EHRHORN Alpha 5841 User manual

Ehrhorn Technotogical Operations, Inc.

4975 North 30th Street

Colora o Springs, CO 80919

OPERATING AND TECHNICAL MANUAL

HIGH FREQUENCY LINEAR POWER AMPLIFIERS

MODELS PA-76, PA-76P, and PA-76C

EHRHORN TECHNOLOGICAL OPERATIONS, INC.

R vis d May 1, 1977

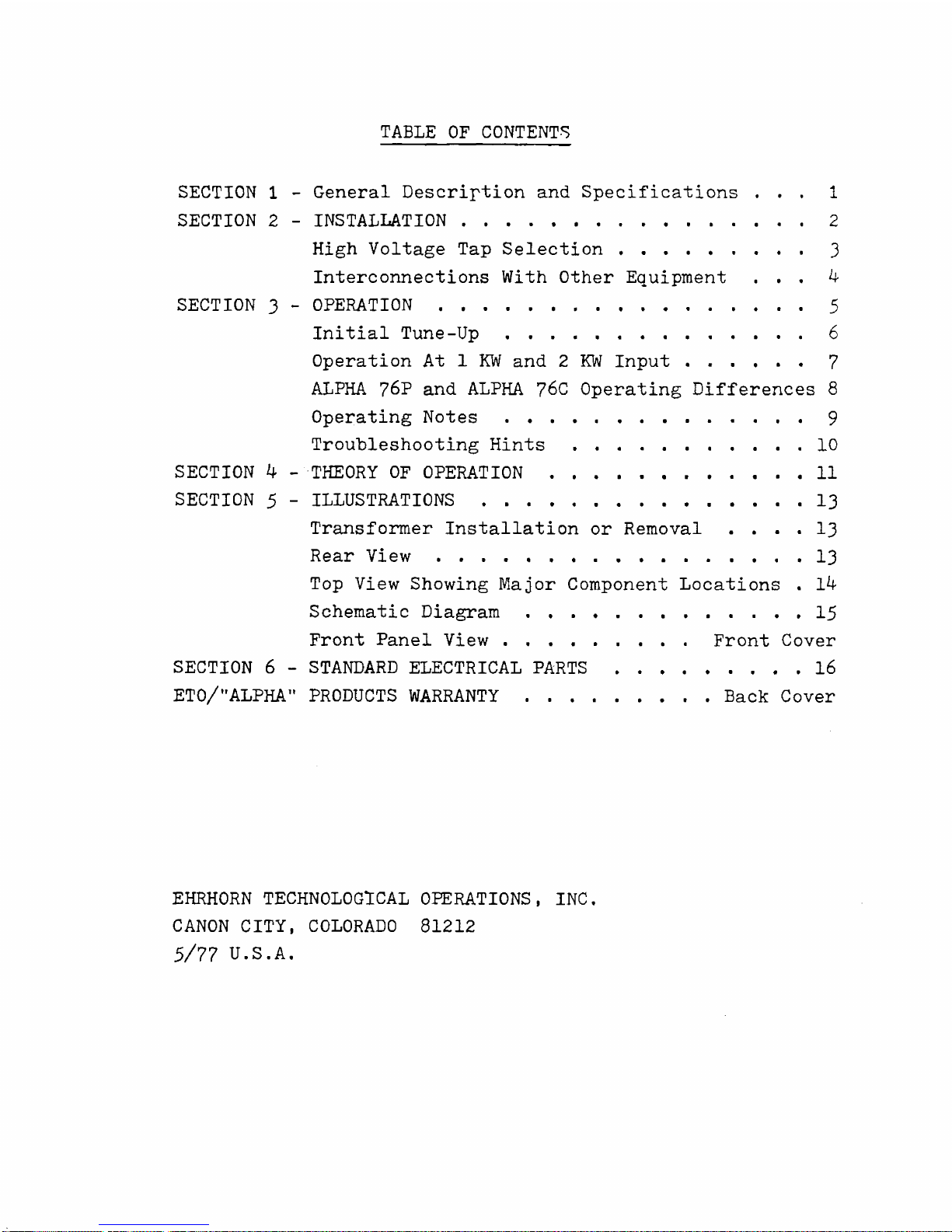

TABLE OF CONTENTS

SECTION 1

SECTION 2

SECTION 3

SECTION k -

SECTION 5 -

SECTION 6 -

ET0/"ALPHA"

- G n ral D scription and Sp cifications

■ INSTALLATION

High Voltag Tap S l ction

...............

3

Int rconn ctions With Oth r Equipm nt . . . 4

• OPERATION 5

Initial Tun -Up

........................

6

Op ration At 1 KW and 2 KW Input

.........

7

ALPHA 76P and ALPHA 7&C Op rating Diff r nc s 8

Op rating Not s

........................

9

Troubl shooting Hints

..................

10

THEORY OF OPERATION

....................

11

ILLUSTRATIONS

..........................

13

Transform r Installation or R moval . . . . 13

R ar V i w

.............................. 13

Top Vi w Showing Major Compon nt Locations . 14

Sch matic Diagram

......................

15

Front Pan l V i w

...............

Front Cov r

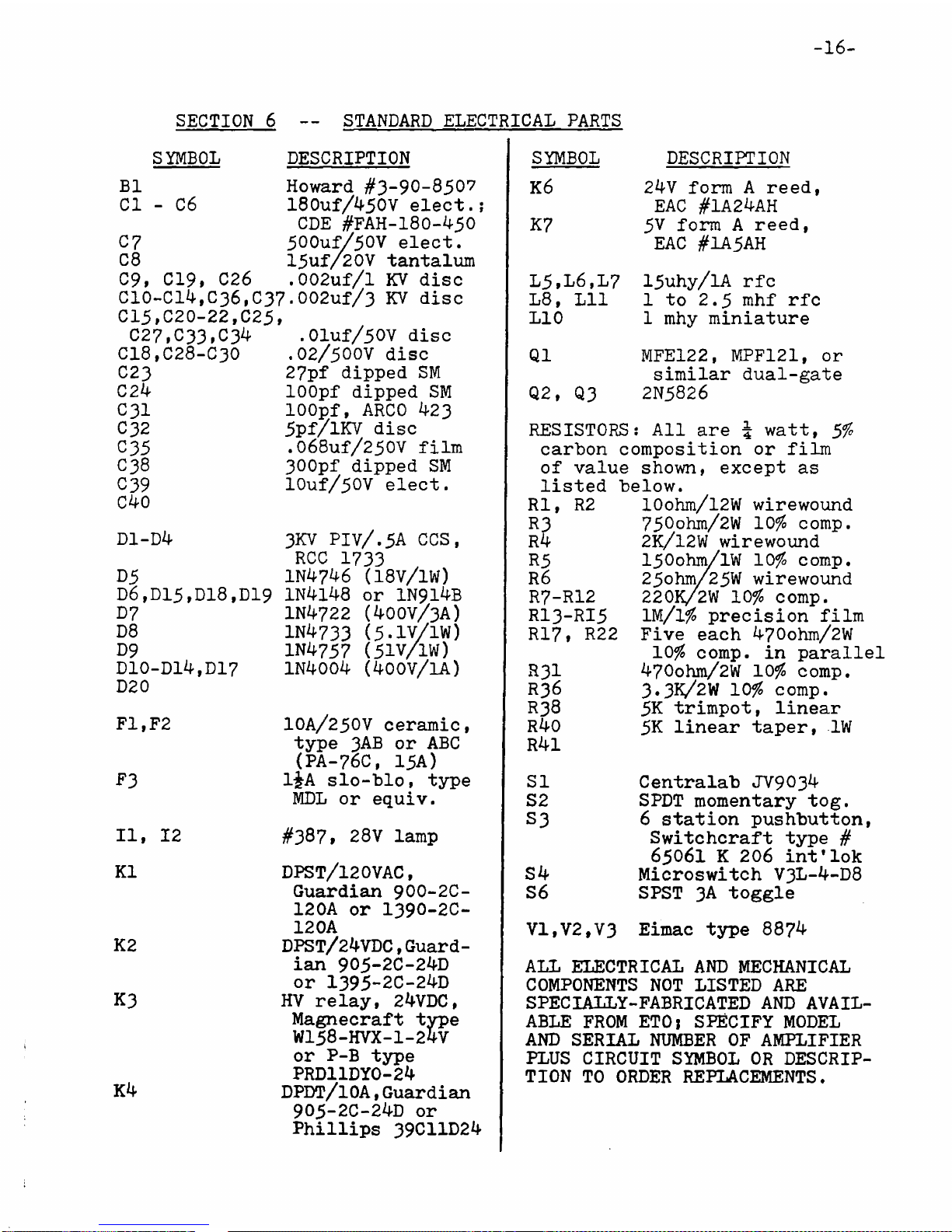

STANDARD ELECTRICAL PARTS

...............

