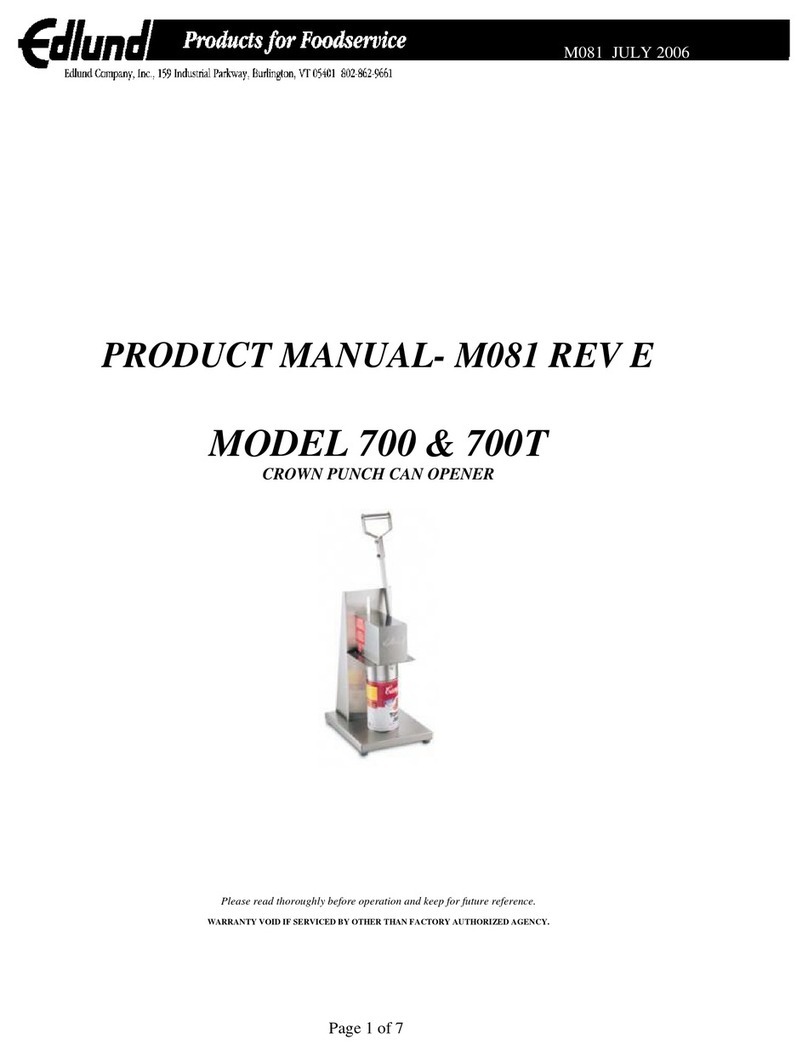

6Edlund Company CROWN PUNCH CAN OPENER, Models 625M and 625

CHAPTER 3 - SETTING UP YOUR EDLUND CROWN PUNCH CAN OPENER

This chapter covers the procedures for setting up your new EDLUND CROWN PUNCH CAN OPENER. You may

find it helpful to review the Controls and Features in (Figure 2 on page 7).

Setup and Operation of the EDLUND CROWN CAN OPENER

1. Unpack the crown punch machine. Check for any loose hardware or damage.

2. Before operation, your new crown punch machine should be sanitized. This will involve removal of the

tooling for sanitation and wash down of the machine. Review the Cleaning instructions on page 10.

3. Insure the "T" handles are tight. They are located behind the head of the crown punch machine. The height,

with the guard ring in place, must be such that when a can is in position under the crown punch, from the

can seam to the lip of the guard ring is approximately 1/8 (3,2mm) to 3/16 (4,8mm), (Figure 3

On page 8).

4. Before starting, always inspect your tooling. The crown punch must be free of nicks, burrs, dents or bent

points. The shearing surface must be dull. The guard ring must seat perfectly on the seam of the can being

opened. The retaining clip must be flat and not deformed.

5. Insure the crown punch, guard ring and clip are in place properly. The two knurled screws that hold the

guard ring in place must be tightened with a flathead screwdriver before operation.

6. Insure the splash guard is on before operation.

7. Connect the air line. The air must be clean and dry. This typically requires a drier on the compressor. A 5

micron filter and coalescing filter are recommended inline before the connection to the crown punch air

inlet. The air requirement is 85 psi at 1 to 2 CFM. Note: No additional inline lubrication is required (the

cylinders and air valves are already greased).

8. The crown punch is a one person operation. Place the can under the guard ring and seat it against the back

of the tab that is slightly lower. Use both hands and press the green buttons at the same time (this insures

the operators hands are clear of the opening area). Hold the green buttons in until the can is completely

opened and then release. Never double press the green buttons when opening a can.

9. Remove the opened can with both hands.

10. Carefully remove the lid from the top of the product and discard. Avoid the perimeter seam area. (safety

gloves are recommended).

11. If the side magnet option is on the crown punch machine (625M), operate the two green buttons as

previously explained then move the can under the magnet and raise the can until the magnet snaps the lid

up and holds it. The magnet will retract and drop the lid with the opening of the next can.

(YELLOW)

AVOID THE SHARP EDGES OF THE LID. DO NOT ATTEMPT TO REMOVE THE LID FROM THE MAGNET BY HAND.

NOTE: The crown punch opener is factory adjusted to open a standard #10 can or the particular size can ordered.

The crown punch knife should penetrate the can just far enough to remove the lid but not so far as to cause

excessive splashing of liquid in the can. If a height adjustment is required, see “Adjusting the Head” in

Chapter 4.