Edwards D397-01-880 User manual

D397-01-880

Issue E

Instruction Manual

TIC Instrument Controller 6-Gauge

Description Item Number

TIC Instrument Controller 6-Gauge D397-01-000

TIC Instrument Controller 6-Gauge Capacitance Manometer D397-02-000

Original Instructions

This page has been intentionally left blank.

Declaration of Conformity

We, Edwards,

Innovation Drive,

Burgess Hill,

West Sussex,

RH15 9TW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised

to assemble the technical file, that the product(s)

TIC Instrument Controller D397-00-000

TIC Instrument Controller 6-Gauge D397-01-000

TIC Instrument Controller 6-Gauge Capacitance Manometer D397-02-000

TIC Turbo Controller 100W D397-11-000

TIC Turbo Controller 200W D397-12-000

TIC Turbo & Instrument Controller 100W D397-21-000

TIC Turbo & Instrument Controller 200W D397-22-000

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN61010-1:2010 Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use – Part 1: General

Requirements

EN61326-1:2013 Electrical Equipment for Measurement Control and Laboratory

(Class B Emissions, Use – EMC Requirements. General requirements

Industrial Immunity)

CAN/CSA-C22.2 Safety requirements for electrical equipment for

No.61010-1-04 measurement, Control and laboratory use – Part 1: General

requirements

UL61010-1, 2nd Edition Safety requirements for electrical equipment for

measurement, Control and laboratory use – Part 1: General

requirements

and fulfils all the relevant provisions of

2014/35/EU Low Voltage Directive

2014/30/EU Electromagnetic Compatibility (EMC) Directive

2012/19/EU Waste from Electrical and Electronic Equipment (WEEE)

Directive

2011/65/EU Restriction of Certain Hazardous Substances (RoHS) Directive

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

20.09.2016, Eastbourne

Larry Marini, Senior Technical Manager Date and Place

P200-03-140 Issue G

This product has been manufactured under a quality management system certified to ISO 9001:2008

P200-10-044

Issue A

Material Declaration

In accordance with the requirements of the Chinese regulatory requirement on the Management Methods for the

Restriction of the Use of Hazardous Substances in Electrical and Electronic Products Order No. 32 (also known as

‘China RoHS2’) and SJ/T 11364 Marking for the Restricted Use of Hazardous Substances in Electronic and Electrical

Products:

Product Product Label Meaning

D39700000 TIC Instrument Controller

D39701000 TIC Instrument Controller 6 Gauge

D39702000 TIC Instrument Controller 6 Gauge

Capacitance Manometer

D39711000 TIC Turbo Controller 100 W

D39712000 TIC Turbo Controller 200 W

D39721000 TIC Turbo and Instrument

Controller 100 W

D39722000 TIC Turbo and Instrument

Controller 200 W

This product contains hazardous substances in at

least one of the homogeneous materials used

which are above the limit requirement in GB/T

26572 as detailed in the declaration table below.

These parts can safely be used for the

environmental protection use period as

indicated.

材料成分声明

Materials Content Declaration

部件名称

Part name

有害物质

Hazardous Substances

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr VI)

多溴联苯

Polybrominated

biphenyls (PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

印刷电路组件 (PCA)

Printed Circuit

Assembly (PCA)

X O X O O O

电缆/电线/连接器

Cable/wire/connector

X O O O O O

机械部件

Mechanical Components X O O O O O

O: 表示该有害物质在该部件的所有均质材料中的含量低于 GB/T 26572 标准规定的限量要求。

O: Indicates that the hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement in GB/T 26572.

X: 表示该有害物质在该部件的至少一种均质材料中的含量超出 GB/T26572 标准规定的限量要求。

X: Indicates that the hazardous substance contained in at least one of the homogeneous materials used for

this part is above the limit requirement of GB/T26572.

