Edwards D397-00-000 User manual

D397-21-880

Issue G

Instruction Manual

Instrument Controller

Description Item Number

TIC Instrument Controller D397-00-000

Declaration of Conformity

We, Edwards

Manor Royal,

Crawley,

West Sussex RH10 9LW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised to

assemble the technical file, that the product(s)

TIC Instrument Controller D397-00-000

TIC Instrument Controller 6-Gauge D397-01-000

TIC Instrument Controller 6-Gauge Capacitance Manometer D397-02-000

TIC Turbo Controller 100W D397-11-000

TIC Turbo Controller 200W D397-12-000

TIC Turbo & Instrument Controller 100W D397-21-000

TIC Turbo & Instrument Controller 200W D397-22-000

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN61010-1:2001 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use – Part 1: General Requirements.

EN61326-1:2006 Electrical Equipment for Measurement Control and Laboratory

(Industrial location, Use – EMC Requirements.

Class B Emissions)

and fulfils all the relevant provisions of

2006/95/EC Low Voltage Directive.

2004/108/EC Electromagnetic Compatibility Directive.

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

11/06/2010, Eastbourne

Mr L Marini, Technical Manage

r

Date and Place

This product has been manufactured under a quality system registered to ISO9001

P200-03-140 Issue C

© Edwards Limited 2009. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

D397-21-880 Issue G

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope and definitions ................................................................................................... 1

1.2 Product description ...................................................................................................... 1

2 Technical data ....................................................................................3

2.1 Electrical data ............................................................................................................ 3

2.2 Operating and storage data ............................................................................................ 3

2.3 Mechanical data .......................................................................................................... 3

2.4 Connections ............................................................................................................... 3

2.4.1 Active gauge connectors ................................................................................................ 3

2.4.2 Logic interface ...........................................................................................................4

2.4.3 Serial communications .................................................................................................. 5

2.4.4 Analogue outputs ........................................................................................................ 6

3 Installation .........................................................................................9

3.1 Unpack and inspect ...................................................................................................... 9

3.2 Fitting the controller .................................................................................................... 9

3.3 Controller electrical connections ....................................................................................12

3.3.1 Connecting the electrical supply .....................................................................................12

3.3.2 Additional earth bonding ..............................................................................................12

3.3.3 Connecting an active gauge ...........................................................................................13

3.3.4 Connecting the logic interface .......................................................................................13

3.3.5 Connecting the serial interface .......................................................................................14

4 Operation ........................................................................................ 17

4.1 Front panel description ................................................................................................17

4.2 Menu structure ..........................................................................................................18

4.3 Navigating the menu ...................................................................................................19

4.4 The view screen .........................................................................................................19

4.5 Turning gauges and relays on/off ....................................................................................19

4.6 Changing list items .....................................................................................................20

4.7 Changing numerical values ............................................................................................20

4.7.1 Entering negative components e.g. 5.00E-03 ......................................................................21

4.8 Gauge setup .............................................................................................................21

4.8.1 Default setup options (all gauges) ...................................................................................22

4.8.2 Gauge status messages .................................................................................................22

4.8.3 Active Pirani Gauge (APG) .............................................................................................22

4.8.4 Active Linear Pirani Gauge (APGX) ...................................................................................23

4.8.5 Active Thermocouple Gauge (ATC-E) control ......................................................................24

4.8.6 Active Strain Gauge (ASG) control ...................................................................................25

4.8.7 Active Inverted Magnetron (AIM) gauge control ....................................................................26

4.8.8 Active Ion Gauge (AIGX-S) control ...................................................................................27

4.8.9 Wide Range Gauge (WRG) .............................................................................................28

4.9 Alarms ....................................................................................................................30

4.10 The main menu ..........................................................................................................30

4.11 Linking gauges ...........................................................................................................30

4.12 Parameters/units .......................................................................................................31

4.13 Screen options ...........................................................................................................31

4.13.1 Organising gauges on the view screen ...............................................................................32

