Order NO.TL1610S009

Issue

Service Manual Rev.

Chapter 1: General Infromation

1-1. Table of Contents

Document control

Chapter 1. General Information ............................................................................... 2

2 stnetnoC fo elbaT.1-1

3 senilediuG lareneG.2-1

3slobmys gninraW dna noituaC.3-1

......................................................................................................... 1

Chapter 2. Product Feature

4serutaeF.1-2

5snoitacificepS.2-2

3slobmys noitacidni noitcnuF.4-1

....................................................................................... 4

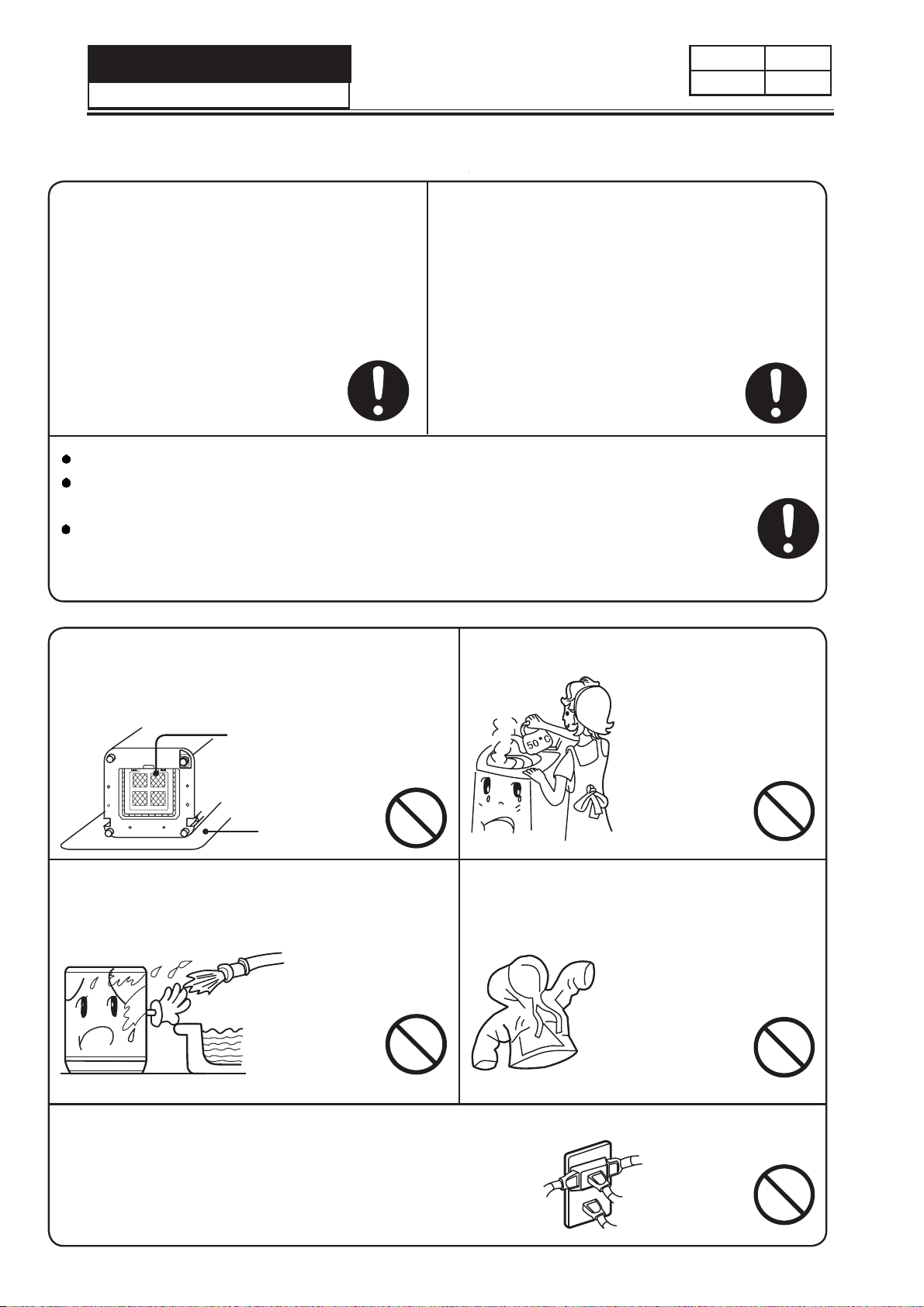

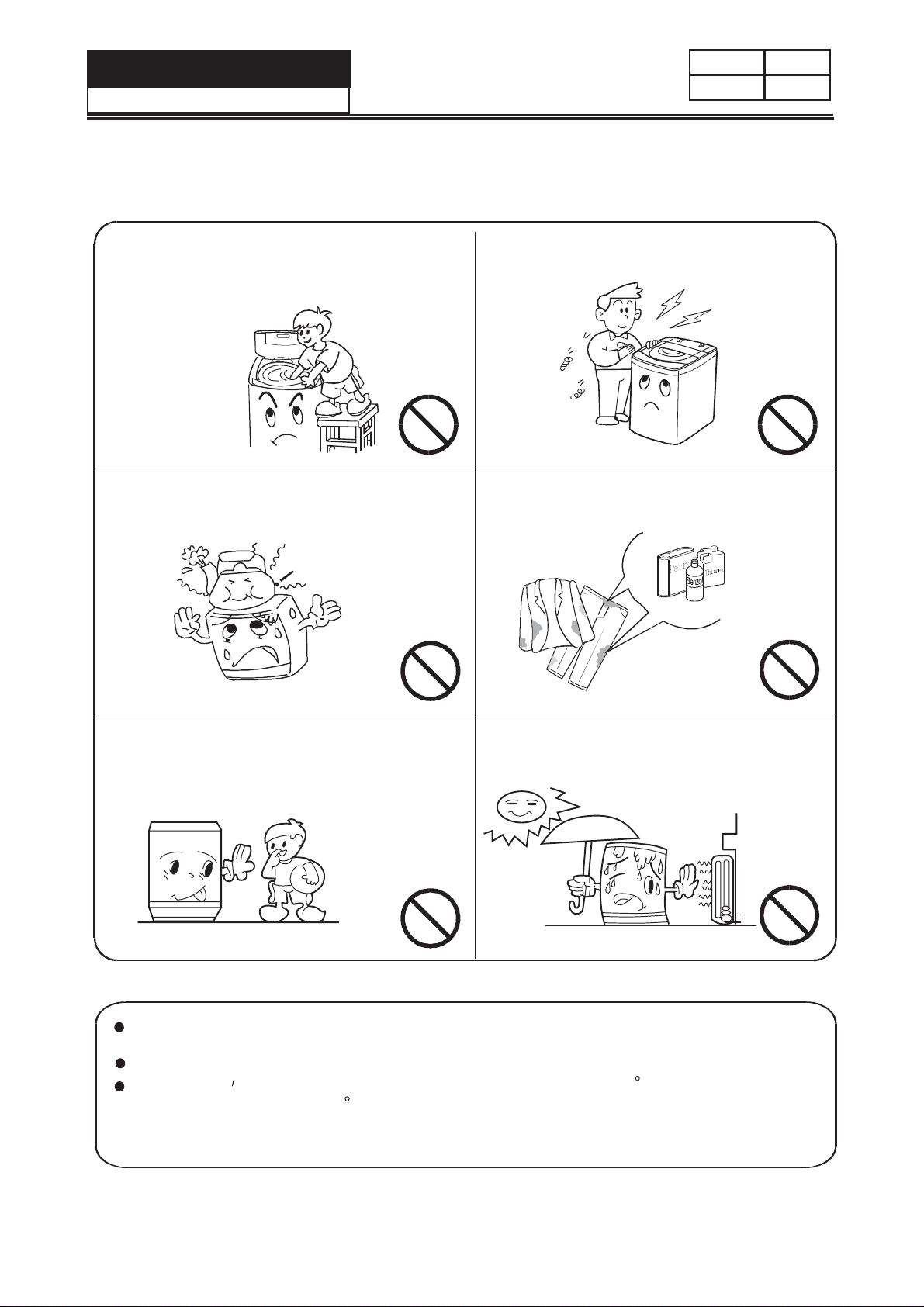

Chapter 3. Safety Precautions

3-1. Safety 6

7snoituac dna gninraW.2-3

Chapter 4. Installation and accessory parts .............................................................

6

8

4-2. Installation the button plate

4-3. Adjustment of the installation position

4-1. Key points in installation

4-4. Usage of operation buttons

4-7. Key points in disassembly

4-5. Product briefs

15

15

Chapter 6. Maintenance service and trouble shooting

.............................................

6-1.

6-2. Trouble shooting charts

6-2-1. No action(the indicator is off)

6-2-2. No water filling

6-2-3. No rotation in washing or(rotate to one direction)

6-2-4. No draining

6-2-5. Keep filling water

6-2-7. Too much spinning noise

6-2-6. No spinning

6-2-8. Too much noise in washing

6-2-9. The tub rotates to one direction(in washing)

6-2-10. Brake time out

Chapter 7. Wiring diagram .................................................................22

.........................

8snisnemiD teN.3-3

8

8

9

11

12

12

16

16

17

17

18

18

19

19

20

20

21

.......................................................................................

.......................................................................................

.....................................................................

.....................................................................

.....................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.........................................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.........................................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

14

Chapter 5. Parts and functions

...................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

.......................................................................................

4-6. Adding washing powder 12

. ............................................................................................