NOTE: These products are EU RoHS compliant, the following Exemptions apply:

6(b)

Lead

as an alloying element in aluminium containing up to 0.4% by weight

6(c) Copper alloy containing up to 4%

lead

by weight

7(a)

Lead

in in high melting temperature type solder (i.e. lead based alloys containing 85% by or more)

7(b)

Lead

in solders for servers, storage and storage array systems, network infrastructure equipment for switching, signalling,

transmission, and network management for telecommunications

7(c) I Electrical and electronic components containing

lead

in a glass or ceramic other than dielectric ceramic in capacitors, e.g.

piezoelectronic devices, or in a glass or ceramic matrix compound

7(c) II

Lead

in dielectric ceramic in capacitors for a rated voltage of 125 V AC or 250 V DC or higher

8(b)

Cadmium

and its compounds in electrical contacts

15

Lead

in solders to complete a viable electrical connection between semiconductor die and carrier within integrated circuit flip

chip packages

34

Lead

in cermet-based trimmer potentiometer elements

© Edwards Limited 2016. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

D397-01-880 Issue E

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope and definitions ................................................................................................... 1

1.2 Product description ...................................................................................................... 1

2 Technical data ....................................................................................3

2.1 Electrical data ............................................................................................................ 3

2.2 Operating and storage data ............................................................................................ 3

2.3 Mechanical data .......................................................................................................... 3

2.4 Connections ............................................................................................................... 3

2.4.1 Active gauge connectors ................................................................................................ 3

2.4.2 Logic interface ...........................................................................................................4

2.4.3 Serial communications .................................................................................................. 6

2.4.4 Analogue outputs ........................................................................................................ 7

3 Installation .........................................................................................9

3.1 Unpack and inspect ...................................................................................................... 9

3.2 Fitting the controller .................................................................................................... 9

3.3 Controller electrical connections ....................................................................................12

3.3.1 Connecting the electrical supply .....................................................................................13

3.3.2 Additional earth bonding ..............................................................................................13

3.3.3 Connecting an active gauge ...........................................................................................13

3.3.4 Connecting the logic interface .......................................................................................14

3.3.5 Connecting the serial interface .......................................................................................15

4 Operation ........................................................................................ 17

4.1 Front panel description ................................................................................................17

4.2 Menu structure ..........................................................................................................18

4.3 Navigating the menu ...................................................................................................19

4.4 The view screen .........................................................................................................20

4.5 Turning gauges and relays ON/OFF ..................................................................................20

4.6 Changing list items .....................................................................................................21

4.7 Changing numerical values ............................................................................................21

4.7.1 Entering negative components e.g. 5.00E-03 ......................................................................21

4.8 Gauge setup .............................................................................................................22

4.8.1 Default setup options (all gauges) ...................................................................................22

4.8.2 Gauge status messages .................................................................................................23

4.8.3 Active Pirani Gauge (APG) .............................................................................................23

4.8.4 Active Linear Pirani Gauge (APGX) ...................................................................................24

4.8.5 Active Thermocouple Gauge (ATC-E) control ......................................................................25

4.8.6 Active Strain Gauge (ASG) control ...................................................................................26

4.8.7 Active Inverted Magnetron (AIM) Gauge control ...................................................................27

4.8.8 Active Ion Gauge (AIGX-S) control ...................................................................................28

4.8.9 Wide Range Gauge (WRG) .............................................................................................29

4.8.10 Ion Gauge Controller (IGC) - gauge type displayed as ‘IONEB’ ..................................................31

4.8.11 Capacitance Manometer Gauges (D39702000 only) ................................................................33

4.9 Alarms ....................................................................................................................34

4.10 The main menu ..........................................................................................................34

4.11 Linking gauges ...........................................................................................................34

4.12 Parameters/Units .......................................................................................................35

4.13 Screen options ...........................................................................................................36

4.13.1 Organising gauges on the view screen ...............................................................................36

MV/06/14

D397-01-880 Issue E

Page ii © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

4.14 Relay setpoint outputs .................................................................................................37

4.15 Service information .....................................................................................................37

4.16 Electrical supply failure ...............................................................................................37

5 Maintenance ..................................................................................... 39

5.1 Safety .....................................................................................................................39

5.2 Fault finding .............................................................................................................39

5.3 Cleaning the controller ................................................................................................40

5.4 Software updates .......................................................................................................40

5.5 Factory defaults .........................................................................................................40

6 Storage and disposal ........................................................................... 41

6.1 Storage ...................................................................................................................41

6.2 Disposal ...................................................................................................................41

7 Service, spares and accessories .............................................................. 43

7.1 Introduction .............................................................................................................43

