EFT BYD Battery-Box HV Series Instruction Manual

BYD Battery-Box HV

Service Guideline from EFT-Systems

Version 2.0

Valid for H 5.1 / 6.4 / 7.7 / 9.0 / 10.2 / 11.5

Important: The installation and all other kinds of works or measurements in combination with the Battery-Box

HV are only allowed by professional and qualified electricians.

This manual is a shortened assistance for the installation of the Battery-Box High Voltage and does not replace

the original manual, which can be found on www.eft-systems.de or www.byd.com. The installation must be

carried out by a trained and qualified electrician. Attention: High Voltage! Improper handling can cause danger

and damage.

CONTENT

CONTENT 2

1. CHECK INSTALLATION 3

2. ERROR ANALYSIS 4

2.1 BCU can not be switched on 4

2.2 BCU system switch falls after a few seconds 4

2.3 Current Alarm: BatteryCommErr 4

2.4 Current Alarm: MonitorCommErr 4

2.5 Communication problem 5

2.6 Current Alarm: BatteryDiff 5

2.7 Current Alarm: UT / OT (e.g Cell_UT) / SysTemp 6

2.8 Current Alarm: Cell_UV1 / Cell_UV2 / Cell_UV3 6

2.9 Current Alarm: DCBusFault 6

2.10 Voltage measurement 7

2.11 Visual Check 8

2.12 Identifying a faulty module (Variant 1) 8

2.13 Identifying a faulty module (Variant 2) 9

3. SERVICE TASKS 10

3.1 BCU replacement 10

3.2 Module Replacement 10

3.3 Charging with external HV charger 10

4. SERVICE CONTACT 11

2

1. CHECK INSTALLATION

Please proceed first with the installation steps by:

No.

Name

Description

0

Inverter installed

correctly?

Please make sure that the connection between the Battery-Box and the inverter

and the installation of the inverter have been carried out correctly. If in doubt,

follow the instructions of the inverter manufacturer.

IMPORTANT: Please install the latest software on the inverter.

1

Configuration

SMA: 4 -8 Battery modules

KOSTAL: 4-9 Battery modules

FRONIUS: 5-9 Battery modules

GOODWE: 4-9 Battery modules

INGETEAM: 4-5 Battery modules

2

DC Power Cable

Make sure that + and - are properly connected.

Check the imprint and the board!

3

Communication cables

Please check:

- CAT5 or higher;

- check the cables and replace them if necessary

- remove not necessary jumpers (see step 20)

4

Grounding

Battery-Box connected directly to the ground-bus of the house.

The battery must not be earthed via the inverter! Otherwise, communication

problems are possible. Correct grounding is absolutely necessary!

5

Installation in the Web

Interface

- Installation Config: Number of Modules + Inverter Manufacturer

- Update: install the latest released software (www.eft-systems.de)

6

State of charge (SOC)

When installed for the first time, the battery will show a predefined SOC of 19%.

This does not correspond to the actual SOC and the battery corrects th eSOC at

the first full charge or discharge. The actual SOC of new modules is about 35%.

Therefore, only perform a module extension if the battery system is close to 35%

SOC. For details see the extension manual (www.eft-systems.de/downloads).

7

Connect to the Internet

(recommended)

Connect the battery to the Internet using an Ethernet cable.

8

Checking the correct

operation

The system runs properly if:

- Home shows RUN and Current Alarm shows no entries

- No error messages on the inverter

- Inverter displays voltage and battery charge correctly

- System charges / discharges

9

Web interface:

Error description

If there are any errors in the section Current Alarm, please follow the instructions

on the following pages.

10

IMPORTANT: If you can not complete the commissioning, then turn off the battery via the system switch on

the BCU before you leave the site.

3

2. ERROR ANALYSIS

Please refer to the general steps before proceeding, see chapter 1.

2.1 BCU can not be switched on

No reaction, LEDs on the BCU board do not light up, although the system switch is switched on.

No.

Name

Description

11

Voltage measurement

Please measure the voltage as shown in step 2.10 .

12

Visual check

See step 2.11

13

BCU exchange

Only if voltage and visual examination look good:

Test another BCU, if available.

2.2 BCU system switch falls after a few seconds

Battery does not stay on for more than 30 seconds. Therefore you can not enter the web interface to read the event codes.

No.

