EHRLE HSC 723 Series User manual

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

1

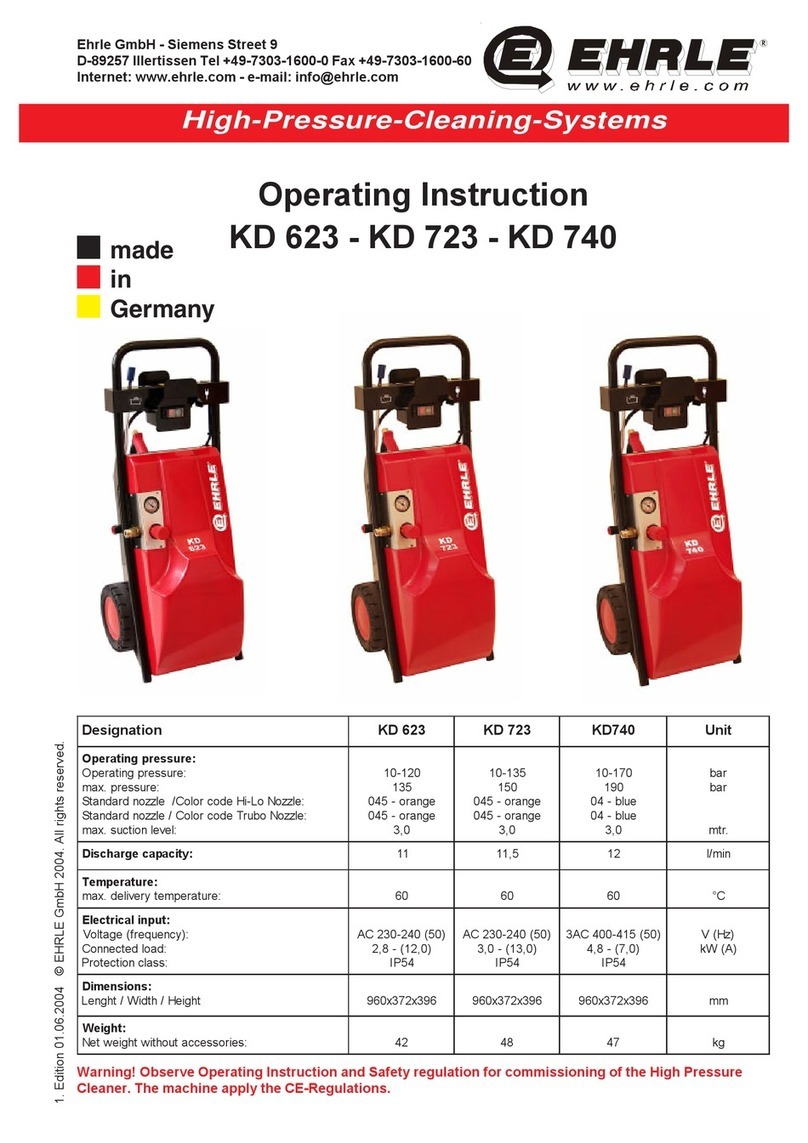

Betriebsanleitung - Operating Instruction

Stationäre Hochdruckreiniger

Heißwasser

Stationary High Pressure Cleaners

Hotwater

Typen - Series

HSC 723 (-ST) - HSC 1140 (-ST) - HS 1240 (-ST) - ölbeheizt/oilheated

HSC 840 (-ST) - HSC 1140 (-ST) - elektrisch beheizt/elect. heated

HSC 1140 -ST - gasbeheizt / natural gas-heated

2. Au age 06.10.2010 - 2. Edition 06.10.2010 © EHRLE GmbH 2010. Alle Rechte vorbehalten.

VORSICHT: Zur Inbetriebnahme der Hochdruckreiniger die Betriebsanleitung beachten.

WARNING: Observe Operating Instruction for commissioning the High Pressure Cleaners.

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

65

Operating Instruction

for

Stationary High Pressure Cleaners

Hotwater

Series

HSC 723 (-ST) - HSC 1140 (-ST) - HS 1240 (-ST) - ölbeheizt/oilheated

HSC 840 (-ST) - HSC 1140 (-ST) - elektrisch beheizt/elect. heated

HSC 1140 -ST - gasbeheizt / natural gas-heated

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

66

Preface

With purchasing the EHRLE High Pressure Cleaner you are the owner of a high

quality product. Besides the outstanding features our High Pressure Cleaners are:

• Ease of operation

• Reliable

• Environmentally friendly

Our High Pressure Cleaners meet national and international safety standards and

have received the approval of international agencies and laboratories. All High

Pressure Cleaners meet the European Conformity CE Standard.

This operating instruction contains the operation, maintenance and repair for the

stationary High Pressure Cleaner series:

• HS 623, HS 840, HS 1040, HS 1240, HSC 623, HSC 1040

• HSE 800, HSE 1000,

• HSG 1240.

