will lock in

place.

4. For Model 270, place a nut (N019) on screw (S050) and install into threaded hole in stop in throat of housing. This will be

adjusted later. (See Fig. 1)

5. Install the two lever arm mounts assemblies (A2812/A2812C) over the studs on the bottom inside of the housing

(A273/A273C/A2731). Secure with four nuts (N019) and lock washers (W018) but do not tighten at this time.

6. Attach the cam assembly consisting of height adjuster (A054), lock nut (N054), clevis (C243), cam (C192), shoulder screw (S299),

lock washer (W018) and lock nut (N056) to bottom of rod end (B202). Screw height adjuster (A054) into bottom of rod end by

turning screw counterclockwise (left hand thread) until space of ¼ inch exists between end of rod end (B202) and hex nut portion of

height adjuster.

7. Slide actuator lever (L065/L065C) through the hole in the housing, through the hole in the bearing mount, through the spacer

(S338) through the hole in the cam assembly and into the opposite bearing mount. With the lever in the raised position, align the hole

in the cam with the hole in the lever. Secure with a 3/16-inch diameter roll pin (P245). Tighten the four nuts (N019) that retain the

bearing mounts (A2812/A2812C).

8. Install the knife holder latch (L066) on right hand shoulder screw (S316) using the knife holder latch screw (S314). Install drive

gear adapter (A055) onto the output gear assembly (A278).

9. Place the shield assembly (A279) over the output shaft with the long side vertical and press in on the top until the shield is locked

in place. Slide the drive gear (G041) over the drive gear adapter and press in on the shield assembly until the gear is locked in place.

10. Install the knife holder (A288) onto the face of the housing by sliding the left hand slot of the knife holder over the left hand

shoulder screw (S317) and keep sliding to the left until the right hand slot of the knife holder engages the right hand shoulder screw

(S316). Rotate the knife holder down and lock in place with the knife holder latch (L066).

11. Set the height adjustment of the drive gear as follows:

A. Lower the actuating lever (L065/L065C) to the bottom and adjust the drive gear up or down by turning height adjuster (A054)

clockwise or counterclockwise until clearance between the bottom of the knife holder and the top of the drive gear is .100-.105 when

measured using gage and feeler gage. Lock height adjuster in place using the lock nut (N054).

12. For Model 270, adjust the lock screw until the cam assembly (A2815) doesn't rotate beyond the top of its arc. Lock the screw in

place using nut (N019).

For Model 270C, install the lock plate (P296) onto the bearing mount assembly (A2812C) using four screws (S049) and lock washers

(W018). Install screw (S048) and lock nut (N019) into the center hole of the lock plate as shown and adjust the screw until the cam

will not travel beyond the top of its arc. Secure the screw using the lock nut N019.

13. Install the switch actuator assembly (A049) and lock nut (N023) into the bottom of the lever assembly. Assemble the roller

switch assembly (A2814) on to the bottom of the frame using two screws (S085) and washers (W012) and (W023). Do not tighten the

two screws at this time.

