EG Aircraft MX2 50CC Giant Scale Aerobatic Aircraft User manual

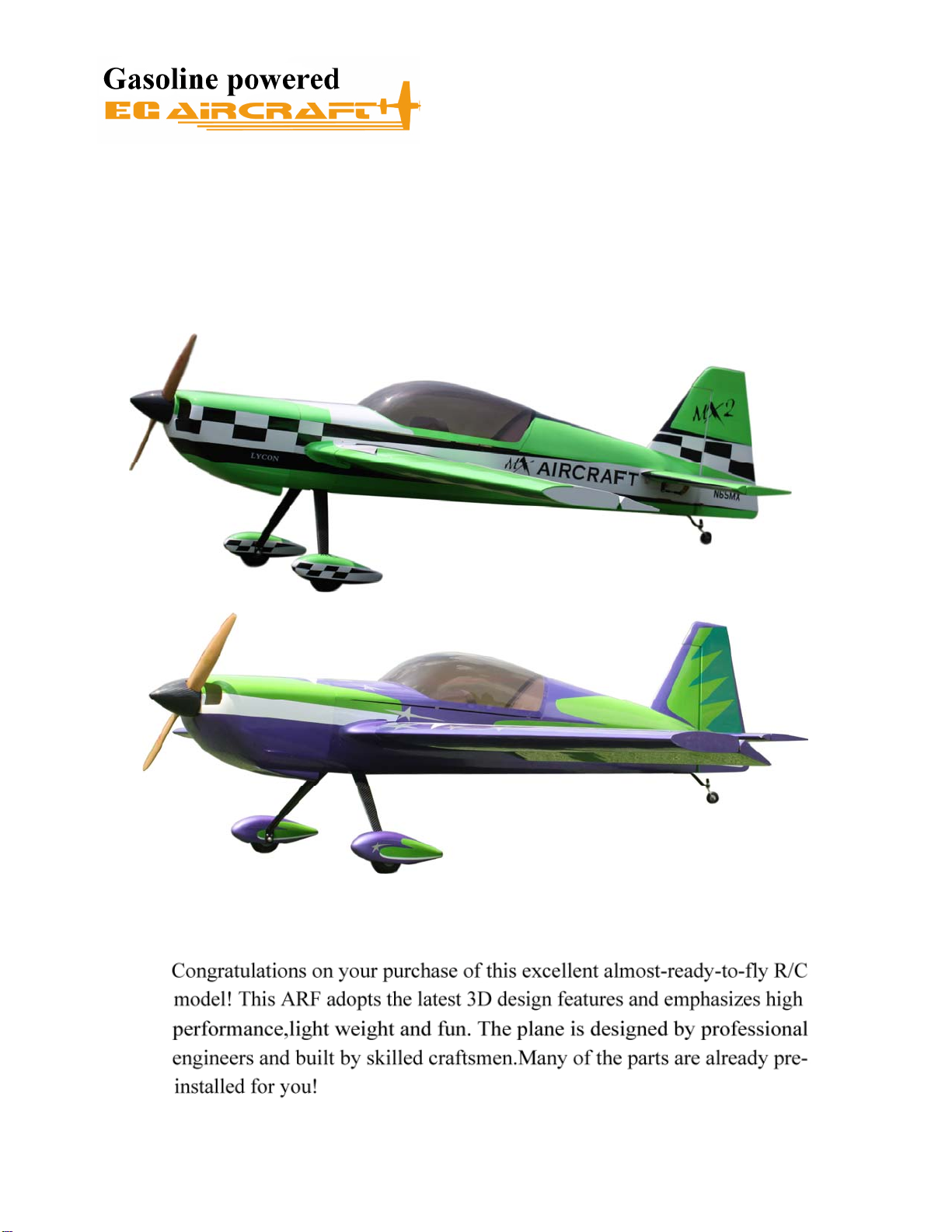

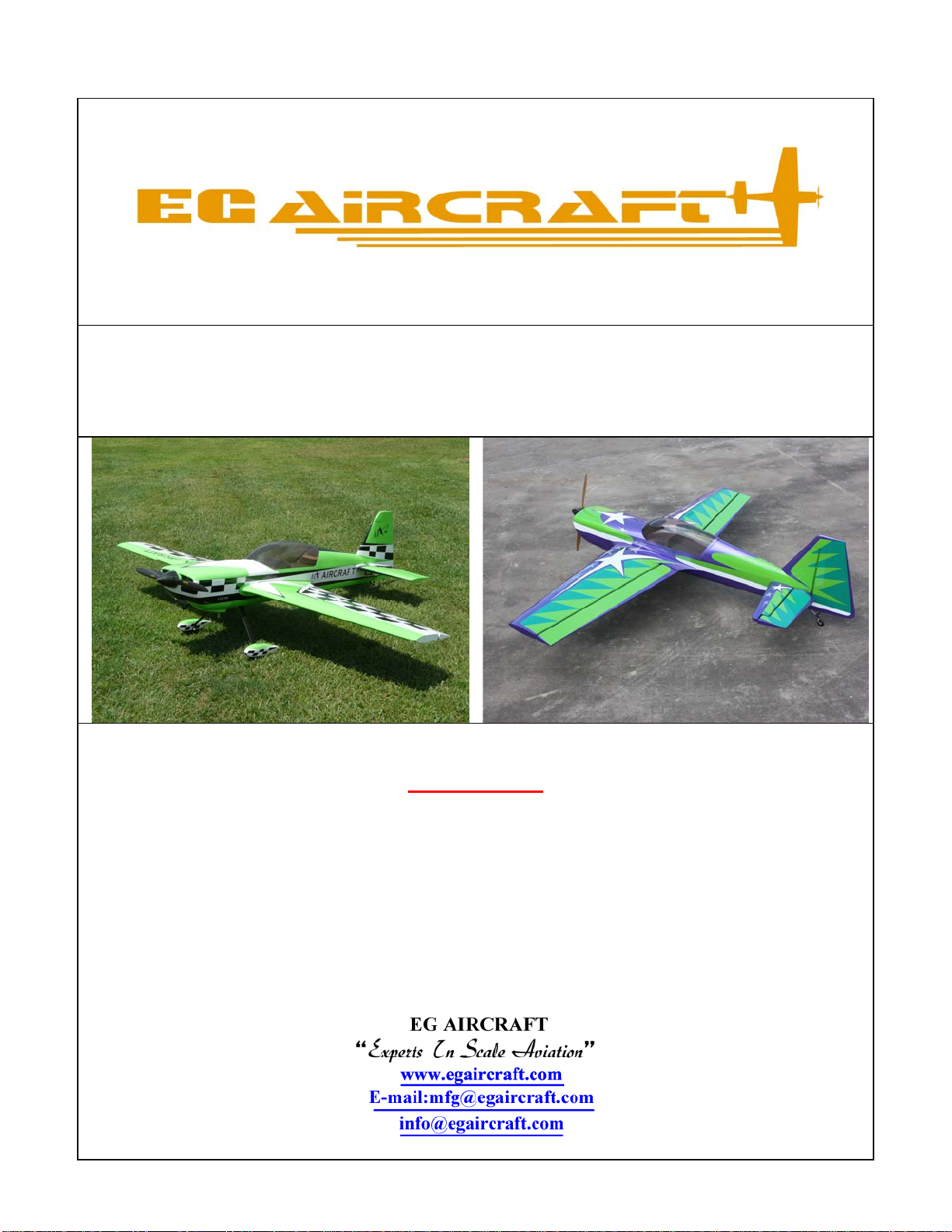

MX2 50CC

Giant Scale Aerobatic Aircraft

0B0B0B

1B1BMX2 50CC

Giant Scale Aerobatic Aircraft

UUUSpecifications:

Scale:30%

Wing Span:89”2260mm

Length:Including spinner82”(2080mm)

Wing Area: 1466 in²(94.6 dm²)

Flying Weight: 16 to 18 lbs(7.3-8.2kg)

Spinner: 3.5”(89mm)

Engine: 45 - 60cc Gas

1BRadio: 4+ Channels

Servos : 6 servos required 180 oz(11 kg/cm)

UUUA QUICK WORD ABOUT SAFETY AND RADIO CONTROL FLYING MODELS

With radio control aircraft, like any hobby or sport, there are certain risks. The operator of these

models is responsible for these risks. If misused or abused, you may cause serious bodily injury and/or

damage to property. With this in mind, you will want to be certain that you build your model carefully

and correctly. If you are not an experienced flier, have your work checked and ask for help in learning to

fly safely. This model aircraft is not a toy and must be operated and flown in a safe manner at all

times. Always perform a pre-flight check of the model including all control surfaces, proper function of

the radio gear, structure, radio range, and any other area relating to the safe operation of this aircraft.

Models are not insurable but operators are. You can obtain coverage through membership in the

Academy of Model Aeronautics (AMA). For an AMA information package call 1-800-435-9262, ext.

292 or visit the AMA website at "HHHUUUwww.modelaircraft.orgUUUHHH".

By the act of using the final assembled model, the purchaser/operator accepts

all resulting liability.

UUU Included Features:

¾Fuselage and Wing incorporate carbon fiber laminations for extra strength

¾Aerofoiled Carbon Fiber Landing Gear

¾Carbon Fiber Wing and Stab Tubes

¾Carbon Fiber Tail Wheel Assembly

¾Extra strength fibre control Horns

¾3.5” (89mm) Carbon Fiber Spinner

¾Anodized Extra Length Heavy Duty Servo Arms

¾Extension Lead Safety Clips

¾High Density Rubber Wheels

¾Top Quality Heavy Duty Hardware including Titanium Pushrods

¾Instrument Panel is included

¾Pre-hinged Control Surfaces

¾Pre-assebled and mounted Gas Tank

¾Installed Servo Wire Guide Tube

¾Covered in Genuine Ultracote / Oracover

¾Complete and Detailed Instructions on CD

UUItems Required to Complete This Model:

•50 - 60 cc gas engine with stock or

aftermarket exhaust systems

•Appropriate propeller for your engine

•All required engine and exhaust mounting

hardware

•Ignition battery and switch

•One quality throttle servo and appropriate

servo arm

•Two heavy duty switches with charging

jacks for the Rx

•Two high quality Rx batteries of significant

capacity to power your choice of servos.

•One Receiver of your choice

UUShop Supplies/Tools

•Covering Iron and heat gun

•Four high quality metal gear servos of 150

in-oz or better for the ailerons and elevators

•One high quality metal gear servo of 250 in-

oz or better for rudder servo.

•Appropriate servo arms for the above

•Heavy duty servo wire extensions. EG

recommends two to three 30” (elevators,

optional tail mounted rudder), two 12”

(ailerons), and three 6” extensions (throttle

and rx extensions). Your installation though

may vary.

•Assortment normal hobby tools such as

screwdrivers, hobby knife, drill and drill

bits, pliers, etc.