16

PRODUCTS WARRANTY

...............

Back Cov r

EHRHORN TECHNOLOGICAL OPERATIONS, INC.

CANON CITY, COLORADO 81212

5/77 U.S.A.

Th ALPHA 76 (mod l PA-76) is a s lf-contain d high fr qu ncy lin

ar pow r amplifi r capabl of continuous op ration at d-c plat

pow r inputs of 2.5 kilowatts PEP for SSB voic and on kilowatt

av rag or continuous carri r with no tim limit (NTL). Th ALPHA

76 is tunabl ov r th rang 1.8-2.0 MHz plus 3_3° MHz, optimiz d

for conv ni nc in th six amat ur bands of 10 through 160 m t rs.

SPECIFICATIONS (Mod l PA-76)

Fr qu ncy Cov rag : 1.8-2.0 and 3-30 MHz (including 10-160 m t rs).

Plat Pow r Input; 2.5 KW PEP/SSB, 1 KW av rag or k y down, CCS.

RF Pow r Output: Typically 1.5 KW PEP/SSB, 650 watts carri r, CCS.

Driv Pow rs Nominal 100 watts PEP, 60 watts carri r.

Input & Output Imp danc s; Nominal 50 ohms r sistiv , unbalanc d;

VSWR 2:1 or l ss.

Distortion: Third ord r IM mor than 30 3b b low 1 KW PEP output.

Harmonics : Mor than 50 db b low m an fundam ntal fr qu ncy output.

Tub Compl m nt; Two Eimac 88?^ c ramic-m tal ground d-grid triod s.

Cooling: Full-cabin t, duct d forc d air; c ntrifugal blow r.

ALC: Adjustabl thr shold, n gativ -going standard as shipp d.

Prot ction: Primary fus s, plat ov rcurr nt r lay, AC and HV

int rlocks.

Primary Pow r: 24QV/10A or 120V/20A, nominal, 50-60 Hz.

Siz and W ight: 7.5"h. x 17"w. x l4.75"d. Shipping wt., 75 lb.

Optional Modifications Availabl :

Lightw ight Hip rsir^ pow r transform r r duc s

n t and shipping w ights by approximat ly 20 lb.

HI/LO (or "SSB/CW-TUNE”) tap chang r lay, front

pan l controll d.

Id ntical with PA-76 abov xc pt tub compl m nt

is thr 8874's, incr asing plat pow r input rat

ing to 3+ KW PEP and typical rf output to 2 KW PEP.

Do s not aff ct long t rm av rag or continuous

pow r ratings.

"Comm rcial" mod l id ntical with PA-76 xc pt

tub compl m nt is thr 8874' pow r transfor

m r is sp cial 2.4 KVA Hip rsir^, and option "R"

is standard. PEP ratings, d-c input 3 KW, typi

cal rf output 2 KW; continuous carri r or long

t rm av rag ratings, d-c input 1.6 KW, rf output

1 KW CCS (RATT, A0, tc.)

-1-

SECTION 1

GENERAL DESCRIPTION

Option "L" --

Option "R" --

Mod l 76? --

Mod l 76C --

2-

Unpacking: Car fully r mov amplifi r and transform r from car

tons; SAVE ALL PACKING MATERIAL FOR RE-USE - SHIPMENT OF THE ALPHA

76 IN OTHER THAN FACTORY PACKING MAY RESULT IN DAMAGE NOT COVERED

UNDER WARRANTY.

Insp ct clos ly for vid nc of shipping damag ; if any is found,

notify d liv ring carri r and s ll r at onc . Compl t warranty

r gistration form and mail to ETO.

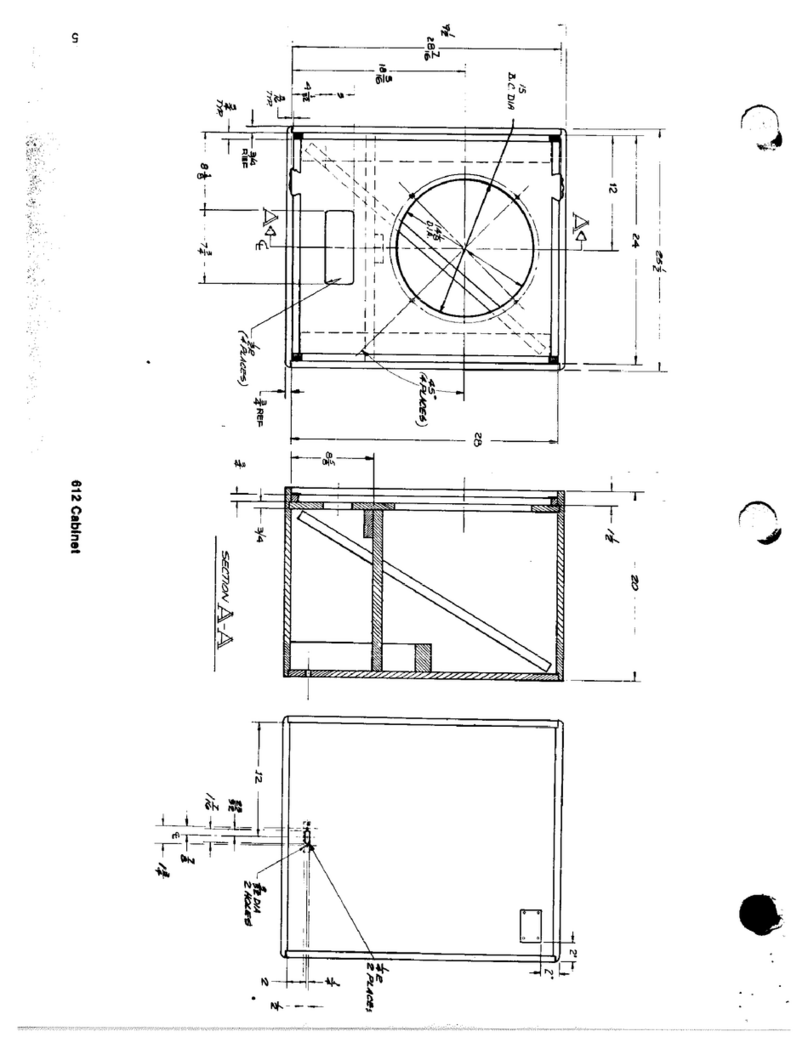

2. Transform r Installation; Th top cov r and th right-hand nd

pan l ass mbly of th amplifi r ar asily r mov d for transform r

installation. R mov th six flat h ad Phillips scr ws from th

top and two pan h ad scr ws from th r ar flang of th top cov r,

and lift it off.

To r mov th right-hand sid pan l ass mbly, r mov th two flat

h ad scr ws at th right dg of th front pan l, two at th dg

of th r ar pan l, and thr pan h ad scr ws at th dg of th

bottom plat . Pull th nd pan l ass mbly straight away from th

main chassis ass mbly.

Ori nt th transform r so that th two multi-pin, mold d plugs on

th transform r harn ss point toward th front of th amplifi r;

mov th corr sponding mating conn ctors in th amplifi r its lf

t mporarily out of th way (it may b n c ssary to tap or ti

on or both of th m out of th way whil installing th transfor

m r) . Car fully slid th transform r into position so that th

i-20 tapp d mounting hol s in its bas lin up with corr sponding

hol s in th amplifi r bas plat . Install th J-20 bolts and

wash rs provid d through th bottom plat , and tight n s cur ly.

Ch ck both pairs of conn ctors visually for prop r mating ori nta

tion (avoid xc ssiv harn ss b nding or twisting, as it may caus

damag to wir s or conn ctor pins) and mat th m firmly, pushing

until th int gral latch s ngag .