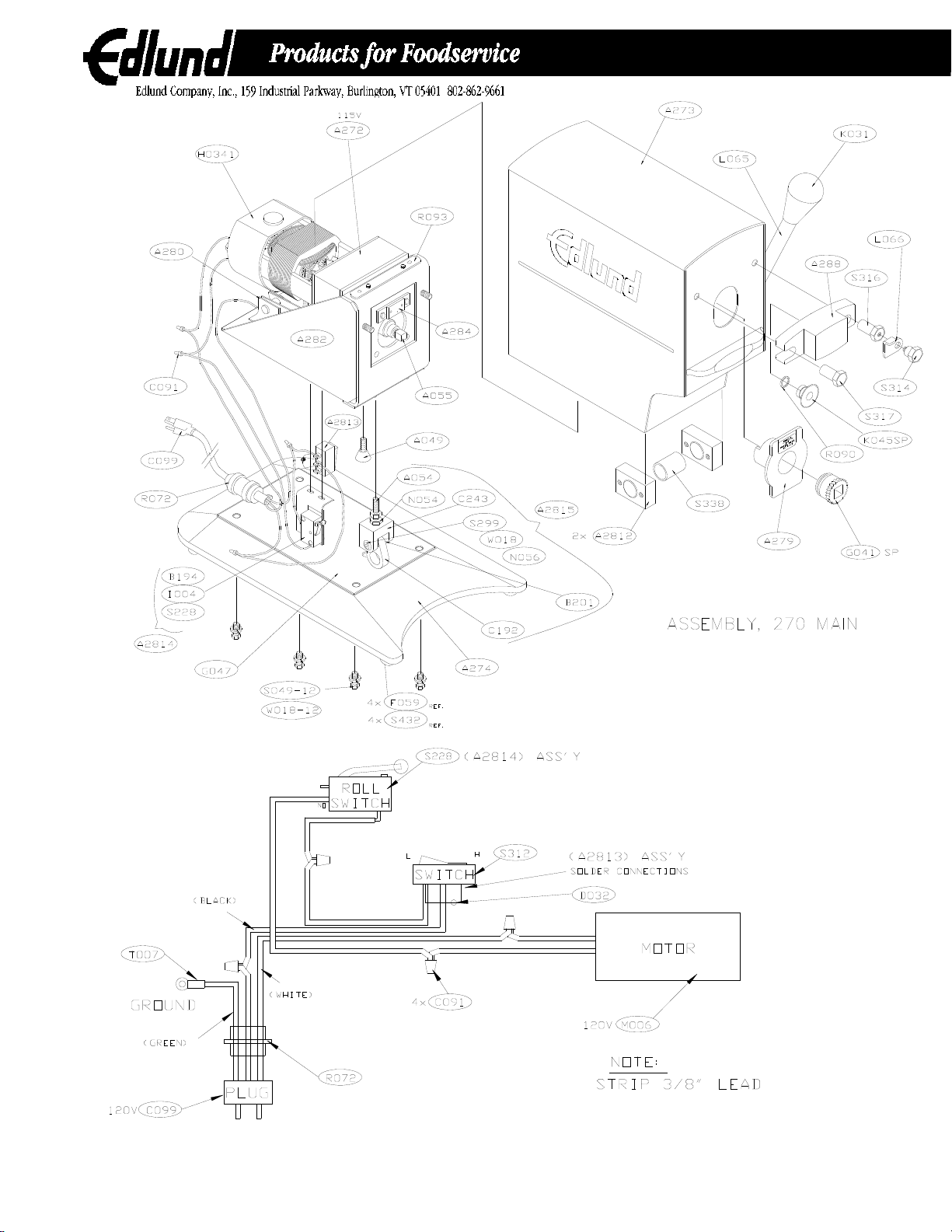

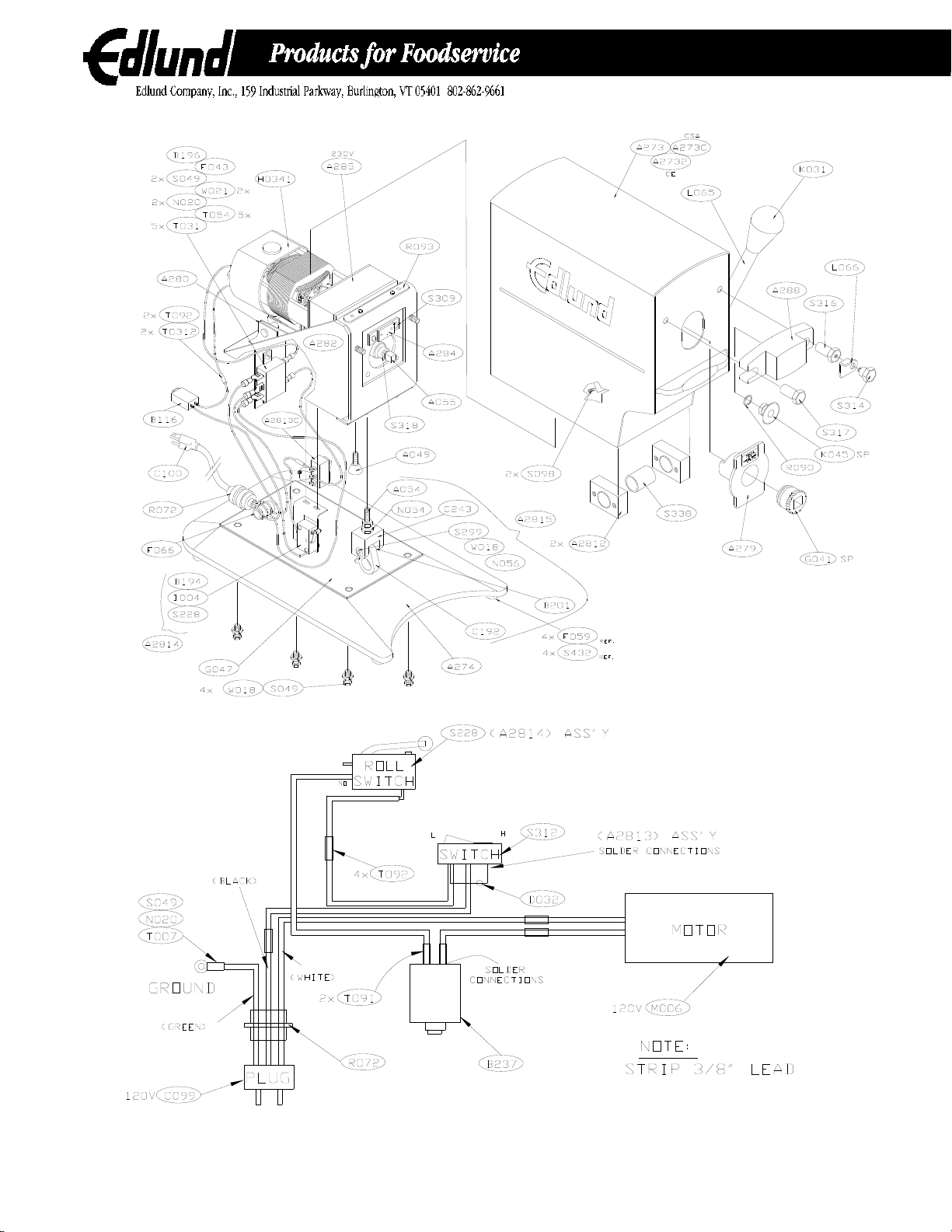

14. Install the rocker switch assembly (A2813) into the rectangular hole in the housing and install the appropriate cord set and strain

relief into the holes in the rear of the housing.

For 230 volt Model 270 or Model 270C, remove the two screws (S049) that secure rear of lever assembly to frame and attach filter

bracket (B196) and filter (F043) to bottom rear of frame and secure by inserting the two screws (S049) back in place.

15. Wire the can openers using the appropriate wiring diagram (Fig. 10 and 11). Bundle wires and tie up using wire tie.

16. Adjust the on position of the motor by pulling actuating lever down until the knife (K045) is even with the top of the gear (G041).

Turn switch actuator and slide the roller switch assembly (A2814) until the roller switch clicks on. Lock the switch actuator in place

using nut (N023) and tighten the two screws (S085) on the roller switch assembly. Install the knob (K031) on the actuating lever.