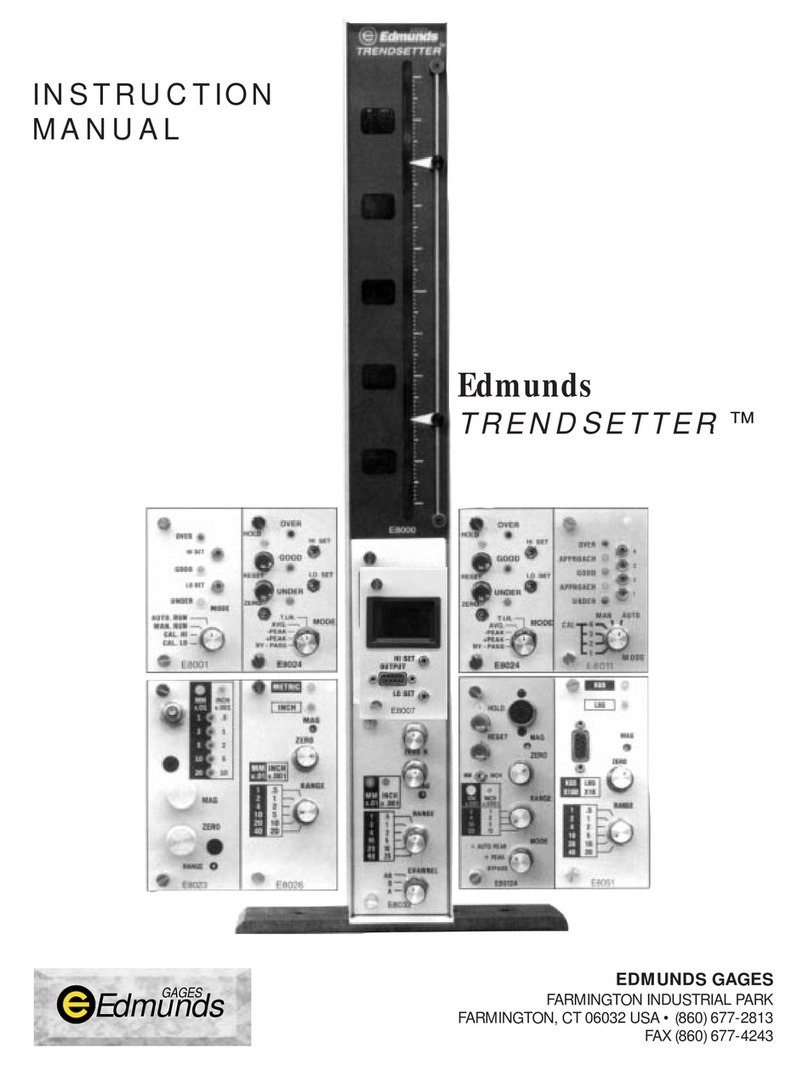

Edmunds Accu-Touch User manual

EDMUNDS GAGES

Accu-TouchTM Amplifier

Instruction Manual

Step 1 –Locate the Accu-touchTM amplifier and respective gage where parts

can be best measured.

Step 2 –Connect the power cord to the rear of amplifier and then to the power

outlet. Attach a suitable air line from the air supply to the inlet of Accu-

touchTM filter, if applicable. Attach any LVDT cables from tooling to the rear of

amplifier noting proper location of connectors. Also attach any air lines from

the tooling to the front of the Accu-touchTM docking unit, if applicable, noting

their proper connection.

Step 3 –Turn on the power switch located at rear of the amplifier near the

power cord. Turn on the air supply pressure if applicable.

Step 4 –Have all the specific information concerning your part measurement

available i.e. max & min check sizes and max & min master calibrated sizes.

Step 5 –Setup Accu-touchTM features as described in section 1 & 2, if

necessary.

Step 6 –Calibrate Accu-touchTM using procedures listed in section 5, 6 & 7.

Step 7 –Measure parts.

Accu

-

Touch

TM

Use

The Accu-TouchTM amplifier is a “comparative”type gaging amplifier displaying

the results on a flat panel touch screen. Precision is (6m) inch with accuracy

being .5% of full scale (LVDT) and .1% full scale (AIR). Linearity will be .25%

full scale.

The Accu-TouchTM amplifier is designed to be used with Edmunds LVDT gage

probes and also two master system air tooling when used with the optional

“docking unit”. No inference to compatibility with other types or brands of

LVDT probes is implied or guaranteed.