3» El ctrical Installation: If th amplifi r is to b us d with th

typ of a-c mains arrang m nt for which it has b n factory-wir d

(220-250V, 50-60 Hz, 1 phas , unl ss oth rwis sp cifi d) th nd

pan l and top cov r may b r plac d. If chang -ov r to 110-125V

pow r is n c ssary, mak th following chang s first:

Chang -Ov r to 110-125V Op ration - (Th amplifi r will op rat

normally on 110-125V, 50-60 Hz pow r if th primary supply cir

cuit is of ad quat capacity to d liv r th r quir d curr nt with

r asonabl r gulation (approximat ly 20 amps p ak, 5-10 amps av r

ag at full pow r, xc pt PA-76C up to 15 amps av rag ). To

chang from 220-250V to 110-125V op ration:

(a) Locat R4 (2000 ohm/12 watt r sistor mount d just abov th

RELAY jack on th r ar pan l); install a short jump r of #22

or larg r wir across its lugs, shorting it out.

(b) Locat th 9 pin transform r plug P2. Th transform r l ad

wir originally in th pin 3 position of P2 must b mov d tc>

th pin 2 position in th mold d sh ll? also, th l ad orig

inally in th pin 6 position must b mov d to th pin 5 hol .

CAUTION! DO NOT ATTEMPT TO REMOVE THE CRIMPED-ON PINS FROM

THE PLUG WITHOUT AN APPROPRIATE EXTRACTION TOOL AS DAMAGE TO

SECTION 2

INSTALLATION

I

3

PINS OR CONNECTOR IS AIMOST CERTAIN TO RESULT. On r qu st,

ETO will supply at no charg xtra push-in pins with short

l ads attach d. Onc th amplifi r is chang d ov r for 110-

125 volt op ration, it is strongly urg d that a conspicuous

lab l or tag b attach d to th pow r cabl to avoid accid ntal

conn ction to 220-250 volt lin s lat r on.

Pow r Cabl Conn ction - Th gr n wir of th amplifi r pow r

cabl is a chassis saf ty ground, and must always (and only) b

conn ct d to th saf ty ground of th a-c mains -- NEVER to on

of th "hot" pow r wir s. Th black and whit wir s ar int r

chang abl and should b conn ct d to th two "hot" conductors

of th s rvic .

4. High Voltag Tap S l ction: If your amplifi r do s not contain

th high voltag tap chang r lay with a front pan l Hl/LO switch,

it was shipp d from th factory with th int rnal HV tap conn ct d

for full pow r SSB op ration. This conn ction is also suitabl

for k y d CW and for int rmitt nt duty FSK or SSTV op ration at up

to on kilowatt d-c input. For continuous or oth rwis h avy-duty

carri r op ration, slightly high r ffici ncy and cool r op ration

may b achi v d by moving th int rnal tap to th m dium voltag

(MV) position, as follows:

(a) DISCONNECT A-C POWER; r mov amplifi r top cov r; short crowbar.

(b) On HV & control circuit board locat d at right, front of th

chassis, not short loop of blu HV wir t rminat d in a f mal

quick-conn ct (QC) lug. For normal high voltag SSB op ration

this blu wir is mat d with anoth r blu HV wir from th main

wiring harn ss ..• via th r ar-most doubl mal QC lug on th

circuit board. To conn ct inst ad th m dium voltag tap, r

mov only th f mal QC lug conn ct d to th short blu jump r

wir and push it fully on to th front-most mal QC lug (which

is alr ady also conn ct d to a gr n HV wir from th harn ss).

No-load plat voltag will th r by b r duc d from 2.4 KV (HI)

to approximat ly 1.6 KV (LO).

It is d sirabl that you familiariz yours lf with amplifi r op ra

tion, and p rform initial tun -up, using th "L O ” tap. A chart of

TUNE and LOAD control s ttings d t rmin d und r th s conditions

will th n p rmit pr s tting th controls v ry clos ly wh n changing

fr qu ncy th r aft r, r quiring only minor touch-up in op ration.

NOTE* Us of th optional HV tap chang r lay p rmits conv ni nt

(and on-th -air l gal) tun -up at on kilowatt input; switching

th n to th HI position pr par s th amplifi r instantly for full

pow r SSB op ration at 2+ KW. PEP input -- without furth r adjustm nt.

5* Physical Locationt Th ALPHA 76 must b locat d so that intak of

cool air through th r ar pan l, and xhaust of hot air through

th top cov r p rforations, is not imp d d in any way. A minimum

of 4 to 6 inch s of cl aranc should b allow d b hind and abov

th amplifi r cabin t for air circulation. B car ful not to

block th top-cov r xhaust op nings with log books or quipm nt.

4

6. RF And Control Conn ctions : Int rconn ction of th ALPHA 76 for

op ration with any popular transc iv r or xcit r is xtr m ly

simpl . Conn ct th r ar pan l jacks as follows:

RF INPUT - Us a standard "RCA" typ plug and RG-58C/U or similar

small 50 ohm coaxial cabl to conn ct to transc iv r or xcit r

"rf output” or ’’ant nna" conn ctor. K p cabl short if possibl .

RF OUTPUT - Us a standard PL-259 ("UHF" typ ) plug and RG-8A/U

or similar 50 ohm coaxial cabl to conn ct to ant nna syst m.

RELAY - Us a standard "phono-typ " patch cabl to conn ct this

jack to contacts which ar "op n" on r c iv and "short d" on

transmit ("N.O." -- normally op n). Such contacts ar usually

availabl on th r ar pan l of th xcit r or transc iv r in th

form of a matching "phono" conn ctor. A f w transc iv rs, such

as Atlas and Drak uni*t^ may r quir sp cial conn ctors for

tying into th ir int rnal transmit-r c iv r lay contacts.

NOTE: Wh n th amplifi r is OFF or in th RECEIVE condition with

no short across th RELAY lin , th RF OUTPUT conn ctor is int rnally

conn ct d dir ctly to th RF INPUT conn ctor, providing normal

"transc iv -typ " ant nna input to th r c iv r.

ALC - For us with conv ntional transc iv rs having n gativ -

going ALC syst ms, simply patch this jack to th mating ALC jack

on th transc iv r (or xcit r), using standard "phono” cabl .

C rtain solid-stat transc iv rs utiliz positiv -going ALC which

r quir s slight modification of th amplifi r's ALC circuit, or

us of an adapt r, if ALC f dback is to b mploy d. Normally

it is quit satisfactory to simply us th transc iv r's int rnal

ALC syst m with Atlas, Triton, and similar radios.

-5-

1. Control Functions:

BAND - S l cts tuning rang of amplifi r, indicating th nominal

c nt r of th rang in MHz.

TUNE - Controls amplifi r r sonant fr qu ncy. In g n ral, high r

fr qu ncy bands (28 & 21 MHz, tc.) tun n ar r to th ”0"

nd of th v rni r dial scal , whil low r-fr qu ncy bands

(3*5 and 1.8 MHz) tun mor in th 50 to 100 rang .

LOAD - Controls d gr of amplifi r loading. High r bands (28 &

21 MHz) load prop rly toward th 70-100 nd of th v rni r

dial scal , low r bands mor in th 0-50 rang . In g n ral,

adjusting toward a high r numb r r sults in a h avi r load

ing of th amplifi r.

ON/OFF - Controls main a-c pow r to amplifi r. Also s rv s as

"r s t" control aft r pow r turn-off by ov rcurr nt r lay.

Hl/LO - (Optional on PA-76 and PA-76P, standard on PA-76C) S l cts

"high" or "m dium" HV tap for SSB or CW/TUNE/FSK/SSTV op ra

tion, r sp ctiv ly.

PUSH BUTTONS -

STBY: Disabl s amplifi r chang ov r r lay, th r by p rmit

ting "straight-through" op ration of xcit r/trans

c iv r whil amplifi r r mains r ady for us . M t r

monitors amplifi r high voltag (HV: 3 KV full scal ).

OPERATE-HV (2nd button): P rmits normal op ration of ampli

fi r whil m t r monitors HV.

GRID: Normal op ration, m t r monitors grid curr nt (150

milliamp r s full scal ).

PLATE: Normal op ration, m t r monitors plat curr nt

(1.5 amp r s full scal ).

