Edmunds TRENDSETTER User manual

INSTRUCTION

MANUAL

Edmunds

GAGES

EDMUNDS GAGES

FARMINGTON INDUSTRIAL PARK

FARMINGTON, CT 06032 USA • (860) 677-2813

FAX (860) 677-4243

Edmunds

TRENDSETTER

™

TRENDSETTER™

Ever since it’s emergence in 1977, the Trendsetter™ gaging column has been the most reliable and

technologically advanced column gage in the world. With both electric and air-to-electric capabili-

ties, the Trendsetter™ is on the cutting edge of component and design technology while continuing

to provide the user-friendly ease you’ve come to expect from all Edmunds products.

The overwhelming success of the Trendsetter™ reflects a company-wide commitment to continual

technological improvement, technical integration, and customer satisfaction. This unique gaging-

column has been, and will continue to be, a dynamic and evolutionary technological achievement;

a reliable and responsive instrument perfectly suited to a constantly changing gaging environment.

EDMUNDS GAGES

Farmington Industrial Park

Farmington, CT 06032 USA

Tel (860) 677-2813

Fax (860) 677-4243

2

TABLE OF CONTENTS Page

1. Introduction ................................................................................................................... 2

2. General Description

2-1 Electronic Gaging

2-1.1 Preparing For Use........................................................................................ 4

2-1.2 Operation with LVDT Cartridges................................................................. 5

2-1.3 Mastering..................................................................................................... 5

2-1.4 Front Panel Magnification Adjustment........................................................ 5

2-1.5 Main Mag Adjustment ................................................................................. 6

2-1.6 Balance ........................................................................................................ 6

2-2 Air/Electronic Gaging.............................................................................................. 7

2-2.1 Preparing For Use........................................................................................ 7

2-2.2 Setting the Air Reading................................................................................ 8

2-2.3 Mastering..................................................................................................... 9

2-2.4 Setting to Tooling other than Edmunds..................................................... 10

3. Technical Description

3-1 E8000 Main Frame Assembly.............................................................................. 11

3-2 E8001 Limit Light Module 3 Point........................................................................ 14

3-3 E8007 Multipoint Classifying Module .................................................................. 16

3-4 E8011 Limit Light Module 5 Point........................................................................ 18

3-5 E8023 Air/Electronic Module................................................................................ 20

3-5.1 Air/Electronic Maintenance....................................................................... 22

3-5.2 Block Diagrams E8023.............................................................................. 24

3-6 E8024 T.I.R. Module with Limit Lights................................................................. 25

3-7 E8026 Sum & Difference Module......................................................................... 29

3-7.1 Block Diagrams E8026.............................................................................. 32

3-8 E8032 (2) Channel LVDT Module......................................................................... 33

3-8.1 Block Diagrams E8032.............................................................................. 35

3-9 E8051 Strain Gage Module.................................................................................. 36

3-9.1 Block Diagrams E8051.............................................................................. 38

3-10 E80124 High Speed O.D. Module ......................................................................39

4. Trendsetter™ System Programming........................................................................... 41

4-1.1 Trendsetter™ Programming Diagram .............................................................. 43

4-1.2 Trendsetter™ Systems Programming.............................................................. 44

5. Matrix Pin Header Programming................................................................................. 45

5-1.1 Programming Example-Clearance Comparator............................................... 45

5-1.2 Programming Example-Squareness/Taper...................................................... 46

6. Accessories

6-1 E8204 Relay Interface Cabinet............................................................................. 49

3

EDMUNDS TRENDSETTER™

2.1 ELECTRONIC GAGING

2-1.1 Preparing For Use - Electronic Gaging

This opening description will be as brief as possible in an effort to minimize setup time. A more

complete description of the column and it’s modules will be found later in the manual. To form a

firm three point support for the column, unscrew the front screw at the bottom of the long foot and

remount the foot on the front screw. The foot should be perpendicular to the column. This foot

will also serve as a connector for multiple column setups.

With the power switch off, plug in one or two gage probes into the A & B input sockets located in

the rear of the column. Next, plug in the 100-240 VAC/50-60 Hz supply to the back of the column.

4

2-1.2 Operation of Trendsetter™ with LVDT Electronic Probes

Using the power switch located at the rear of the column, turn the unit on. Depending upon your

application, select the input channel as required: A, B, or AB. Next, check the Inch, Metric, indica-

tor light to see if the gage is set to the required measurement system. Depress the contacts on the

probe to see if the column moves in the correct direction for the movement of the contacts; i.e., for

an O.D. measurement, a large part will cause the probe tip to move in. Any depression on the probe

tip should move the bargraph display in an upward direction. If either of these functions is incorrect,

remove the module as follows: switch the column off, unscrew the two module retraining screws,

and gently pull the module out. Do not touch the matrix I/O pin headers; the function of these units

can be found later in this write-up.

Check that the Inch and Metric Pin Headers as well as the polarity switches are in their correct

position. Replace the module by lining up the top and bottom edges of the board with it’s card

guides and sliding back until it locates in its electrical socket. Screw in the two module retaining

screws to secure the module and switch power on. The full scale range of the readout should now

be set.

To select a range, if it has not already been decided, it is best to select one that is two to three

times greater than the tolerance being checked. This will allow for good approach and oversize

range. If parts are being matched or segregated into classes and are all in tolerance, much more of

the full scale range can be used.