•Thick and Thin CA adhesives

•30 minute Epoxy

•Isopropyl alcohol

•Ruler or tape measure

•Blue thread-lock or equivalent

UUNote:UU As with all kits, it’s a good idea to read all the instructions and study the parts

before you begin construction. Handle the parts of this kit with care so you do not

damage any of the structure or covering. Inspect all the parts for any shipping

damage and report any issues to EG as soon as you can. Make sure you have a flat

and sturdy workbench and follow all safety advice for the tools and adhesives you

plan to use.

UUAIRCRAFT COVERING:UU

1. With all ARFs, varying temperatures and storage delays can cause covering material to loosen over

time and transportation. EG recommends lightly going over all the covering with a covering iron set

at medium temperatures. Be sure to use a soft cover over your iron so you do not scratch the covering

surface. Be sure you go over all seams and edges of the covering to assure it is secure to the airframe

and other covering. Be careful not to apply too much heat or you may cause bubbles or damage to the

covering. A heat gun may also be used along with a soft cotton cloth to shrink and adhere the

covering. Again, be extremely careful when using a heat gun.

2. If you plan to install a heavier than typical engine you may opt to use the rear fuselage mount for the

rudder servo. If so then carefully cut the covering away from the rear servo mount on either side. If

not leave these intact. Servo openings should be cut from corner to corner and the covering ironed

down on the inside. Other holes can be cut out using either a sharp hobby knife or the tip of a hot

soldering iron. The latter technique acts to seal the covering edges as you cut away.

3. Be sure to seal any exposed wood with a thin coating of epoxy to prevent engine oil from soaking

in. This is especially important around the engine compartment and servo openings with exposed

areas.

4. Some modelers prefer to seal the hinge gaps using strips of appropriate covering or clear trim tape.

We have found this to be helpful with models intended for higher speed flight or models with

unusually large hinge gaps. EG aircraft utilize a very tight double beveled hinge line and do not

normally require this step. Sealing the hinge gaps is therefore left as an option for the modeler.

UURUDDER INSTALLATION:UU

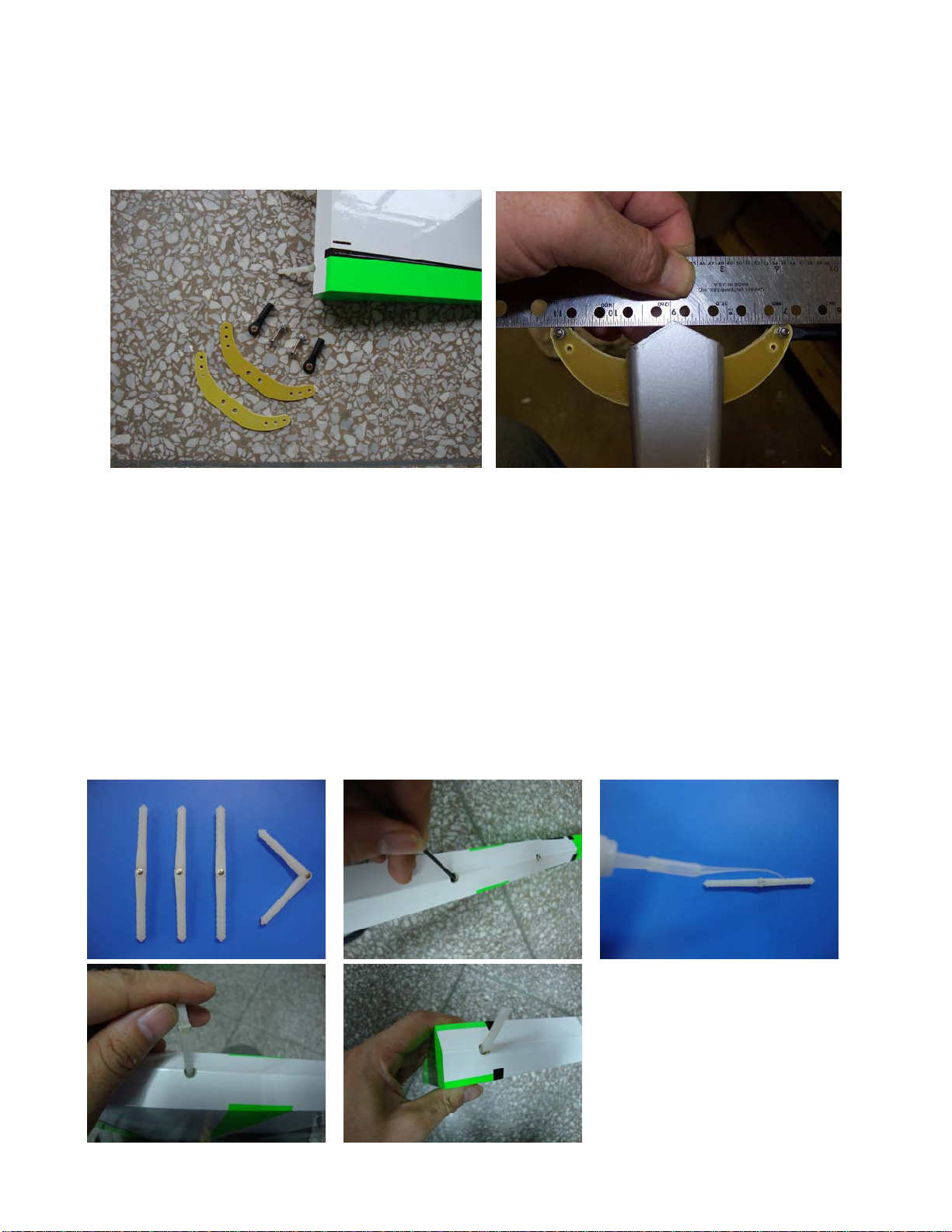

1. It is much easier to install the twin control horns before installing the rudder. Locate the fiberglass

rudder control horns, ball links, and associated bolts and nylon-insert lock nuts. Use some fine sandpaper

to roughen up the center areas of the two control horns so that the glue adheres better. Using a sharp

hobby knife cut the covering away from the slots in the rudder and trial fit the two control horns.