7.2 Service ....................................................................................................................43

7.3 Spares .....................................................................................................................43

7.4 Accessories ...............................................................................................................43

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 Pin connections for an 8-way FCC/RJ45 ............................................................................. 4

2 Pin connections for a 15-way sub-miniature 'D' type socket ...................................................... 4

3 Pin connections for a 9-way sub-miniature 'D' type socket ........................................................ 6

4 Pin connection for 4-way analogue output connector ............................................................. 7

5 Bench mounted TIC dimensions (mm) ...............................................................................10

6 Front panel removal ....................................................................................................11

7 Rack mounting of a TIC ................................................................................................11

8 Panel cutout drawing ..................................................................................................12

9 Rear panel connections ................................................................................................12

10 IBM PC RS232 interface - 9-way ......................................................................................15

11 IBM PC RS232 interface - 25-way .....................................................................................16

12 RS485 TIC network ......................................................................................................16

13 Front panel display .....................................................................................................17

14 View screen shortcuts ..................................................................................................18

15 Menu structure ..........................................................................................................19

16 New gauge connected ..................................................................................................20

17 Changing numerical values ............................................................................................21

18 Gauge setup screen .....................................................................................................22

19 Gauge setup screen APGX-M ..........................................................................................24

20 Gauge setup screen ASG ...............................................................................................26

21 Gauge setup screen AIGX ..............................................................................................28

22 Gauge setup screen WRG ..............................................................................................30

23 Setup screen IGC ........................................................................................................32

24 Setup screen Capacitance Manometer ..............................................................................34

25 Controlled item .........................................................................................................35

26 Control setup ............................................................................................................35

27 Gauge order set up .....................................................................................................36

© Edwards Limited 2016. All rights reserved. Page iii

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

D397-01-880 Issue E

Tables

Table Page

1 Compatible equipment for the TIC Instrument Controller 6-Gauge ............................................. 2

2 Gauge connector pin-out ............................................................................................... 4

3 Logic interface connector pin-out .................................................................................... 5

4 Serial communications connector pin-out ........................................................................... 6

5 Pin allocation for analogue outputs ................................................................................... 7

6 Component checklist .................................................................................................... 9

7 Capacitance manometer gauges ......................................................................................13

8 Other gauges ............................................................................................................13

9 Logic connector Edwards accessories ................................................................................14

10 Front panel symbols and their functions ............................................................................17

11 Default setup options (all gauges) ...................................................................................22

12 Gauge status messages .................................................................................................23

13 Error/diagnostic monitoring APG .....................................................................................23

14 Setup options APGX .....................................................................................................24

15 Error/diagnostic monitoring APGX ...................................................................................25

16 ATC-D and ATC-M gauge tubes ........................................................................................25

17 Error/diagnostic monitoring ATC-E ..................................................................................26

18 Setup options ASG ......................................................................................................26

19 Error diagnostic monitoring ASG ......................................................................................27

20 Error/diagnostic monitoring AIM .....................................................................................27

21 Setup options AIGX .....................................................................................................28

22 Error/diagnostic monitoring AIGX ....................................................................................29

23 Setup options WRG .....................................................................................................29

24 Error/diagnostic monitoring WRG ....................................................................................30

25 Setup options IGC .......................................................................................................31

26 Diagnostic messages ....................................................................................................32

27 Setup options Capacitance Manometer ..............................................................................33

28 Fault finding .............................................................................................................39

29 Factory default settings ...............................................................................................40

30 Accessories ...............................................................................................................43

Trademark credits

Barocel®is a registered trademark of TBA

This page has been intentionally left blank.

D397-01-880 Issue E

Page iv © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

© Edwards Limited 2016. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Introduction

D397-01-880 Issue E

1Introduction

1.1 Scope and definitions

This manual provides Installation, Operation and Maintenance instructions for the Edwards TIC Instrument Controller

6-Gauge. The controller must be used as specified in this manual. Read this manual before installing and operating

the controller.

Important safety information is highlighted as WARNING and CAUTION instructions; these instructions must be

obeyed. The use of WARNINGS and CAUTIONS is defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

The units used throughout this manual conform to the SI international system of units of measurement.

