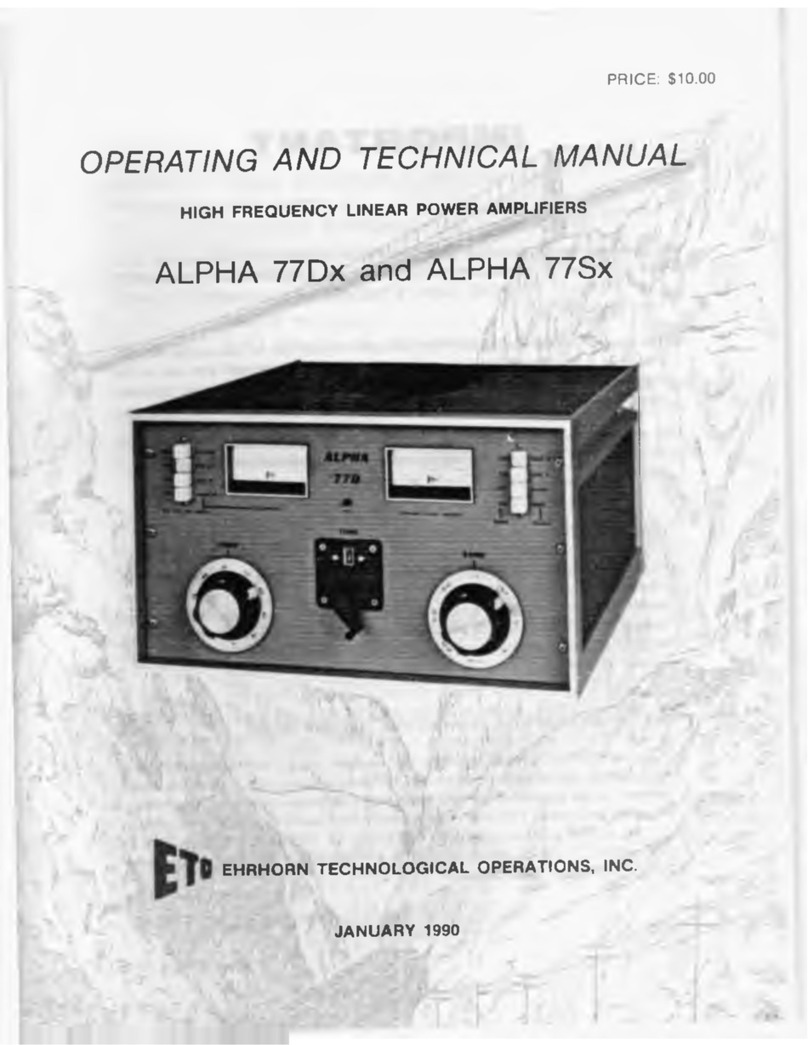

EHRHORN PA-77 User manual

INSTRUCTION AND TECHNICAL MANUAL

IDODEL PA-77 LINEAR POWER AMPLIFIER

r«C#tt0£Q«$tA* tftft »x v-jK: ...

EHRHORN TECHNOLOGICAL OPERATIONS, INC.

BROOKSVILLE, FLORIDA 3351

November 1, 197

i

TABLE OF CONTENTS

TABLE OF CONTENTS.......................................................................... i

STANDARD WARRANTY.......................................................................... i i

SECTION 1 - GENERAL DESCRIPTION AND SPECIFICATIONS. . 1

SECTION - INSTALLATION .........................................................

REAR PANEL INTERCONNECTIONS

..........................

4

SECTION 3 - OPERATION .................................................................. 5

CONTROL FUNCTIONS

................................................ 5

TUNE-UP PROCEDURE ................................................ 6

FINAL OPERATIONAL ADJUSTMENTS, M ON I TOR ING B

PROTECTIVE DEVICES, OPERATING PRECAUTIONS 9

SECTION 4 - MAINTENANCE AND TROUBLESHOOTING..................1

SECTION 5 - THEORY OF OPERATION............................................14

SECTION 6 - ILLUSTRATION S.........................................................19

TOP V IE W ....................................................................19

BOTTOM V IE W ............................................................. 0

REMOVAL OF POWER S U P PL Y

...................................

1

CIRCUIT DIAGRAM (SCH EM A TIC)

..........................

EHRHORN TECHNOLOGICAL OPERATIONS, INC.

i i

STANDARD WARRANTY

EHRHORN TECHNOLOGICAL OPERATIONS, INC. (ETO) marrants each nan

product manufactured by it to be fre e from d e fe ctive m a terial or

morkmanship and agrees to remedy any such defect or to fu rn ish a

nem part in exchange fo r any part of any u n it of it s manufacture

which under normal in s ta lla tio n , use, and service d isclo ses such

d e fe ct, provided the unit is d e live red by the omner to us or to

our authorized dealer or d is trib u to r from mhom purchased, in ta c t,

fo r our exam ination, roith a l l tran sp o rtatio n charges prepaid,

u/ithin ninety davs from the date of sale to o rig in a l purchaser,

provided that (1 ) such exam ination d isclo ses in our judgment that

i t is thus d efe ctive and that ( ) a prop erly completed m arranty

re g is tra tio n form has been m ailed to ETO m ithin fiv e (5 ) days

a fte r date of sale to o rig in a l purchaser.

NOTEi Do not under any circum stances ratu rn equipment to ETO

m ithout rece ivin g e x p lic it au th o riz atio n fo r such

retu rn from us in advance. Shipment of equipment in

other than approved fa cto ry packing may void th is mar-

ra n ty. Should a m alfunction be suspected, co ntact your

s e llin g dealer or the ETO service department mith f u ll

d e ta ils of the d iffic u lty before attem pting re p a irs or

return fo r a e rv ice .

This m arranty does not extend to any of our products mhich have

been subjected to m isuse, n e g le ct, accid en t, in c o rre ct m iring

not our omn, improper in s ta lla tio n , or to use in v io la tio n of

s p e c ific a tio n s and in s tru c tio n s furn ished by us, nor to units

mhich have been rep aired or a lte re d outside our fa c to ry , nor in

cases mhere the s e r ia l number th ereof haa been ramoved, a lte re d ,

or defeced, nor to u n ita used m ith accessories not manufactured

or recommended by us, nor to the high pomer tran sm ittin g tu b e (s ).

Transm itting tubee are marranted by th e ir m anufacturer and the

m arranty is adm inistered by ETO.

This marranty is in lie u of a l l other m arranties expressed or

im plied and no rep resen ta tive or peraon is authorized to assume

fo r ETO any other lia b i li t y in connection m ith the sale of our

products.

ETO reserves the rig h t to make such changes or improvements to

it s products mhich i t may deem d e sira b le , m ithout o b lig a tin g

it s e l f to make such changes or improvements a v a ila b le fo r it s

p revio u sly manufactured products.

EHRHORN TECHNOLOGICAL OPERATIONS, INC. BROOKSVILLE, FLORIDA

- -

5ECTI0N

INSTALLATION

1. Unpacking i Open th9 marked end of both outer and inner cartons

and c a re fu lly remove the plastic-tiirapped a m p lifie r. If d i f f i

cu lty is experienced, it may be necessary to also open the op

posite end of both cartons so th at the u nit may be pushed out.

SAVE ALL PACKING MATERIAL FOR RE-USEi ANY SHIPMENT OF THE ALPHA

77 IN OTHER THAN FACTORY-DESIGNED PACKING MAY VOID THE WARRANTY.

C a re fu lly inspect fo r shipping damage. Remove the sin g le screui

securing the top cover and s lid » the cover open. REMOVE THE FOAM

BLOCK WEDGED BETWEEN THE PLATE COIL AND THE AIR EXHAUST ASSEMBLY.