The unit comes with a one year warranty from date of factory shipment.

Damage caused by shipping, handling, “unclean”electrical power,

contaminated compressed air supply or mis-use voids any warranty.

Tampering with internal components and loading software programs also

violates the warranty.

Basic

Amplifier (4) input p/n E7204

Amplifier (4) input w/formula generator p/n E7204A

Docking unit (1) input p/n E7110

Docking unit (2) input p/n E7120

Docking unit (3) input p/n E7130

Docking unit (4) input p/n E7140

Accessories

Coalescing Filter p/n P-NUM-F32E-04AM

Memory Stick p/n 4570642

Auto-Air shutoff (1 & 2 inputs) p/n 5917040

Auto-Air shutoff (3 & 4 inputs) p/n 5917041

USB 2-pedal Footswitch p/n 5917035

Preface

Hardware

What you need

Setup - section 1

Features - section 2

Formulas –section 3

Database setup –section 4

Setup Database 4.1

Export/Import Setups 4.2

Manual calibration –section 5

Setting pneumatic mag –section 6

Software calibration –section 7

Auto air-shutoff setup –section 8

Measuring –section 9

Data offload setup –section 10

Setup Report –section 11

Utilities –section 12

Password protection –12.1

About - 12.2

Date/Time 12.3

Screen Colors 12.4

Backup 12.5

Notes

Appendix A –Formula Generator

Definitions

Troubleshooting

Contents

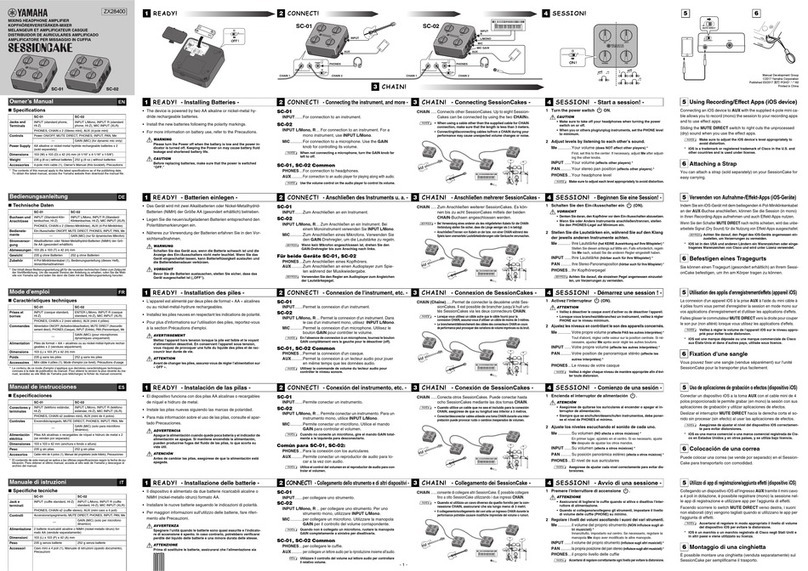

Front view

Amplifier

Touch screen

Front USB port - data offload only

Zero adjusting screw

Mag adjusting screw

Air hose, tooling connection

Docking unit air gaging –optional

Rear view

Power on/off switch

RS232C serial port

LVDT ports

rear USB port - data offload

or optional data send/TIR

reset footswitch

LVDT jumper cable,

docking unit to amplifier

Air supply inlet

Filter

Regulator

Auto-air shutoff connection - optional

Ha

rdware

5.1 - Utilities: *1electrical power –110/240 VAC, 50/60 HZ.

*2Compressed air supply –60 PSI & 3 CFM minimum.

5.2 - Reference material: units of measure –English/Metric

upper and lower part limits

setting master *3calibrated sizes

5.3 - Measuring tooling: LVDT probes –open setup

electronic bore plug –I.D. measurement

electronic ring gage –O.D. measurement

air plug –I.D. measurement

air ring –O.D. measurement

special gage

5.4 –Setting masters: max & min or *4zero size masters -

gageblocks or other types of masters –for

electronic “open”setup gaging

ring type –for electronic or air gaging of I.D.’s

cylindrical OD type –for electronic or air gaging

of O.D.’s

Footnotes:

1.) electrical power should be “clean”and stable without large fluctuations otherwise internal

damage of electrical components can occur voiding warranty. In such cases a isolation

transformer is recommended.