Set the range knob to the desired value. The corresponding digital scale values will be shown

alongside the bargraph scale. The setup is now ready for mastering.

2-1.3 Mastering

There are two basic approaches to mastering:

1.) Min. and Max. masters

2.) Mean or zero master

Setting to a Mean Master

Place the mean master in a fixture and turn the zero knob to bring the scale to zero or to the actual

calibrated size of the master.

Setting to Min. & Max. Masters

Place the max. master in the gage and, with the zero knob, adjust the column to the upper limit

reading. Remove the max. master and replace with the min. master. The reading should rise to the

lower limit. If, due to a poor initial calibration (or a non 1:1 ratio in the lever arms of the gage), the

lower limit is not achieved, the magnification should be altered.

2-1.4 Front Panel Magnification Trim

Place one master in the gage. Set one limit at the desired point with the zero knob. Apply the other

master and, with a small screwdriver, adjust the recessed “mag” screw until the column moves to

the desired point. Reapply the other master and, if necessary, readjust until both masters move the

column the required amount. This front adjust screw will allow for a trim of approximately 20% and

will change all inputs; A, B, and AB.

In some cases, where transducers other than Edmunds’ gage probes are being used, or where

levers change the 1:1 ratio of input to output, the rear adjustments on the circuit board may need to

be used.

5

To insure the success of your mastering procedure and the stability of the gage, the set points

should be re-checked with the masters at frequent intervals. The need for constant mastering will

decrease as the Trendsetter™ and the gage demonstrate stability and repeatability. Frequent mas-

tering will ensure that there are no loose contacts, and that the system is not experiencing any drift.

These potential failures can be found only by frequent mastering under production conditions.

2-1.5 Main Magnification Adjustment

At the lower back of the column is an inspection panel held in position with two screws. Removal of

this panel will expose calibration trim pot screws labeled Cal. A and Cal. B. Each input should be

set independently, using some basic measuring means such as a micrometer drive, gage blocks, or

if a single probe is being used in the fixture, this may be used with the master or with shims. Switch

to Channel A on the front of the column and set probe A to its low limit. Adjust the front zero knob

to the low column reading.

Move the probe tip the mastering distance by one of the described methods and turn the Cal. A pot

to bring the column reading to the high position. Re-check, and if, necessary, repeat between mas-

ter points to obtain the desired column movement between min. and max. master positions.

Repeat this procedure for probe B with the front panel switch turned to Channel B. With both A & B

set for magnification, replace the rear inspection panel. If both probes are being used as A & B, turn

to Channel AB and do any final master trimming on the front pot as previously described.

2-1.6 Balance

One final word on calibration is the concept of balance. Balance is the final “trimming out” of all

system magnification errors. It should be noted that balance only concerns differential measure-

ments; when both probes are measuring a diameter for example. Also, lack of balance is one of the

chief causes of poor system repeatability.

Balance is easily achieved and observed by the use of a simple mechanical balancing fixture. The

fixture clamps the A and B probes in opposing positions, and with the use of a micrometer, moves

the probes in exactly equal, but opposite directions. Such a fixture is available through Edmunds

Gages as BG29412. To check balance, complete the calibrations as described in the previous sec-

tions. Mount the A and B probes in the balancing fixture. Adjust each probe to its mechanical zero

as observed on the Trendsetter™ bargraph display. Then with the range switch set to desired appli-

cation range, and the polarity/function switches set to A+B mode, rotate the micrometer head

some convenient distance. This distance should not exceed 2x the selected range. Observe the

bargraph, it should remain fixed at zero under these conditions. If, for example, the Trendsetter™ is

set to the 0.005 inch range and the micrometer head is rotated thru 0.010 inch, the bargraph should

remain exactly at its zero position. Any movement observed on the scale indicates the system is

out of balance.

To achieve balance, a magnification adjustment is required to one channel only. First, reset the sys-

tem back to its zero starting point. Next, offset the micrometer head and adjust the B channel mag

through the rear cover. The initial amount of adjustment should be small, say no more than 1/4 turn

on the B mag pot.

Observe the bargraph, did the error get greater or smaller? If greater, turn the mag pot in the oppo-

site direction. If smaller, adjust the pot in the same direction until the bargraph remains on zero, with

the micrometer rotated thru its range. To achieve a greater degree of balance, increase the systems

sensitivity via the range switch. With a little practice and patience, balances in the order of 25

microinches or less are easily obtained!

6

When no further balance can be obtained from the system, restore the system to its initial state.

Using masters, recheck the systems mag and zero. If magnification requires adjusting, use the front

panel mag pot only, as any rear panel adjustment will nullify the balance procedure.

Balancing in a Gage Fixture

Balance may also be obtained in a gage fixture. The procedure is similar to the proceeding section

except the max master and the gage fixture are used in place of the balancing fixture.Place the max

master in the gage fixture, adjust the Trendsetter™ display to zero, push the master in a direction

which is parallel to the plane that the gage probes are mounted in. The Trendsetter™ readout

should remain fixed at zero. If any movement is observed, adjust one rear panel mag pot as

described in the preceding section. Repeat the procedure several times until no movement is

observed on the Trendsetter™ display. Restore the system to its original settings, and recheck cali-

bration with max/min masters. Remember to use the front panel mag only, as any further rear panel

adjustment will nullify the balance procedure.