2. Mix up some 30 minute epoxy and coat the inside of the slots and the center of the control horns. Hint:

a scrap piece of 1/16” ply, toothpick, or old hobby blade can be used to coat the inside of the rudder slots.

Slide the control horns in place and make sure they are centered perfectly by using a ruler to measure

between the pivot holes and the hinge line. Wipe any excess glue off with isopropyl alcohol and paper

towels. Install the ball links, bolts and nuts into the holes to help assure alignment of both control horns

while the glue cures. Set aside until cured.

3. The holes for the supplied hinge points are predrilled. Locate the hinge points and dry fit the hinges

and rudder into place and test the operation. The hinges should seat fully into the holes so that the hinge

line gap is minimal while still allowing full rudder deflection.

4. Before gluing the hinges in you must first clean the hinges of any mold release agent using isopropyl

alcohol. EG also recommends scuffing up the plastic with light sandpaper for maximum glue adhesion.

5. Mix up some 30 minute epoxy and using a toothpick or small wooden dowel coat the inside of each

hinge hole with epoxy. Also put a thin layer of epoxy on one side of the hinge points. Install this end into

the holes of the rudder and make sure each hinge is properly aligned at exactly 90 degrees to the hinge

line.

6. Now coat the other end of the hinge points with epoxy and install the rudder into the trailing edge of

the vertical stabilizer. Again, make sure the hinges remain in proper alignment. Using paper towels and

some isopropyl alcohol clean off any excess epoxy from the hinges and surrounding areas.

7. Make sure the rudder is fully seated so that the hinge gap is minimal while still allowing full

deflection of the rudder. When satisfied, use some masking tape to hold the rudder in place along the

bottom and counterbalance. After the epoxy has cured, remove the masking tape and check for proper

operation. If the hinges are dry some light oil carefully placed on each hinge will help greatly.

UULANDING GEAR ASSEMBLY:UU

1. Locate the supplied main and tail wheel landing gear parts and sort them out on your workbench.

2. Bolt the main gear to the bottom of the fuselage using the supplied bolts. Use a small drop of thread-

lock to secure the bolts in place.

3.Install the main wheel axles to the composite landing gear and tighten the nylon-insert lock nut. Install

one wheel collar onto the axle. Use a second wheel collar as a guide to leave a gap on the inboard of the

axle. Use a small drop of thread-lock and tighten in place. Slide the wheel onto the axle and install a

second wheel collar also using thread-lock on the set screw.

4. Fit the wheel pant in place and install using the two supplied screws. Use thread-lock to secure the

screws in place. Repeat the above steps for the other main gear.