To insure th at the BB77 a m p lifie r tube is prop erly seated in it s

socket, grasp the s ta in le s s s te e l anode clamp rin g securing the

bottom of the rad silico n e rubber a ir exhaust hood and preas firm

ly domnmard. The hood should be amooth and free of m rin kles.

Make certa in that the vacuum va ria b le ca p acito r (in the lomer,

right-hand corner of the r f compartment) ia aecurely fastened and

operates smoothly mhen the "TUNE" crank is ro tated .

In the event of damage, n o tify the tran sp o rtatio n company immedi

a t e ly . Complete and m ail the m arranty re g is tra tio n form to ETO

m ithin 5 day at no marranty c la im (s ) can be considered otherm ise.

Cloae and fasten the top cover, confirm ing that it a re a r lip con

ta cts and actuates the a-c in te rlo c k near the cool a ir in tak e.

. P h ys ic al In s ta lla tio n ! The ALPHA 77 must be located so that

intake of cool a ir and exhaust of hot a ir behind the rear panel

is not impeded in any uiay, and so th at hot a ir exhaust m ill not

s ig n ific a n tly re c irc u la te in to the cool a ir in tak e. Under no

circum stances should the back of the a m p lifie r be less than six

inches from any m all, d ra p eries, or other o b stru ctio n s. A two-

inch copper "bend” or elbom, e ith e r ^° or 45° "DfflV" type as

a v a ila b le from plumbing supply houses, may be used to d e fle ct

the exhaust a ir floui if necessary.

Room heating may be v ir t u a lly elim in ated as a by-product of

a m p lifie r op eration, and cooling system noise even fu rth e r cu t,

i f exhaust a i r is ducted outdoors using a s u ita b le duct not le ss

than three inches in in side diam eter. S ig n ific a n t back pressure

must not be generated! e le c tric dryer vent fit tin g s uiith magnetic-

la tc h in g outside fla p s , fo r example, are in to le ra b le , as they

m ill prevent adequate a ir flow and may re s u lt in seriou s damage

to the tube and the a m p lifie r. Normal blouier speed should be

increased s lig h tly mhen exhaust a ir is ducted more than a fetu

inches; check mith your d ealer or the E.T .O . fa cto ry fo r a d vice.

- -

5ECTI0N

INSTALLATION

1. Unpacking i Open th9 marked end of both outer and inner cartons

and c a re fu lly remove the plastic-tiirapped a m p lifie r. I f d i f f i

cu lty is experienced, it may be necessary to also open the op

posite end of both cartons so th at the u nit may be pushed out.

SAVE ALL PACKING MATERIAL FOR RE-USEi ANY SHIPMENT OF THE ALPHA

77 IN OTHER THAN FACTORY-DESIGNED PACKING WAY VOID THE WARRANTY.

C a re fu lly inspect fo r shipping damage. Remove the sin g le screm

securing the top cover and s lid » the cover open. REMOVE THE FOAM

BLOCK WEDGED BETWEEN THE PLATE COIL AND THE AIR EXHAUST ASSEMBLY.

To insure th at the BB77 a m p lifie r tube is prop erly seated in it s

socket, grasp the s ta in le s s s te e l anode clamp rin g securing the

bottom of the rad silico n e rubber a ir exhaust hood and preas firm

ly domnmard. The hood should be amooth and free of m rinkles.

Make certa in that tha vacuum va ria b le ca p acito r (in the lorner,

right-hand corner of tha r f compartment) ia aecurely fastened and

operates smoothly rnhen the "TUNE" crank is ro tated .

In the event of damage, n o tify the tran sp o rtatio n company immedi

a t e ly . Complete and m ail the uiarranty re g is tra tio n form to ETO

rnithin 5 dayai no uiarranty cla im (s) can be considered otherw ise.

Cloae and fasten the top cover, confirm ing that it a re a r lip con

ta cts and actuates the a-c in te rlo c k near the cool a ir in tak e.

. P h ys ic al In s ta lla tio n ! The ALPHA 77 must be located so that

intake of cool a ir and exhaust of hot a ir behind the rear panel

is not impeded in any uiay, and so th at hot a ir exhaust m ill not

s ig n ific a n tly re c irc u la te in to the cool a ir in tak e. Under no

circum stances should the back of the a m p lifie r be less than six

inches from any m all, d ra p eries, or other o b stru ctio n s. A two-

inch copper "bend” or elbom, e ith e r ^° or 45° "DfflV" type as

a v a ila b le from plumbing supply houses, may be used to d e fle ct

the exhaust a ir flom if n ecessary.

Room heating may be v ir t u a lly elim in ated as a by-product of

a m p lifie r op eration, and cooling system noise even fu rth e r cu t,

i f exhaust a i r is ducted outdoors using a s u ita b le duct not le ss

than three inches in in side diam eter. S ig n ific a n t back pressure

must not be generated! e le c tric dryer vent fit tin g s uiith magnetic-

la tc h in g outside fla p s , fo r example, are in to le ra b le , as they

m ill prevent adequate a ir flow and may re s u lt in seriou s damage

to the tube and the a m p lifie r. Normal blomer speed should be

increased s lig h tly rnhen exhaust a ir is ducted more than a fetu

inches; check mith your d ealer or the E.T .O . fa cto ry fo r a d vice.