2.) Clean & dry compressed air is required. Normal compressed air (shop air) can contaminate the

docking units effecting stability of the readings and voiding warranty. In such cases a coalescing

air filter is recommended to be installed on the inlet to the docking unit. The elements in this

filter require periodic checking and replacement.

3.) Certifications by a traceable calibration lab are recommended to ensure the setup and results of

calibration are as accurate as possible.

4.) A zero or nominal master can be used but not recommended by Edmunds Gages for electronic

gaging only. Two masters are required for air gaging.

What you need

1.1 –Main screen - shown with 4 check results.

1.2 - For a new setup, touch “Setup”, “Setup Access”menu appears.

1.2.1 –Touch “Measurement Setup”, setup now appears - if unlocked or if

password protection has not been enabled.

1.2.2- The (11) selectable items related to for your use are available to be

selected or entered by touching each software key.

Setup

–

section 1

2.1 - Sensor type –touch to select “electric”for electronic gaging or

air-auto for air gaging.

2.2 - Units –touch “inch”or “mm”based on application.

2.3 - Resolution –touch as many times as necessary to select

3resolution required for application. Two to six decimal place

resolutions available.

2.4 - Mode - touch and select by touching one of four available methods

of displaying the reading. “Live”, “TIR”, “+PEAK”, “-PEAK”.

2.5 - Description –touch and enter letters, numbers or characters

using software keyboard to give a name for this measurement

feature, ten maximum. Touch “Done”when complete.

2.6 - Measurement –touch and select by touching input based on

which connection is being used for this feature being measured. Note

LVDT cable connection on rear of amplifier and 4polarity of

application.

Features

–

section 2

2.7 - 5Nominal –touch and enter the nominal size of your application

using the software keyboard as a “whole”number if using absolute

method or zero’s if using deviation method. Touch “Done”when

complete.

2.8 - Upper limit/Lower limit –touch and enter the upper and lower

limits of the *6part tolerance using the software keyboard. Enter

upper & lower limits as deviation (+/-) from zero or both as “whole”

numbers matching “nominal”setup, do not mix. Touch “Done”when

complete each time.

2.9 - Master 1 size/Master 2 size –touch and enter master 1 always

maximum size & master 2 always minimum size of the masters using

software keyboard. Use sizes from certifications if masters are out of

original tolerance gages were manufactured to. Enter both max &

min sizes as deviation from zero or both as “whole”numbers

matching “nominal”and “part limits”, do not mix. Touch “Done”

when complete each time. If using a single master for electronic

gaging only, use Master 1 and touch “disable”for Master 2.

2.10 - Additional checks - If more than one measurement is to be

setup, touch “add”key and repeat above setups for each

measurement. If not, touch “done”key and proceed to calibration.

Features

-

continued

3.1 –Formulas –if the standard measurement choices shown under

“Measurement”do not apply or if a special combination of inputs or formulas

are required, the formula generator option is available. The formula generator

is available on base version E7204A. Upgrade to this version is available for

purchased.

3.1.1 –Measurement –the available formulas can be viewed in the

Measurement setup. Touch the Setup software key and Setup Access menu

appears. Enter the password if required, if not touch the Measurement Setup

key to display the first check.

3.1.2 –Touch the Measurement software key to display the available

Measurement formulas. If one of the formulas shown can be used for the

application, touch to select it which will exit you to the check menu. Touch

Next for other checks and repeat the process. Touch the Done key when

finished. Use the “View Equation”so see the actual mathematical equation

assigned to the formula.

3.1.3 –If none of the available formulas is applicable, the special Formula

Generator options will be required. Touch the Cancel key to exit to the check

menu and touch the Done key to exit to main menu.

Measurement (Formula)

–

section 3

3.2.1 –Formula Generator - Touch the Setup software key and Setup Access

menu appears. Enter the password if required, if not touch the System Setup

key to display System Setup.

3.2.2 –If the optional Formula Generator (base version E7204A) has been

purchased, the Formula Generator key will be present. Touch this key to view

the existing formulas.

3.2.3 –Existing formulas –touch each to review their function should they be

applicable. Touch Done key each time to exit their function.

Measurement (Formula)

–

continued

3.2.4 –If one of the existing formulas is not appropriate, touch the New

Formula software key at the lower left of the screen and formula generator

screen allowing the creation of the formula appears.

See (Appendix A –Formula Generator) for complete description.

3.2.5 - Gaging formulas –need to be understood as applied to the application

before the formula generator can be utilized. The Formula generator allows

Inputs or Checks to be algebraically combined.