2.2 AIR/ELECTRONIC GAGING

2-2.1 Preparing For Use - A/E Gaging

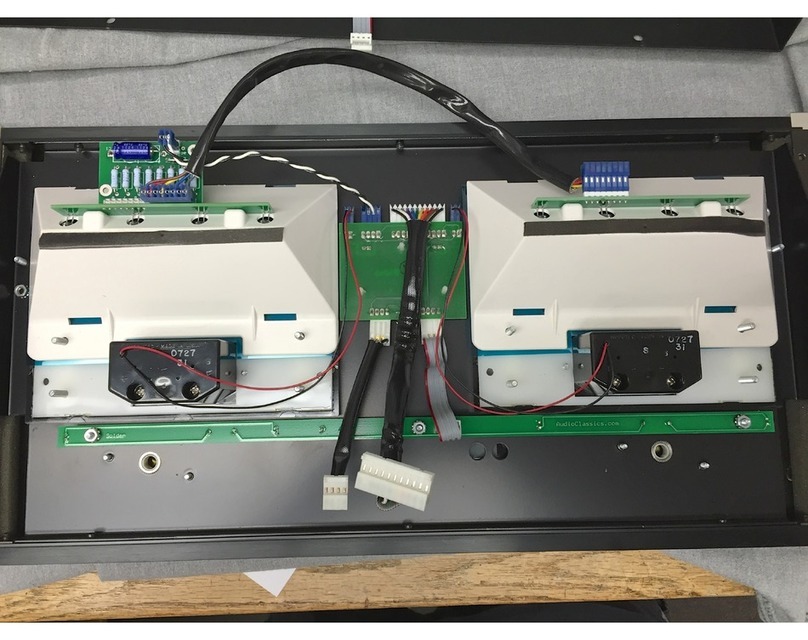

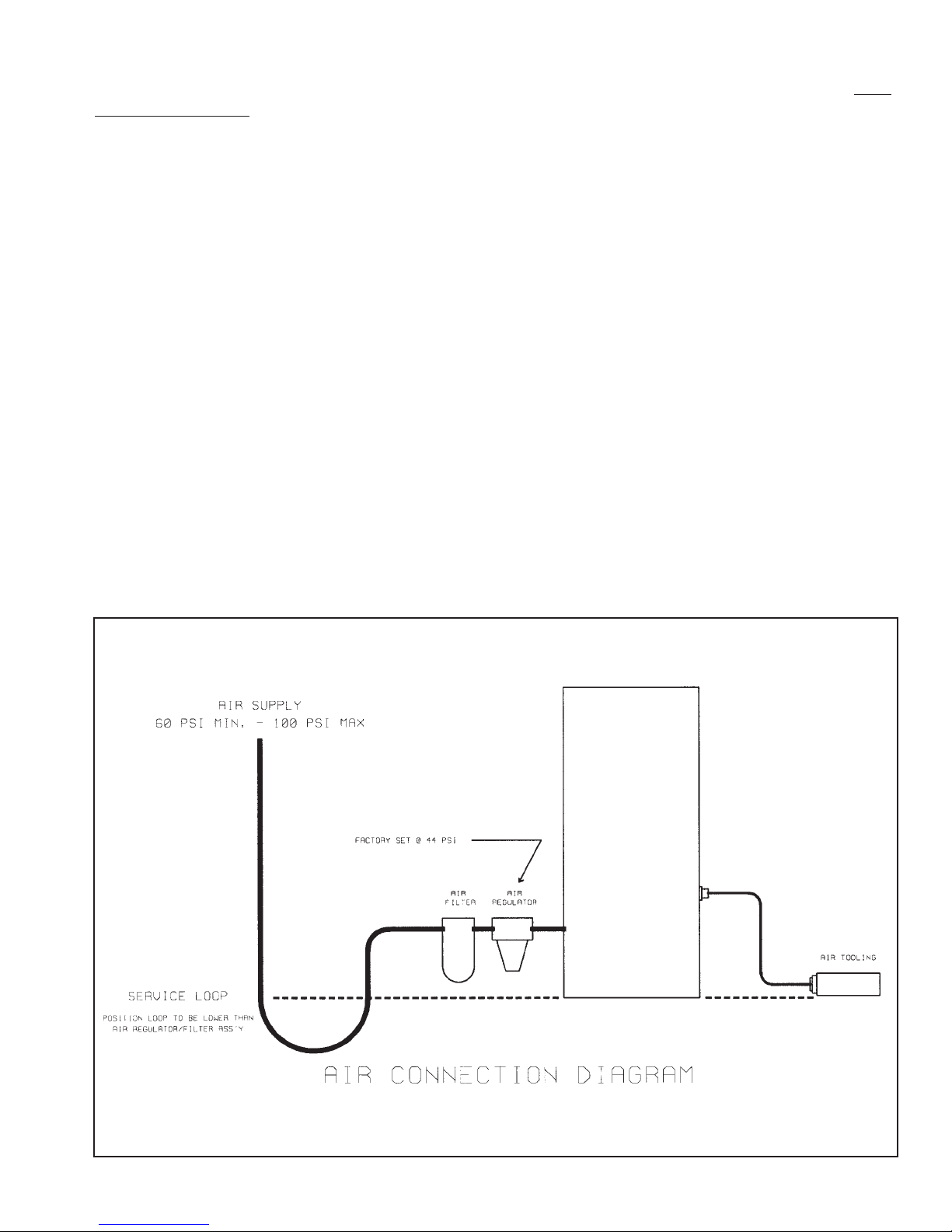

Before operation, the front foot should be set at 90° to column as described before. The air regula-

tor and filter should be mounted on the column. Unscrew the two screws holding the back foot and

turn 180° allowing the regulator and filter bracket to be mounted as shown. See photo on page 8

for correct installation.