4.14 Relay setpoint outputs .................................................................................................32

4.15 Service information .....................................................................................................32

4.16 Electrical supply failure ...............................................................................................32

gea/0054/07/09

D397-21-880 Issue G

Page ii © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

5 Maintenance ..................................................................................... 33

5.1 Safety .....................................................................................................................33

5.2 Fault finding .............................................................................................................33

5.3 Cleaning the controller ................................................................................................34

5.4 Software updates .......................................................................................................34

5.5 Factory defaults .........................................................................................................34

6 Storage and disposal ........................................................................... 35

6.1 Storage ...................................................................................................................35

6.2 Disposal ...................................................................................................................35

7 Service, spares and accessories .............................................................. 37

7.1 Service ....................................................................................................................37

7.2 Spares .....................................................................................................................37

7.3 Accessories ...............................................................................................................37

Index .............................................................................................. 39

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 Pin connections for an 8-way FCC/RJ45 ............................................................................. 4

2 Pin connection for a 15-way sub-minature ‘D’ type socket ....................................................... 4

3 Pin connections for a 9-way sub-miniature 'D' type socket ........................................................ 6

4 Pin connection for 4-way analogue output connector ............................................................. 6

5 Bench mounted TIC dimensions (mm) ...............................................................................10

6 Front panel removal ....................................................................................................10

7 Rack mounting of a TIC ................................................................................................11

8 Panel cut out drawing ..................................................................................................11

9 Rear panel connections ................................................................................................12

10 IBM PC RS232 interface - 9-way ......................................................................................14

11 IBM PC RS232 interface - 25-way .....................................................................................14

12 RS485 TIC network ......................................................................................................15

13 Front panel display .....................................................................................................17

14 View screen shortcuts ..................................................................................................18

15 Menu structure ..........................................................................................................18

16 New gauge connected ..................................................................................................19

17 Changing numerical values ............................................................................................20

18 Gauge setup screen .....................................................................................................22

19 Gauge setup screen APGX-M ..........................................................................................24

20 Gauge setup screen ASG ...............................................................................................26

21 Gauge setup screen AIGX ..............................................................................................28

22 Gauge setup screen WRG ..............................................................................................29

23 Controlled item .........................................................................................................30

24 Control setup ............................................................................................................31

25 Gauge order set up .....................................................................................................32

© Edwards Limited 2009. All rights reserved. Page iii

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

D397-21-880 Issue G

Tables

Table Page

1 Compatible equipment for the Instrument Controller ............................................................. 1

2 Gauge connector pin-out ............................................................................................... 4

3 Logic interface connector pin-out .................................................................................... 5

4 Serial communications connector pin-out ........................................................................... 6

5 Pin allocation for analogue outputs ................................................................................... 7

6 Component checklist .................................................................................................... 9

7 Front panel symbols and their functions ............................................................................17

8 Default setup options (all gauges) ...................................................................................21

9 Gauge status messages .................................................................................................22

10 Error/diagnostic monitoring APG .....................................................................................23

11 Setup options APGX .....................................................................................................23

12 Error/diagnostic monitoring APGX ...................................................................................24

13 ATC-D and ATC-M gauge tubes ........................................................................................24

14 Error/diagnostic monitoring ATC-E ..................................................................................25

15 Setup options ASG ......................................................................................................25

16 Error diagnostic monitoring ASG ......................................................................................26

17 Error/diagnostic monitoring AIM .....................................................................................27

18 Setup options AIGX .....................................................................................................27

19 Error/diagnostic monitoring AIM .....................................................................................28

20 Setup options WRG .....................................................................................................29

21 Error/diagnostic monitoring WRG ....................................................................................29

22 Fault finding .............................................................................................................33

23 Factory default settings ...............................................................................................34

24 Accessories ...............................................................................................................37

This page has been intentionally left blank.