Name

Description

14

Voltage measurement

Please measure the voltage as shown in step 2.10 .

15

Check the individual

modules (variant 2)

See step 2.13

2.3 Current Alarm: BatteryCommErr

Error probably caused by a communication failure between two modules or within a module.

No.

Name

Description

16

Visual check

See step 2.11

17

Check the individual

modules (variant 2)

See step 2.12

2.4 Current Alarm: MonitorCommErr

Error probably caused by the battery module on top or the BCU.

No.

Name

Description

18

Visual check

See step 2.11

19

Check BCU and top

module

Remove the top module from the tower.

- If the "MonitorCommError" error is no longer displayed in Current Alarm , the

topmost module may be faulty. If available, exchange the module with another

one.

- If the error "MonitorCommError" continues to be displayed, the error could be

due to the BCU. If available, exchange the BCU as a test.

4

2.5 Communication problem

Inverter reports communication problem

Battery-Box System State under Home shows STANDBY / IDLE

Current Alarm: InverterCommError

No.

Name

Description

20

Jumper

See short instructions - please check:

SMA: only jumper JP1

KOSTAL: only jumper JP2

FRONIUS: leave both jumpers (except for variant 2, see quick guide)

GOODWE: leave both jumpers connected

21

Grounding

Connected Battery-Box directly to the ground-bus of the house. Only with a correct

grounding of the battery, a trouble-free and secure data transmission can be

guaranteed. The battery must not be earthed via the inverter! Otherwise,

communication problems are possible. Correct grounding is absolutely

necessary!

22

Communication cable

Replace the communication cable (min. CAT5!)

23

Use other communication

port (J5 instead of J2)

The BCU has two identical communication ports, labeled J2 and J5. The short

guide show the wiring at J2. If there are any communication problems, try to

connect the PINs to J5 instead.

24

Disconnect from the

network

Please check the local network and completely disconnect the system from the

network in order to exclude communication interference caused by switches or

WLAN repeaters (multicasting).

25

Restart the entire system

Generally:

- Switch off: Battery off > Inverter off

- wait at least 10 minutes!

- Switch on: inverter on > battery on

Kostal (the order is important):

- unplug Ethernet cable from inverter

- turn off the system: battery off > inverter DC switch off > AC off > unplug PV

strings

- wait at least 10 minutes

- turn on system: plug in PV strings > AC on > inverter DC switch on > battery on

- connect Ethernet cable once system is running again

2.6 Current Alarm: BatteryDiff

Error probably caused by a faulty battery extension.

No.

Name

Description

26

Battery recently

extended?

(new modules added)

If the battery system has recently been extended:

Remove the new modules from the system and follow the instruction on how to

correctly extend the system (see extension manual)

If no module extension has taken place and all modules have been installed at the

same time, please contact EFT-Systems. Please make a screenshot of the section

RUN Data on the web interface.

5

2.7 Current Alarm: UT / OT (e.g Cell_UT) / SysTemp

System has detected a temperature which is too high (>50°C) or too low (<-10°C).

No.

Name

Description

27

SysTemp

If SysTemp in Run Data is OK (-10°C to +50°C):

Test another BCU, if available

28

Charge_UT / OT

Cell_UT / OT

If maxCellTemp or minCellTemp is outside the range -10°C to +50°C: Check

temperatures under Run Data for each module. If only one module deviates, then

try to remove this module or replace ist, if a replacement module is available.

2.8 Current Alarm: Cell_UV1 / Cell_UV2 / Cell_UV3

Error Probably caused by undervoltage or a faulty sensor.

No.

Name

Description

29

UV1

Recharge of the battery by the inverter is necessary. Please go through the above

steps (especially: check communication, install updates, restart the entire system).

If not recharge by inverter is not possible, a charger may be required. Switch off

the battery and contact EFT-Systems (screenshots).

30

UV2

If the battery is not being charged by the inverter immediately after restarting, then

switch off the battery after a few minutes and contact EFT-Systems (screenshots,

voltage). Charger necessary.

31

UV3

Immediately turn off the battery and contact EFT-Systems.

2.9 Current Alarm: DCBusFault

No.

Name

Description

32

DC Power cables

Make sure that + and - are properly connected.

Check the imprint and the board!

33

Disconnect the battery

from the inverter

For testing, please disconnect the inverter completely from the battery

(communication cable and DC cable). If the error persists, then try another BCU, if

available.

