MAKINEX DPC-2200 User manual

DUAL PRESSURE CLEANER

DPC-2200

OPERATOR’S MANUAL

Rev 0920

Table of Contents

INTRODUCTION ...............................................................................................................................................1

DISCLAIMER ........................................................................................................................................................2

ABOUT THIS MANUAL.........................................................................................................................................3

KEY TERMS..........................................................................................................................................................3

SAFETY INFORMATION ....................................................................................................................................4

EMERGENCY INFORMATION...............................................................................................................................8

SAFETY DECALS ...................................................................................................................................................8

PRODUCT DESCRIPTION AND SPECIFICATION ................................................................................................10

OVERALL MACHINE DIMENSIONS.....................................................................................................................11

CONTROLS AND FEATURES...............................................................................................................................13

OPERATION ...................................................................................................................................................15

OIL LEVEL CHECK...............................................................................................................................................15

REFUELING........................................................................................................................................................16

OPERATING YOUR PRESSURE CLEANER............................................................................................................17

1. HOW TO PRE-START PRESSURE CLEANER ...........................................................................................17

2. ATTACHING HIGH-PRESSURE HOSE TO SPRAY-GUN ...........................................................................17

3. CONNECT GARDEN HOSE TO WATER INLET CONNECTION .................................................................18

4. ADJUST VALVE POSTION TO SURFACE-CLEANER ................................................................................19

5. START THE ENGINE..............................................................................................................................19

6. TWO TYPES OF OPERATION ................................................................................................................20

7. NOZZLE................................................................................................................................................20

8. RETRACTABLE HANDLES......................................................................................................................21

9. STOPPING THE PRESSURE CLEANER....................................................................................................21

MAINTENANCE ..............................................................................................................................................22

GENERAL RECOMMENDATIONS: ......................................................................................................................22

GENERAL MAINTENANCE .................................................................................................................................23

CLEAN DEBRIS...............................................................................................................................................23

CHECK AND CLEAN INLET FILTER ..................................................................................................................23

CHECK HIGH PRESSURE HOSE.......................................................................................................................23

CHECK SPRAY GUN........................................................................................................................................24

CHECK WAND................................................................................................................................................24

NOZZLE MAINTENANCE ................................................................................................................................24

PUMP MAINTENANCE ......................................................................................................................................25

CHANGING PUMP OIL...................................................................................................................................25

CHECKING PUMP OIL LEVEL..........................................................................................................................26

LENGTHY PUMP LAY-OFFS............................................................................................................................27

PUTTING THE PUMP BACK INTO SERVICE.....................................................................................................27

SURFACE-CLEANER MAINTENANCE..................................................................................................................28

ENGINE MAINTENANCE ....................................................................................................................................28

STORAGE...........................................................................................................................................................28

STORAGE WITH FUEL IN TANK......................................................................................................................28

RUST PREVENTION IN CYLINDERS.................................................................................................................28

STORAGE OF PRESSURE CLEANER ................................................................................................................29

OTHER STORAGE TIPS ...................................................................................................................................29

TROUBLESHOOTING.......................................................................................................................................30

LIMITED WARRANTY......................................................................................................................................32

WARRANTY EXCLUSIONS ..................................................................................................................................33

OWNER’S RESPONSIBILITY UNDER LIMITED WARRANTY: ................................................................................34

CONTACT INFORMATION...............................................................................................................................35

APPENDIX A- RISK ASSESSMENT .......................................................................................................................35

Page 1 of 38

INTRODUCTION

Thank you for purchasing a MAKINEX product.

This manual provides information and procedures to safely operate and maintain

the Dual Pressure Cleaner DPC-2200 Range. For your own safety and protection

from injury, carefully read, understand and observe the safety instructions

described in this manual.

Keep this manual or a copy of it with the machine. If you lose this manual or need

an additional copy, please contact MAKINEX. This machine is designed and built

with user safety in mind; however, it can present hazards if improperly operated

and serviced. Please follow the operating instructions carefully. If there are any

questions regarding operating or servicing of this machine, please contact

MAKINEX.

The information contained in this manual was based on machines in production at

the time of publication. MAKINEX reserves the right to change any portion of this

information without notice.

All rights, especially copying and distribution rights are reserved.

Copyright 2019 by MAKINEX.

No part of this publication may be reproduced in any form or by any means,

electronic or mechanical, including photocopying, without express written

permission from MAKINEX.