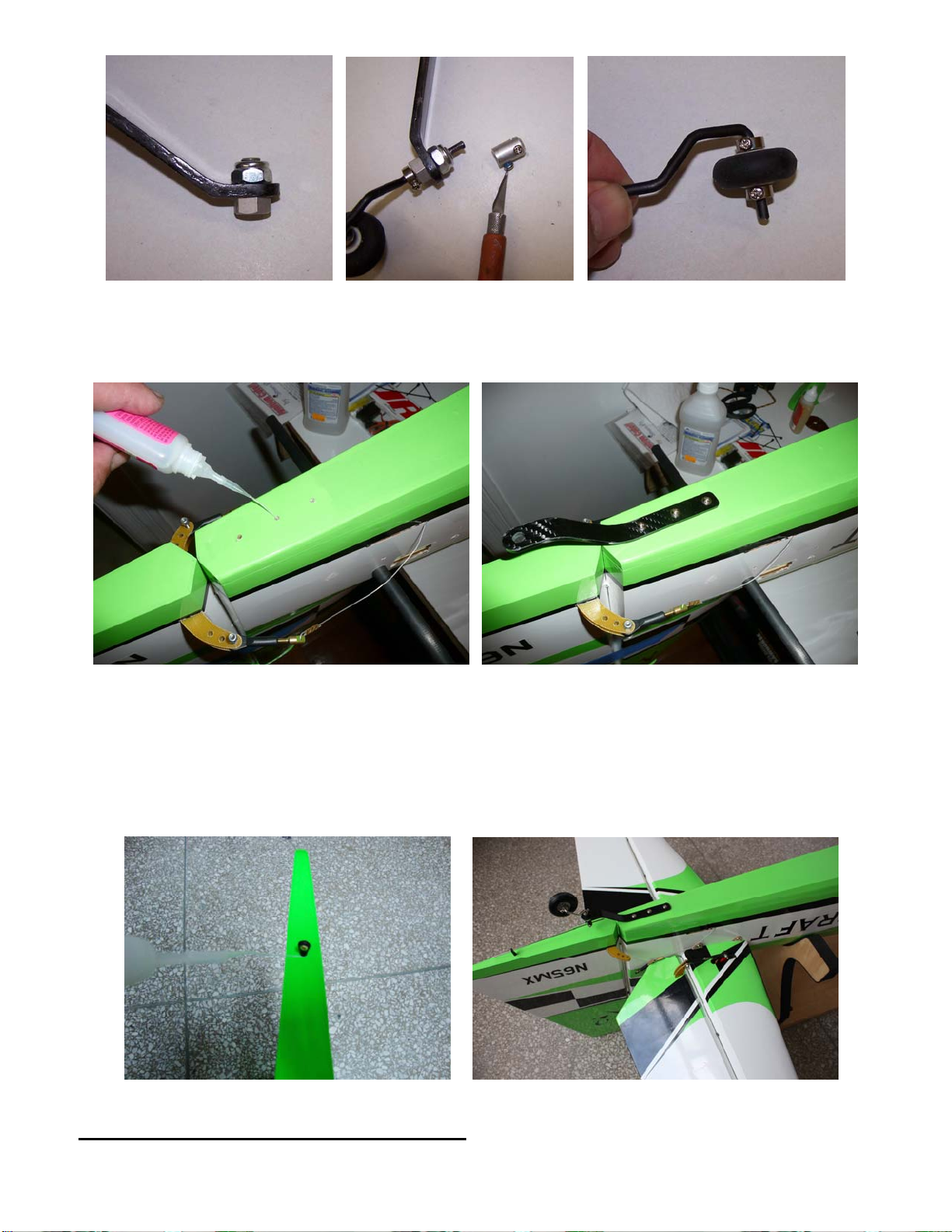

5. Begin the tail wheel assembly by installing the shaft bushing and lock nut into the large hole at the rear

of the tail wheel bracket. Slide a wheel collar onto the pre-bent tail wheel wire and tighten in place as

shown. Now slide the wire into the bottom of the bushing and install the steering post and tighten the

screws firmly. Install the wheel using two supplied wheel collars. Again, the use of thread-lock on any

metal to metal screw is advised.

6. Center the tail wheel bracket on the rear of the fuselage and screw in place using three of the supplied

wood screws. Remove the screws and harden the holes with a drop of thin CA. Allow the CA to cure

and then permanently install the tail wheel bracket.

7. Locate the ball link end for the tail wheel wire and drill a small hole a few inches from the rear of the

rudder along the bottom (this may already be done for you). Glue this in place with thick CA or epoxy.

Slide the steering wire through this guide and into the aluminum steering arm. Tighten the set screw

firmly. Test the deflection of the rudder to make sure there is no binding and that the steering wire does

not slide out of the support guide.

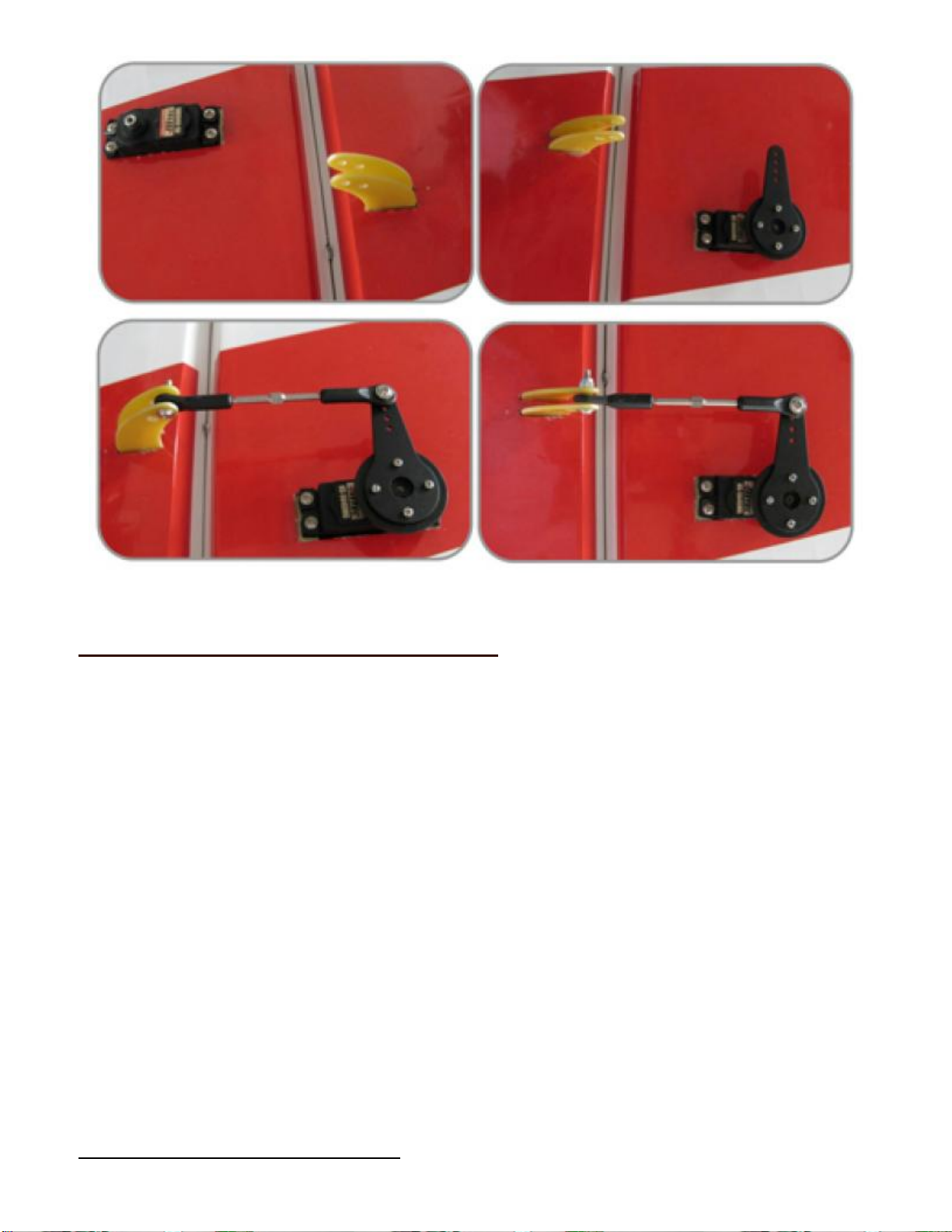

UURUDDER CONTROL INSTALLATION:UU

1. The ARF is supplied with a high quality set of pull-pull cables and ball-links. Servo openings are

provided in the aft section of the fuselage below the horizontal stabilizer for those builders using an