FWD: Normal op ration, m t r monitors rf forward pow r

(2000 watts full scal ).

REFL: Normal op ration, m t r monitors rf r fl ct d pow r

(200 watts full scal ) for d t rmining load VSWR.

ALC (r ar pan l adjustm nt) - S ts driv pow r l v l at which

ALC voltag b gins to ris from z ro; s ts "ALC thr shold."

2. Tun -Up Proc dur :

(a) GENERAL - Th nd goal of tun -up is to adjust th amplifi r

for maximum pow r output at th int nd d/d sir d l v l of

driv pow r and d-c plat input. If a st ady carri r at a

fix d pow r l v l is appli d to th RF INPUT and th ALPHA 76

TUNE and LOAD controls ar prop rly adjust d to yi ld th

maximum availabl rf pow r output, th amplifi r is automatic

ally s t up prop rly for th b st combination of ffici ncy

and lin arity possibl at that driv l v l.

SECTION 3

OPERATION

-6-

If th driv pow r is incr as d b yond th tun -up l v l

aft r th final TUNE/LOAD adjustm nts, flattopping and un

d sirabl distortion (on SSB) will r sult, along with grid

curr nt gr atly in xc ss of normal.

If driv pow r is r duc d b low th tun -up l v l without fur

th r adjustm nt of TUNE and LOAD controls, amplifi r ffici ncy

will b r duc d. Both of th s stat m nts ar applicabl to

any lin ar amplifi r of th typ s us d for high pow r amat ur

and similar s rvic .

It is th r for ss ntial that th amplifi r b adjust d for

maximum rf output at th driv and d-c input pow rs which ar

to b mploy d in normal op ration, WITH ONE IMPORTANT EXCEPTION:

if th plat voltag is chang d without changing also th TUNE

and LOAD adjustm nts, th r sulting pow r l v l which will yi ld

optimum p rformanc at th n w plat voltag will vary in pro

portion to th squar of th plat voltag chang . For xampl ,

if th ALPHA 76 is tun d up for maximum output with 1400 VDC

plat voltag and with th driv l v l s t so that th r sult

ant maximum output is about 700 watts ( quival nt to a d-c

input of roughly 1000 watts), THEN if th plat voltag is

incr as d to 2000 VDC th amplifi r will automatically p rform

optimally at about 700 X (2000/1400)2 = 1400 watts rf output,

corr sponding to approximat ly 2000 watts d-c input.

In g n ral, th final op rating adjustm nt aft r basic tun -

up should b to adjust xcitation (driv ) from th xcit r or

transc iv r so that th GRID curr nt m t r indication just

r ach s about 50 mad (l/3 scal ) k y-down or on voic p aks.

(b) INITIAL TUNE-UP - S l ct m dium plat voltag by ith r placing

th pan l switch controlling th (optional) HV tap chang r lay

into its L0 (down) position or s l cting th int rnal MV tap

b for installing th amplifi r cov r during installation.. Mak

c rtain that th top cov r is prop rly fast n d in plac .

(1) Pr ss STBY button and mom ntarily lift th ON toggl .

Th pan l m t r should imm diat ly illuminat r d or

amb r and indicat 1,5 KV (mid-scal ) + 100 V. Th

blow r should start imm diat ly and xhaust air should

b r adily d t ctabl flowing from th top cov r v nts.

(2) Wh n th tub warm-up d lay is compl t d in 45 to 90

s conds, th m t r will chang from amb r to pal gr n,

indicating ’’r ady" to transmit. S t controls to th pr

liminary points indicat d in Tabl I b low, d p nding

on th d sir d op rating fr qu ncy.

TABLE I -- PRELIMINARY SETTINGS FOR INITIAL TUNE-UP

FREQ.. MHZ

1.8 BAND TUNE LOAD FREQ. BAND TUNE LOAD

1.8 84 30 7.1 7 50 45

2.0 1.8 75 25 14.15 14 21 70

3.6 3.5 53 38 21.20 21 10 82

3.9 3.5 42 48 28.70 28 08 85

(3) Pr ss PLATE button and switch xcit r to CW or TUNE;

th pan l m t r should turn amb r to indicat 'transmit.'

7

(4) V ry slowly incr as xcit r carri r output until th

amplifi r pan l m t r indicat s plat curr nt of 0.5

amps (1/3 scal ). Pr ss FWD button and car fully ad

just LOAD control for maximum m t r indication. Th n

adjust TUNE for maximum m t r r ading, and r p at th

proc ss of alt rnat ly adjusting first LOAD, th n TUNE,

until no furth r incr as in FWD pow r is obtainabl .

(5) Pr ss PLATE button and not m t r indication; th d sir d

r ading for on kilowatt d-c input is approximat ly 0.7

amp (sinc 0.7 amp X 1400 volts = 980 watts input).

(6) If th plat curr nt in st p (5) was l ss than 0.7 amp,

incr as xcit r carri r output slightly and r p at th

LOAD/TUNE adjustm nt proc ss of st ps (4) and (5) again.

If th plat curr nt in st p (5) is gr at r than 0.7 amp,

d cr as xcit r output slightly and r p at th LOAD/TUNE

proc ss of st ps (4) and (5) again.

(7) Continu making slight corr ctions in driv pow r, and

th n .adjusting LOAD and TUNE alt rnat ly for maximum

FWD pow r output until, aft r th final adjustm nt, th

PLATE curr nt m t r indication is v ry clos to 0,7 amp.

(8) Th ALPHA 76 is now corr ctly adjust d for op ration at

on kilowatt d-c input using th m dium plat voltag

tap.

(c) OPERATION AT 1 KW INPUT (KEY-DOWN OR PEP) - Tun up as

in (b) just abov . L av amplifi r in m dium ('LO*) plat

voltag condition. Ch ck xcit r rf output (mik gain,

cw l v l, or rf output control, as applicabl ) to insur

that k y-down amplifi r GRID curr nt r ading is about

50-75 ma (1/3 to l/2 scal ). On SSB s t mik gain or

xcit r rf output l v l so that GRID curr nt r ading on

sp ch p aks do s not xc d 40-50 ma (l ss than 1/3 scal ).

(d) OPERATION ON SSB AT 2+ KW PEP INPUT - Tun up xactly as

in (b) abov . R mov xcitation. Switch (optional) HV

tap-chang r lay to 'HI* position if availabl ; oth rwis

r mov all pow r from amplifi r, op n top cov r, and chang

ov r to high voltag tap position as d scrib d on pag 3i

paragraph 4 (blu -to-blu wir s). R plac cov r, r conn ct

a-c pow r, and switch ALPHA 76 ON,

Wh n m t r lights gr n, switch xcit r to SSB and sp ak

normally into th mik whil adjusting mik gain (or rf

output) control so that high st m t r swings with th PLATE

button d pr ss d r ach approximat ly 0.45 amp (just und r

l/3 of full scal ), OR until high st GRID curr nt swings

r ach 50 ma (1/3 scal ), which v r occurs first.

Maximum (U.S.) amat ur pow r input of on kilowatt av rag

corr sponds to high st PLATE m t r swings of about 0.45

amp, as d scrib d abov , provid d that plat voltag (HV)

drops to approximat ly 2.2 KV on sp ch p aks. D p nding

on individual voic and xcit r charact ristics, it may

b d sirabl to initially adjust for loading slightly

light r (or h avi r) than d scrib d abov so that SSB

sp ch p aks of 0.45 amps PLATE and 30-5° ma GRID curr nt

occur simultan ously.

I

8

( ) TUNE-UP UNDER "HV" CONDITIONS - Wh n th optional HV tap

chang r lay is not includ d, th ALPHA 76 may saf ly "b

tun d-up with maximum plat voltag appli d so that th in

t rnal taps n d not b chang d. Extra car must b x rcis d,

to avoid abusing th amplifi r or tub s, to insur that (a)

driv pow r is k pt low and adjust d v ry car fully, with LOAD

adjust d first and TUNE s cond at ach st p and that (b) PLATE

curr nt is not p rmitt d to xc d 0.7 amp for long r than 15-

20 s conds at a tim , nor 1.0 amp at any tim .