Connect the short hose from the regulator output connector to the hose connector labeled 44.

Next, couple the tooling hose to the front gage connector. Be sure that the small plastic sleeve is

positioned correctly to insure a good seal clamp on both hoses. Tighten the brass nuts.

7

Connect the main air supply (60 PSI min) to the filter input. A turn off valve or a quick disconnect

should be used for this connection to enable the air line to readily be disconnected from the col-

umn. Connect the readout power connector to 100-240 VAC/50-60 Hz supply. Turn the power on,

turn the air supply on.

Air Consumption

Typical air consumption for Edmunds tooling is as follows; 1.50 CFM per nozzle with the air tool

inserted into a working piece part or 1.67 CFM per nozzle when the air tool is vented to atmos-

phere.

2-2.2 Setting the Air Reading

The air unit has three air amplification ranges: low, medium and high. It can be run in inch or Metric

units with the high and low readings either at the top or bottom of the scale. The pin headers to

control these functions are located on the A/E module and are not readily accessible to the opera-

tor. To gain access to the air amplification, inch/metric, and polarity pin headers, the module should

be removed with the main power switch and air supply turned off.

1.) Remove both air lines from regulator and tooling.

2.) Unscrew the two front panel screws and carefully pull

the module out.

3.) Select the proper headers and reinsert the module.

All Edmunds air tooling is marked with the full scale range for which it is intended to operate. Since

overall range of air gaging is limited, the tooling is designed to operate on one scale only.

8

Unauthorized switching of ranges may affect the performance and linearity of the tooling. The tool-

ing should be used with the following magnifications:

Marked Range Air Amplification

.010” /0.2mm Low

.005” /0.1mm Low

.002” / .05mm Med

.001” / .02mm Med/High

.0005”/ .01mm High

To set the range of the module on the bargraph, turn the front panel range switch to required posi-

tion using a small screwdriver inserted thru the front panel.

2-2.3 Mastering

1.) Check the two master sizes and determine the set points on the bargraph scale. With an

air plug, the smaller size is on the bottom. Set the pointers on the side cursor to the 2 set

points. Usually this will be with zero in the middle.

2.) Place the large-sized, or maximum ring gage master over the air plug nozzles.

3.) Adjust the top knob (M) to align the column with the to pointer.

4.) Place the minimum ring gage master over the air plug nozzle.

9

5.) Note carefully the deviation between the column position and the minus (“-”) pointer posi-

tion. Adjust bottom knob “Z” so that the column passes the minus (“-”) pointer and over-

corrects by a distance approximately 3 times the deviation just noted when using low

amplification.

NOTE: Medium amplification has a correction factor of 10 times. High amplification has a

correction factor of 30 times.

6.) Adjust the top knob “M” to align the column with the minus (“-”) pointer.

7.) Repeat steps 2 to 6 until the maximum and minimum ring gage masters bring the column

in line with the plus (“+”) and minus (“-”) pointers, respectively.

If the module has limit lights, adjust the Cal. high and Cal. low to the set points. These may also be

used instead of the cursor points and should be preset before mastering the gage for ease of

setup. (See Setting Limit Lights.)

2-2.4 Setting to Tooling other than Supplied by Edmunds

The Trendsetter™ will operate with just about any brand of air tooling, regardless of the system for

which such tooling was originally designed. Use of the Trendsetter™ with tooling manufactured for

a type of system other than Edmunds, may require some trial and error to determine the best air

amplification choice for the most stable and linear readings.When tooling (from another system) is

being used with the column, the scale and magnification must be altered to suit that particular

tooling.

Flow system tooling, which has a very shallow nozzle drop, will show very high magnification when

used on a Trendsetter™. This might necessitate a change to a lower air amplification on the 3 range

pin header.

Differential type tooling will show a slightly lower magnification than the restriction bleed tooling,

and may possibly require a high air amplification setting.

To setup these types of tooling, the following steps should help: gently close off the zero “bleed”

knob and mag restriction knob; taking care not to screw in too tightly. With the max. master on the

tooling, the column should be off scale at the bottom or top, depending on I.D. or O.D. readings.

Slowly unscrew the mag knob until the column comes on scale. Stop at the mastering point on the

scale. The gage has been set to its highest possible magnification for this tooling. Replace the max.

master with the min. The column will move to a new position. If it is not at the min. mastering point,

the magnification is not sufficient for this setup. In this case, shut the unit down, turn off air and

electric supply, remove the module and switch to the next higher air amplification using the range

pin header.

The maximum that either knob can be unscrewed is approximately five turns before the system

becomes unstable. This may occur before, depending on the air flow required to operate the tool-

ing, and will be clearly shown by column instability. None of these situations will occur when using

normal restriction bleed type tooling, as provided by Edmunds. The air circuit is completely com-

patible with Edmunds E series air gages.

10

3.0 DETAILED DESCRIPTION

E8000 - MAIN FRAME ASSEMBLY

3-1 Functional Description - Rev. D.