-3-

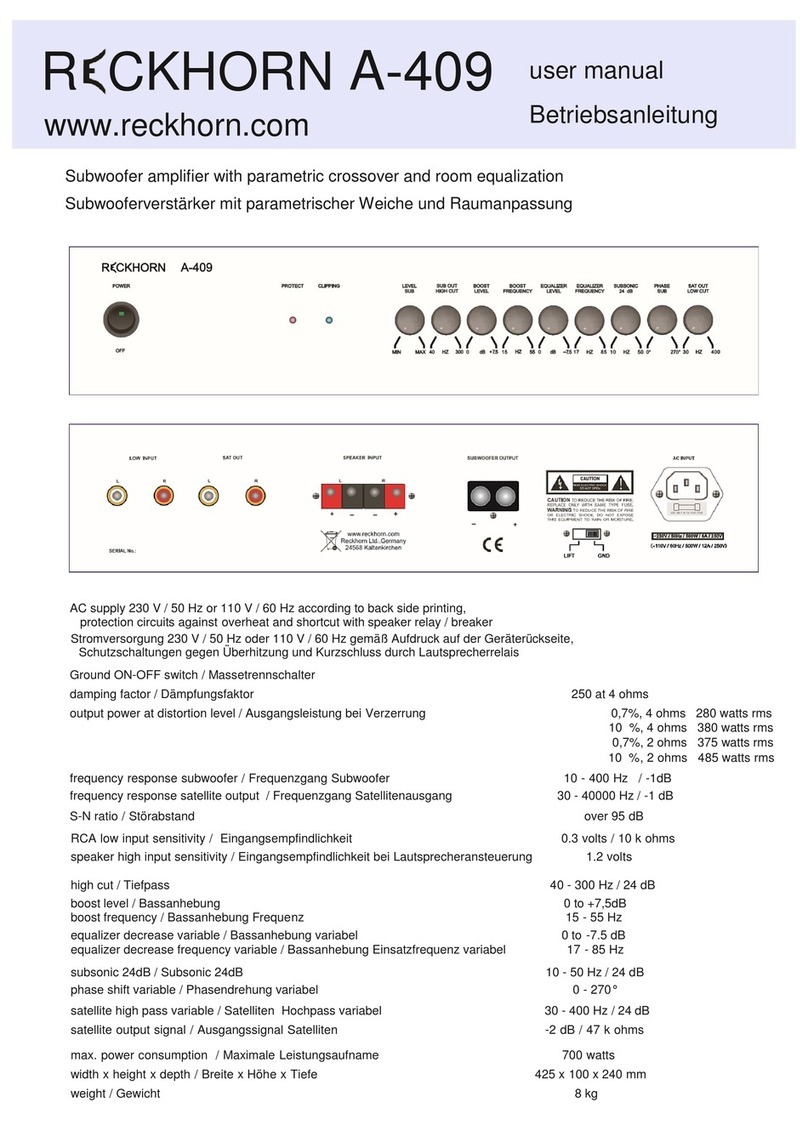

3. E le c tr ic a l In s ta lla tio n i (S 99 illu s tr a tio n on next page)

A-C Pomer - The ALPHA 77 is designed fo r operation from a 0 to

50 v o lt, 50 to 60 Hz, three w ire sin o le phase source. With

proper adaptation it may also be operated from 1 0/ 08 v o lt three

phase pouier, or from tuio w ire 110-1 5 or 0- 50 v o lt pouier. !£.

TWO WIRE OR THREE PHASE PRIIHARY POWER fllUST BE UTILIZED. CONTACT

THE ETO FACTORY FOR SPEC IFIC INSTRUCTIONS!

For normal 0- 50 v o lt 3 uiire operation, service m iring should

be no sm aller than three mire #1 AWG copper in order to insure

good re g u latio n i lin e pro tection by standard ( not slom blom) 0

ampere fuses or c ir c u it breaker is d e s ira b le . When in s ta llin g

a su itab le pomer plug on the cable supp lied , be certa in th at the

oreen mire connects to pomer n e u tra l.

RF OUT - DO NOT OPERATE THE AMPLIFIER AT ANY TIME WITHOUT A

PROPERLY IMPE DANCE-MATCHED LOAD CONNECTED TO THIS RECEPTACLE.

Use a standard PL- 59 "UHF typ e" plug and RG-B/U co ax ial cab le,

or e q u ivale n t, to connect to the antenna or dummy load.

RLY - An external short across th is lin e , usu ally by means of

transm it-receive re la y contacts in the e x cite r (o r tra n s c e iv e r),

places the ALPHA 77's in te rn a l tran sm it-receive re la y s in the

transm it co n d ition. In the re ceive co n d ition, then, the antenna

is fed back to the RF IN jack as required by most popular tran s

ceive rs and tran sm itte r- re ce iver com binations.

RF IN - The RF output of the e x c ite r or tra n sc e iv e r is connected

to th is jack using a standard "BNC" type plug and RG-5B/U coaxial

cab le, or e q u iv ale n t. With the ALPHA 77 OFF. or in CW or SSB

mith the ex ternal re la y lin e not shorted (normal receive condi

tio n ), the antenna connected to the am p lifie r is fed back through

the in te rn a l rela ys to the RF IN jack to provide normal re c e iv e r

or tra n sc e iv e r received - sig n al input from the antenna,

RCVR ANT - The output of a b u ilt- in e le c tro n ic T/r srnitch is

a v a ila b le a t th is jack to provide rece iver siq n al input fo r f u ll

break-in keyed CW operatio n, provided that (1) the in te rn a l t/R

changeover re la y s of the ALPHA 77 are in the tran sm it co n d ition,

( ) operation is in or near the amateur 3 .5, 7, 14, 1, or 8 MHz

bands, and (3) the ALPHA 77 is properly adjusted (tuned and loaded)

fo r operation on the band to be received . When the ALPHA 77's

BK»IN button is pushed the in te rn a l t/r re la y s are a u to m a tically

locked in the transm it cond ition to perm it use of th is featu re

and re c e iv e r antenna input is a v a ila b le only a t the RCVR ANT jack.

This featu re is most u sefu l only rnhen used m ith an e x c ite r or

tra n s c e iv e r uihich is it s e lf capable of true instantaneous CW

break-in operation (th e Signal/One CX7, fo r exam ple). When the

e x c ite r or tra n sce iv e r employs manual or "U0X" delay T/r sm itching

on CW (KWM- , Heath SB-se ries, Drake T-4 or TR-series, e t c . ), i t

m ill be most convenient to sim ply employ co nventional T/R co ntrol

mith the ALPHA 77 as described under " RLY" above.

ALC - Provides co n tro l voltage fo r use mith suitably-equipped

e x c ite rs/tra n s ce iv e rs such as C o llin s , Heath. Not recommended

mith Signal/One CX7. Threshold-adjust adjustm ent on rear panel.

ALPHA 77 REAR PANEL

INTERCONNECTIONS WITH TRANSCEIVERS. TRANSMITTERS * AND RECEIVERS

Warm a ir

exhaust

Wain a-c power

input connector

Primary line fuses

(Use 15 ampere,

standard-blow

on]vi Little fu se

type 3AB or Buss

type ABC)

To antenna

(Use UHF-type plug,

PL- 59 or equiv.,

with 50 ohm coaxia'l

cable, RG-8A/U or

larger)

To transceiver "antenna" —

or transm itter "rf out

put" connector

(Use BNC-type plug (UG-

88/U or aquiv.) with

50 ohm RG-58/U cable)

ALC threshold adjust

(Turn counterclock

wise to increase

ALC s e n s itivity )

ALC control voltage output

(Use phono-type shielded

cable to connect to

transceiver or transm it

ter "ALC" input jack if

desired* Use not recom

mended with CX7/CX7-A.)

_______

it-receive relay control

(Use phono-type cable to connect

to transceiver or transm itter

relay contacts which are open

on receive, shortad on transm it.

Tay also be shortad to permit

use of electronic T/R switch

in "SSB" or "CUT mode.)

Electronic T/R switch output

(Use phono plug with 50 ohm coaxial

cable to provide receiver antenna

input for CUI break-in ("BK IN" mode)

or special purposes. See te x t.)

_5_

SECTION 3

OPERATION

1. Control Fu n ctlonsi

a. NODE CONTROL PUSH BUTTONS — The fou r buttons to the rig h t

of trie HLM Tfc C lIRHLN [ meter co n trol pouier on-off and opera

tio n a l mode of the ALPHA 77.

OFF - F u lly depressing th is button sw itches off a ll a-c pomer.

The button illu m in a tes red whenever (1 ) a ll fou r buttons are

out, ( ) the plate overcurrent re la y has actuated, popping

out the p revio u sly- selected mode button, or (3) the top cover

in te rlo c k sw itch is open and one of the mode buttons pressed.

When a l l four buttons are out (accom plished by lio h tly press

ing any one of them which is not alread y depressed) , the

cooling blouier operates but a l l other a-c power is removed.

BK-IN - Sets up am p lifie r operating conditions ex a ctly lik e

CIO button (see next paragraph below) except that in te rn a l

T7R changeover re la y s are locked in the transm it condition

so th at re c e iv e r antenna input is a v a ila b le at RCVR ANT jack

fo r f u ll break-in CW operation w ithout the n e ce ssity fo r

providing an ex tern al short on the RLY lin e . Receiver input

is not a v a ila b le at the RF IN jack in th is mode.

CW - Applies proper p late and bias voltages fo r operation at

up to approxim ately 1.5 k ilo w atts input PEP or c a rr ie r (CW,

FSK, SSTV, SSB, e tc .) continuous duty. Transm it-receive (T/R)

sw itching operation is "norm al," w ith an external contact

closure on the RLY lin e required fo r transm it and re c eiver

antenna input provided to the RF IN jack on re ceiv e .

