3

Operator´s Manual Park Ranger 2150 Suction sweeperOperator´s Manual Park Ranger 2150 Suction sweeper

1. General information

The Park Ranger 2150 suction sweeper unit is the most

eective choice for maintenance sweeping tasks on

footpaths, pavements, car parks, stairwells etc. The sweeper

unit features a breglass high tip hopper, a rotation cast

fresh water tank and twin front brushes. It is a robust and

compact machine with low noise operation.

The dust is fully under control with the Park Ranger 2150

suction sweeper unit. Two spray jets tted on the front

brushes dampen the sweeping area and bind the dust. The

collecting tank features an innovative lter system binding

even the smallest dust particles inside the hopper. Hopper

dischargefollows directly from the drivers seat.

When sweeping in dry sweeping conditions the brush speed

can be adjusted in order to reduce the amount of dust swirled

up by the rotating brushes.

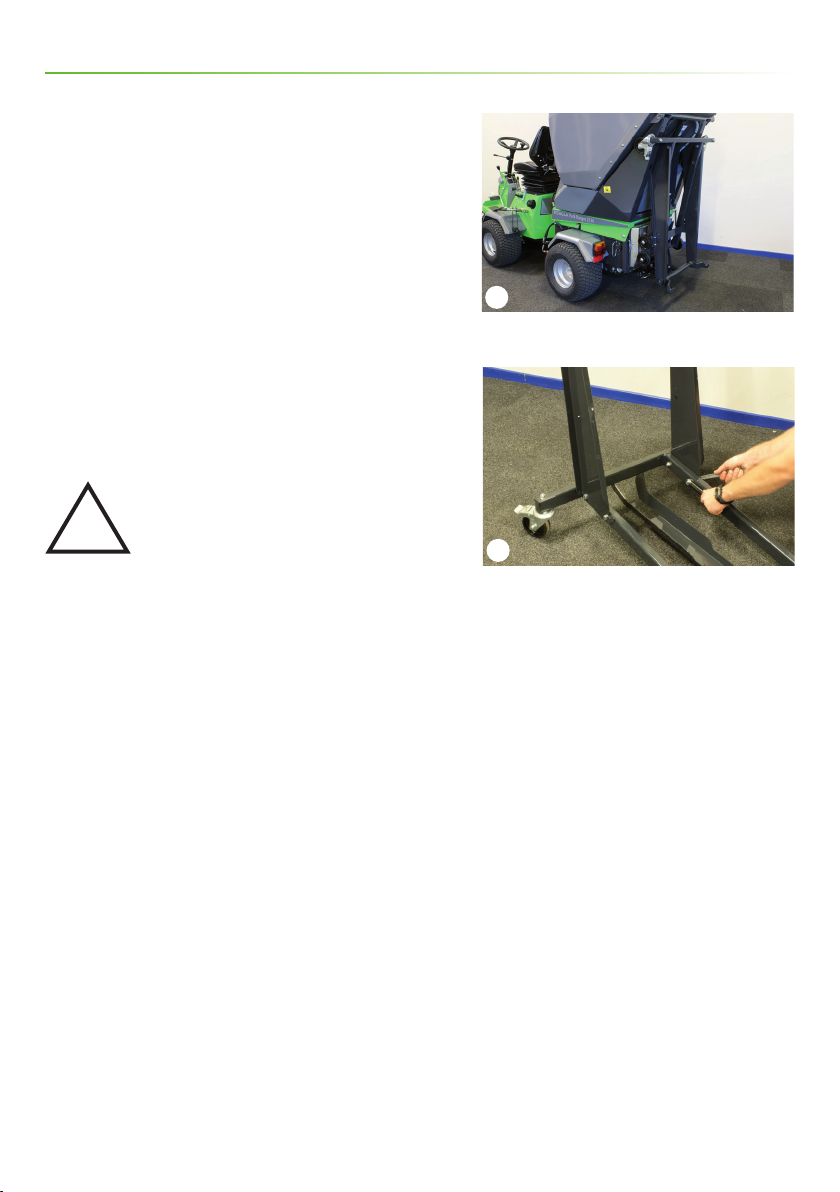

Attaching and detaching of the suction sweeper unit is quick

and easy with the special designed roller stand. The front

brushes and the collecting tank are dismounted directly on

the stand, which ensures the driver an easy handling and

a minimum storage room. With the Park Ranger 2150 the

changeover from one attachment to another is done in less

than 4 minutes - no tools required.

Additional Side Brush - Optional equipment

A hydraulically operated third brush increases the sweeping

path to 1660 mm and makes it easy to keep also hard

accessible angles and corners neat and clean.

Remote vac hose - Optional equipment

The remote vac hose is ideal for the cleaning of places with

dicult access like between parked bicycles, on basements

stairs etc. The 6 m long hose is kept on the top of the hopper

and is always within reach.

Contents

Introduction ....................................................................................2

Contents........................................................................................3

General information..............................................................................4

1.1 Safety.....................................................................................4

1.2 EU Declaration of Conformity.................................................................6

1.3 Technical data .............................................................................7

Operator´s Manual ...............................................................................8

2.1 Assembling the hopper frame ................................................................8

2.2 Assembly/Disassembly......................................................................9

2.3 Important before starting ..................................................................16

2.4 Start-Up .................................................................................17

2.5 Hopper discharge .........................................................................19

2.6 Adjustment...............................................................................20

Service and maintaince ..........................................................................23

3.1 Cleaning/replacing lter system and turbine ..................................................23

3.2 Maintenance .............................................................................24

3.3 Troubleshooting...........................................................................26

Conditions .....................................................................................29

4.1 Warranty.................................................................................29

4.2 Complaints ...............................................................................30

4.3 Disposal..................................................................................30

Wearing parts .................................................................................31

5.1 Wearing parts - Park Ranger 2150 suction sweeper .............................................31

Notes ........................................................................................33