The following warning labels are on the controller:

1.2 Product description

The TIC Instrument Controller 6-Gauge is provided with a large clear graphics display, easy-to-use control interface

via a keypad, an RS232/485 interface for control and data monitoring on a remote PC and a logic interface for

interface with associated system hardware.

The compatible instruments that can be used with the TIC Instrument Controller 6-Gauge are listed in Table 1.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Warning - refer to accompanying documentation.

Edwards offer European customers a recycling service.

WARNING

Improper use of the equipment could cause damage to it or injury to people. The user is

responsible for the safe operation and monitoring of the equipment. Hazardous voltages should not

be connected to this unit except where specified.

D397-01-880 Issue E

Page 2 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Introduction

Table 1 - Compatible equipment for the TIC Instrument Controller 6-Gauge

TIC variant Compatibility

TIC Instrument Controller 6-Gauge Up to 6 active gauges including: APG, APGX, ATC, ASG,

AIM, WRG, AIGX and IGC

TIC Instrument Controller 6-Gauge Capacitance

Manometer Up to 6 active gauges including: APG, APGX, ATC, ASG,

AIM, WRG, AIGX, IGC and Capacitance Manometers 600,

622, 655 and 658

© Edwards Limited 2016. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

D397-01-880 Issue E

2Technicaldata

2.1 Electrical data

2.2 Operating and storage data

2.3 Mechanical data

2.4 Connections

2.4.1 Active gauge connectors

Connector type CEE/IEC 320

Electrical supply 100 - 240 V a.c. 50/60 Hz

Power consumption 160 VA maximum (rated power consumption is based upon

maximum specified load)

Fuse The unit is self-protecting and has no user replaceable

fuse. The unit will recover once any overload is removed.

Overvoltage category 2

Earth stud M4

Ambient operating temperature range 0 °C to 40 °C (measured underneath TIC)

Ambient storage temperature range -30 °C to 70 °C

Maximum ambient operating humidity Max 90% RH non condensing at 40 °C

Maximum operating altitude 3000 m max

IP rating 20

Pollution degree 2

Indoor use only

Weight 1.7 kg

Connector type FCC/RJ45, 8-way (refer to Figure 1)

Maximum power rating See Section 3.3

Input voltage range -0.3 V to 13 V

Output ID current 33 µA, 0 V to 13 V

Control output

Active <0.8 V d.c. (2 mA max

Inactive open (internal pull-up to 24 V)

Control input

Low <2.0 V d.c. (Iout<160 µA)

High >3.5 V d.c. (internally pulled up to 24 V)

D397-01-880 Issue E

Page 4 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

Figure 1 - Pin connections for an 8-way FCC/RJ45

2.4.2 Logic interface

Figure 2 - Pin connections for a 15-way sub-miniature 'D' type socket

Table 2 - Gauge connector pin-out

Pin Allocation

1 Power supply positive

2 Power supply common

3Signalinput

4 Identification

5Signalcommon

6Controlline1

7Controlline2

8 Power supply negative for Capacitance Manometer

N/C for all other versions

Connector type 25-way sub-miniature 'D' type socket (refer to Figure 2)

Power supply 24 V d.c.

Maximum output power See Section 3.3

Control output

active <1.1 V d.c. (Iout < 20 mA), <0.8 V d.c. (Iout < 2 mA)

inactive open

Control input

low <2.0 V d.c. (Iout<160 µA)

high 3.5 V to 24 V d.c. (internal pull up to 24 V)

Analogue output 0 to 10 V (5 mA max)

50 mV resolution

© Edwards Limited 2016. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

D397-01-880 Issue E

Table 3 - Logic interface connector pin-out

Pin Allocation

1Screen

2 Analogue output signal

3Setpoint1output

4 Do not connect

5Setpoint5output

6Setpoint4output

7Powersupplycommon

8 Do not connect

9 Gauge 1 enable input

10 Power supply common

11 Power supply positive

12 Power supply common

13 Power supply common

14 Analogue output common

15 Setpoint 2 output

16 Setpoint 3 output

17 Do not connect

18 Alarm output

19 Setpoint 6 output

20 Gauge 2 enable input

21 Gauge 3 enable input

22 Do not connect

23 Do not connect

24 Do not connect

25 System interlock input (SYSI)

D397-01-880 Issue E

Page 6 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

2.4.3 Serial communications

Figure 3 - Pin connections for a 9-way sub-miniature 'D' type socket

Connector type 9-way sub-miniature 'D' type socket (refer to Figure 3)