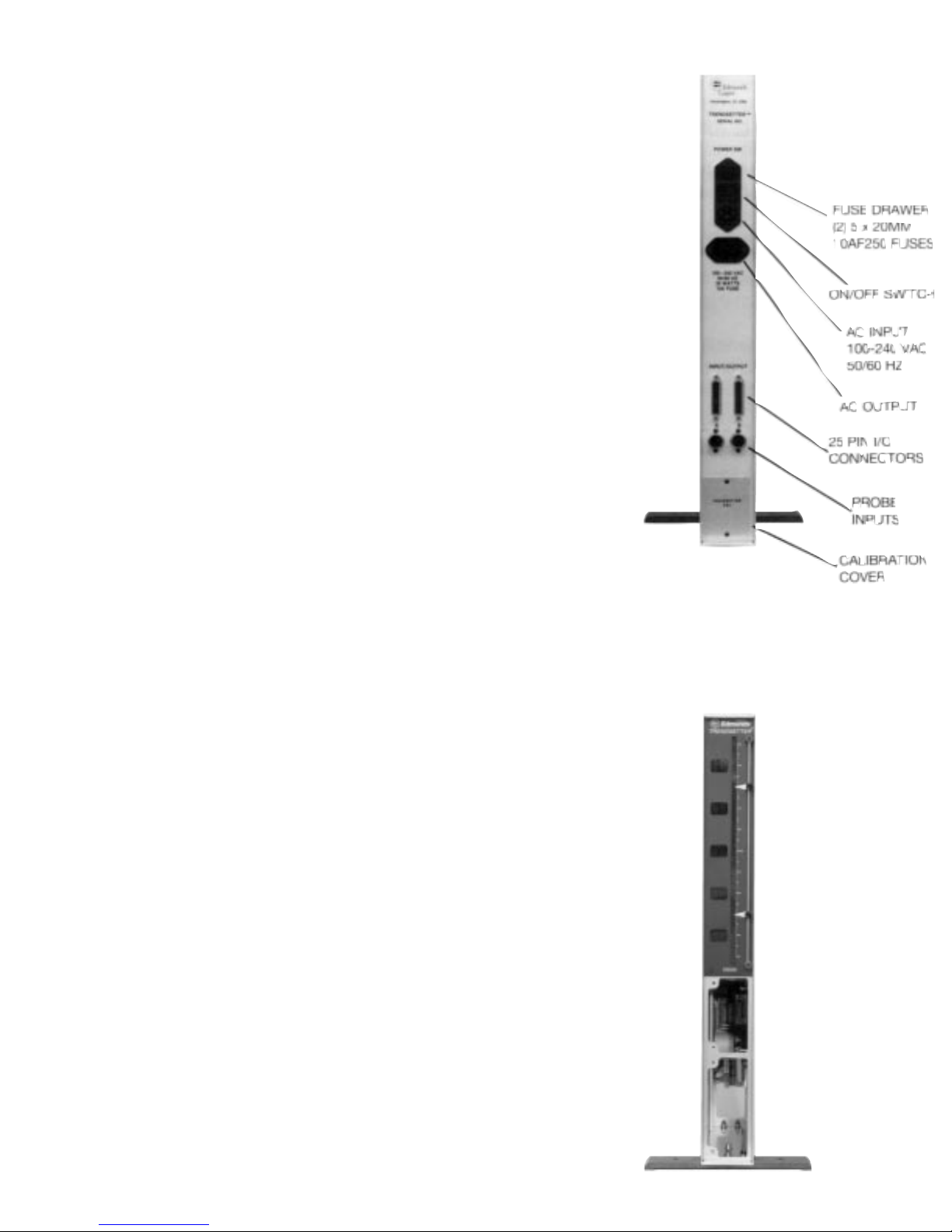

The E8000 Main Frame Assembly is the focal

point for the various plug in modules associated

with the Trendsetter™ system.

The Main Frame provides mechanical support,

interface wiring, I/O connections, power supplies

and a bargraph readout.The Main Frame mea-

sures 21.25” high, 2.50” wide, 9.00” deep.

Cabinet construction is aluminum.

An internal power supply generates +/- 15 VDC

regulated at +/- 1 AMP, and + 5 VDC at 3.0

amps. These voltages drive the display board

electronics, and any combination of plug in

modules.

The power supply is of the universal type, in that

it automatically adjusts to any line voltage from

100 VAC to 240 VAC, 50/60 Hertz.

Power consumption is 35 watts maximum. 15

watts is more typical and will drive a full compli-

ment of plug in modules.

A 10 inch, 101 point bargraph display is the pri-

mary means of readout. The 101 points give a

readable resolution of 1%. Digital scale readouts

are placed alongside the bargraph display for

ease of interpreting scales. Range switches on

various modules, have encoding logic which

supplies range information to a numeric display

library.

Additionally a 10 position dip switch, located

inside the rear panel and adjacent to the I/O

connectors, provides a simple means for

enabling any lower bay high level output signal

to reach the 10 line analog buss. The dip switch

numbers correspond to user programmable lines

1-10.

Upper Bay Modules

If the gage is to be used without an upper mod-

ule, a jumper must be installed from pin 13 to pin

15 on the upper 15 pin socket. However, if a

module is to be installed, check that the jumper

is removed.