(1) For On Kilowatt Input With HI Plat Voltag , follow th

sam basic proc dur as d scrib d in st ps (4) through

(7) xc pt mak all adjustm nts for a final "targ t"

PLATE curr nt of approximat ly 0.45 amp (X approx. 2.2 KV =

1000 watts input). (R f r nc : pag 7*)

(2) For 2+ KW PEP SSB Op ration, tim up in HV just as in st ps

(4) through (7) on pag 7 for L0 voltag tun -up xc pt

th final plat curr nt goal is 1.0 amp at th nd of th

last LOAD/TUNE adjustm nt it ration. (NOT LEGAL ON ANTENNA!)

ALWAYS ADJUST LOAD CONTROL FIRST, THEN TUNE! Vary th

xcitation in small st ps, as n c ssary, until th d sir d

plat curr nt is achi v d at maximum output. Th n switch

xcit r/transc iv r to SSB and adjust mik gain as d scrib d

on pag 7«

NOTE! Wh n op rating at on kilowatt carri r or PEP input in

th HI plat voltag condition, th maximum driv pow r

r quir d is only about 50 watts, typically. S v r

ov rdriv may r sult in s rious damag to tub s or rf

tuning circuits which may not b cov r d by warranty.

3* ALPHA 76P and ALPHA 76C Op rating Diff r nc s:

(a) Plat curr nt valu s r f rr d to in pr vious pag s in conn ction

with tun -up and op ration of th ALPHA 76 may g n rally b

incr as d by 40-50# for th thr tub "P" and "C" mod ls;

corr sponding grid curr nts will typically incr as 40-50$ as

w ll. This allows both th 76P and th 76C to op rat at

40-50$ high r l v ls of p ak or int rmitt nt pow r input and

output.

(b) Th xtra-duty 2.4 KVA Hip rsi3®pow r transform r us d in

mod l ALPHA 76C p rmits this mod l to op rat at a long-t rm

av rag or continuous pow r l v l approximat ly 50-60$ gr at r

than that of th ALPHA 76 or 76P — about 1.5-1«6 KW d-c input

and 1 KW rf output, continuous duty, v rsus 1.0 KW d-c input

maximum (continuous or av rag ) for th 76 and 76P.

(c) Extra caution is r quir d in using th ALPHA 76P to guard

against accid ntally xc ding th long-t rm/CCS av rag d-c

input rating of 1 KW. This normally is not a probl m xc pt

possibly in th v nt of continuous k y-down op ration or

continuous SSB transmission with h avy sp ch proc ssing.

(c) PA-76C mploys 15 amp, typ 3AB or ABC fus s. With all mod ls,

20 amp 3AB or ABC fus s may b substitut d for 120V op ration.

-9

4. Op rating Not s:

(a) TUBES - Th 8874 c ramic triod s ar xtr m ly rugg d and

normally op rat with a larg margin of saf ty. Th y will

d liv r outstanding s rvic lif IF not damag d by grossly

xc ssiv grid dissipation or airflow blockag (k p th

intak and xhaust v nt ar as cl ar!) Do not allow av rag

plat curr nt p r tub to xc d 0.35 amp for mor than 15-

30 s conds, nor v r to xc d 0.5 amp. Do not allow grid

curr nt to v r xc d full scal (150 ma); normal op ration

r quir s only 50-60 ma.

(b) INTERLOCKS - Th ALPHA 76 (all v rsions) is quipp d with

switch s which shut off a-c pow r and short out th high

voltag pow r supply wh n th cov r is not s cur ly fast n d

in plac . THESE PROTECTIVE INTERLOCKS ARE PROVIDED TO PRO

TECT YOU AGAINST POTENTIALLY FATAL ELECTRIC SHOCK RESULTING

FROM CONTACT WITH OPERATING VOLTAGES INSIDE THE AMPLIFIER.

THE AMPLIFIER SHOULD NEVER BE ENERGIZED WITH THE COVER REMOVED

AND INTERLOCKS DEFEATED EXCEPT BY THOROUGHLY TRAINED AND

KNOWLEDGABLE SERVICE PERSONNEL!

(c) FUSES - Exc pt in rar instanc s of compon nt failur , th

blowing of on or both primary lin fus s indicat s that th

maximum saf av rag pow r input capability of th amplifi r

has b n substantially xc d d. DO NOT SUBSTITUTE OVERSIZED

FUSES xc pt as not d on th pr vious pag .

Th slo-blo fus F3 locat d just b hind th front pan l pr

v nts burn-out of th st p-start r sistors and HV r ctifi rs

in th v nt of abnormal turn-on conditions or HV faults.

DO NOT SUBSTITUTE a fus of diff r nt typ or rating.

(d) PLATE OVERCURRENT RELAY - This r lay functions primarily to

d - n rgiz th primary pow r quickly in th v nt of a fault

in th HV circuitry or grossly xc ssiv driv conditions.

Th r lay should not b r li d on to pr v nt ith r short-

or long-t rm ov rdriv ; that is th op rator's r sponsibility.

Should th ov rcurr nt r lay trip, r moving all a-c pow r from

th amplifi r, it is ss ntial to d t rmin and corr ct th

caus b for r -applying pow r by actuating th . ON toggl .

( ) MAINTENANCE AND TROUBLESHOOTING - Most appar nt failur s and

probl ms with th ALPHA 76 s ri s r sult from op rators' fail

ur to r ad and thoroughly und rstand th cont nts of this

manual, as w ll as basic lin ar amplifi r principl s --

rath r than from actual quipm nt d f cts.

Amplifi r int riors, particularly th high voltag d-c ar as

of th pow r supply and rf compartm nt, should b cl an d

fr qu ntly nough (with a soft brush and a vacuum cl an r) to

pr v nt visibl accumulation of dust. If xtr m ly dusty

conditions pr vail, it may b advisabl to s cur a thin

plastic air filt r, of th typ us d in window air condition rs,

across th air intak ar a.