The WARNINGS, CAUTIONS and NOTES in this operating instruction are de ned as

follows:

Warning precedes operating procedures, instructions, etc., which,

if not strictly observed, could result in personal injury or loss of life.

Warning precedes also, when device misuse could result in personal

injury or loss of life.

Attention precedes operating procedures, instructions, etc., which, if

not strictly observed, could result in damage to the High Pressure

Cleaner. Attention precedes also, when device misuse could result in

damage to the High Pressure Cleaner.

Note precedes or follows, when additional information is presented.

For the High Pressure Cleaner commissioning and operation observe

the operating instruction.

Only specially trained and quali ed personal are allowed to perform

High Pressure Cleaner installation, maintenance and repair.

ATTENTION

NOTE

WARNING

WARNING

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

67

The gas red High Pressure Cleaner HSG 1240 is equipped with a gas burner from

manufacturer HANSA (original equipment manufacturer). The scope of delivery of the

series HSG includes the “Installation and Operating Instructions” from HANSA.

Observe the “Installation and Operating Instructions” for the gas burner.

The gas red High Pressure Cleaner HSG 1240 is certi ed by the DVGW (Deutscher

Verein des Gas- und Wasserfaches).

CE-Number: CE 0085AR0179.

Address

DVGW Deutscher Verein des Gas- und Wasserfaches

Technisch-Wissenschaftliche Vereinigung

Postfach 14 03 62

53058 Bonn

Josef-Wimmer-Str. 1-3

53123 Bonn

The circuit diagrams in section 4 show the wiring of the general standard High

Pressure Cleaners. The detailled device speci c information shows the circuit diagram

contained in the terminal box of every delivered High Pressure Cleaner.

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

68

Table of content

Technical description

1 Technical description .......................................................................................72

1.1 General information ........................................................................................72

1.2 Utilization ........................................................................................................74

1.3 Total view of stationary High Pressure Cleaner ..............................................74

1.4 Technical data .................................................................................................78

1.4.1 Technical data for series HS 623, HS 840 and HS 1040................................. 78

1.4.2 Technical data for series HS 1240 and HSG 1240 .........................................80

1.4.3 Technical data for series HSE 800 and HSE 1000 .........................................81

1.5 General function of High Pressure Cleaner ....................................................82

1.5.1 General function of series HS .........................................................................82

1.5.2 General function of series HSE........................................................................84

1.5.3 General function of series HSG ......................................................................86

Commissioning and operation

2 Commissioning and operation ........................................................................88

2.1 Precautions to prevent accidents ....................................................................88

2.2 Installation of the High Pressure Cleaner .......................................................89

2.2.1 General ...........................................................................................................89

2.2.2 Locating the High Pressure Cleaner central unit ............................................91

2.2.3 Installing the High Pressure Cleaner central unit ............................................94

2.2.4 Electrical connection for the High Pressure Cleaner ......................................96

2.2.5 Water supply connection for the High Pressure Cleaner ................................98

2.2.6 Installing the fuel oil supply for series HS .......................................................99

2.2.7 Installing the natural gas supply for series HSG ...........................................101

2.2.8 Installing the detergent supply ......................................................................102

2.2.9 Installing the high pressure pipes .................................................................102

2.2.10 Installing the cleaning equipment ..................................................................103

2.2.11 Installing the remote control ..........................................................................103

2.2.12 Installing the self service coin acceptor ........................................................104

2.2.13 Installing the chimney for series HS and HSG ..............................................105

2.3 Commissioning and operation ......................................................................106

2.3.1 Before rst commissioning ............................................................................106

2.3.2 Oil burner check and adjustment for series HS ............................................106

2.3.3 Gas burner check and adjustment for series HSG .......................................107

2.3.4 Commissioning the High Pressure Cleaner ..................................................108

2.3.5 Operating the High Pressure Cleaner via self service coin acceptor ............112

2.4 Applying the cleaning detergent (chemical) ..................................................112

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

69

2.5 Decommissioning the High Pressure Cleaner ...............................................113

2.6 Guidelines, Regulations, Certi cates ............................................................114

2.6.1 Guidelines for pressure vessels and steam boiler regulation ........................114

2.6.2 Guidelines for liquid sprayers ........................................................................114

2.6.3 Manufacturer tests and certi cates ...............................................................115

2.6.4 Emissions regulations ...................................................................................115

2.6.5 Notes for place of use ...................................................................................115

Maintenance and Repair

3 Maintenance and repair .................................................................................116

3.1 Care for the High Pressure Cleaner ..............................................................116

3.1.1 Cleaning the High Pressure Cleaner .............................................................116

3.1.2 Anti freeze protection ....................................................................................116

3.2 Maintenance for the High Pressure Cleaners ...............................................116

3.2.1 Daily maintenance .........................................................................................117

3.2.2 Weekly maintenance .....................................................................................117

3.2.3 Monthly maintenance (or after 150 operating hours) for series HS ...............117

3.2.4 Six monthly maintenance or on condition ......................................................118

3.2.5 Yearly maintenance .......................................................................................118

3.2.6 Oil change .....................................................................................................118