11

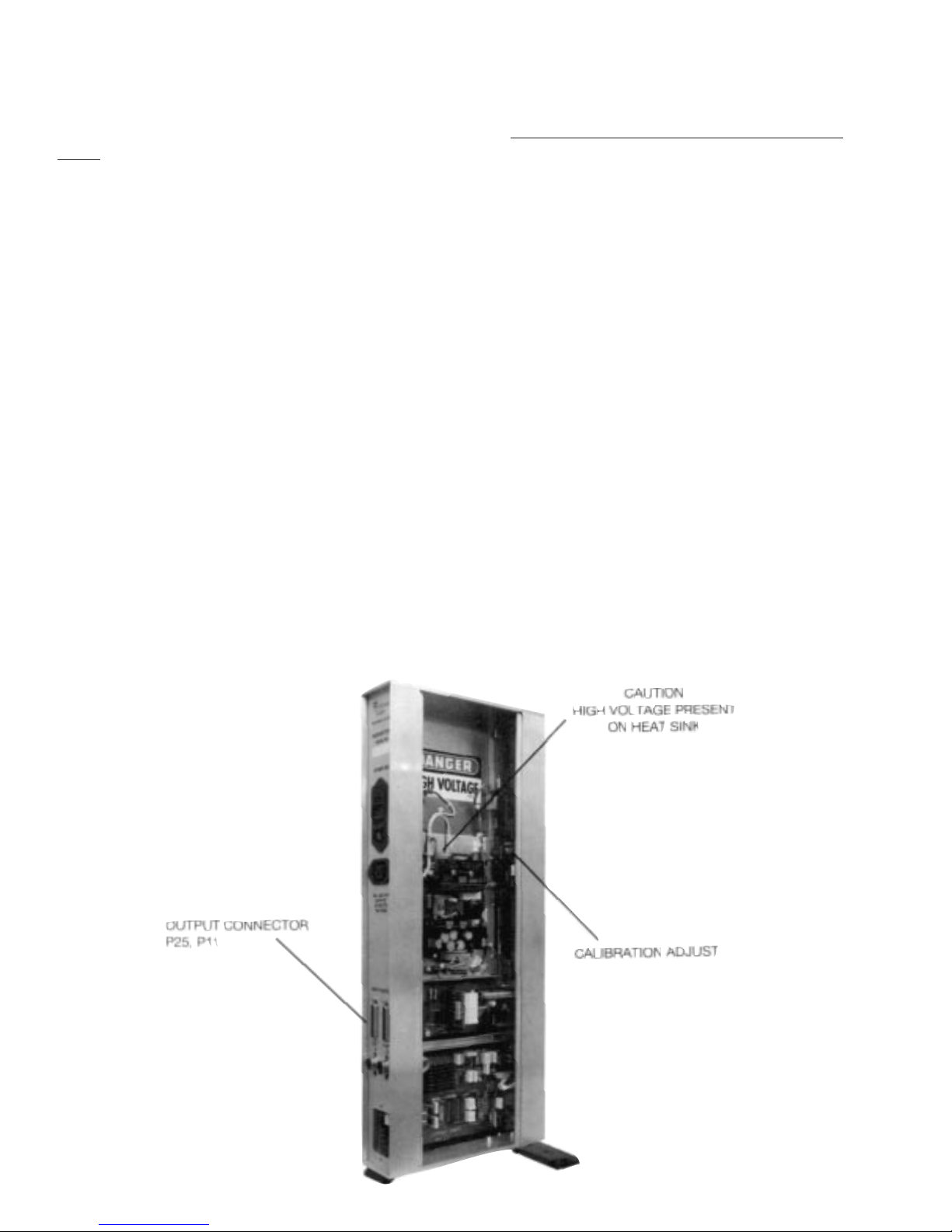

CAUTION! OBSERVE HIGH VOLTAGES PRESENT WITHIN TRENDSETTER™ CABINET

Main Frame Calibration

Calibration consists of furnishing a +/- 2.500 volt input to the display card, and adjusting the gain

pot. Before attempting, remove all plug-in modules, and observe all high voltage safety precau-

tions.1. Completely remove all AC power.

2. Facing the instrument, remove the top and left hand side covers.

3. Re-connect AC power.

4. Energize the instrument and allow to warm-up for a period of 5 minutes.

5. Apply + 2.500 volt signal to P25 of output connector, and D.C. common to P11, and

adjust gain pot for full scale.

6. Repeat step 5 with - 2.500 volt, and readjust if necessary.

7. Repeat step 4-6 until +/- full scale and center zero have been set.

Repair

Most integrated circuit components located on the display card are socket mounted for ease of

service. The seven segment digital readouts and bargraph displays are easily replaced should a fail-

ure occur. To replace these components:

1. Completely remove all AC power.

2. Remove top cover plate.

3. Remove 2 screws holding pointer rail assembly.

4. Slide out plastic display bezel.

5. Unplug connectors. Slide display assembly out of case.

6. Remove faulty component and replace with spare.

7. Re-assemble in reverse order.

12

The Common Buss

On an application that requires the output of a measuring head to be fed into more than one col-

umn for adding, averaging, checking clearance, etc., the output signal from the column is fed into a

common buss wired to the 25 pin I/O connectors. A 25 pin connector cable is plugged into each of

the columns and feeds the signal into all columns where it may or may not be used (as required).

See matrix switching and examples.