RS232 transmit

Mark < - 8 V (Iout max: -8 mA)

Space > +8 V (Iout max: +8 mA)

RS232 receive

Mark < +1.0 V (Iin max: -2.0 mA)

Space >+2.0 V (Iin max: +2.0 mA)

Maximum input ±12 V

RS232 protocol 9600 baud, 1 stop bit, 8 data bits, no parity

RS485

Output differential >1.5 V (Iout max: ±25 mA)

Input differential threshold >±0.2 V (Iin max: ±1 mA)

Maximum input -7.0 V to +12 V

Bus load The TIC applies one unit load to the RS485 bus.

Table 4 - Serial communications connector pin-out

Pin Allocation

1N/C

2RS232transmit

3RS232receive

4N/C

5RS232common

6N/C

7N/C

8RS485dataA

9RS485dataB

© Edwards Limited 2016. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

D397-01-880 Issue E

2.4.4 Analogue outputs

Figure 4 - Pin connection for 4-way analogue output connector

Connector type Phoenix 2.5 mm 4-way

mating half Phoenix FK-MC 0.5/4-ST-2.5

(available from Edwards as 5000 17005)

Short circuit protection All signals

Max load

Gauge signals ±1 mA

Common ±3 mA

Output voltages

Gauge connected Gauge signal voltage (±2% ±15 mv when in range 0 to +10 V)

Gauge disconnected 12 V (±1.3 V)

Table 5 - Pin allocation for analogue outputs

Pin Allocation

Gauges 1-3 (Top Ports) Gauges 4-6 (Lower Ports)

1 Gauge 1 signal Gauge 4 signal

2 Gauge 2 signal Gauge 5 signal

3 Gauge 3 signal Gauge 6 signal

4 Common (0 V) Common (0 V)

gea/d39701/f4

1234

D397-01-880 Issue E

Page 8 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

© Edwards Limited 2016. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

D397-01-880 Issue E

3 Installation

3.1 Unpack and inspect

Remove all of the packaging material and check the controller. If the controller is damaged, follow the Edwards

return of equipment procedures that are laid out in the back of this manual. Do not use the controller if it is damaged.

Check that the package contains the items that are listed in Table 6. If any of these items are missing, notify the

supplier in writing within three days. If the controller is not to be used immediately, store the controller in suitable

conditions as described in Section 6.1.

3.2 Fitting the controller

CAUTION

Rubber feet must be fitted (Figure 5, item 1) so that there are correct clearances for air circulation. If not, the

performance of the controller may be affected at high operating temperatures.

The controller can be used on a bench top or can be fitted in a rack or cabinet. Figure 5 shows the dimensions of the

TIC that are required for bench top use.

Note: If the interlocks are not used, the logic interface adaptor must be fitted to the 25-way connector.

Table 6 - Component checklist

Quantity Description Check ()

1 Controller

1 Quick Guide and Health and Safety Information

1TICCD

2 Rear non-slip feet

1Logicinterfaceplug

2 Analogue output mating half connectors

WARNING

If access to the IEC connector is restricted an additional isolation device should be provided, which

will be easily accessible by an operator.

D397-01-880 Issue E

Page 10 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

Figure 5 - Bench mounted TIC dimensions (mm)

If a controller is fitted in a rack, cabinet or panel, follow the directions given in Figure 6, 7and 8.

CAUTION

Allow 150 mm at the rear for cables. Allow 50 mm top and bottom and 15 mm to the sides for sufficient air

circulation. Do not cover any of the ventilation holes.

CAUTION

This unit is IP20 rated. Please ensure that the unit is not installed where fluids can enter into the controller.

CAUTION

The unit must be supported at the rear.

WARNING

Ensure that all electrical wiring is safely secured so that people cannot trip on them.

1. Rubber foot

© Edwards Limited 2016. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

D397-01-880 Issue E

Figure 6 - Front panel removal

Remove the bench top adaptor (Figure 6, item 1) by removing the four screws (Figure 6, item 2).