D397-21-880 Issue G

Page iv © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

© Edwards Limited 2009. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Introduction

D397-21-880 Issue G

1Introduction

1.1 Scope and definitions

This manual provides Installation, Operation and Maintenance instructions for the Edwards Instrument Controller.

You must use the Controller as specified in this manual.

Read this manual before you install and operate the Edwards Instrument Controller. Important safety information is

highlighted as WARNING and CAUTION instructions; you must obey these instructions. The use of WARNINGS and

CAUTIONS is defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

Throughout this manual, page, figure or table numbers are sequential.

The following IEC warning label appears on the controller:

1.2 Product description

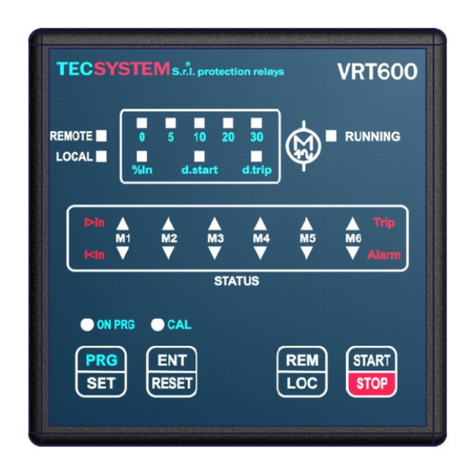

The Instrument Controller is provided with a large clear graphics display, easy-to-use control interface via a touch

sensitive keypad, an RS232/485 interface for control and data monitoring on a remote PC and a logic interface for

interface with associated system hardware.

The compatible instruments that can be used with the Instrument Controller are listed in Table 1.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

WARNING

Warning - refer to accompanying documentation.

Edwards offer European customers a recycling service.

WARNING

Improper use of the equipment could cause damage to it or injury to people. The user is

responsible for the safe operation and monitoring of the equipment. Hazardous voltages should not

be connected to this unit except where specified.

Table 1 - Compatible equipment for the Instrument Controller

TIC variant Compatibility

TIC Instrument Controller Up to 3 active gauges including: APG, APGX, ATC, ASG, AIM, WRG and AIGX

D397-21-880 Issue G

Page 2 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

© Edwards Limited 2009. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

D397-21-880 Issue G

2Technicaldata

2.1 Electrical data

2.2 Operating and storage data

2.3 Mechanical data

2.4 Connections

2.4.1 Active gauge connectors

Connector type CEE/IEC 320

Electrical supply 90 to 264 V a.c. 47 to 63 Hz

Power consumption

TIC Instrument Controller 55 VA maximum (D397-00-000)

Peak inrush current 5 A at 110 V a.c D397-00-000

12 A at 240 V a.c D397-00-000

Fuse The unit is self-protecting and has no user replaceable

fuse. The unit will recover once any overload is removed.

Earth Stud M4

Ambient operating temperature range 0 °C to 40 °C

Ambient storage temperature range -30 °C to 70 °C

Maximum ambient operating humidity Max 90% RH non condensing at 40 °C

Maximum operating altitude 3000 m max

IP rating 20

Weight

TIC Instrument Controller 1.3 kg

Connector type FCC/RJ45, 8-way (refer to Figure 1)

Power supply 24 V d.c.

Maximum power rating 21 W total for the three gauges

Input voltage range -0.5 V to 15 V

Output ID current 33 µA, 0 V to 13 V

Control output active: <0.8 V d.c. (2 mA max)

inactive: open (internal pull-up to 24 V)

Control input low: <2.0 V d.c. (Iout<160 µA)

high: >3.5 V d.c. (internally pulled up to 24 V)

D397-21-880 Issue G

Page 4 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

Figure 1 - Pin connections for an 8-way FCC/RJ45

2.4.2 Logic interface

Figure 2 - Pin connection for a 15-way sub-minature ‘D’ type socket

Table 2 - Gauge connector pin-out

Pin Allocation

1 Power supply positive

2Powersupplycommon

3Signalinput

4 Identification

5 Signal common

6Controlline1

7Controlline2

8N/C

Connector type 25-way sub-miniature 'D' type socket (refer to Figure 2)

Power supply 24 V d.c.