Rear Panel 25 Pin I/O Connector Assignments

Pin Number Input Connector Output Connector

1Analog Output 1 "

2 Analog Output 2 "

3 Analog Output 3 "

4 Analog Output 4 "

5 Analog Output 5 "

6 Analog Output 6 "

7 Analog Output 7 "

8 Analog Output 8 "

9 Analog Output 9 "

10 Analog Output 10 "

11 Analog Common "

12 High Output Comparator "

13 Good Output Comparator "

14 Low Output Comparator "

15 Write/Disable "

16 Reset "

17 NC "

18 NC "

19 NC "

20 TIR Reset "

21 NC "

22 NC "

23 NC "

24 Isolated Common "

25 NC High Level Output

NC = No Connection

13

E8001 - LIMIT LIGHT MODULE

3-2 Functional Description

The E8001 limit light module electronically com-

pares a lower bay input signal, against two oper-

ator calibrated set points. The E8001 module

sorts the input signal into one of three classes.

1. Over — Input signal is greater than the

high limit setpoint.

2. Good — Input signal is less than high limit,

greater than low limit setpoint.

3. Under — Input signal is less than the low

limit setpoint.

High Limit Setpoint

This control pot is located on the front panel and

is adjustable using a screwdriver.

Low Limit Setpoint

Similarly, operator calibration of this control

determines the low limit setpoint.

14

Mode Switch

The front panel mode switch has four functions.

1. Cal Low — When set to this position the readout displays the position of the low limit

setpoint.

2. Cal High — When set to this position the readout displays the high limit setpoint.

3. Man Run — This is the most frequently used position of the mode switch. When in this

position, the limit lights (over, good, under) follow the instantaneous value of the lower

bay module. This position disables the remote interface.

4. Auto Run — This position of the mode switch is used in conjunction with semiautomatic

gage fixtures and enables the remote interface.

Setting Limit Lights

The limit light module is common to the electronic and the air/electronic units and the same setting

procedure applies. Be sure that the column range switch is set to the correct position. Determine

the high and low limit points that are to be set. Set the mode switch to Cal. low and with a screw-

driver, turn the low set adjust screw and bring the column reading up to the predetermined low limit

size.

Turn the mode switch to Cal. high and, with a screwdriver, turn the high set adjust screw and bring

the column reading up to the desired high limit size. The column limit lights are now set. If the

Trendsetter™ is being used on a simple fixture, turn the mode switch to “manual run”. In this

mode, the limit lights will go on and off as the Trendsetter™ passes the preset points.

Remote Interface — Two user control lines present on the I/O connectors located on the rear

panel of the Trendsetter™ mainframe, allow an external controller to command four special

operating modes. These modes are as follows:

1. Reset — All latches cleared, limit lights and logic outputs off.

2. Follow — Same as manual run, limit lights and logic outputs follow the

signal input.

3. Latch and follow — Limit lights and logic outputs follow signal input and

latch any over or under excursions. Latches are cleared by returning to either reset

or follow mode.

4. Hold — Limit lights and logic outputs are locked into their present status,

and ignore all signal input. This condition is cleared by returning to reset or follow

mode.

To activate these special modes, turn the function switch to Auto Run position.

Determine the desired function and, using the truth tables, apply a 5-24 VDC command to the I/O

pins listed. These signals must be positive with respect to user common P24.

0 = Off State

1 = On State

Truth Table - Rear Panel I/O

P15 Write Disable P16 Reset Function

Off 0 Off 0 Follow (default)

Off 0 On 1 Latch and Follow

On 1 On 1 Hold

On 1 Off 0 Reset

Outputs

Three optically isolated outputs, representing over, good, and under, are available to the user

through the rear panel I/O connectors. The outputs are open collector NPN OPTO transistors,

whose emitters are referenced to user common P24.

The transistors may be pulled to a maximum of 24 VDC. Their main function is to interface to the

E8204 relay interface cabinet.

OUTPUT CODES REAR PANEL I/O

Condition P12 Over P13 Good P14 Under

Under Off 0 Off 0 On 1

Good Off 0 On 1 Off 0

Over On 1 Off 0 Off 0

15

16

E8007 - MULTIPOINT CLASSIFYING MODULE

3-3 Functional Description

The E8007 multipoint classifying module monitors analog data

from lower bay signal conditioning modules and digitizes these

signals into a two digit, seven segment display.

Input signals are conditioned using the high set, low set pots.

This allows the user to compress or expand the specified display

information over any portion of the Trendsetter™ scale.

A front panel output connector provides an interface to program-

mable controllers or external logic. The connector’s output is

custom programmed to a user specified code. The electrical

output code is current sourcing and has a resolution of 8 bits. To

utilize this function, a customer supplied external power source

is required. The power supply’s positive output is connected to

Pin 9 of the module. The power supply ground is referenced to

the load.

Controls

Adjustments

The Low and High set adjustments on the front of the E8007 module require the use of a small flat

blade screwdriver. The Low Set adjusts the magnification or spread of the display and the High Set

adjusts the zero position of the display.

Magnification is increased when the Low Set screw is turned in a clockwise direction, and is

decreased when turned in a counter-clockwise direction. The numerical display of the E8007 does

not reflect the change in magnification that occurs when the Low Set screw is turned. A trial and

error method will be employed until the operator obtains a feel for the amount of adjustment

required.

Set Up Procedure

1. Place either master into the gage.

2. Using the “Zero” knob on the TrendsetterTM lower bay module, set the bargraph display

to the lowest position on scale where classifying is to begin.

3. Adjust the High Set screw to display the first classification character being utilized.

Example: If “0” is the lowest classification point, adjust the display to read “00”. Rotate

the High Set screw until the display changes to “UU”. Now rotate the High Set screw

until the display changes back to “0”.