3.2.7 Descaling the High Pressure Cleaner ...........................................................119

3.2.8 Checking the high pressure hose .................................................................120

3.3 Repair of the High Pressure Cleaners ..........................................................120

3.3.1 Troubleshooting ............................................................................................120

3.3.2 Replacing components .................................................................................123

Safety instructions gas-burner

4 Safety instructions gas-burner ......................................................................124

4.1 Instructions ..................................................................................................124

4.2 Behavior at smell of gas ...............................................................................124

Wiring diagrams

5 Wiring diagrams ............................................................................................126

5.1 HS 623, HS 840, HS 1040, Wiring Diagram (Sheet 1 of 3) .......................... 127

5.2 HSE 800, 18 kW, Wiring Diagram (Sheet 1 of 3) ..........................................128

5.3 HSE 1000, 24 kW, Wiring Diagram (Sheet 1 of 3) ........................................129

5.4 HSE 1000, 30 kW, Wiring Diagram (Sheet 1 of 3) ........................................130

5.5 HSG 1240, Wiring Diagram (Sheet 1 of 3) ....................................................131

5.6 HS 623, HS 840, HS 1040, Wiring Diagram (Sheet 2 of 3) ..........................132

5.7 HSE 800, 18 kW / 24 kW, HSE 1000, 24 kW / 30 kW

Wiring Diagram (Sheet 2 of 3) ......................................................................133

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

70

5.8 HSG 1240, Wiring Diagram (Sheet 2 of 3) ....................................................134

5.9 Typ HS, Typ HSE, Typ HSG, Wiring Diagram (Sheet 3 of 3) ........................135

Spare parts catalogue

6 Spare parts ...................................................................................................136

6.1 Stationary High Pressure Cleaner ................................................................137

6.1.1 Components of Stationary High Pressure Cleaner Hotwater

(Sheet 1 of 2) ................................................................................................137

6.1.2 Components of Stationary High Pressure Cleaner Hotwater

(Sheet 2 of 2) ................................................................................................139

6.2 Oil burner (Series HS) ...................................................................................141

6.3 Heating coil with oat container (Series HS) .................................................143

6.4 Safety parts ..................................................................................................145

6.5 Boiler .............................................................................................................147

6.5.1 Electric boiler (Series HSE) ..........................................................................147

6.5.2 Gas boiler (Series HSG)................................................................................149

6.6 Unloader valve ..............................................................................................151

6.7 Pump HS 623, HS 840 ..................................................................................153

6.8 Pump crankcase HS 623, HS 840 ................................................................155

6.9 Pump HS 1040 ..............................................................................................157

6.10 Pump HSE 1000, HSG 1240.........................................................................159

6.11 Pump HS 1240 ..............................................................................................161

6.12 Pump HSE 800 .............................................................................................163

Terminal boxes

7 Terminal boxes ..............................................................................................167

7.1 Terminal box HS 623, HS 840, HS 1040, HS 1240 .......................................167

7.2 Terminal box HSG 1240 ................................................................................169

7.3 Terminal box HSE 800, 18 kW ......................................................................171

7.4 Terminal box HSE 800, 24 kW, HSE 1000, 24 kW ........................................173

7.5 Terminal box HSE 1000, 30 kW.....................................................................175

List of gures

Figure 1 Stationary High Pressure Cleaner of series HS (oil red),

general example for installation (sheet 1 of 2) ................................................75

Figure 2 Stationary High Pressure Cleaner of series HS (oil red),

general example for installation (sheet 2 of 2) ................................................77

Figure 3 High Pressure Cleaner series HS, functional diagram ....................................83

Figure 4 High Pressure Cleaner series HSE, functional diagram .................................85

Figure 5 High Pressure Cleaner series HSG, functional diagram .................................87

Figure 6 Tip over hazard for un xed central unit ...........................................................90

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

71

Figure 7 Dimensions for installing the central unit of series HS, HSE and HSG

on the oor mounting device (front view) ........................................................92

Figure 8 Dimensions for installing the central unit of series HS, HSE and HSG

on the oor mounting device (side view) .........................................................93

Figure 9 Installing the central unit on the oor mounting device ...................................94

Fig. 10 Installing the central unit via wall mounting device .........................................95

Fig. 11 Dimensions for the fuel oil pipes ...................................................................100

Fig. 12 Central unit control panel of series HS .........................................................110

Fig. 13 Central unit control panel of series HSE and HSG .......................................111

Fig. 14 Block-electrode and fuel oil nozzle ................................................................118

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

72

1 Technical description

1.1 General information

The stationary High Pressure Cleaners (hotwater) are divided into the catego-

ries

• Series HS, HSC: High Pressure Cleaner oil red,

• Series HSE: High Pressure Cleaner electric heated,

• Series HSG: High Pressure Cleaner gas red.