SSB - A pplies proper plate and bias voltag es fo r continuous

duty SSB voice operation at inputs up to 3 k ilo w atts PEP,

1.5 k ilo w atts average. T/R co n trol fu nctio ns same as described

above under CW.

b. BIETER PUSH BUTTONS — These four buttons sw itch the m ultim eter

to in d ica te high voltage (HV. - 5000 VDC f u ll s c a le ), grid

current ( GRID - 500 f u ll s c a le ), forward RF power ( FWD - 5 KW

f u ll s c a le ), or re fle c te d RF power ( REFL - 500 raatts f u ll

s c a le ). HV. and GRID in d ic a tio n s are referenced to the 0-5

black meter sc a le , FWD and REFL re fe r to the red RF WATTS

s ca 1 e .

c. LOAD — Controls p late loading, which is minimum (correspond

ing to maximum loading capacitance) when set a t or near zero

d ia l reading and maximum a t the high-numbered end of the s c a le .

Clockwise ro tatio n always increases plate load ing .

d. TUNE — Counter d ia l co n tro ls the vacuum va ria b le p late tuning

c a p a c ito r, maximum capacitance occurs at f u ll counterclockw ise

ro ta tio n , corresponding to near-zero counter readings.

-b-

e. BAND — The approximate a m p lifie r plate tuning/loading range

a v a ila b le is ind icated in MHz on the s k irt of the knob. Thus

the 0 meter (14 mHz) amateur band is covered in the 1 -1B band.

. Tune-Up Procedure!

a. GENERAL — Correct loading adjustment and drive le v e l is

extrem ely im portant to insure that any power a m p lifie r w ill

handle it s rated power w ithout damage or excessive d is to rtio n .

Unless an in - lin e oscillo sco pe is used continuously to insure

proper a m p lifie r op eration, i t is ab so lu tely e s s e n tia l th at

p late tuning and loading be i n it ia ll y adjusted a t a c a re fu lly

contro lle d le v e l of e x cita tio n (as in d icated by d-c g rid cur

ren t) and th at operating d rive le v e l th e re a fte r be clo se ly

monitored to insure that i t does not exceed the maximum which

can be handled s a fe ly and lin e a rly by the a m p lifie r under that

p a rtic u la r set of adjustm ents.

b. BIETER READINGS — When operating w ith a transm itted sig n al of

steady, unvarying am plitude - such as key-down c a rrie r on CUI

or FSK - a m p lifie r operating conditions are accu rately shown

by the m onitoring m eters. W ith a rap id ly- varyin g SSB s ig n a l,

however, the instantaneous current and power le v e ls which

a c tu a lly occur are much g reater in magnitude than the values

in d icated by the m eters, since the m echanical in e r tia of a

meter prevents its fo llow in g a ra p id ly changing s ig n a l. In

general the actu al peaks of grid and p late current are a t

le a s t two to three times as great as ind icated by the m eters.

It is therefo re e s s e n tia l that the tuning in s tru c tio n s given

below be follow ed f a it h fu lly to insure low d is to rtio n opera

tio n w ithout danger of damaging the ALPHA 77. The use of a

m onitoring RF oscillo scop e w ill of course perm it some fu rth er

refinem ent of adjustm ents under a ctu a l operating con d itions.

c. IN ITIA L TUNE-UP —

(1) Press OFF and HV. push buttons! connect a-c power cord.

( ) Set BAND. TUNE. and LOAD con trols to the appropriate

prelim in ary se ttin g s shown below fo r the band in use.

band (mHz) TUNE load ( TEST 1

3-5 100 55 3, B

5-B 170 60 7.

B-1 170 70 -

1 -1B 175 55 14.

IB- 4 1B0 65 1.3

4-30 10 75 B.6

♦NOTEi "TEST FREQ." is th at a t which these se ttin g s

should be very n early accurate when feeding a 50

ohm, matched re s is tiv e load.

-7-

(3) Insure that a su itab le matched load fo r the frequency to

be used is connected to the a m p lifie r's RF OUT ja ck.

(4 ) Leaving the ALPHA 77 o ff, tune e x c ite r fo r normal opera

tio n in accordance w ith it s m anufacturer's in s tru c tio n s .

Then, w ith e x cite r d e liv e rin g rated c a rrie r output (th ru

the "o ff" a m p lifie r) to the load . . .

(5) Press f i r s t the a m p lifie r’ s FWD m ultim eter button and then

REFL. noting the re sp e ctive meter d e fle c tio n s . Reduce

e x c ite r output to zero and return i t to standby co n d itio n .

I f the REFL d e fle ctio n exceeds the FUID in d ic a tio n , load

SUIR is excessive (more than il) and must be corrected

before proceeding w ith tune-up of the ALPHA 77,

(6) Press HV. and £UJ_ buttons) both buttons should lig h t up and

the m ultim eter should in d icate approxim ately .4 KV. Press

SSB and confirm approxim ately 3.7 to 4.0 KV HV in d ic a tio n .

Press CUI again and allo w 00 to 1 0 seconds, as required,

fo r the ALPHA 77's warm-up delay re la y to clo se .

NOTE i U n til the delay rela y clo se s, and whenever the grid

overcurrent re la y has trip p ed , the a m p lifie r's in te rn a l

T/R changeover rela ys are locked in the "re c e iv e " condition»

any app lied d rive power w ill simply be fed through to the

load. I t is im portant that d rive power not be present at

the moment of T/R re la y clo sure, or damage to the vacuum

re la y s w ill re s u lt from "hot sw itch in g ." RF output from

high power e x cite rs or tra n sce ivers must also be reduced

to a le v e l su itab le fo r d rivin g the ALPHA 77 before the

T/R relays close and drive is applied to the a m p lifie r.

To avoid damage, the a m p lifie r’ s ex ternal re la y contro l

lin e (to RLY jack) should be manually disabled (w ith a

switch or by unplugging it ) whenever the e x c ite r is operated

"s tra ig h t through" w hile w aiting fo r the ALPHA 77’ s delay

re la y to clo s e.

(7) Press GRID button. W ith e x cite r in the unmodulated c a rr ie r

mode ("T u n e," "CW," or "Lock K ey ," depending on it s m odel),

slouily in crease c a rrie r output u n til the ALPHA 77 GRID

m ultim eter in d ica tio n is "1 " (100 ma) on the black sc a le .

Rotate TUNE crank to the plate Currant d ip, which should be

found w ith in a turn or two of the p relim inary settin g s.

Reduce ex c ite r output co n tro l to m aintain 100 ma GRID cur

ren t in d ic a tio n , and repeat th is e x c ite r output adjustm ent

a fte r every chanoe in tuning and/or loadlnQ which re s u lts

in an in d ic a tio n above 150 ma or below 00 ma.

NOTEi (domantary grid cu rren t in d ica tin g in excess of about

350 ma w ill actuate the g rid overcurrent re la y , au to m atically

la tch in g the ALPHA 77 in the "re c e iv e " co n dition) drive power

w ill feed through to the load but the a m p lifie r cannot be

driven to grid or p la te current u n til the overcurrent re lay

is resat by turning the a m p lifie r OFF fo r to 3 seconds.

A fte r re-pushing the desired mode button a b rie f period w ill

u su a lly be required fo r the time delay re la y to close ag ain .

(0) If no c le a r p la te current dip is found near the in d icated

prelim inary se ttin g , press the FWD button and tune fo r a

maximum in in d icated RF output power. (This may be neces

sary i f the ch aracter of your load d iffe rs su b s ta n tia lly

from 50 ohms re s is tiv e or if the Operating frequency is

fa r removed from the "TEST FREQ." shown in the c h a rt.)