Maximum output power 5 W

Control output active: <1.1 V d.c. (Iout <20 mA)

<0.8 V d.c. (Iout <2 mA)

inactive: open (internal pull up to 24 V)

Control input low: <2.0 V d.c. (Iout<160 µA)

high: 3.5 V to 24 V d.c. (internal pull up to 24 V)

Analogue output 0 to 10 V (5 mA max)

50 mV resolution

© Edwards Limited 2009. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

D397-21-880 Issue G

2.4.3 Serial communications

Table 3 - Logic interface connector pin-out

Pin Allocation

1Screen

2 Analogue output signal

3 Setpoint 1 output

4 Do not connect

5 Setpoint 5 output

6 Setpoint 4 output

7Powersupplycommon

8 Do not connect

9 Gauge 1 enable input

10 Power supply common

11 Power supply positive

12 Power supply common

13 Power supply common

14 Analogue output common

15 Setpoint 2 output

16 Setpoint 3 output

17 Do not connect

18 Alarm output

19 Setpoint 6 output

20 Gauge 2 enable input

21 Gauge 3 enable input

22 Do not connect

23 Do not connect

24 Do not connect

25 System interlock input (SYSI)

Connector type 9-way sub-miniature 'D' type socket (refer to Figure 3)

RS232 transmit mark: <- 8 V (Iout max: -8 mA)

space: >+8 V (Iout max: +8 mA)

RS232 receive mark: <+1.0 V (Iin max: -2.0 mA)

space: >+2.0 V (Iin max: +2.0 mA)

maximum input: ±12 V

RS232 protocol 9600 baud, 1 stop bit, 8 data bits, no parity

RS485 Output differential: >1.5 V (Iout max: ±25 mA)

Input differential threshold: >± 0.2 V (Iin max: ±1 mA)

Maximum input: -7.0 V to +12 V

Bus load The TIC applies one unit load to the RS485 bus.

D397-21-880 Issue G

Page 6 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

Figure 3 - Pin connections for a 9-way sub-miniature 'D' type socket

2.4.4 Analogue outputs

Figure 4 - Pin connection for 4-way analogue output connector

Table 4 - Serial communications connector pin-out

Pin Allocation

1N/C

2RS232transmit

3RS232receive

4N/C

5RS232common

6N/C

7N/C

8RS485dataA

9RS485dataB

Connector type Phoenix 2.5 mm 4-way

mating half Phoenix FK-MC 0.5/4-ST-2.5

(available from Edwards as 5000 17005)

Short circuit protection All signals

Max load Gauge signals: ±1 mA

Common: ±3 mA

Output voltages

Gauge connected: Gauge signal voltage

(±2% ± 15 mv when in range 0 to +10 V)

Gauge connected 12 V (±1.3 V)

gea/d39701/f4

1234

© Edwards Limited 2009. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Technical data

D397-21-880 Issue G

Table 5 - Pin allocation for analogue outputs

Pin Allocation

Gauges 1-3 (Top Ports)

1 Gauge 1 signal

2 Gauge 2 signal

3 Gauge 3 signal

4 Common (0 V)

D397-21-880 Issue G

Page 8 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

© Edwards Limited 2009. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

D397-21-880 Issue G

3 Installation

3.1 Unpack and inspect

Remove all of the packaging material and check the Controller. If the Controller is damaged, follow the Edwards

return of equipment procedures that are laid out in the back of this manual. Do not use the Controller if it is

damaged.

Check that your package contains the items that are listed in Table 6. If any of these items are missing, notify your

supplier in writing within three days. If the Controller is not to be used immediately, store the Controller in suitable

conditions as described in Section 6.1.

3.2 Fitting the controller

CAUTION

Rubber feet must be fitted (Figure 5, item 1) so that there are correct clearances for air circulation. If you do

not, the performance of the Controller may be affected at high operating temperatures.