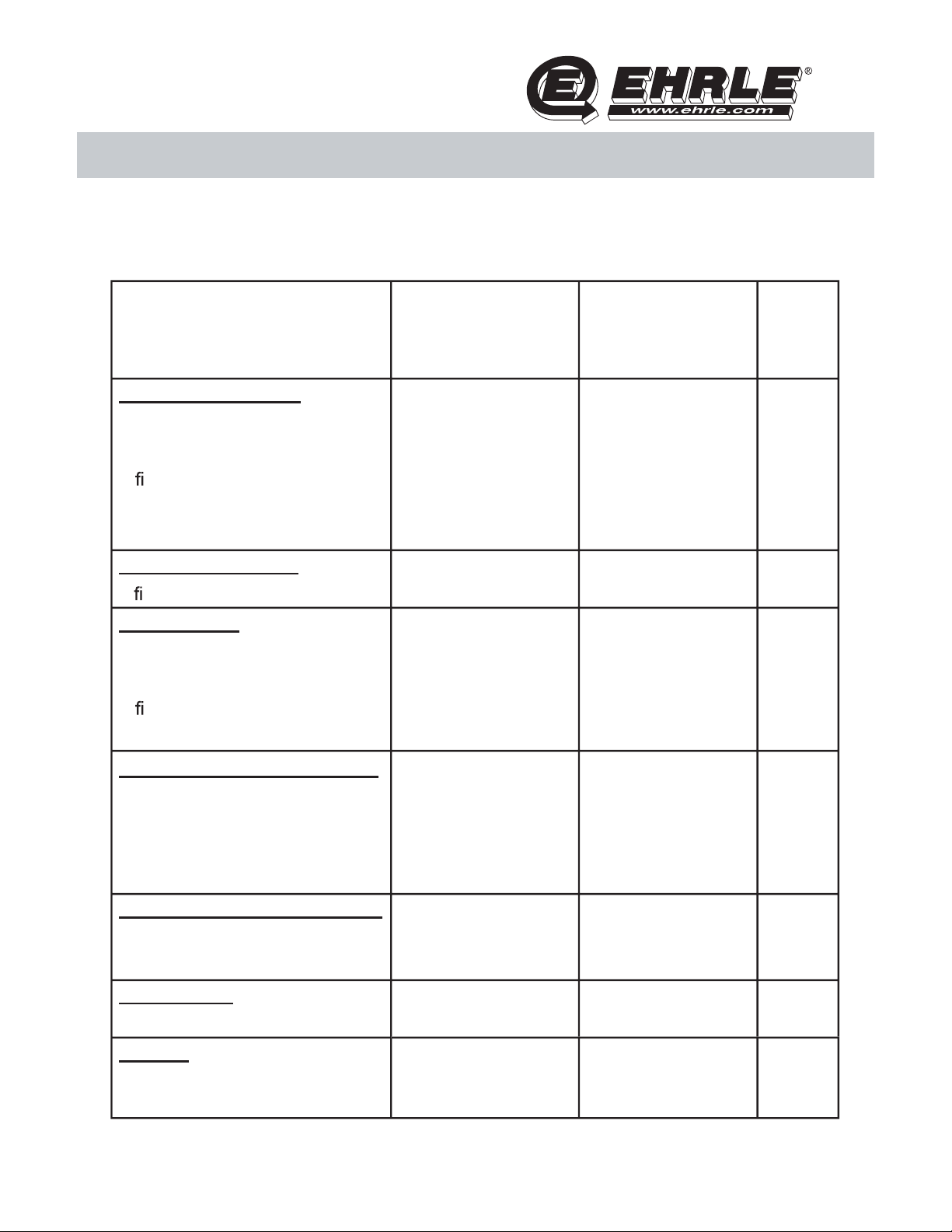

The table below shows the three categories in reference to work site.

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

73

Category Type Work site (condition

Series HS

High Pressure Cleaner

oil red

HS 623, HS 840,

HS 1040,

HS 1140,

HSC 623,

HSC 1040

Electrical power (mains) is availa-

ble at the site. The exhaust can be

ued off with a chimney or direct

into the atmosphere.

Typical application for industry e.

g. car dealer ships, transport com-

panies and shippers, rail and bus

companies, farming, livestock and

arible, construction

companies, hire industry, highways

and transport, plant and machinery

maintenance re-brigades etc.