Press GRID button and continue.

(9) With e x c iter adjusted to provide 1.5 (150 ma) a m p lifie r

GRID current reading a t the plate current dip, note the

plate current. If less than 0.650 amperes (about /3 of

f u ll scale on the p late currBnt m eter), increase loading

by s lig h t clockw ise ro tatio n of the LOftD knob (toward a

higher d ia l reading on the knob s k ir t ), then re-dip p late

curren t w ith the TUNE crank.

(10) Repeat step (9) u n til 0.650 amperes plate curren t at the

TUNE dip is achieved w ith 150 ma GRID readin g. I f at any

time p late cu rrent at the dip (w ith 150 ma GRID) is more

than 0.650 amperes, reduce loading by s lig h t reduction in

the LOftD knob reading and repeat as in (9) u n til the desired

plate and grid cu rren ts occur to g ether.

(11) Press HV button and confirm that voltage under 0.650 amperes

plate current load is approxim ately 000. NOTE i Since th is

tune-up procedure re su lts in plate input s u b s ta n tia lly in

excess of one k ilo w a tt, it cannot be le g a lly performed into

an antenna by amateur service s ta tio n s . Stay le g al and

avoid unnecessary tune-up in te rfe re n ce by using a dummy

load fo r in i t i a l tune-up. Inexpensive u n its such as the

Heathkit "Cantenna" are e n tire ly su ita b le fo r such use.

(1 ) The ftLPHft 77 is now propBrly adjusted fo r high power SSB,

CW, FSK, SSTV, and other s e rvic e s. See the in s tru c tio n s

which fo llo w fo r fu rth e r d e ta ils on each in d iv id u a l mode

and on amateur service operation. Turn o ff e x cite r.

F in a l O perational Adjustments and M onitoring:

a. HIGH POWER SSB — ftLL SERVICES — A fte r completing prelim inary

tune-up as above, press SSB button. With e x c ite r in SSB mode,

using e ith e r a two-tone te s t sig n al or normal speech in to the

microphone, slow ly increase e x c ite r output w hile watching the

ALPHA 77 plate current m eter.

(1) For le g a l amateur operation at 1 KW d-c inp u t, adju st

e x cita tio n le v e l so that occasional highest plate meter

pe aks reach approxim ately 0. 00 to 0. 50 amperes,

ty p ic a lly corresponding to peak envelope power (PEP)

inputs in excess of KHI.

( ) For SSB operation at maximum rated inpu t, a dju st e x c ita tio n

fo r highest plate curren t peaks of approxim ately 0.4 amps,

ty p ic a lly corresponding to PEP inputs exceeding 3 KW.

-9-

NOTEi GRID OVERCURRENT RELAY KICK-DUT DURING SSB OPERATION is

a c le a r and d e fin ite in d icatio n of excessive d rive power, at

le a s t on peaks, fo r the degree of a m p lifie r loading employed.

This problem w ill not g e n erally occur when employing e x cite rs

or tra n sce ivers in the 100 w att cla s s , such as C o llin s S-Line

and Heath SB-Line u n its. Nor w ill it occur w ith higher-power

d rive rs employing oroperlv-ad justed r f envelope c lip p in g . The

CX7/CX7-A, and other e x c ite rs or tra n sce ivers employing a u x il

ia ry r f clip p e rs such as the Comdel and DX Engineering u n its,

should be set fo r moderate clip p in g — at le a s t B-1 db --

w hile the SSB r f output le v e l is adjusted as in ( ) above.

T hereafter the output contro l should never be set above th is

pre-set p o in t, although i t may be reduced, and the clip p in g

varied up or down, at w ill. Heavier p late loading in step

(10) above w ill also permit operation a t g reater e x c ita tio n

and pla te power inp ut le v e ls than s p e c ifie d , under certa in

co n d itio n s. Contact the ETO fa cto ry fo r inform ation on spe

c if ic ap p lic a tio n s .

b. Clll. FSK. SSTV. OR NBFIfl OPERATION — AMATEUR SERVICE — For

maximum e ffic ie n c y at one k ilo w att c a rr ie r or "key down" inp ut,

perform in it ia l tune-up in section .c above fo r an a m p lifie r

p late current of 0.400 to 0.450 amperes a t the d ip, m aintaining

in d icated g rid cu rren t at 100 to 150 ma as before. Operate at

th is le v e l in the CU mode) sw itching to SSB. i t is possible

to run approxim ately k ilo w atts PEP input w ithout re - a d ju st

ment or excessive d is to rtio n (corresponding p late cu rren t meter

peaks should not exceed 0. 00 am peres).

c. CHI. FSK. SSTV. OR NBFIfl OPERATION — WAXIWUW RATED POKIER —

m aintain approxim ately 0.650 to 0.700 ampere p late cu rrent and

150 ma grid cu rre n t, using CUI mode on ly, fo r continuous s e rvice .

For in te rm itte n t se rvice (50^ duty cy c le , 5 minutes maximum on,

5 minutes o ff) the SSB mode may be used, loading fo r 0,500 ampere

p late current and not more than 100 ma g rid cu rre n t,

d.

Am

LINEAR ( DSB OR SSB. WITH CARRIER) OPERATION -- Ulhile the

ALPHA 77 is capable of providing as much as 15 decib els power

gain (30 X) w ith a 100$ am plitude modulated s ig n a l, proper

tuning and d rive adjustm ent is ra th er more c r it ic a l than in

other types of op eration. If such operation is contem plated,

contact the ETO fa c to ry fo r s p e c ific in s tru c tio n s .

4. P ro te ctiv e Devices and Operating Preca u tio n si

a. PRimARY FUSES — The prim ary a-c lin e input to the ALPHA 77 is

provided with 15 ampere, 50 v o lt, standard-blow fuses, e ith e r

L ittle fu s e type 3AB or Buss type ABC. Do not under any circum

stances replace these fuses w ith sloui-bloui. alass-bodv. or

higher-cap acity tvp e sl

The fuses sp e cifie d w ill r e lia b ly handle any input power le v e l

which is not damaging to the ALPHA 77. A blown fuse in d ic ate s

(1) excessive and unsafe average power inp ut, ( ) component

fa ilu r e , or (3 ) a povuer surge, such as due to lig h tn in g .

-10-

b. PLATE OVERCURRENT BREAKER — I f a m p lifie r plate current

su b s ta n tia lly exceeds safe operating le v e ls (approxim ately

1.0 ampere fo r b rie f "key dcuin" periods or 1.3 amperes peak)

the p late current p ro te ctive system m ill t r ip , as in d icated

by "k ickin g -o u t" of the previously-depressed mode pushbutton.

The OFF pushbutton is illu m in a te d red and power is removed

from a l l c irc u its except the cooling blouier, which continues

to operate. A fte r removing e x c ita tio n and co rre ctin g the cause

of overload, the ALPHA 77 may be returned to service by simply

pressing the desired mode button and w aitin g fo r the time delay

to clo s e . (See paragraph d. below .)

c. GRID OVERCURRENT BREAKER — As described p revio usly (pages 7

and 9) th is re la y trip s when g rid current exceeds about 350

ma. Since no useful purpose is ever served by operating at

peak d-c g rid current in excess of 00 ma (as would be in d i

cated on the grid current meter i f it were p h y s ic a lly capable

of fo llo w in g instantaneous current v a ria tio n s during voice

o p eratio n ), trip p in g of th is h io h lv- re lia b le g rid re la y should

be taken as a strong In d ic a tio n of improper operating c o n d itio n s!