1

-10-

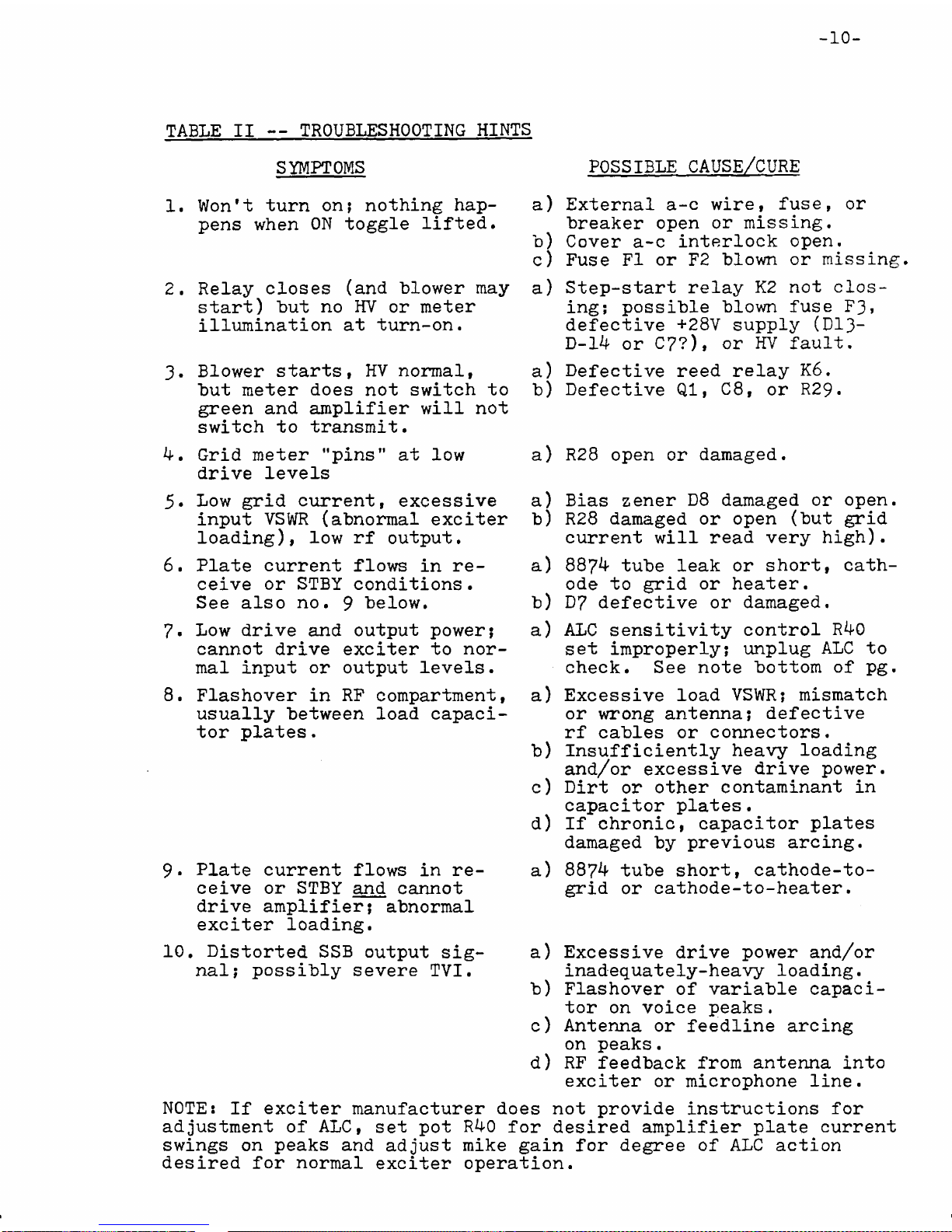

TABLE II -- TROUBLESHOOTING HINTS

SYMPTOMS

1. Won't turn on; nothing hap

p ns wh n ON toggl lift d.

2. R lay clos s (and blow r may

start) but no HV or m t r

illumination at turn-on.

3. Blow r starts, HV normal,

but m t r do s not switch to

gr n and amplifi r will not

switch to transmit.

4. Grid m t r "pins

driv l v ls

5.

6.

7.

8.

9-

nat low

Low grid curr nt, xc ssiv

input VSWR (abnormal xcit r

loading), low rf output.

Plat curr nt flows in r

c iv or STBY conditions.

S also no. 9 b low.

Low driv and output pow r;

cannot driv xcit r to nor

mal input or output l v ls.

Flashov r in RF compartm nt,

usually b tw n load capaci

tor plat s.

Plat curr nt flows in r

c iv or STBY and cannot

driv amplifi r; abnormal

xcit r loading.

a)

D

C

a

b

a

b

a

a

10. Distort d SSB output sig

nal; possibly s v r TVI. Exc ssiv driv pow r and/or

inad quat ly-h avy loading.

Flashov r of variabl capaci

tor on voic p aks.

Ant nna or f dlin arcing

on p aks.

RF f dback from ant nna into

xcit r or microphon lin .

NOTE: If xcit r manufactur r do s not provid instructions for

adjustm nt of ALC, s t pot R40 for d sir d amplifi r plat curr nt

swings on p aks and adjust mik gain for d gr of ALC action

d sir d for normal xcit r op ration.

POSSIBLE CAUSE/CURE

Ext rnal a-c wir , fus , or

br ak r op n or missing.

Cov r a-c int rlock op n.

Fus FI or F2 blown or missing

St p-start r lay K2 not clos

ing; possibl blown fus F3»

d f ctiv +28V supply (D13-

D-14 or C7?)» or HV fault.

D f ctiv r d r lay K6.

D f ctiv Q1, C8, or R29.

R28 op n or damag d.

Bias z n r D8 damag d or op n.

R28 damag d or op n (but grid

curr nt will r ad v ry high).

8874 tub l ak or short, cath

od to grid or h at r.

D7 d f ctiv or damag d.

ALC s nsitivity control R40

s t improp rly; unplug ALC to

ch ck. S not bottom of pg.

Exc ssiv load VSWR; mismatch

or wrong ant nna; d f ctiv

rf cabl s or conn ctors.

Insuffici ntly h avy loading

and/or xc ssiv driv pow r.

Dirt or oth r contaminant in

capacitor plat s.

If chronic, capacitor plat s

damag d by pr vious arcing.

8874 tub short, cathod -to-

grid or cathod -to-h at r.