Any type of reproduction or distribution not authorised MAKINEX represents an

infringement of valid copyrights and will be persecuted. We expressly reserve the

right to make technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

DPC-2200 USER MANUAL Page 2 of 38

DISCLAIMER

MAKINEX and its affiliates take no responsibility for any damage, injury or death

resulting from the incorrect or unsafe use of this product. Use of this product

should be undertaken by competent persons only. It is the operator’s responsibility

to ensure that the following safety procedures are followed. If you are unsure, do

not operate this product.

Record the model and serial numbers as well as date and place of purchase for

future reference. Have this information available when ordering parts and when

making technical or warranty inquiries

MAKINEX SUPPORT

Refer to contact details on pg. 35

MODEL NO.

DPC-2200

SERIAL NO.

DATE OF PURCHASE

PURCHASE LOCATION

DPC-2200 USER MANUAL Page 3 of 38

ABOUT THIS MANUAL

This manual uses the following symbols to help differentiate between different

kinds of information. The safety symbol is used with a key word to alert you to

potential hazards in operating and owning power equipment. Follow all safety

messages to avoid or reduce the risk of serious injury or death.

KEY TERMS

READ

CAREFULLY

READ CAREFULLY –refers to important information that

should be paid careful attention.

CAUTION

CAUTION - indicates a potential hazardous situation which,

if not avoided, may result in minor or moderate injury

WARNING

WARNING –indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury

DANGER

DANGER –indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury

PROHIBITED

PROHIBITED –identifies actions that should never be

carried out by anyone interacting with the machine.

These safety warnings do not eliminate all possible hazards that could occur

therefore it is essential to use common sense and to strictly follow any

instructions to prevent accidents.

DPC-2200 USER MANUAL Page 4 of 38

SAFETY INFORMATION

WARNING

Read this manual thoroughly before operating your

pressure cleaner. Failure to follow instructions could

result in serious injury or death

DANGER

RISK OF EXPLOSION OR FIRE

Fuel and its vapours are extremely flammable and

explosive

Fire or explosion can cause severe burns or death

ALWAYS shut off engine and allow it to cool a least 2 minutes before adding

fuel to the tank

ALWAYS use care in filling tank to avoid spilling fuel. Move pressure cleaner

away from fuelling area before starting engine.

ALWAYS keep maximum fuel level below top of tank to allow for expansion.

ALWAYS operate and use equipment in well ventilated areas free from

obstructions. Equip areas with fire extinguishers suitable for gasoline fires

ALWAYS keep pressure cleaner a minimum of 1.2m away from surfaces (such

as houses, automobiles, or live plants) that could be damaged from muffler

exhaust heat.

ALWAYS store fuel in an OSHA approved container, in a secure location away

from work area.

NEVER spray flammable liquids.

In the event of a fuel spill, ensure machine and entire area is cleaned of excess

before operation.

DANGER

RISK OF BREATHING

Running engine gives off Carbon Monoxide, an

odourless, colourless, poisonous gas.

Breathing Carbon Monoxide can cause nausea,

fainting or death.

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting or poisoning.

ALWAYS operate pressure cleaner in a well-ventilated area. Avoid enclosed

areas such as garages, basements etc.

DPC-2200 USER MANUAL Page 5 of 38

ALWAYS keep exhaust gas from entering a confined area through windows,

doors, ventilation intakes, or other openings.

ALWAYS follow manufacturer’s recommendations, use a respirator or mask

whenever there is a chance that vapours may be inhaled.

If the operating area becomes enclosed, turn off engine and release system

pressure by pulling gun trigger. Immediately leave the affected area.

WARNING

RISK OF FALL HAZARD

Use of pressure cleaner can create puddles and

slippery surfaces.

Kick back from spray gun can cause you to fall.

Keep operating area clear of all persons, pets and obstacles.

DO NOT operate the product when fatigued or under the influence of alcohol

or drugs. Stay alert at all times.

DO NOT operate the machine with missing or broken parts.

NEVER leave wand unattended while unit is running.

Keep children away from pressure cleaner at all times.

DO NOT overreach or stand on an unstable support. If you become unstable

during use, release the trigger and stop engine if necessary. Re-assess

operating area before commencing operation.

The cleaning area should have adequate slopes and drainage to reduce the

possibility of a fall due to slippery surfaces. If the area becomes slippery or

unstable, turn off engine and release system pressure by pulling gun trigger.

Allow the area to drain and assess when suitable to operate again.