For electronic gaging applications using LVDTs, the gaging formula will be

dependent upon the specific gaging application.

Gaging probes used within any system are strategically mounted to contact

the work piece at specified locations to perform measurements. The number of

probes used and their position determine the construction of the formula.

Two directly opposing LVDT probes combined to measure the OD of a shaft

would each have a polarity and mag number of (+) 1.000. The probes normal

operation defines the polarity as (+) when the tip is depressed. Thus as the

diameter grows, the probes are depressed providing positive readings

indicating a larger part diameter. The formula in this case would be “A+B”

where LVDT probes are connected to “A”and “B”inputs.

Measurement (Formula)

–

continued

It may be necessary to apply a multiplier to the probes outputs depending on

the application. The multiplier is determined by the number of probes used to

perform the measurement or to correct any chordal error if they are not

equally spaced. Examples:

(2) LVDTS –directly opposed, polarity/mag = (+) 1.000

Formula = A+B

(3) LVDTS –120 degrees equally space, polarity/mag = (+) .667

Formula = (A*.667) + (B*.667) + (C*.667) or (A+B+C)*.667

(4) LVDTS –90 degrees equally space, polarity/mag = (+) .5

Formula = (A*.5) + (B*.5) + (C*.5) + (D*.5) or “(A+B+C+D)*.5

For air gaging applications, the gaging formula will always be (+)1.000 outside

measurements and (-)1.000 for inside measurements. The formulas would be

“A”and “-A”

Checks can also be combine algebraically. As an example, air plug that

measures a part ID at two elevations with one labeled as the large diameter

using input A and displays as Check #1 while the other labeled as the small

diameter measured using input B and displays as Check #2. The difference

then being Taper as Check #3 can be defined as Check #1 minus Check #2.

Check #1, Large Diameter - Formula = A

Check #2, Small Diameter - Formula = B

Check #3, Taper - Formula = C1 - C2

3.2.6 –Example –to create the “Taper”formula, start by touching the

Description key to enter a Formula name. A software keyboard will popup

allowing up to (14) alpha/numeric characters to be selected. Touch the Done

key when finished.

Measurement (Formula)

–

continued

3.2.6.1 –Select the “Type”key to select the “Multi-Check”format instead of the

default “Input”format. Enter the formula “C1-C2”by selecting C1 under

“Check”selection box. Select minus “-“under the “Operators”selection box.

Select C2 under the “Check”selection box.

3.2.6.2 –Once the formula has been entered, touch the Verify key. This will

verify the formula has been entered correctly and can be used by the system.

Note that the formula must be verified before you can select “Done”and exit

the screen.

Measurement (Formula)

–

continued

4.1 - Copies of the entire setups can be stored onboard of the Accutouch

amplifier for future use. With optional version setups can be

Exported/Imported to USB drive.

4.1.1 –storing new setups - touch “Setup”, “Setup Access”menu appears.

Touch “System Setup”key, System Setup”menu now appears1(if unlocked or

if password protection has not been enabled).

Touch the “Setup Database”key and the menu to store setups appears.

Database setup

–

section 4

4.1.2 –Naming Setup - the first step is to name the new setup by touching the

Setup Name key. A software keyboard will appear allowing up to ten alpha

numeric characters to be selected. Once finished press the Done key.

4.1.3 –Saving a Setup - the setup can be saved to the Accu-touchTM memory

by touching the “Save to DB”key. Once saved the name will appear in the list.

Touch the “Done”key when finished which will exit you out one level to the

“System Setup”menu. If complete, touch the “Done”key and the main screen

will appear.

4.1.4 –Recalling existing setups –select the setup needing to be loaded by

touching the setup name shown or scrolling down or up to the setup name

required. Once the required setup name is highlighted, touch the “Load from

DB”key and the system will respond with a warning before overwriting the

existing setup. If loading a new program, touch the YES key and the setup will

load with a “Load Complete”message when finished. Touch the “OK”key and

if finished, touch the “Done”key. If not, touch the NO key and select the

appropriate name. Touch Done key to exit.

4.1.5 –Deleting an existing setup –touch the setup name or scroll down to the

setup name using the side bar until it is highlighted. Touch the Delete from

DB key and a pop up warning menu will appear asking “Delete Setup : XYZ

Deleted From Database? YES NO”. If this is the setup to delete, touch the YES

key. If not touch the NO key and select the appropriate name. Touch Done key

to exit.