I

SECTION 4

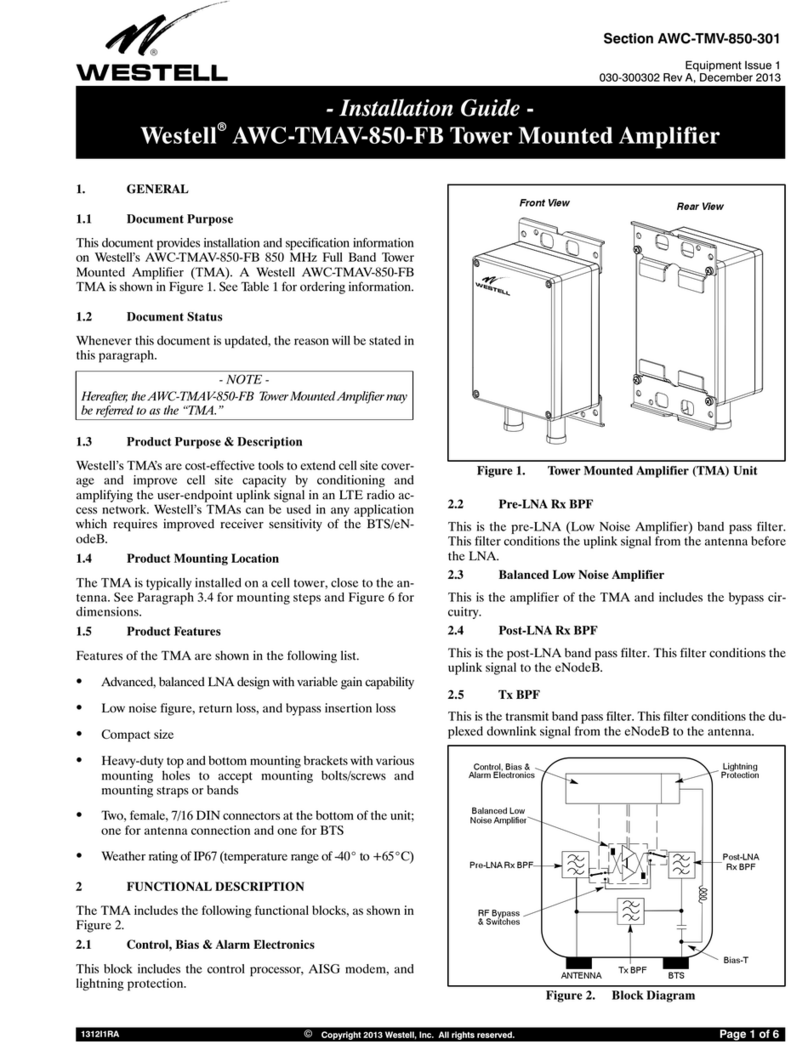

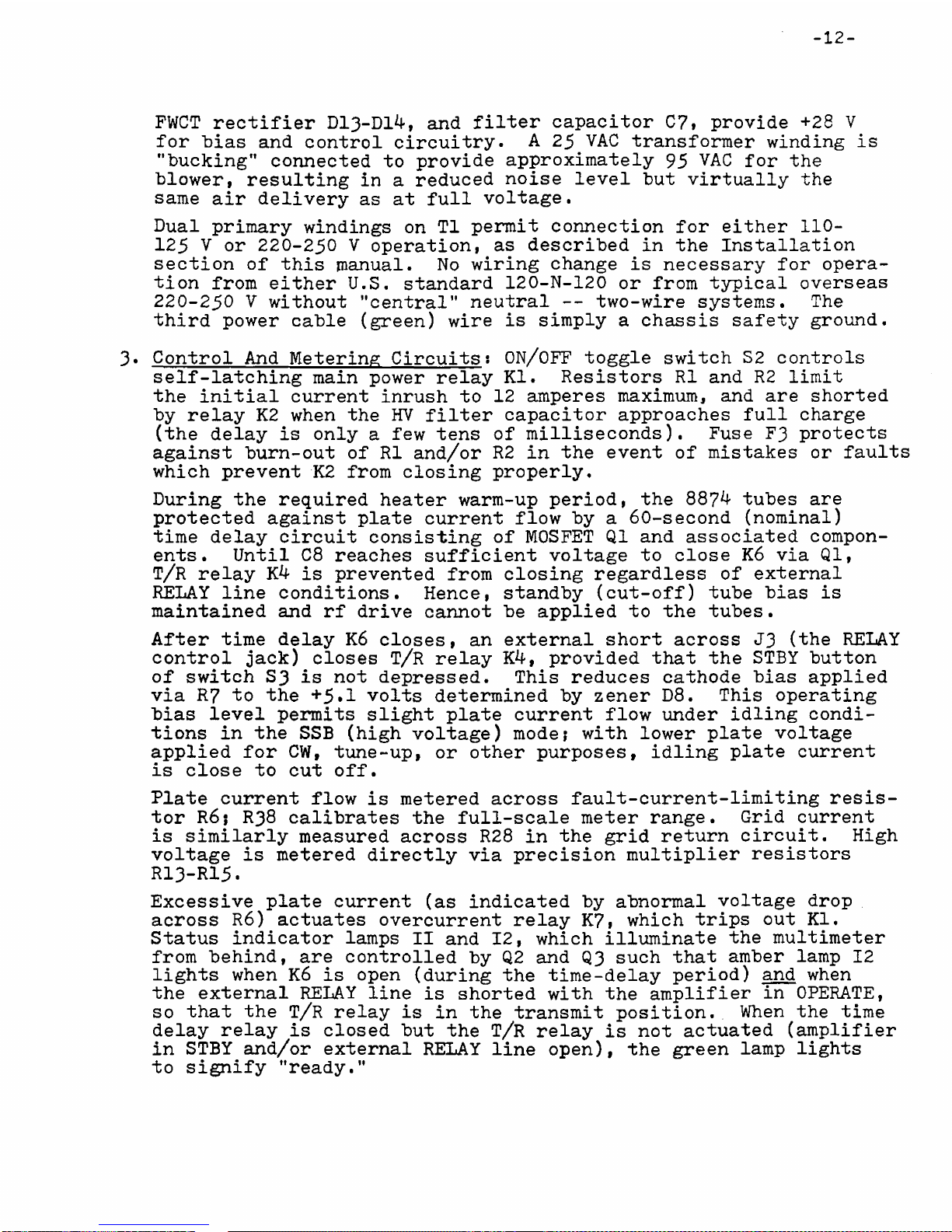

RF Amplifi r S ction: Tub s VI and V2 (and V3 in mod ls 76P and

76C) ar parall l-conn ct d in a ground d grid configuration.

+28 volts of cathod bias is appli d via R7 and L7 to cut off

plat curr nt during non-transmit p riods; bias is r duc d to an

op rating l v l of 5«1 volts wh n th ant nna r lay is actuat d.

RF xcitation is appli d to th cathod s via a broadband, toroidal

f rrit matching transform r, T2. R sistor n tworks R17 and (in

standard mod l 76 only) R22 stablish a nominal driv pow r r

quir m nt of 100 watts PEP and h lp provid a 50 ohm input imp d

anc •

Th plat output circuit is a full pi-L n twork consisting of

C16, L1-L2-L3, C17> and L4. Th pi-L provid s harmonic suppr ssion

substantially b tt r than a simpl pi n twork, as w ll as som what

b tt r ffici ncy in this application.

An rf dir ctional wattm t r, consisting of L9 and associat d com

pon nts, s ns s forward and r fl ct d pow r in th rf output lin

for display on th pan l m t r wh n s l ct d by push-buttons FWD

and REFL, r sp ctiv ly.

Excitation voltag is d t ct d and filt r d by ALC r ctifi r C23-

C24, D15, and associat d compon nts. Th driv l v l at which

n gativ -going ALC is g n rat d (i. ., th thr shold l v l) is

s t by r ar-pan l pot ntiom t r R40 which back-bias s D15.

R lay K4 switch s th ant nna straight through to th xcit r

wh n th amplifi r is OFF or in STBY or r c iv conditions, p r

mitting normal transc iv op ration. K4 switch s th ALPHA 76

into th transmit configuration wh n an xt rnal short is plac d

across RELAY control jack, J3-

Pow r Supply: Transform r T1 is a 1.5 KVA continuous-s rvic unit

(2.4 KVA Hip rsilSXcor in PA-76C only) which suppli s all r

quir d a-c op rating voltag s for th amplifi r.

High voltag d-c for th tub anod s is r ctifi d by a full-wav

bridg , D1-D4, and filt r d by a 30 mfd., 2.7 KV capacitor con

sisting of C1-C6 in s ri s. Th s comput r-grad l ctrolytic

capacitors ar factory capacitanc -match d to insur uniform a-c

rippl voltag distribution and long s rvic lif .

High voltag may b r duc d from th normal SSB valu of 2.2-2.4

KV to approximat ly 1.4-1.6 KV by taking th HV r ctifi r input

from an alt rnat transform r tap. A high voltag tap-chang

r lay, K3 (standard in PA-76C, optional in oth r mod ls), control

l d by Hl/LO toggl switch S6, p rmits making this s l ction from

th front pan l. In units without th HV r lay, th s l ction is

mad with quick-conn ct lugs on th HV circuit board.

Cov r int rlock switch S4 pr v nts actuation of main pow r r lay

K1 unl ss th top cov r is s cur d in plac . Saf ty "crowbar"

S5 plac s a low-r sistanc short across th HV supply (and dis

charg s th filt r capacitors) wh n v r th cov r is op n.

THEORY OF OPERATION

12

FWCT r ctifi r D13-D14, and filt r capacitor C7, provid +28 V

for bias and control circuitry. A 25 VAC transform r winding is

"bucking” conn ct d to provid approximat ly 95 VAC for th

blow r, r sulting in a r duc d nois l v l but virtually th

sam air d liv ry as at full voltag .

Dual primary windings on T1 p rmit conn ction for ith r 110-

125 V or 220-250 V op ration, as d scrib d in th Installation

s ction of this manual. No wiring chang is n c ssary for op ra

tion from ith r U.S. standard 120-N-120 or from typical ov rs as

220-250 V without "c ntral" n utral -- two-wir syst ms. Th

third pow r cabl (gr n) wir is simply a chassis saf ty ground.

3. Control And M t ring Circuits 1 ON/OFF toggl switch S2 controls

s lf-latching main pow r r lay Kl. R sistors R1 and R2 limit

th initial curr nt inrush to 12 amp r s maximum, and ar short d

by r lay K2 wh n th HV filt r capacitor approach s full charg

(th d lay is only a f w t ns of millis conds). Fus F3 prot cts

against burn-out of R1 and/or R2 in th v nt of mistak s or faults

which pr v nt K2 from closing prop rly.

During th r quir d h at r warm-up p riod, th 8874 tub s ar

prot ct d against plat curr nt flow by a 60-s cond (nominal)

tim d lay circuit consisting of MOSFET Q1 and associat d compon

nts. Until C8 r ach s suffici nt voltag to clos K6 via Ql,

T/R r lay K4 is pr v nt d from closing r gardl ss of xt rnal

RELAY lin conditions. H nc , standby (cut-off) tub bias is

maintain d and rf driv cannot b appli d to th tub s.

Aft r tim d lay K6 clos s, an xt rnal short across J3 (th RELAY

control jack) clos s T/R r lay K4, provid d that th STBY button

of switch S3 is not d pr ss d. This r duc s cathod bias appli d

via R7 to th +5*1 volts d t rmin d by z n r D8. This op rating

bias l v l p rmits slight plat curr nt flow und r idling condi

tions in th SSB (high voltag ) mod ? with low r plat voltag

appli d for CW, tun -up, or oth r purpos s, idling plat curr nt

is clos to cut off.

Plat curr nt flow is m t r d across fault-curr nt-limiting r sis

tor R6; R38 calibrat s th full-scal m t r rang . Grid curr nt

is similarly m asur d across R28 in th grid r turn circuit. High

voltag is m t r d dir ctly via pr cision multipli r r sistors

R13-R15.

Exc ssiv plat curr nt (as indicat d by abnormal voltag drop

across R6) actuat s ov rcurr nt r lay K7, which trips out Kl,

Status indicator lamps II and 12, which illuminat th multim t r

from b hind, ar controll d by Q2 and Q3 such that amb r lamp 12

lights wh n K6 is op n (during th tim -d lay p riod) and wh n

th xt rnal RELAY lin is short d with th amplifi r in OPERATE,

so that th T/R r lay is in th transmit position. Wh n th tim

d lay r lay is clos d but th T/R r lay is not actuat d (amplifi r

in STBY and/or xt rnal RELAY lin op n), th gr n lamp lights

to signify "r ady."