Series HSE

High Pressure Cleaner

electric heated

HSE 800,

HSE 1000

Electrical power (mains) is availa-

ble at the site. The exhaust from

an oil or gas red High Pressure

Cleaner is undesirable or prohi-

bited. Typical application for food

industry, supermarkets, abatoirs,

meat packing plants, sh industry,

hospitals, hotels, restaurants,

swimming pools, chemical

industry, airports etc.

Series HSG

High Pressure Cleaner

gas res

HSG 1240

Electrical power (mains) is availa-

ble at the site. The exhaust can be

ued off with a chimney or direct

into the atmosphere.

This High Pressure Cleaner may

be used in establishments, facto-

ries and workshops with modern

energy supplies such as natural

gas or L.P.G.

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

74

1.2 Utilization

The High Pressure Cleaner series HS, HSE and HSG are in general used for

cleaning:

• Car dealer ships, transport companies and shippers, rail and bus companies,

• Fire brigades and automatic brush wash systems for pre-cleaning vehicles,

• Construction companies,

• Food industry, sanitary facilities,

• Chemical industry,

• Hospitals, large kitchens, swimming pools, catering.

Besides cleaning generally contaminated surfaces the EHRLE High Pressure

Cleaners shows its excellent features and optimum cleaning power when clea-

ning

• grease, oil or fat contaminated surfaces,

• tar contaminated surfaces,

• chemical contaminated surfaces etc,

The easy operateable and adjustable High Pressure Cleaner, e.g. setting the

water temperature, admixing and diluting the cleaning detergent, adjusting the

operating pressure and special nozzles ensure also optimum cleaning for dif -

cult tasks like tenacious encrusted contaminations.