6

2.10 Voltage measurement

ATTENTION: High voltage!

The nominal voltage is obtained by multiplying the number of modules by 50V. Nominal system voltage should

therefore be in the range 200V-450V.

If the measured voltage deviates significantly from the nominal value, please check the electrical voltage at the

individual modules, as shown below:

Positive

Negative

Measurement:

7

2.11 Visual Check

The PINs should not be bent or touch each other. Otherwise, a short circuit with a damage to the BCU is possible.

Correct

defect

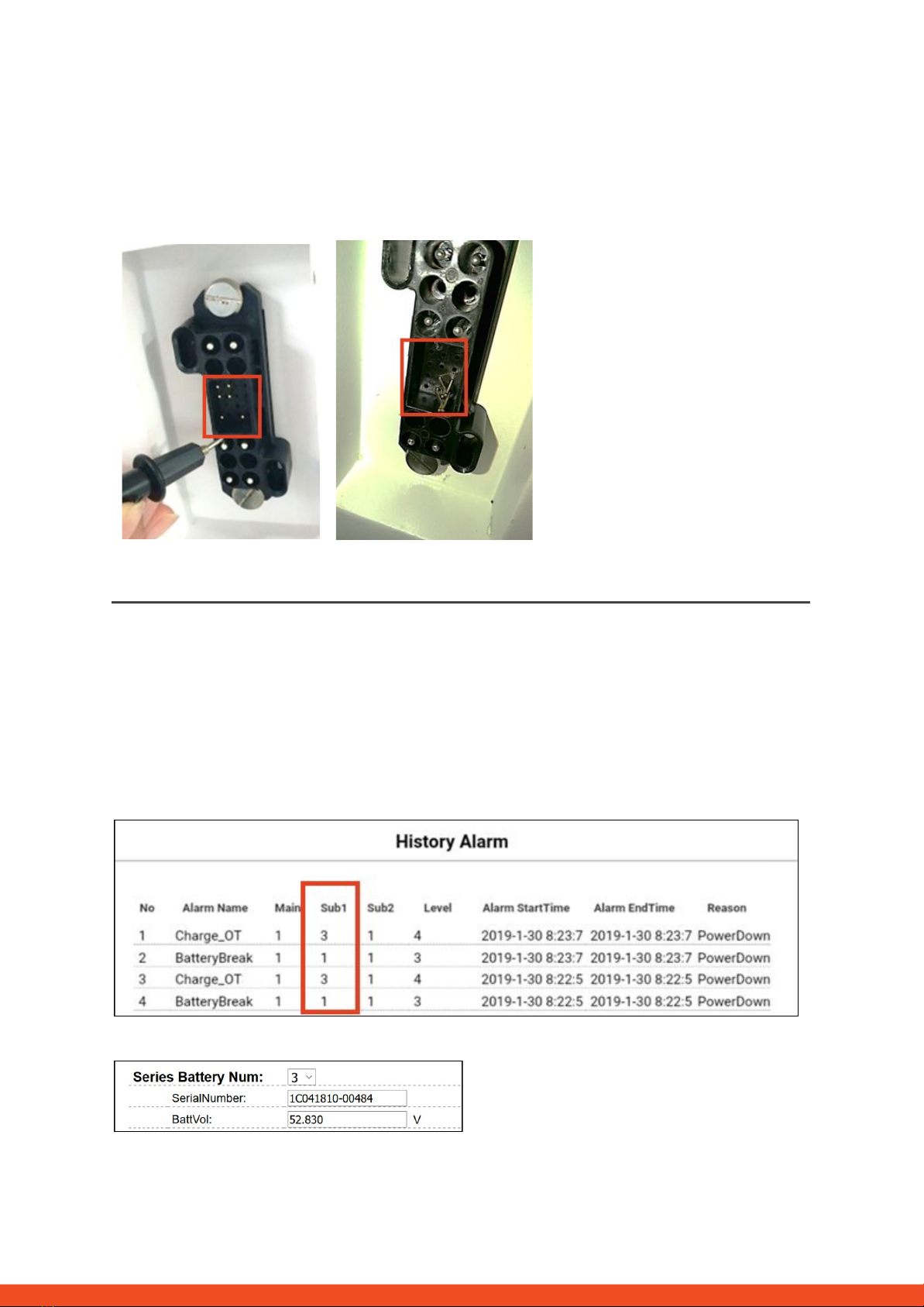

2.12 Identifying a faulty module (Variant 1)

In the web-interface of the battery, event messages and also error codes are displayed. "Current Alarm" shows

current and active messages. Past messages are logged in the “History Alarm”. If an error is displayed in the