Tripping of the grid overcurrent re la y is in d icated by la tch in g

of the a m p lifie r in the "re c e iv e " cond ition and, in la te produc

tio n a m p lifie rs , by extinguishin g of the meter illu m in a tin g lamps.

The most probable causes are s u b s ta n tia lly excessive d rive power,

to o - lig h t p late loading (o r bo th), or an in c o rre c t or d e fective

load. (See discu ssio n a t top of page 9 .) To reset the grid

re la y , press OFF. w a it -3 seconds, then press desired mode but

ton and w ait fo r the tim e delay to cloee.

d. WAREI-UP TIME DELAY — The rugged, high-gain, h ig h - lin e a rity

Eimac BB77/3CX1500A7 a m p lifie r tube employed in the ALPHA 77

re quires approxim ately 90 seconds' filam en t warm-up p rio r to

a p p lic a tio n of r- f d riv e . U n til the in te rn a l e le c tro n ic time

delay c ir c u it operates, the ALPHA 77's T/R changeover re la y s

are locked in the "re c e iv e " condition (see page 7, para. 6 ).

In la te production a m p lifie rs the m eter-illu m inating lamps do

not lig h t u n til the tim e delay clo se s, thus providing a "ready"

in d ic a tio n .

When a m p lifie r power is o ff fo r any length of tim e, the time

delay begins to re s e t. Upon re-ap p lica tio n of power the time

requ ired fo r the delay re la y to close depends upon preceding

length of "o ff" time, and w ill vary from a few seconds to the

f u ll nominal 90 seconds.

e . AfflPLIFIER-READY INDICATION — During the warm-up time delay

period and whenever the grid overcurren t re la y is trip p e d ,

the ALPHA 77’ s in te rn a l vacuum T/R re la y s are locked in the

"re c e iv e " p o sitio n regard less of mode sw itch or ex tern al re la y

co n tro l lin e cond itio n s. I f e x c ita tio n is ap p lie d , i t w ill ba

fed d ire c tly through to the load w ithout causing g rid or p late

cu rren t to flo w (see im portant note on page 7, para. 6 ). In

la te production ALPHA 7 7's the meter lamps are extinguished

during warm-up delay or grid -o vercurren t-trip ped co n d itio n s,

and lig h t up when normal operating condition s e x is t.

-11-

f . DRIVE POKIER VERSUS LOADING ADJUSTMENT — Sa fe, lo w - d isto rtion

operation of any lin e a r power a m p lifie r demands th at plate

loading be s u ffic ie n tly heavy fo r the drive power le v e l employed,

and th at re su ltan t operating conditions not exceed maximum safe

(o r lin e a r) c a p a b ilitie s of the tube and equipment.

The ALPHA 77 incorpo rates a large margin of sa fe ty in a l l

im portant param eters when operated a t or near rated cond itio n s.

It is , i f anything, le s s c r it ic a l of adjustm ent than other

a m p lifie rs of sim ila r power le v e l, w ith one exception! the

ALPHA 77's g rid overcurrent re la y system w ill not perm it the

a m p lifie r to be g rossly overdriven in to the fla t-to p p in g and

severe d is to rtio n conditions possible w ith a m p lifie rs not so

equipped. It does not under any circum stances lim it the power

c a p a b ility of the a m p lifie r, but simply req u ires th at a d ju st

ments be reasonably proper fo r high power operation.

ETO fa cto ry personnel w ill be happy to provide advice and

inform ation r e la tiv e to sp e c ia l a p p lic a tio n s , or to p ra c tic a l

operating-cond itions problems not covered in th is manual.

SECTION 4

MAINTENANCE AND TROUBLESHOOTING

most apparent problems w ith the ALPHA 77 re s u lt from users* fa ilu re

to read and thoroughly digest the contents of th is manual, ra th er

than from actual equipment problems.

I t is im portant th a t the in t e rio r of the ALPHA 77, and p a rtic u la rly

the high vo ltag e d-c areas of power supply and r- f compartment, be

be cleaned fre q u e n tly enough (w ith a so ft brush and vacuum cleaner)

to prevent v is ib le accum ulation of dust and d ir t . If excessive d ir t

is a problem, contact the fa cto ry fo r a ir f i l t e r recommendations.

The fo llo w in g chart suggests the most probable causes fo r severa l

common symptoms of apparent o p eratio nal trouble i

symptom PROBABLE CAUSE( S)

1. A m p lifie r com pletely in o p erative !

no pushbutton illu m in a tio n or high

vo ltage in d ic a tio n ) meters dark.

a) Blown prim ary fuse FI or F .

b) Improper primary a-c supply

connections at power plug.

c) In te rn a l plugs P , P3, or

P4 not prop erly mated.

. A ll four right-hand push buttons

"o u t," OFF button illu m in ated red. a) Desired button not pressed

firm ly by operator.

b) Pla te overcu rrent re la y ac

tuated.

3. BK-IN. CH). or SSB button deoressed

and illu m in a te d , but OFF button also

illu m in a te d ) no high vo lta g e .

a) Top cover a-c pouier in te rlo ck

sw itch not closed) lid loose.

4. Depressed pushbutton illu m in a ted

on mode sw itch but no high vo ltag e,

meters and meter buttons dark.

a) One prim ary fuse blown or one

side of a-c lin e open.

b) In c o rre c t a-c plug w irin g .

5. No grid or plate current w ith

normal drive from e x cite r: am p lifie r

lig h ts up norm ally and HV norm al.

a) No ex ternal contact closure

on RLy lin e in CW_ or SSB mode.

b) Time delay re la y not closed.

c) Grid overcurrent re la y actu ate

d) Input re la y K4 damaged.

-13-

6 . Lorn plate cu rren t, lorn or no g rid

current« excessive drive pouter

req u ired . CAUTION! Damaae to PA-77

m ill re s u lt from attenuated oo eration !

a) D efective bias sw itch tra n s

is to rs Q4 and Q5, or a s so c i

ated components, e s p e c ia lly

diodes D17 or D18.

b) A m p lifier on wrong band.

c) Input tuned c ir c u it m is-tuned.

7. Pla te current of 0 to 150 made

flow s w ith e x cite r turned o ff. a) Bias sw itch tr a n s is to r Q4 or

Q5 d e fe ctiv e .

b) Leakage (p a rt ia l sh ort) on

cathode lin e or p a r tia l tube

grid-cathode short.

8. Pla te cu rrent meter d e fle c ts back

wards; HV meter in d ica te s lower than

normal no-load voltage w ithout d riv e .

a) G rid-filam ent short in tube.

b) Short on cathode lin e to gnd.

9. Grid or p late overcurren t re lay

actuates on vo ice peaks. a) Excessive drive power.

b) Inadequate loading or plate

de-tuned from resonance.

c) D efective antenna or fe e d lin e ,

po ssibly arcin g on peaks.

10. Blower in te rm itte n tly sw itches

to high speed during operatio n. a) Abnormally low speed blower

operation. Reduce value of

R5B — contact fa c to ry .

b) A m p lifier not tuned p roperly.

c) A ir leak due to im properly

secured bottom cover.

11. Evidence of excessive tube heat

ing or blower stays on high speed. a) Blockage of normal a irflo w .

b) Excessive p late d issip atio n

due to m is-tuning or overdrive

c) Excessive re c ircu la tio n of hot

exhaust a ir back to a ir intake

-14-

SECTION 5

THEORY OF OPE RATI ON

1. BB77/3CX1500A7 RF AMPLIFIER CIRCUIT! Referrin g to the ALPHA 77

schem atic diagram, the r-f sectio n of the equipment is to the

le f t , w ith the BB77 potuer am p lifie r it s e lf at the top and the

a u x ilia ry c irc u itry (most of which is p h y s ic a lly located on the

T/R printed c ir c u it board) below.