Database setup

-

continued

4.2 –Export/Import Setups (option included on E7204A units)

The export/import option provides the ability to export and import setups

to/from a qualified USB drive. This option is useful when there is a need to

copy a setup from one Accu-touchTM unit to another. It also provides a way to

backup the setups externally incase setup parameters accidentally get

changed or corrupt.

4.2.1 - Export Setup –Insert Edmunds qualified USB drive into either USB

ports. Select the setup to export by touching the setup name shown or

scrolling down or up to the setup name required. Once the required setup

name is highlighted, touch the “Export to USB”key and the system will

respond with a “YES”“NO”prompt to confirm. If the setup already exists on

the USB drive, a warning before overwriting the existing setup will be

displayed. The setups will be exported to “AccuTouchSetups”directory on the

USB drive. The “AccuTouchSetups”directory will be created if does not

already exists.

4.2.2 –Import a Setup - Insert Edmunds qualified USB drive into either USB

ports. The USB drive must contain valid setup file(s) located in

“AccuTouchSetups”directory on the USB drive. Touch the “Import from USB”

key and the system will display the available setups for import that are located

on the USB drive.

Database setup

-

continued

Select the setup to import by touching the setup name shown or scrolling

down or up to the setup name required. The system will respond with a “YES”

“NO”prompt to confirm. . If the setup already exists in the internal database a

warning before overwriting the existing setup will be displayed.

5.1 - Manual adjustment –performed first time gage is used with amplifier.

5.1.1.1- Electronic gaging - “single master”, touch “Calibrate”key and

“Measure 1”will appear.

5.1.1.2 -Touch “Adv Cal Input Setup”key and the manual calibration menu

appears. Touch “select displayed results”if necessary to display

“Uncalibrated”.

5.1.1.3 - The Uncalibrated reading is now displayed in the digital window.

Place the master on the gage and read the value. If the reading is

within (200x) of the resolution selected of the zero master calibrated

size, touch the “Reset”key and then the “Done”key. If not, manually

adjust the LVDT gagehead to change the digital reading so it is.

Touch the “Reset”key and then the “Done”key when complete or

“Next”for another check and repeat this process.

5.1.1.4- Once complete, go to Software Calibration section 6.

Manual calibration

–

section 5

5.1.2.1- Electronic gaging “two master”,touch “Calibrate”key and

“Measure 1”will appear (as previously shown).

5.1.2.2 - Touch “Adv Cal Input Setup”key and the manual calibration menu

appears. Touch “select displayed results”if necessary to display

“Uncalibrated”(as previously shown).

5.1.2.3 - The uncalibrated reading is now displayed in the digital window.

Place Master 1 on the gage and read its value. If the reading is within

200x of the resolution selected of the masters calibrated size, replace

it with Master 2. If it is not within this limit, manually adjust the

LVDT gagehead to change the digital reading of Master 1 so it is.

Once adjustment for Master 1 is complete, replace it with Master 2

and read what its size is. If the difference displayed between Master

1 & Master 2 is within 25% of the actual spread, touch the “Reset”

key and then the “Done”key when complete or “Next”for another

check and repeat this process. If the spread is not within this limit,

there is a mechanical issue with the gage that needs to be addressed

before continuing.

5.1.3.1- Air gaging “two master”,touch “Calibrate”key and “Measure 1”will

appear (as previously shown).

5.1.3.2- Touch “Adv Cal Input Setup”key and the manual calibration menu

appears. Touch “select displayed results”if necessary to display

“Uncalibrated”(as previously shown) .

5.1.3.3- The uncalibrated reading is now displayed in the digital window.

Place Master 1 on the gage and read its value. If the reading is within

200x of the resolution selected of the masters calibrated size, replace

it with Master 2. If it is not within this limit, manually adjust the

“zero”screw on the a/e docking unit so it is. Once adjustment for

Master 1 is complete, replace it with Master 2 and read what its size

is. If the difference displayed between Master 1 and Master 2 is

within 50% of the actual spread, touch the “Reset”key and then the

“Done”key when complete or “Next”for another check and repeat

this process. If the spread is not within this limit, the “mag”or

“spread”needs to be adjusted. Go to Section 5 “Setting Pneumatic

Mag”for instructions.

5.1.3.4- Once complete, go to Software Calibration section 7.

Manual calibration

-

continued

Table of contents

Other Edmunds Amplifier manuals