SECTION S — ILLUSTRATIONS

FIGURE 1 - Transform r Installation or R moval

-1k-

FIC-URE 3 - Top Vi w Showing Ma.ior Compon nt Locations

1K1-K2-K3 UNDERNEATH

NOTES:

A R22-5 EACH470/2w:FA-?fc ONLf

A PA-76CJP0NL (V3CKTY)

SOME UHITS QIFFE« S u M l*

,^ \ ¿*/i2W EXCEPT SOME 3»02*

WITH 3.3K PARALLEL, SHORTEO

FOR 120V ©M_Y

A

A

OPTIONAL MV RELAY (K3>

XFMR LEAO .COLORS APPLY TO STO

PA-76 XFMR ONLY; HIPERSIL XFMR

WIRE COLORS VARY

— JJ jjE

l*MCTEt

ALL eUTl

"<

9. ALL O's IN4004 UNLEi

7. ALL CAPACITORS IKV UNLESS NOTED

fi. ALL RESISTORS 5 © lO% /IW UNLESS NOTEO

I * meter switThI-» m V

ALL BUTTONS, SHOV*

OUT

N4004 UNLESS NOTED EHRHORN TECHNOLOGICAL OPERATIONS, INC.

Can n City, C l rad

MODELS PA-76 ano 76C & 76P

Dwg n o : SCHEMATIC

-16-

SECTION 6 STANDARD ELECTRICAL PARTS

SYMBOL DESCRIPTION

B1

Cl - C6

07

C8

09f 019t

C10-C14,

015,020-

C27,C33

C18,C28-

C23

02k

C31

C32

O35

038

039

C40

D1-D4

Howard #3-90-8507

180uf/450V l ct.;

CDE #FAH-l80-450

500uf/50V l ct.

15uf/20V tantalum

C26 .002uf/l KV disc

C36,C37-002uf/3 KV disc

22,02^t

,C34 ,01uf/50V disc

C30 .02/500V disc

27pf dipp d SM

lOOpf dipp d SM

lOOpf, ARCO 423

5pf/lKV disc

.068uf/250V film

300pf dipp d SM

10uf/50V l ct.

D5

D6,D15 »D18,D19

D7

D8

D9

D10-D14,D17

D20

F1,F2

3KV PIV/.5A CCS,

RCC 1733

IN4746 (18V/1W)

1N4148 or 1N914B

1N4722 (400V/3A)

1N4733 (5-1V/1W)

1N4757 (5IV/IW)

1N4004 (400V/1A)

F3

II, 12

K1

K2

K3

K4

IOA/25OV c ramic,

typ 3AB or ABC

(PA-76C, 15A)

1¿A slo-blo, typ

MDL or quiv.

#387» 28V lamp

DPST/12OVAC,

Guardian 900-2C-

12OA or I390-2C-

12 OA

DPST/ 24VDC, Guard

ian 905-2C-24D

or 1395-2C-24D

HV r lay, 24VDC,

Magn craft typ

W158-HVX-1-2ÍV

or P-B typ

PRD11DY0-24

DPDT/lOA,Guardian

905-2C-24D or

Phillips 39C11D24

SYMBOL

K6

K7

L5,L6,L7

L8, Lll

L10

Q1

Q2, Q3

24V form A r d,

EAC #1A24AH

5V form A r d,

EAC #1A5AH

15uhy/lA rfc

1 to 2.5 mhf rfc

1 mhy miniatur

MFE122, MPF121, or

similar dual-gat

2N5826

DESCRIPTION

RESISTORS: All ar \ watt, 5$

carbon composition or film

of valu shown, xc pt as

list d b low.

RI, R2

R3

R4

R5

R6

R7-R12

RI3-RI5

RI7, R22

R3I

R36

R38

R40

R4l

51

52

53

10ohm/l2W wir wound

75°ohm/2W 10$ comp.

2K/12W wir wound

150ohm/lW 10$ comp.

25ohm/25W wir wound

220K/2W 10# comp.

lM/l# pr cision film

Fiv ach 470ohm/2W

10# comp, in parall l

470ohm/2W 10# comp.

3.3K/2W 10# comp.

5K trimpot, lin ar

5K lin ar tap r, 1W

S4

S6

C ntralab JV9034

SPDT mom ntary tog.

6 station pushbutton,

Switchcraft typ #

65061 K 206 int'lok

Microswitch V3L-4-D8

SPST 3A toggl

VI,V2,V3 Eimac typ 8874

ALL ELECTRICAL AND MECHANICAL

COMPONENTS NOT LISTED ARE

SPECIAIiY-FABRICATED AND AVAIL

ABLE FROM ETO; SPECIFY MODEL

AND SERIAL NUMBER OF AMPLIFIER

PLUS CIRCUIT SYMBOL OR DESCRIP

TION TO ORDER REPLACEMENTS.

ETO/"ALPHA" PRODUCTS WARRANTY

EHRHORN TECHNOLOGICAL OPERATIONS, INC.(ETO) WARRANTS AS FOLLOWS

EACH NEW ELECTRONIC PRODUCT OF ITS MANUFACTURE:

(1) Workmanship and all compon nts xc pt rf pow r tub s ar

guarant d for EIGHTEEN MONTHS (VOMAX only, tw lv months)

from dat of original purchas if us d xclusiv ly in

lic ns d amat ur radio s rvic , and for nin ty days if

us d in non-amat ur s rvic .

(2) Pow r tub s ar warrant d by th ir manufactur r; ETO will

assist own rs in s curing warranty s rvic if r qu st d.

(3) Warranty do s not apply to r pair of damag r sulting from

improp r maint nanc or r pair, misus , n gl ct, abus , or

improp r installation, nor to units not op rat d in accord

anc with sp cifications and instructions furnish d by ETO,

nor to units r pair d or alt r d by p rsons not authoriz d

by ETO, nor in cas s wh r th s rial numb r has b n r

mov d, alt r d, or d fac d.

(4) If a malfunction is susp ct d, b for att mpting r pairs or

r turning quipm nt to ETO for s rvic th own r shall con

tact s lling d al r or factory s rvic d partm nt, providing

mod l and s rial numb rs plus d tails of quipm nt hook-up,

acc ssory quipm nt us d, op rating conditions, and abnor

maliti s obs rv d. ETO will furnish a n w part in xchang

for any cov r d d f ctiv part or, if it is d t rmin d that

factory s rvic is r quir d, will authoriz r turn to factory.

Equipm nt authoriz d for r turn shall b shipp d fully pr paid

and insur d via Unit d Parc l or air fr ight (to Colorado

Springs airport only), using only FACTORY APPROVED PACKING;

REMOVE POWER TRANSFORMER BEFORE SHIPPING ANY UNIT WHICH WAS

ORIGINALLY SHIPPED FROM THE FACTORY WITH TRANSFORMER REMOVED!

(5) In ord r to r c iv warranty s rvic , own r must hav r turn d

a compl t d warranty r gistration form to ETO within 15 days

of original purchas , or must provid proof of purchas dat

wh n r qu sting s rvic . Warranty will b transf rr d to sub

s qu nt own r provid d h notifi s ETO in writing of his nam ,

addr ss, dat of purchas , and th quipm nt mod l and s rial.

(6) No p rson is authoriz d to assum for ETO any liability,

oth r than as s t forth in this warranty, in conn ction with

our products. ETO r s rv s th right to chang its products

as it d ms d sirabl , without obligating its lf to mak

such chang s availabl for pr viously manufactur d products.

(UNDER PROVISIONS OF THE FEDERAL MAGNUSON-MOSS WARRANTY ACT,

THIS WARRANTY POLICY IS CLASSIFIED AS A LIMITED WARRANTY.)

EHRHORN TECHNOLOGICAL OPERATIONS, INC.

Ehihom Technological Operations, Inc. .

4975 No th 30th St eet W 7 7

Colo ado Sp ings, CO 80919

Table of contents

Other EHRHORN Amplifier manuals