The Controller can be used on a bench-top or can be fitted in a rack or cabinet. Figure 5 shows the dimensions of the

TIC that are required for bench top use.

Note: If the interlocks are not used the logic interface adaptor must be fitted to the 25-way connector.

Table 6 - Component checklist

Quantity Description Check (9)

1 Controller

1 Quick Guide and Health and Safety Information

1TICCD

2 Rear non-slip feet

1 Logic interface plug

1 Analogue output mating half connectors

WARNING

If access to the IEC connector is restricted an additional isolation device should be provided, which

will be easily accessible by an operator.

D397-21-880 Issue G

Page 10 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

Figure 5 - Bench mounted TIC dimensions (mm)

If a Controller is fitted in a rack, cabinet or panel, follow the directions given in Figure 6, 7and 8.

CAUTION

Allow 150 mm at the rear for cables. Allow 50 mm top and bottom and 15 mm to the sides for sufficient air

circulation. Do not cover any of the ventilation holes.

CAUTION

This unit is IP20 rated. Please ensure that the unit is not installed where fluids can enter into the controller.

CAUTION

The unit must be supported at the rear.

Figure 6 - Front panel removal

WARNING

Ensure that all electrical wiring is safely secured so that people cannot trip on them.

1. Rubber foot

1. Bench top adaptor

2. Fixing screw and washer

© Edwards Limited 2009. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

D397-21-880 Issue G

zRemove the bench top adaptor (Figure 6, item 1) by removing the four screws (Figure 6, item 2).

zSlide the Controller into the 19" rack or panel cut out. The use of 19" rack guide rails (Figure 7, item 2) and

support at the rear of the Controller is recommended as shown in Figure 7. The panel cut out information is

defined in Figure 8.

zFix the Controller in place using the four screws removed previously (Figure 7, item 1).

Figure 7 - Rack mounting of a TIC

Figure 8 - Panel cut out drawing

1. Fixing

screw and

washer

2. 19" rack

guide rails

D397-21-880 Issue G

Page 12 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

3.3 Controller electrical connections

CAUTION

Do not connect Barocel capacitance manometers to the TIC. Doing so will result in damage to the gauge and will

invalidate the warranty.

Figure 9 - Rear panel connections

3.3.1 Connecting the electrical supply

Ensure that the electrical supply switch is set to 'off' and then connect the Controller to the electrical supply with an

appropriate supply cable.

3.3.2 Additional earth bonding

The electrical supply cable normally provides protective earthing for electrical safety. If this is not the case, or if

additional earth bonding is required, then the earth stud on the rear of the Controller (Figure 9, item 4) should be

connected to your vacuum system earth.

Connect a suitably earthed cable between the two nuts fitted to the earth stud on the rear of the TIC.

Note: Do not remove the bottom nut from the earth stud.

WARNING

High voltages exist in the Controller when it is operating. Ensure that the Controller is earthed and

observe all appropriate safety precautions for the safe installation and handling of electrical

equipment. If you do not, there will be a danger of injury or death to people by electric shock.

1. Gauge inputs

2. Logic interface

3. Serial communications port

4. Earth stud

5. Mains input

6. Mains on/off

7. Analogue outputs

© Edwards Limited 2009. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

D397-21-880 Issue G

3.3.3 Connecting an active gauge

CAUTION

Do not connect Barocel capacitance manometers to the TIC. Doing so will result in damage to the gauge and will

invalidate the warranty.

Up to three compatible active gauges can be fitted to the gauge connectors on the rear panel. Connect the gauges

using Edwards active gauge cables to each of the three gauge sockets on the rear of the TIC.

Note: Only one AIGX gauge can be connected to the TIC at a time.

3.3.4 Connecting the logic interface

3.3.4.1 Introduction

Note: In most applications it will be preferable not to earth the logic interface power supply common to prevent

earth loops inadvertently occurring.