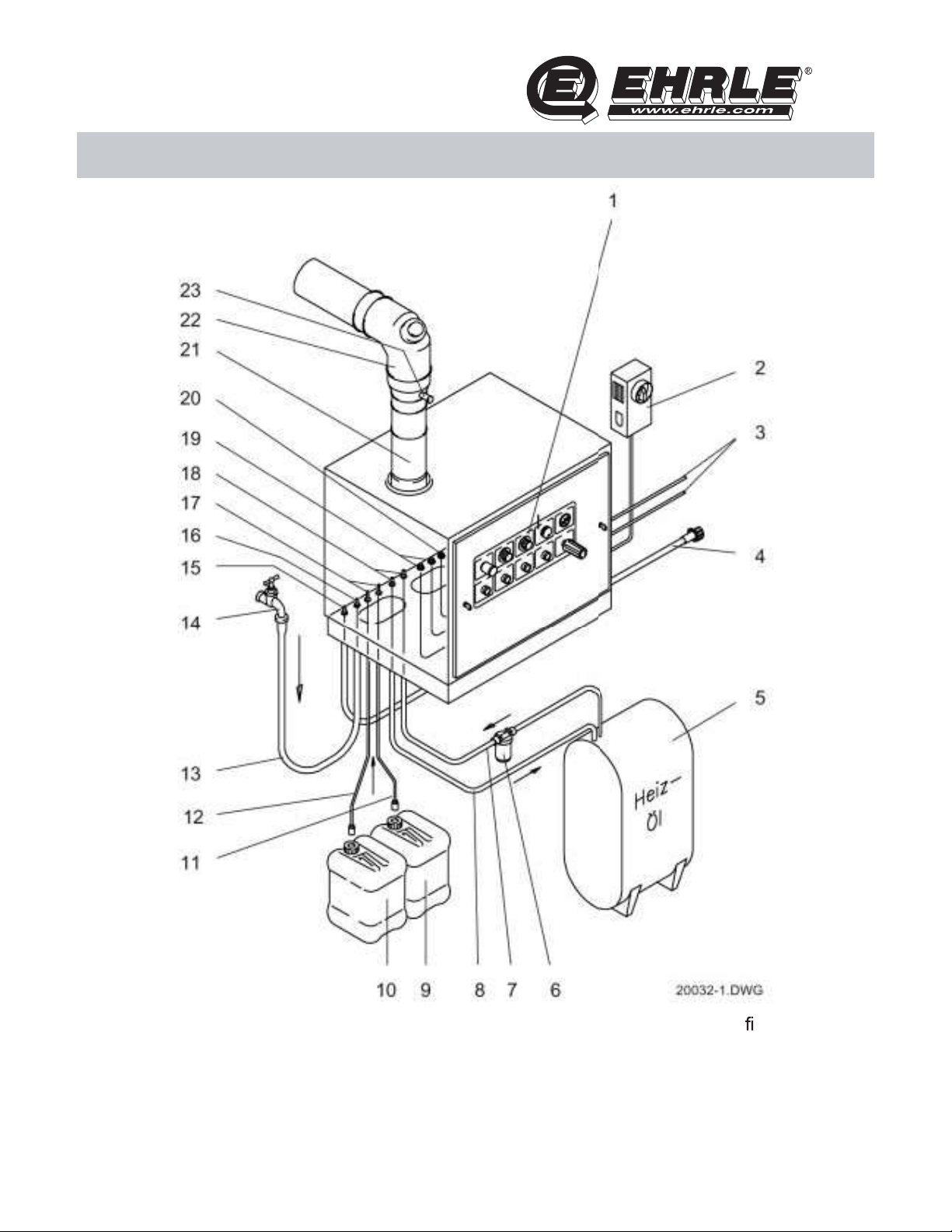

1.3 Total view of stationary High Pressure Cleaner

The following gures show a general installation example for the stationary

High Pressure Cleaner oil red (series HS). Special accessories and options

allow customization to nearly every site. The series HS includes as follows:

• HS 623, HS 840, HS 1040, HS 1240.

For further information to installation of the series HSE and HSG

contact the manufacturer EHRLE.

NOTE

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

75

Figure 1 Stationary High Pressure Cleaner of series HS (oil red),

general example for installation (sheet 1 of 2)