Current Alarm or History Alarm then Sub1 shows which module is affected. Please note: The module number has

nothing to do with the stacking order! The module numbering is based on the production date and the oldest

module has the number 1. The corresponding serial number can be obtained in "RUN Data" if you select the

module number there. In the example below, the message "Charge_OT" is reported by module 3.

In Run Data, the correct serial number can be found for module 3:

8

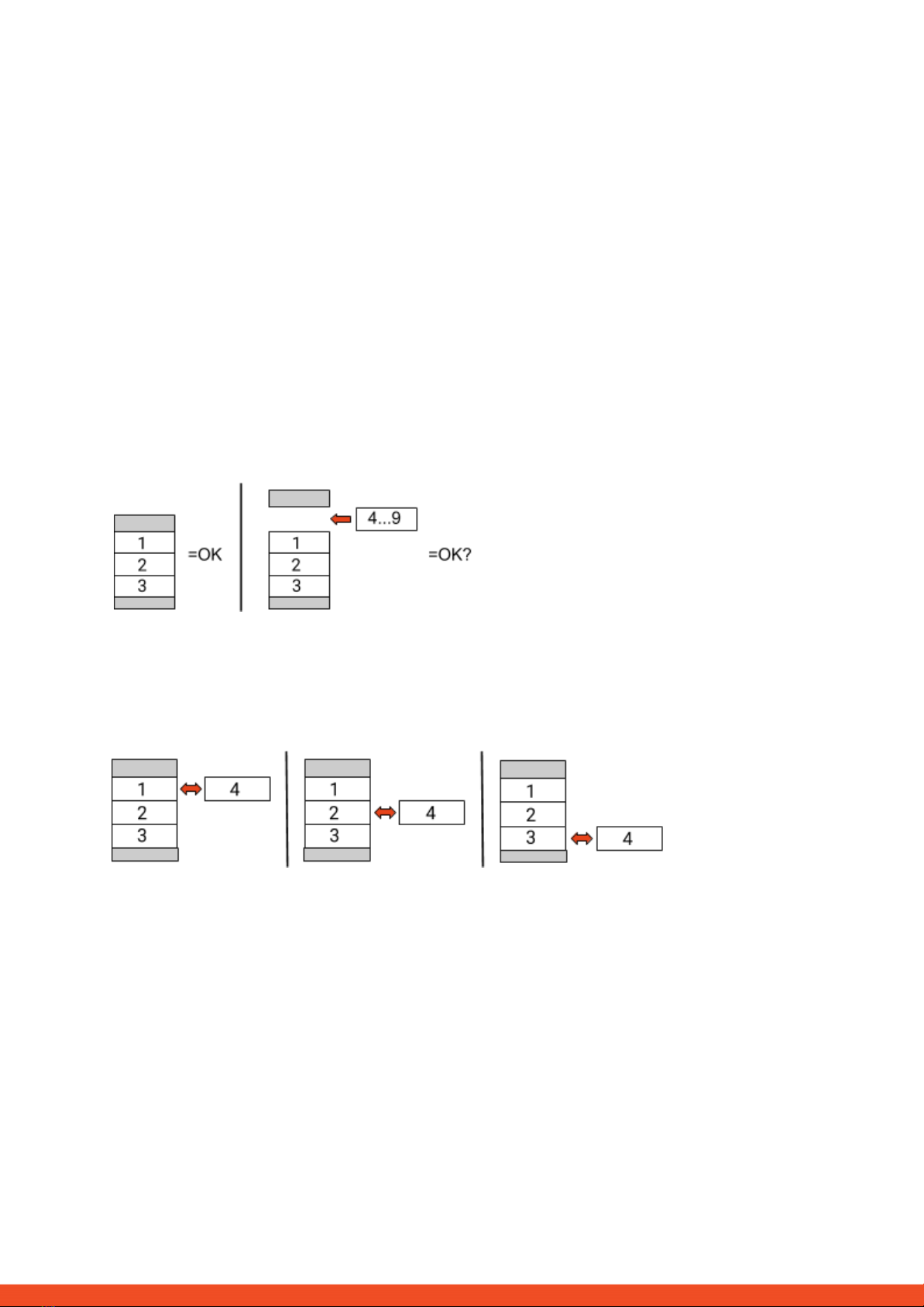

2.13 Identifying a faulty module (Variant 2)

Important:

- The number of modules must always be adapted in the Web Interface (Installation Config) as soon as

modules are added or removed from the system.