CAUTION

Do not connect voltages greater than 24 V to the logic interface.

The logic interface provides a number of signals that can be used for monitoring the status of your vacuum system,

and for controlling certain aspects of its operation. These signals can be broadly divided into two groups, control

inputs and status outputs.

3.3.4.2 Using control inputs

Control inputs provide a means of controlling the operation of the TIC and the associated vacuum system from

external sources.

Gauge 1, 2, 3 Enable Pins 9, 20, 21): The gauge enable inputs can be used to control the operation of the gauges. If

gauge enable is open, the associated gauge cannot be turned on, and will turn off if it is operating. To enable the

gauges, connect the required gauge enable line to 0 V.

Note: Only gauges that can be turned on and off will respond to this input. Refer to the gauge manual for further

details.

SYSI: The System interlock input can be used to interlock the TIC to a system fail or control signal. When 'SYSI' is open,

all gauges will turn off. The TIC will also trip into the fail condition. To clear the system interlock and allow the

gauges to start, connect 'SYSI' to 0 V.

Note: Only gauges that can be turned on and off will respond to this input. Refer to the gauge manual for further

details.

3.3.4.3 Using status outputs

Status outputs provide a means for external systems to react based upon the current state of the TIC.

Relay setpoints: The setpoint outputs can be used to interface to external logic or can be used to drive relays. Each

output can be configured in software to activate at a certain pressure. Refer to Section 4.11 for how to configure

these outputs. Each relay can be manually controlled. Refer to Section 4.5.

WARNING

’SYSI’ is not fail safe and should not be relied upon for safety critical applications.

D397-21-880 Issue G

Page 14 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Installation

Two types of relay box are available as options from Edwards with either 3 or 6 relay outputs.

The relay box has built in relays that can switch external loads and provides a connector to interface to an external

system. Refer to the relay box instructions for further information on using the setpoint outputs.

To drive a relay without a relay box, connect the coil of a suitable 24 V d.c. relay between 'Setpoint Output' (negative)

and 'Power Supply Positive' (positive).

Alarm: Alarm can be used to interface to external logic or can be used to drive a relay. This output is normally active

and will become inactive in the event of an alarm condition.

To drive a relay, connect the coil of a suitable 24 V d.c. relay between 'Alarm Output' (negative) and 'Power Supply

Positive' (positive).

Note: Total current drawn from 24 V pin on logic connector should be 208 mA maximum.

3.3.5 Connecting the serial interface

The TIC has two serial communications protocols built in, RS232 and RS485. RS232 is the simplest interface and can

be used to allow a host PC to control the TIC. RS485 allows a host PC to control a small network of TICs.

3.3.5.1 Connecting RS232

The TIC is fitted with a 9-way 'D' type socket on the rear panel, refer to Figure 9, item 3. The interface uses two lines

for data transfers and an additional line as a signal common. Hardware handshaking is not implemented.

If connecting to an IBM compatible PC fitted with a 9-way 'D' type socket then a 'straight through' male-female 9-way

extension cable can be used to connect the TIC to the computer as shown in Figure 10. Connection to an IBM PC fitted

with a 25-way serial connector should be made as shown in Figure 11.

Use shielded cable for the interface to reduce interference problems and limit the length of the RS232 link to less

than 10 metres. For longer links, either install line drivers or use RS485.

Figure 10 - IBM PC RS232 interface - 9-way

Figure 11 - IBM PC RS232 interface - 25-way

Other manuals for D397-00-000

1

This manual suits for next models

1

Table of contents

Other Edwards Control System manuals

Popular Control System manuals by other brands

Landi Renzo

Landi Renzo A1 V05 Installation and adjustment manual

Landi Renzo

Landi Renzo A1 V05 Installation and adjustment manual

Niles

Niles SVL-1 Installation & operation guide

CYPRES

CYPRES S6AL211A94 manual

Crestron

Crestron CP4-R quick start

Philips

Philips Allegiant LTC 8500 Series Instructions for use