W ith tran sm it/rece ive (T/R) changeover relays K4 and K5 in the

receive cond ition shown, r- f from the e x c ite r (o r tra n sce iv e r)

a rriv in g at RF IN jack J6 passes via the norm ally closed contacts

of K5 to the rf wattm eter coupler assembly (to ro id L13 and a sso c i

ated components) d ire c tly to the RF OUT connector JB . S im ila rly ,

received sig n als a rriv in g at JB from the antenna feed d ir e c tly

through the a m p lifie r to J6 , perm ittin g conven tion al connections

fo r a l l popular tran sc e iv e rs and tra n sm itte r- re ceiv e r com binations.

When the T/R re lays K4 and K5 are switched to the tran sm it condi

tio n , K5a disconnects JB and the r f wattm eter from J6 and connects

them to the a m p lifie r output. K4a connects the in put sig n al from

J6 v ia blocking cap acito r CB to the cathode of the BB77 tube, which

operates as a grounded-grid a m p lifie r. Ulhen s lid e sw itch S1 is

moved toward the tube, a pre-tuned resonant tank c ir c u it w ith "Q"

of approxim ately two (tapped c o il L1 and padder capacito rs C1 thru

C6) is switched in to maximize a m p lifie r lin e a r ity and e ffic ie n c y .

The input tank c ir c u it is fa cto ry pre-tuned fo r the center of each

amateur band) fo r operation a t s u b s ta n tia lly d iffe re n t frequencies

the app ropriate padder (C1 thru C6) may be re-adjusted fo r minimum

input SUIR, or the input tank may be disconnected, w ith only modest

reduction in lin e a r ity and e ffic ie n c y , by p o sitio n in g the s lid e r

of S1 away from the tube.

A pi-L plate tank c ir c u it provides e x c e lle n t suppression of her-

monics in the a m p lifie r output, as w e ll es re la tiv e ly constant

operating ” Q" (nom inally 15) and impedance matching c a p ab ility

across the e n tire frequency renge. Use of vacuum tuning cap acito r

C17,with it s very low minimum capacitan ce, sm all s iz e , and high

vo ltag e ra tin g , enhances e ffic ie n c y on the highest frequency bands

by m aintaining normal "Q" there) the vacuum capacito r sls o provides

e n o n - c ritic a l tuning c h a ra c te ris tic , precise r e - s e tta b ilit y , and

a high degree of freedom from flesh - o ve r. A heavy, silv e r- p la te d

copper c o il is used a t L4 fo r e ffic ie n c y . In the in te re s t of

p h y sical compactness w ithout excessive in te r- c o il s tra y couplin g,

husky to ro id a l inducto rs are used at L5 (in the 3-5 KlHz band,

where core lo sses are in s ig n ific a n t) and a t L6, the L-network

ind uctor (where r- f cu rre n t, and hence core lo sses, sre low because

of the very low operating "Q" of the L-netw ork).

Because C19 is switched in only on 8-1 IHHz and lower frequency

bands, loading adjustm ent is r e la tiv e ly uniform and n o n - c ritic a l

on a l l bands; C1B provides needed ad d itio n a l capecitance for the

3-5 IdHz range.

LB feeds d-c plate voltage to the BB77 and L9, in combination w ith

C13 and C44, provides a d d itio n a l r- f decoupling. R4B provides

-15-

fa u lt currgnt lim itin g to protgct c ir c u it components in ths svsnt

of momentary high voltage fla s h o v s r.

The r- f wattm eter c irc u it is con ven tio n al, w ith C45 providing the

re fle c te d power n u ll adjustment and re s is to rs R5 and R51 selected

to y ie ld fu ll- s c a le poster of 500 w atts re fle c te d and 5000 w atts

forw ard.

. ELECTRONIC BIAS SWITCHi P o s itiv e bias is ap p lied to the cathode

of the 8877 tub* to cut o ff p late current com pletely when no r-f

e x c ita tio n is prgsent (thus g lim in atin g heat gengration and power

waste due to id lin g plate c u rren t, as w ell as preventing tube

id lin g noise from in te rfg rin g w ith proper operation of the e le c

tro n ic T/R sw itch , ae described la t e r ). Choke L provides r- f

is o la tio n fo r thg b ias supply and feeds approxim ately +55 v o lts

d-c, from thg power supply v ia R13, to the 8877 cathodg. W ith

no r- f g x c ita tio n tra n s is to r aw itch Q4-Q5 remains "o f f ," and the

fu l l 55 v o lts is appligd to the 8877, com pletely cu ttin g o ff plate

cu rrg n t.

In order to g s ta b lis h proper opgrating b ia s, r- f e x c ita tio n sig n a l

from thg output of K4a is sampled via C5 /R34, r e c tifie d by D17/D18,

and the re s u lta n t d-c uegd to sw itch Q4-Q5 "o n ." As l i t t l e as

100- 00 m illiw a tts of d rive power is e u ffic ig n t to f u lly sw itch

on Q5, which is a type e p e c ific a lly eelected becausg of it s vgry

low co llg cto r- to -em ittg r gatu ration voltage — about 0.5 v o lt maxi

mum. C16 is largg enough to hold the b ias sw itch "on" w hile d rive

is app lig d , gvgn though thg r-f envelope va rig s at an audio ra te .

The cathodg-to-grid (g rid cu rre n t) c ir c u it is completgd to ground

(g rid ) v ia R 0, across which is developed a d-c vo ltage prop o rtional

to g rid currgn t but lges than 0.5 v o lts undgr a l l normal opgrating

co n d itio n s. Thus, when drive is prgsent and Q4-Q5 switched "o n ,"

the opergting bias co n siste of the re g u latin g drop across zener

diode D13 (8 to 1 v o lts , dgpending on the production s g rie s ) plus

le ss than one v o lt drop acroes Q5 and R 0.

Thg d-c voltagg drop across R 0 serves two purposeei (1 ) i t is

fgd to m ultim etgr H v ia R to provide a meter in d ic a tio n of d-c

grid cu rrg n t, and ( ) i t d rive s the grid overcurren t re la y d riv e r,

Q .

3. GRID OVERCURRENT RELAYi At low vslu es of grid current Q remaine

cut o ff. When thg drop acroes R 0 due to g rid current flow is

such as to providg a g rid meter in d icatio n of approxim ately 350 to

400 ma, however, Q is driven e u ffic ie n tly in to conduction to close

re la y K8 which is immgdiately latched ehut by it e own norm ally open

co ntacts v ia R55. C30 provides s u ffic ie n t time conetant to prevent

re la y actu a tio n by occa eio n al, is o la te d high-currgnt sp ikes, and to

prevent re la y "c h a ttg rin g " upon ac tu a tio n . Q -K8 operate from the

+18 v o lt d-c buss regulatgd by zener D9| oncg K8 is actuated and

latched it «ay be rgggt by sw itching a-c power o ff long enough fo r

the +18 v o lt busg to f a l l bglow K B's hold-in volta g e -- about 5 vdc.

A ctuation of K8 opene the c o il return of time dglay re la y K9, thus

locking the T/R re la y s in the "rg c e iv e " condition u n til K8 is re s e t.