engine heavier than a typical 50 cc engine or needing to move weight aft. The below instructions are for

the pull-pull cable option.

2. Install your rudder servo into the precut location in the fuselage. You will need 3 inch arms on the

servo(s). Or you can mount the supplied rudder arm to your circular servo arm. Set up your radio

accordingly and center the rudder servo. The geometry of your servo arm relative to the rudder horn is

critical for proper rudder operation without binding or excess cable slack.

3. Locate the pull-pull cable set, threaded couplers, brass swaging tubes, and ball-links. If the cable is

one long piece, cut it into two equal length pieces. Thread one end of the one cable through a brass tube

and then through one of the threaded couplers. Run the cable back through the brass tube and then loop it

back through a second time. Using a set of crimping pliers, place three crimps just tight enough not to cut

the brass tube but enough to securely hold the wire in place. Cut off the excess cable with wire cutters.

Wick thin CA into the brass tube to help hold the cable secure. Repeat for the other cable.

4. Thread the couplers about half way into the ball links of the rudder. Hint: remove the ball links from

the rudder horn first to make this step easier and then re-install once the couplers are threaded on.

Feed the loose end of each cable into the cable slots at the rear of the fuselage and feed them forward

towards the servo mount location. A coat hanger with a hook on the end can be useful here if you

can’t reach the cable.

5. Use your radio system to center the rudder servo and attach either the supplied arm or an appropriate

arm for your servo. Thread one of the ball links about half way onto one of the threaded couplers. Feed

the loose end of one of the cables through a brass tube and then through the threaded coupler. Holding

the rudder centered, adjust the cable length as tight as possible while checking the ball link position over

the servo arm. When satisfied with the position, pinch the cable around the threaded coupler and then

feed the loose end back through the brass tube. Loop the cable back through the brass tube as before and

crimp the brass tube three times just tight enough not to cut the brass tube but enough to securely hold the

wire in place. Cut off the excess cable with wire cutters. Wick thin CA into the brass tube to help hold

the cable secure. Repeat for the other cable. Hint: Once you have established the position of the

threaded coupler on the cable, you can remove the ball link from the rudder horn to give you more

working slack in the fuselage. Re-install the ball link prior to setting the other cable.

6. Check the operation of the rudder using your radio and make sure there is no binding and the cables

are adjusted properly. You may have to tighten the cables after a few flights as they may stretch slightly

from the initial installation.

UUENGINE, EXHAUST, & FUEL SYSTEM INSTALLATION:

1. Templates are provided in the kit for both DA and 3W 50 cc engines. These templates can be used to

align any engine as long as you properly align the center guide lines on the firewall. Select the proper

guide for your engine and mark and drill the mounting holes and cut out the center as indicated. Notice

that the engine center line is offset to the left to compensate for the right thrust built into the engine box.

2. Place the cowling in place on the fuselage and measure the distance from the firewall to about 1/2” in

front of the cowling. This figure represents the back of the spinner and will help you determine if you

need to space your engine out from the firewall using washers or additional wood. Mount your engine

securely using bolts, washers, and locknuts and according the manufacture’s instructions. The use of

thread-lock is also highly recommended for the engine bolts. The pictures below show the DA50 engine

installation.

3. Mount the ignition module according to the manufacturer’s instructions. The best place to mount it is

on the side or top of the engine box. Secure the pickup lead and ignition wires with zip ties so that they

do not vibrate or touch any hot part of the engine or exhaust. The picture below shows the DA50 engine

installation. The author prefers to protect the ignition wires with cable wrap to prevent wear of the mesh

shielding.

4. Mount your ignition battery securely to the engine box. A typical location is on the side or top of the

engine box. The ignition switch should be mounted to the fuselage side wall just behind the cowling.

Secure all cable connections neatly and firmly.

5. Assemble the throttle servo mount using the supplied laser cut parts. This mount can be used to locate

the servo further back in the fuse to suit your engine or specific installation. The throttle servo can also be

mounted in the supplied cutout on the bottom of the engine box. Make sure you do not have any the

ignition module close to this servo. Mount your throttle servo, complete your linkage setup and check for

proper operation with no binding.

6. The fuel tank is preassembled. Complete the installation in the fuselage using zip ties or velcro straps

to hold the tank in position. Connect a fuel line between the tank and carb, a fuel line between the tank

vent and the bottom of the fuselage, and a fill line to a fueling port which can be mounted on the fuselage

side opposite your ignition switch. Make sure your vent line does not come close to any hot exhaust part

such as the muffler or canister. EG recommends the use of small zip ties or fuel line clamps to secure the

lines to the tank.

7. There are many options for exhaust systems including canisters of all sizes, stock mufflers, and

inverted Pitts style mufflers. Follow the manufacturer’s instructions for your exhaust system paying

attention to vibration mounts if required and air flow requirements. Trial fit your exhaust system now and

work out any additional supports, but do not permanently install the system until you fit the cowling in the

next steps.