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

76

1 Control panel component of central unit

2 Main switch equipment of infrastructure

3 Cord remote control accessories

4 High pressure hose 1,5 m accessories

5 Fuel oil container equipment of infrastructure

6 Fuel supply device with lter accessories

7 Fuel oil suction pipe accessories

8 Fuel oil return pipe accessories

9 Detergent container I accessories

10 Detergent container II accessories

11 Detergent suction hose (I) accessories

12 Detergent suction hose (II) accessories

13 Water supply hose accessories

14 Shut off valve equipment of infrastructure

15 High pressure hose connection central unit interface

16 Water supply central unit interface

17 Detergent connection central unit interface

18 Connection fuel oil suction hose central unit interface

19 Wire joint cord remote control central unit interface

20 Wire joint electrical cord central unit interface

21 Adjustable chimney accessories

22 Chimney accessories

23 Adapter 120/150 accessories

with test hole

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

77

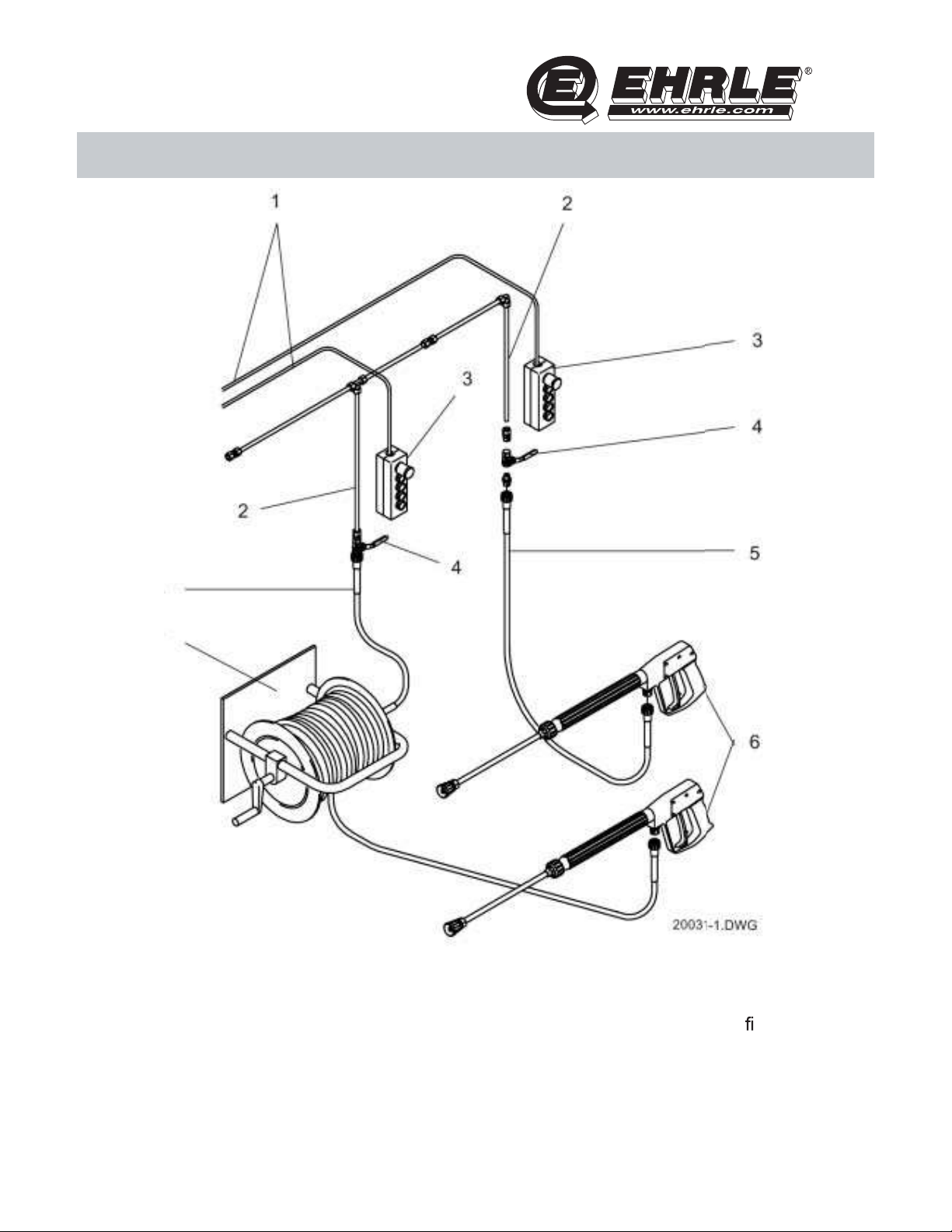

Figure 2 Stationary High Pressure Cleaner of series HS (oil red),

general example for installation (sheet 2 of 2)

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

78

1 Cord remote control accessories

2 High pressure pipe accessories

3 Remote control accessories

4 High pressure block valve accessories

5 High pressure hose accessories

6 Trigger gun with spray lance accessories

7 Hose reel (wall xture) accessories

8 High pressure hose 1,5 m accessories

1.4 Technical data

1.4.1 Technical data for series HS 623, HS 840, HS 1040, HSC 623, HSC 1040

The table below shows the High Pressure Cleaner technical data for series

HS 623, HS 840, HS 1040, HSC 623 and HSC 1040.

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

79

Designation HS 623

HSC 623 HS 840 HS 1040

HSC 1040 Unit

Operating pressure:

Standard nozzle

Hot water (with standard nozzle)

In nitely variable

Permissible operating pressure

Max. reaction force

B

2505

110

30 - 110

130

28

B

25045

150

30 - 150

170

37

B

2505

180

30 - 180

200

49

B

MEG

bar

bar

bar

N

Discharge capacity:

In nitely variable (water) 330 - 660 390 - 780 520 - 1000 l/h

Temperature:

Max. delivery temperature

Max. operating temperature

In nitely variable

Heating capacity (net)

T

30

98

30 - 98

46

T

30

98

30 - 98

50

T

30

98

30 - 98

63

T

°C

°C

°C

kW

Electrical input power (mains):

Voltage (frequency)

Consumption

Facility power outlet requires

fuse with

N

AC 230 ~ (50)

3,0

16 (inert)

1

N

3 x 400 ~ (50)

5,6

16 (inert)

1

N

3 x 400 ~ (50)

7,9

20 (inert)

1

N

V (Hz)

kW

A

Oil consumption:

Max. oil consumption

For temperature increase of 50 K

F

4,6

3,3

F

5,0

3,6

F

5,5

5,4

F

kg/h

kg/h

Capacities and suction quantity:

H. P. Pump motor oil W 15/40

Chemical suction quantity

F

0,5

0 - 10

F

0,5

0 - 10

F

0,6

0 - 10

F

l

l/h

Dimensions:

Length x Width x Height

A

830x650x690

A

830x650x690

A

830x650x690

A

mm

Weight:

Weight of machine without

accessories

G

130

G

135

G

140

G

kg

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

80

1.4.2 Technical data for series HS 1240 and HSG 1240

The table below shows the High Pressure Cleaner technical data for series

HS 1240 and HSG 1240.

Designation HS 1240 HSG 1240 Unit

Operating pressure:

Standard nozzle

Hot water (with standard nozzle)

In nitely variable

Permissible operating pressure

Max. reaction force

B

2507

160

30 - 1600

180

43

B

2505

180

30 - 180

200

49

B

MEG

bar

bar

bar

N

Discharge capacity:

In nitely variable (water) 600 - 1200 520 - 1000 l/h

Temperature:

Max. delivery temperature

Max. operating temperature

In nitely variable

Heating capacity (net)

T

30

98

30 - 98

65

T

60

80

30 - 80

54

T

°C

°C

°C

kW

Electrical input power (mains):

Voltage (frequency)

Consumption

Facility power outlet requires

fuse with

N

3 x 400 ~ (50)

7,9

20 (inert)

1

N

3 x 400 ~ (50)

7,9

20 (inert)

1

N

V (Hz)

kW

A

Oil or gas consumption:

Max. fuel consumption

For temperature increase of 50 K

F

4,6 (oil)

3,3 (oil)

F

4,9 m³ gas H

4,9 m³ gas H

F

kg/h

kg/h

Capacities and suction quantity:

H. P. Pump motor oil W 15/40

Chemical suction quantity

F

0,5

0 - 10

F

0,6

0 - 10

F

l

l/h

Dimensions:

Length x Width x Height

A

830x650x690

A

830x650x690

A

mm

Weight:

Weight of machine without accessories

G

140

G

135

G

kg

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

81

1.4.3 Technical data for series HSE 800 and HSE 1000

The table below shows the High Pressure Cleaner technical data for series

HSE 800 and HSE 1000.