Slide the controller into the 19" rack or panel cut out. The use of 19" rack guide rails (Figure 7, item 2) and

support at the rear of the controller is recommended as shown in Figure 7. The panel cut out information is

defined in Figure 8.

Fix the controller in place using the four screws removed previously (Figure 7, item 1).

Figure 7 - Rack mounting of a TIC

1. Bench top adaptor

2. Fixing screw and washer

1. Fixing screw and washer

2. 19" rack guide rails

D397-01-880 Issue E

Page 12 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

Figure 8 - Panel cutout drawing

3.3 Controller electrical connections

Note: IGC Controllers are supported by both TIC 6-Gauge Controllers using gauge channels 4-6. Capacitance

Manometers are only supported by TIC 6-Gauge Controller D39702000 using gauge channels 4-6.

Figure 9 - Rear panel connections

1. Gauge inputs (1-3)

2. Logic interface

3. Serial communications port

4. Earth stud

5. Mains input

6. Mains on/off

7. Gauge inputs (4-6)

8. Analogue outputs

This manual suits for next models

2

Table of contents

Other Edwards Control System manuals

Popular Control System manuals by other brands

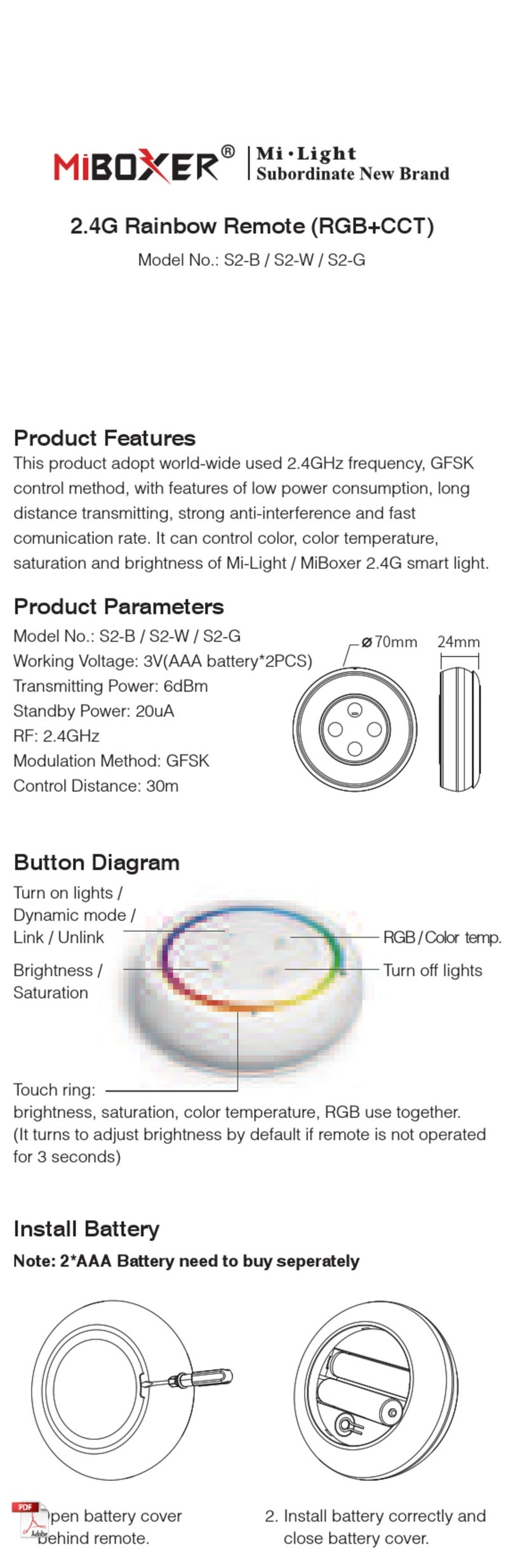

Miboxer

Miboxer Rainbow Remote S2-B user manual

Buderus

Buderus HS 2102 Service manual

National Instruments

National Instruments FOUNDATION NI-FBUS Hardware and Software User Manual

Pall

Pall iCELLis 500+ Instructions for use

PS Engineering

PS Engineering PAC45 System With MultiTalker Pilot's guide and operation manual

Lifebreath

Lifebreath max series Homeowner's guide