4. Using the “Zero” knob on the TrendsetterTM lower bay module, set the bargraph display

to the highest position on scale where classifying is to end. If the character displayed on

the E8007 is larger than desired, the magnification is too large. If the character displayed

is smaller than desired, the magnification is too small.

5. Depending on the type of adjustment required turn the Low Set screw 5 turns in the

respective direction required. (Clockwise to increase, Counter-Clockwise to decrease)

6. Using the “Zero” knob on the TrendsetterTM lower bay module, set the bargraph display

to the lowest position on scale.

7. Using the “Zero” knob on the TrendsetterTM lower bay module, set the bargraph display

to the highest position on scale where classifying is to end. If the character displayed is

correct, no further adjustments are needed. If the character displayed is in error, repeat

the above procedure until the display characters correspond to the bargraph settings.

Electrical Connections, Front Panel Connector

Pin

1 Output Bit 1

2 Output Bit 2

3 Output Bit 3

4 Output Bit 4

5 Output Bit 5

6 Output Bit 6

7 Output Bit 7

8 Output Bit 8

9 + External customer supplied power source

External logic signals may command the E8007 module to be placed into a holding mode, which

corresponds to the hold command of the E8001, E8011, E8024 modules. (See below truth table)

0 = Off State

1 = On State

P15 Write Disable P16 Reset Function

Off 0 Off 0 Follow (Default)

Off 0 On 1 Hold

On 1 Off 0 Hold

On 1 On 1 Hold

17

E8011 - FIVE POINT LIMIT LIGHT MODULE

3-4 Functional Description

The E8011 module compares four precalibrated setpoints against a lower bay signal and sorts the

signal into five classes. The five classes are defined as follows:

1. Over — input signal is greater than high limit.

2. Approach — input signal is between

good and high limits.

3. Good — input signal is between approach limits.

4. Approach — input signal is between good

and under limits.

5. Under — input signal is less than under limit.

Logical outputs representing the status of the

limit lights are connected to the 25 pin I/O buss.

Controls

High, low, approach setpoints are located on the front panel and

adjusted with a screwdriver. To calibrate a setpoint, select the

desired setpoint using the mode switch. With a small screwdriver

adjust the associated 22 turn pot. The bargraph display will indi-

cate the position of the setpoint.

To ensure a successful operation: the low setpoint must be less

than the low approach setpoint, the low approach setpoint must be less than the upper approach

setpoint, the upper approach setpoint must be less than the high setpoint.

Mode Switch

The front panel mode switch has six positions.

1. Cal. Low - see above

2. Cal. Low approach - see above

3. Cal. Upper approach - see above

4. Cal. High - see above

5. Man. Run - This the most frequently used position of the mode switch. When used in this posi-

tion, the limit lights follow the instantaneous value of the lower bay module. This position dis-

ables the remote interface.

6. Auto Run - This position of the mode switch is used in conjunction with semiautomatic gage

fixtures.

Remote Interface — Two user control lines present on the I/O connectors located on the rear

panel of the Trendsetter™ mainframe, allow an external controller to com-

mand four special operating modes. These modes are as follows:

1. Reset — All latches cleared, limit lights and logical outputs off.

2. Follow — Same as manual run. Limit lights and logic outputs follow the input signal.

18

3. Latch — Limit lights and logic latch the most positive and excursion of the analog input.

Latches are Follow cleared by returning to reset or follow modes.

4. Hold — Limit lights and logic are locked into their present status and ignore any signal

input. This condition is cleared by returning to reset or follow mode.

To activate any of these special modes, turn the function switch to the auto run position. Determine

the desired function and, using the truth table, apply a 5-24 VDC command to the I/O pins as listed.

These voltages must be positive with respect to user common P24.

0 = Off State

1 = On State

Truth Table Rear Panel I/O

P15 Write Disable P16 Reset Function

Off 0 Off 0 Follow (Default)

Off 0 On 1 Latch

On 1 On 1 Hold

On 1 Off 0 Reset

Outputs

Three optically isolated outputs, representing over, good, under, and approach are encoded and

available to the user through the 25 pin I/O connectors (See Table). The outputs are open collector

NPN OPTO transistors whose emitters are referenced to user common P24 of the I/O connector.

The transistor may be pulled to a maximum of 24 VDC.

Output Codes Rear Panel I/O

Condition P12 Over P13 Good P14 Under

Under Off 0 Off 0 On 1

Under Approach Off 0 On 1 On 1

Good Off 0 On 1 Off 0

Over Approach On 1 On 1 Off 0

Over On 1 Off 0 Off 0

19

20

E8023 - AIR/ELECTRONIC SIGNAL CONDITIONING MODULE

3-5 Functional Description

The E8023 Air/Electronic module converts pneumatic pressure from air gage tooling, into a calibrat-

ed electrical signal.

The module contains an air/electronic transducer assembly, three selectable fixed gains, polarity

reversal, inch/mm selection, a 10 position pin header allowing access to the I/O busses, and a 5

position range encoding switch to signal the readout display.

Two 3/8” bulkhead fittings provide a convenient means for attaching the air supply and air gage

tooling to the module.

Controls

Mag Adjustment

Mag adjustment is carried out by means of a pneumatic

needle valve assembly which is part of the A/E transduc-

er assembly. The needle valve has a useful travel of 5

turns.

Zero Adjustment

Zero adjustment is also a needle valve assembly, with a

useful travel of 5 turns.

Table of contents

Other Edmunds Amplifier manuals