Optional

servo location

100 cc servo location

optional servo location

Typical fuel

dot location

UUCOWLING INSTALLATION:UU

1. Fit the cowling in place and make any cutouts necessary to clear your engine and exhaust components.

Trial fit and trim as necessary being careful and accurate. Be sure to allow enough air exit area in the

bottom of the cowling to provide adequate air flow over the engine. Some modelers may prefer to build

baffling in the front of the cowling to assist air flow over the cylinders. This can be done using scrap

pieces of balsa trimmed to fit your engine installation. Be sure to fuel proof all exposed wood. When

satisfied with the final fit, attach the cowling to the fuselage using the six supplied screws and rubber

washers screwed into the cowl ring. Note the bottom two screws are inserted from the front of the

firewall while the top four are installed from inside the fusealge or back of the firewall.

2. Install the propeller and spinner. Large gasoline engines are very powerful and can cause damage to

persons or property if propellers and spinners are not installed properly. Follow the manufacturer’s

instructions and make sure your props are well balanced, properly drilled, and display no cracks or chips.

UUHORIZONTAL STABILIZER AND ELEVATOR CONTROLS ASSEMBLY:UU

1. Install the fiberglass control horns in the same way as you did the rudder horns. Do not cut the

covering on the top side of the elevators but be sure to fully seat the horns into each elevator. You

may need to trim off some of the control horns as shown in the picture below to fully seat the horns in

the elevators. Again, EG recommends you temporarily install the ball link onto the horns while the

glue cures. This will assure proper alignment of each horn.

2. Install your elevator servo into the root of the horizontal stabilizer making sure the servo wire exits

towards the leading edge of the stab.

3. Use your radio to set the servo center position and install the large control horn onto the servo.

Assemble the control rod and ball links and adjust the control linkage for proper geometry. When

satisfied, screw the ball link to the servo arm. The servo arm should be as close to perpendicular to the

control rod as possible while the elevator is at neutral. Double check all screws, bolts and nuts to assure

proper installation and operation without binding.

4. To install the horizontal stabilizers you first need to install two 30” servo wire extensions in the

fuselage so that they extend from the radio compartment to the aft openings. A servo wire tunnel is

provided in the fuselage to guide the wires.

5. Slide the stabilizer carbon fiber tube into the fuselage and install both stabs onto the tube. Connect the

servo wires and secure the connections with either the supplied clips, tape, or likewise. Use the supplied

screws and rubber washers to secure the stabilizers to the fuselage.

UUWING AND AILERON CONTROLS ASSEMBLY:UU

1. Install the fiberglass control horns in a similar fashion as described above. Again, make sure they are

properly aligned to each other and fully seated in their respective slots.

2. Cut the covering from the aileron servo openings from corner to corner and iron down inside the

openings. Connect servo wire extensions to your servos and secure the connections with the supplied

clips, your own clips, or tape. Feed the servo wires into the wing and out the root. Install the servos and

screw firmly in place.

3. Use your radio to set the centers of each servo and then assemble and adjust the length of each control

rod. The servo arm should be as close to perpendicular to the control rod as possible while the elevator is

at neutral. Double check all screws, bolts and nuts to assure proper installation and operation without

binding. Check the final radio operation of the ailerons and make sure there is no binding and equal

throw up and down.

UUFINAL RADIO SYSTEM INSTALLATION:

1. Whether you 72 MHz systems or the newer 2.4 GHz systems, proper radio installation and care is vital

to the safe and reliable operation of your aircraft. Follow the manufacturer’s instruction for installation

guidance of receivers and batteries paying attention to factors such as vibration isolation, adequate

cooling, and clearances.

2. Mount your reciever(s) securely in a location which provides a clean and maintenance free solution to

your setup. All servo wires should be neatly routed and secured in place so they will not come loose or

flop around during flight.

3. The fuselage ply sides provide space to mount your switches just below the canopy. Mount your

switches according to the manufacturer’s instructions and route your wires safely and securely as above.

4. Your receiver battery(s) can be mounted in a variety of locations depending on your balance needs.

Regardless of where you mount your batteries it is vital that they are very secure with no possibity of

coming loose. Use double sided Velcro to hold the batteries from sliding around and then use zip ties or

Velcro straps to secure them tightly in place.

5. Servo and battery leads are the life blood of your aircraft. Make sure all wires are top quality and

connectors are tight and display no loose pins or frayed wires. Servo clips are provided in the kit for your

convenience. These servo clips can even be glued to the wood structure using CA if desired.

6. Check all radio programming and control surface operations thoroughly before your initial flight.

Check your radio range according to the radio manufacturer’s instructions both with the engine off and

running.

UUBALANCING and PRE-FLIGHT:

1. Most state of the art aerobatic aircraft allow for a wide margin for balancing depending on what level

of precision or freestyle the pilot prefers. To perform properly without being too pitch sensitive, you must

not go too aft on the CG. EG recommends an initial CG setting of 6.0 – 7.0 inches behind the leading

edge of the wing at the root. More experienced pilots may want to set the CG further aft for more 3D

capability. Varying weights of engines and radio gear will dictate how you should install each. The

batteries can easily be located pretty much anywhere in the fuselage. For those using a heavier than

typical engine, servo cutouts are provided in the rear of the fuselage for the rudder servo(s). These

options should allow you to balance the model without adding any weight.