- Please perform a visual check of the communication pins according to step 2.11 for each module.

1. Build the Battery-Box with only 3 Modules (+ Base and BCU). Adjust module amount in the Web Interface under

Installation Config. Note: The module amount must be adjusted whenever the number of modules is changed.

2. Check status:

Note:

The battery status is OK when battery is on (Air Switch up and WIFI available) & no errors are shown (Web

Interface: Current Alarm). Otherwise, the battery status is NOT OK.

OK:

Add one module at a time, adjust module number in web interface and check again. If battery status turns to

“NOT OK”, then the defect module is identified to be the one that has been added newly.

NOT OK:

The defect module is probably one of the 3 modules in the tower. Take one of the spare modules and exchange

each of the 3 modules with the spare module one at a time. Check the battery status after each step. If battery

status turns to “OK”, the defect module is the one that was exchanged.

3. If the defective module is found, it may be replaced by a new replacement module. Please contact

EFT-Systems.

9

3. SERVICE TASKS

Please go through the general steps beforehand, see chapter 1.

3.1 BCU replacement

Have you detected a faulty BCU?:

After replacing the BCU, please do not forget to re-do the configuration in the web interface (enter the number of

modules and inverter brand) and install the latest BCU software approved for the inverter.

3.2 Module Replacement

Have you detected a faulty module?:

In the meantime you can use the battery system with the remaining modules and a correspondingly reduced

capacity (take into account the minimum number of modules).

Please note: It is important that all modules of a battery tower have a similar state of charge (SOC) with a

tolerance of 5%. New modules have about 35% SOC. If the remaining modules have not yet been put into

operation (not charged / discharged), the new module can easily be added. Otherwise, it is basically a module

extension. In this case, please add the new module to the system only when the system has a SOC between 30%

and 40% (see extension manual).

3.3 Charging with external HV charger

You will receive a charger from us (eg because of the message "Cell_UV")?

Each module should be individually connected to the charger and charged to the same state of charge (SOC).

The charger has a display in which you can set the desired SOC. It's enough if you select 10% SOC. It is very

important that all modules receive exactly the same amount of energy and come to the same SOC level. Please

pay attention to the display or charging time. Before charging, the module must have been at rest for at least 30

minutes. If the charging process is interrupted, then you have to wait at least 30 minutes before the module can

be recharged. (Otherwise the SOC will not be correct)

10

4. SERVICE CONTACT

Please note that this document is intended as a quick reference guide to quickly resolve common problems.

Further information and detailed installation assistance can be found at www.eft-systems.de.

To ensure a smooth process, please register yourself and the system under www.eft-systems.de.

For further help please contact:

EFT-Systems GmbH

Mail: [email protected]

Phone: +49 9352 8523999

IMPORTANT:

In order to be able to process a service case, it is absolutely necessary to get the serial number of the BCU and

all error-specific information, see the table below:

No.

Name

Description

A

Serial number BCU

At the system switch or on the Web interface (Device Information)

B

Photo of the BCU

Complete BCU (inside)

C

Photos of

Communication port

(PIN) in the BCU and

inverter.

In the BCU (detail photo) and on the inverter

D

D1

D2

D3

D4

D5

Screenshots of the web

interface:

- Device Information

- Installation Config

- Current Alarm

- History Alarm

- Run Data

On the web interface

E

Serial number of the

faulty module

(Note: only necessary, if a

faulty module was found!)

On top of the module or on the side of it.

F

Inverter serial number and

model

Important for EFT Systems to analyze and resolve the problem at system level

with the inverter partner.

G

If necessary: Delivery

address

If replacement parts are required we need:

- Complete delivery address (including country)

- Contact person

- Telephone number

H

Additional information

If available, please support us with additional information (eg comments /

information displayed on inverter / additional photos of the system / voltages / ...).

11

This manual suits for next models

6

Table of contents