Designation HSE 800 HSE 1000 Unit

Operating pressure:

Standard nozzle

Hot water (with standard nozzle)

In nitely variable

Permissible operating pressure

Max. reaction force

B

25045

120

30 - 120

130

28

B

2505

180

30 - 180

200

49

B

MEG

bar

bar

bar

N

Discharge capacity:

In nitely variable (water) 390 - 780 500 - 1000 l/h

Temperature:

Max. delivery temperature

Max. operating temperature

In nitely variable

Heating capacity (net)

T

30

70

30 - 70

18/24

T

30

70

30 - 70

24/30

T

°C

°C

°C

kW

Electrical input power (mains):

Voltage (frequency)

Consumption

Facility power outlet requires

fuse with

N

3 x 400 ~ (50)

23/32

35/50 (inert)

1

N

3 x 400 ~ (50)

32/38

50/63 (inert)

1

N

V (Hz)

kW

A

Capacities and suction quantity:

H. P. Pump motor oil W 15/40

Chemical suction quantity

F

0,5

0 - 10

F

0,5

0 - 10

F

l

l/h

Dimensions:

Length x Width x Height

A

830x650x690

A

830x650x690

A

mm

Weight:

Weight of machine without

accessories

G

120

G

125

G

kg

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

82

1.5 General function of High Pressure Cleaner

1.5.1 General function of series HS and HSC

The water from the water system ows through the water inlet (01) to the oat

container (02), when the trigger gun (17) is activated (see gure 3). The low

water cut off (03) switches off the High Pressure Cleaner, when the oat con-

tainer (02) is empty.

The high pressure pump (05) absorbes the water from the oat container (02)

through the low pressure injector (04). The high pressure pump (05) pressuri-

zes the water to the adjusted operating pressure.

The pressure switch (07) monitors the operating pressure. It switches on the

fuel pump (26) for the oil burner (27) in the heat exchanger (14), when the

pressure exceeds 25 bar.

When the trigger gun (17) is activated, the water is pumped through the unloa-

der valve (08). This is an adjustable control element for reducing the operation

pressure.

After the non return valve (09), which is integrated in the unloader valve (08),

the pressure gauge (10) indicates the operating pressure. The pressure switch

(11) switches on the High Pressure Cleaner, when the trigger gun (17) is

activated and the pressure is under a threshold of 25 bar.

The safety valve (12) prevents an unallowed pressure increase. Then the

water will be turned outside by the safety valve drain.

Via the ow switch (13) the water is fed to the heat exchanger (14). The ow

switch (13) switches off the oil burner (27) in the heat exchanger (14), when

the water ow is too less. The thermostat (15) is used for setting the desired

water temperature.

Depending on the chemical metering valve (20) setting the cleaning detergent

may be admixed to the water from one of two external connected cleaning

detergent containers (18 or 19).

The chemical low pressure injector (04) causes a suction in the cleaning

detergent path, when the high pressure pump (05) is activated and the che-

mical metering valve (20) is opened. The resulting underpressure sucks the

cleaning detergent and admixes it through the low pressure injector (04) into

the water circuit. The chemical metering valve (20) provides also the cleaning

detergent dilution adjustment. Whithout underpressure, the non return valve

(21) sepearates the cleaning detergent circuit from the water circuit.

The fuel oil pump (26) conveys the fuel oil from the external installed fuel oil

container through the fuel oil lter (24) to the oil burner (27). The ame control

(23) switches off the High Pressure Cleaner, if failures occur.

Hochdruck-Reinigungs-Systeme High-Pressure-Systems

83

When exceeding the determined exhaust threshold, the maximum thermostat

(28) switches off the High Pressure Cleaner and locks it.

01 Water inlet 10 Pressure gauge 20 Chemical metering valve

02 Float container 11 Pressure switch 21 Non return valve

03 Low water cut off 12 Safety valve 22 Temperature monitoring

04 Chemical low pressure 13 Flow switch for pump

injector 14 Heat exchanger 23 Flame control

05 High pressure pump 15 Thermostat 24 Fuel oil lter

06 Pump motor 16 High pressure outlet 25 Burner motor

07 Pressure switch 17 Trigger gun 26 Fuel oil pump

08 Unloader valve 18 Chemical draw external 27 Oil burner

09 Non return valve 19 Chemical draw external 28 Max. thermostat (exhaust)

Figure 3 High Pressure Cleaner series HS, functional diagram

This manual suits for next models

15

Table of contents

Other EHRLE Pressure Washer manuals