Note: The best way to check your balance is to trim for level flight at about 1/2 to 3/4 throttle and then

roll inverted. The aircraft should maintain level flight with very little to no down elevator input. If the

aircraft climbs when inverted then you’ve probably got your CG too far aft. If the nose drops more than

slightly, then you are most likely nose heavy.

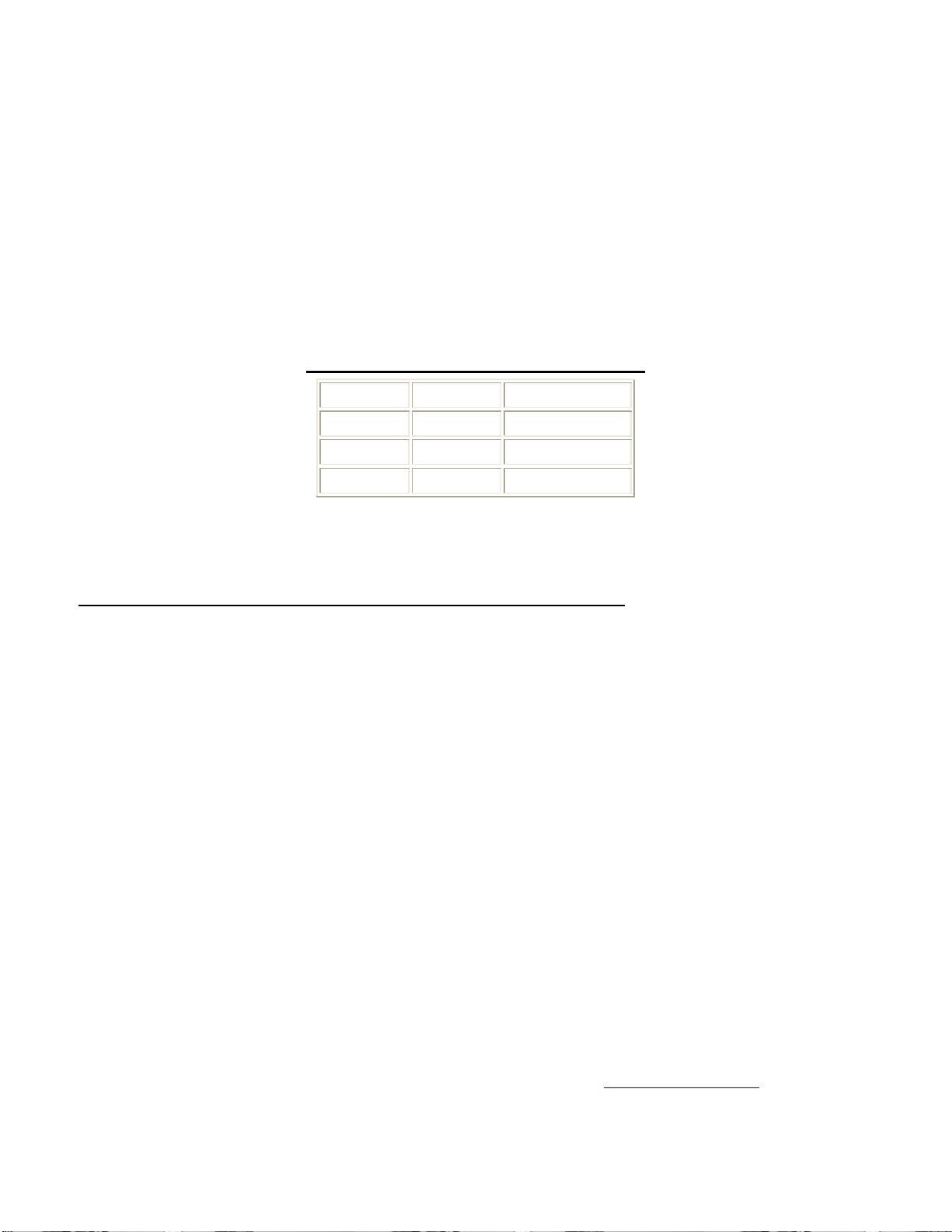

UURecommended control surface deflections:

Low Rate High Rate

Elevator 15 degrees 45-50 degrees

Rudder 25 degrees 40 - 45 degrees

Ailerons 25 degrees 35-40 degrees

UUFINAL ASSEMBLY AND PRE-FLIGHT INSPECTIONS:

1. Before arriving at your flying field, be sure all your batteries are properly charged and all radio

systems are in proper working order.

2. Install the wings onto the fuselage being careful to align the wing tube with the wings and not force it.

The wing tube may be initially tight but will loosen some with use. Guide your servo wires into the

fuselage openings and connect to the proper aileron channels. Servo clips are recommended. Once you

have the wings fully seated in the fuselage tighten the wing bolts inside the fuselage.

3. Fill your fuel tank making sure your vent line is not plugged or capped. With the canopy off, this is a

good time to check for any fuel leaks.

4. Position the canopy in place and tighten the canopy screws. Be sure to use the supplied rubber

washers under the screw heads.

5. If you have removed your horizontal stabilizers, Intall them once again and check all bolts and

connections.

6. Check all control surfaces for secure hinges by performed a slight tug on the control surfaces and

observing if there is any give in the hinges. Check all control rods, ball links, servo screws, etc. for

proper operation and installation.

7. Check your batteries and perform a proper range check once again with the engine off and running. Be

sure all surfaces are moving in the correct direction and the proper amount for your flying setup.

8. You are now ready for your maiden flight! Good luck and enjoy your new aircraft! If you have any

Table of contents

Other EG Aircraft Toy manuals