-16-

4. WARW-UP TIHIE DELflYi Upon ap p lica tio n of pr imary power to the

ALPHA 77, voltage on the +18 v o lt buss regulated by D9 rise s from

zsro to +18 v o lts in less than ons second, and tim ing cap acito r

C 4 begins charging through R57. ItiOSFET Q9 operates as a source

fo llo w er w ith the c o il of K9 as it s load) when the vo ltage across

C 4 reaches approxim ately +9 v o lts , the voltage across relay c o il

K9 is s u ffic ie n t to close it s contacts K9a, uihich la tch the re lay

closed v ia D15 and R56. When K9a clo ses, voltage from the +55 v o lt

d-c buss is fed to the T/R re la y c ir c u it v ia R1 -C 7, as w ell as

(in la te production u n its) to the meter lamps 19 thru 11 .

5. ALC RECTIFIERi R-f drive voltage is sampled v ia ca p a c itiv e d ivid er

C56-C57 and app lied to r e c tif ie r D19, which is back -biased by

d-c voltage from ALC threshold-ad ju st potentiom eter R 6. When

sampled r- f vo ltage peaks exceed the diode b ias le v e l, the sig n al

is re c tifie d and the negative-going ALC control voltage uihich

re s u lts is fed to ALC jack J1 . R35-C58 decouple the bias source

from the r- f d e tecto r, uihile R54-C59 f i l t e r carrier-freq u en cy

components from the ALC con trol sig n al.

6. T/R RELAY SEQUENCING» Components D3 through D35, C 6, C 7, and

R1 serve to ineure that output vacuum T/R re la y K5 closes before

input re lay K4, thus p ro tecting p late c irc u it r- f components of

the a m p lifie r, in cluding K5's con tacts, from “ hot sw itch in g" and

momentary unloaded op eration. Such a situ a tio n may occur when

e x c ite r re lay sequencing is poor, perm itting r- f ex c ita tio n to

be d elivere d to the a m p lifie r sim ultaneously w ith closure of the

relay contro l lin e .

When +55 vdc is in it ia lly applied to the T/R re la y system , e ith e r

by closure of the external relay co n trol lin e through J7 , pushing

of the 8K-IN button, or "k ick in g - in " of time delay re la y K9,

C 7 begins charging through D35 and K5, mom entarily applying

n early the f u ll 55 v o lts to K5's c o il. Sim ultaneously C 6 begins

charging through D3 and R1 , generating a voltage drop across

R1 which b rie fly delays clo sin g of K4. As a re s u lt, although

K4 is sm aller and in h eren tly fa ste r than K5, these in te n tio n a l

R-C tim ing c irc u its insure that K4 w ill close seve ral m illiseco nds

a fte r K5,

7. ELECTRONIC T/R SMITCHi In combination w ith the e le c tro n ic bias

sw itch, th is feature perm its the ALPHA 77's T/R rela y s to be

locked in the "tran sm it" p o sitio n fo r f u ll break-in CW, providing

rece iver input sig nal a t J5 during key-up in te rv a ls . With the

8877 tube cut o ff during periods of no e x c ita tio n (key up) and

K5 closed, received eig n als from the antenna pass "backwards"

through the am p lifie r pi-L output c irc u itt in the process the

network provides s e le c tiv it y and a step-up of impedance and vo lta g e.

Because of the extrem ely high input impedance of tra n s is to r Q1 ,

a self- p ro tecte d , insu lated gate IflOSFET, a very sm all coupling

capacitance C38 (le s s than 1 pf) is s u ffic ie n t to couple the signal

to Q1's input gate. Q1 operates as a high-gm source fo llo w er to

provide near u n ity voltage gain, low n oise, and a low impedance

output (J5 ) to the re c e iv e r. Total input capacitance of Q1 is on

the order of 10 pf, and is reeonated out on each amateur band by

the appr opriate combination of L1D, L11, L1 , L14, and L15.

-17-

R e sis to rs R11 , R47, R4, and R7 — as uiall as the "Q 's" of the

resonating inductors p re vio u sly mentioned — are se le cted to

provide re la tiv e ly uniform o v e ra ll gain (approxim ately 0 db to

+10 db) across the frequency bands covered, as uiell as p o sitive

s t a b ilit y under a l l conditions of a m p lifie r and re ce ive r- in p u t

tuning .

Under tran sm itting co n d itio n s, back-to-back lim ite r diodea D 0

and D 1 , combined uiith the very high s e rie s impedence of C38,

hold the input voltage to Q1 to approxim ately 0.7 v o lta peak,

thus p ro tectin g both Q1 and the re c e iv e r input from damage due

to excessive input vo lta g e . Diodes D30 and D31 serve to protect

Q1 from damage re s u ltin g from p o te n tia l d iffe re n ce s between the

ch assis of the a m p lifie r and the re c e iv e r, p a r tic u la rly at the

moment the re c e ive r antenna cable is plugged in to J5 .

8. BLOWER 1 Whenever the a m p lifie r is in any condition other than

o rr. 1 0 vac ie ap p lied to the blouier B1 v ia R58 (shunted by

normally-open therm ostat S7 ). R58 is fa cto ry adjusted so that

the blouier norm ally operates a t much le ss than f u ll speed,

d e liverin g s u ffic ie n t cooling a ir fo r a l l normal amateur and

commercial ap p licatio n s under most co n d itio n s. The low speed

and extrem ely high q u a lity of the blower combine to yie ld a very

low operating noise le v e l, fu rth e r enhanced by the ducting of

exhauet a ir out the rear of the ALPHA 77.

Under cond itions of eustained excessive p late d issip a tio n re

s u ltin g in higher-than-norma 1 exhaust a ir tem perature, therm ostat

S7 -- located on the exhaust a ir duct — clo s es, sw itching the

blower to f u l l speed u n til a ir tem perature re tu rn s to norm al.

Any cyclin g to f u ll apeed of the blower under normal operating

con d itio n s is an in d ic atio n of e ith e r a ir-flo w blockage or inade

quate id lin g blower speed, and should be corrected prom ptly.

(R58 is mounted v e r t ic a lly , underneath the warm a ir exhauet duct.

To in crease blower id lin g speed, loosen the slider-clam ping screw

and move the s lid e r s lig h tly downward, then re tig h te n . CAUTION!

Always remove the a-o power plug before working insid e the ALPHA 7 7!)

9. POWER CONTROL 1 Pressin g mode buttons BK-IN. CW. or SSB ap p lies

operating vo ltage to main a-c power re la y K1 v ia R3, S9 (the top

cover must be closed and the in te rlo ck actu ate d ), and S5f-D 5,

S5d-D 4, or S5b-D 3, re s p e c tiv e ly . Tha se rie s diodes D 3-D 5,

along w ith R3 and diode D16 acrose the inductance of re la y c o il

K1 , serve to convert the applied a-c voltage to approxim ately

8 vdc fo r hum-free operation of the re la y . Upon cloeure of K1 ,

prim ary voltage is applied to the primary windings of power tra n s

form er T1 through ste p - sta rt re s is to rs R1 and R . These re s is to rs

lim it in i t ia l inrush current to 1 amperes maximum, reg ardless of

other circum stances in t he power supply. Under normal con ditions

the current drawn by T1 w ill drop very ra p id ly as high voltage

f i l t e r cap acito r C36 charges toward f u l l v o ltag e i sim ultaneously,

the drop across R1 and R decreases and a l l transform er vo ltag es

approach norm al. As the + 8 vdc buss approaches normal vo lta g e ,

re la y K clo se s, shorting out R1 and R | the e n tire sta rtin g se

quence requires only a fra c tio n of a second.

Table of contents

Other EHRHORN Amplifier manuals