Be extremely careful if you must use the pressure cleaner from a ladder,

scaffolding, or any other off ground location.

Firmly grasp spray gun with both hands when using high pressure spray to

avoid injury when spray gun kicks back.

NEVER spray near power source.

DPC-2200 USER MANUAL Page 6 of 38

WARNING

RISK OF FLUID INJECTION

The high-pressure stream of water that this equipment

produces can cut through skin and its underlying

tissues, leading to serious injury and possible

amputation. Spray guns trap high pressure, even

when engine is stopped and water is disconnected,

which can cause injury.

Should the spray penetrate the skin, SEEK MEDICAL

ATTENTION IMMEDIATELY

ALWAYS point spray gun in safe direction and squeeze trigger, to release

high pressure, every time you stop the engine.

NEVER aim spray gun at people, animal, or plants.

NEVER place hands in front of nozzle.

Make sure hose and fittings are tightened and in good condition.

DO NOT allow hose to contact muffler.

NEVER attach or remove wand or hose fittings while system is pressurised.

Use only hose and high-pressure accessories rated for pressure higher than

your pressure cleaner’s psi.

To relieve system pressure, shut off engine, turn off water supply, and pull

gun trigger until water stops flowing.

DO NOT allow children to operate pressure cleaner.

NEVER direct the spray jet at any surface that may contain asbestos material.

DO NOT leave spray gun unattended while machine is running.

NEVER use a spray gun which does not have a trigger lock or trigger guard in

place and in working order.

ALWAYS be certain spray gun, nozzles and accessories are correctly

attached.

ALWAYS wear personal protective clothing such as goggles, ear muffs,

gloves, and closed foot wear.

DPC-2200 USER MANUAL Page 7 of 38

DANGER

RISK OF CHEMICAL BURN

Use of acids, toxic or corrosive chemicals,

poisons, insecticides, or any kind of flammable

solvent with this product could result in serious

injury or death.

Wear protective clothing to protect eyes and skin from contact with sprayed

material.

DANGER

RISK OF HOT SURFACES

Contact with hot surfaces, such as engines

exhaust components, could result in serious burn.

During operation, touch only the control surfaces of the pressure cleaner.

Keep children away from the pressure cleaner at all times. They may not be

able to recognise the hazards of this product.

DANGER

RISK OF MOVING PARTS

Starter and other rotating parts can entangle

hands, hair, clothing, or accessories.

DO NOT wear loose clothing, jewellery or anything that may be caught in the

starter or other rotating parts.

Tie up long hair and remove jewellery.

DANGER

RISK OF EYE INJURY

Spray can splash back or propel objects.

ALWAYS wear safety goggles when using this equipment or in vicinity of

where equipment is in use.

Before starting the pressure cleaner, be sure you are wearing adequate safety

goggles.

NEVER substitute safety glasses for safety goggles.

DPC-2200 USER MANUAL Page 8 of 38

EMERGENCY INFORMATION

In the event of an emergency, stop the machine immediately.

1. This product is fitted with a ‘hold to activate’ mechanism which is the spray gun

trigger. Upon releasing grip, the high-pressure water flow will be automatically

stopped.

2. To disable the product, turn the red ignition switch to the ‘off’ position. See

picture below. This will immediately stop the engine.

3. Further to the above, the water flow can be diverted from the spray gun by

turning the 3-way valve to divert the water to the Surface-Cleaner.

Always ensure all safety information is observed before re-commending work.

IGNITION SWITCH

3-WAY VALVE

IGNITION SWITCH

DPC-2200 USER MANUAL Page 9 of 38

SAFETY DECALS

DPC-2200 USER MANUAL Page 10 of 38

PRODUCT DESCRIPTION AND SPECIFICATION

The MAKINEX Dual Pressure Cleaner DPC-2200 Range is a versatile, 2 in 1

compact 2200 psi pressure cleaner. It is designed and engineered to simplify the

process of pressure washing. The pressure cleaner includes a combination of a

rotary cleaner, a spray gun, a control valve, ten metres of high-pressure hose,

heavy duty Italian- made pump, and the reliable Briggs and Stratton XR 950 pull

start engine, all mounted on a compact, easy to transport, durable galvanised steel

frame.

Applicable Australian standards:

- AS4233.1 High Pressure Water Jetting Part 1. Safe Operation and

Maintenance.

- AS4233.2 High Pressure Water Jetting Part 2. Construction and Performance.

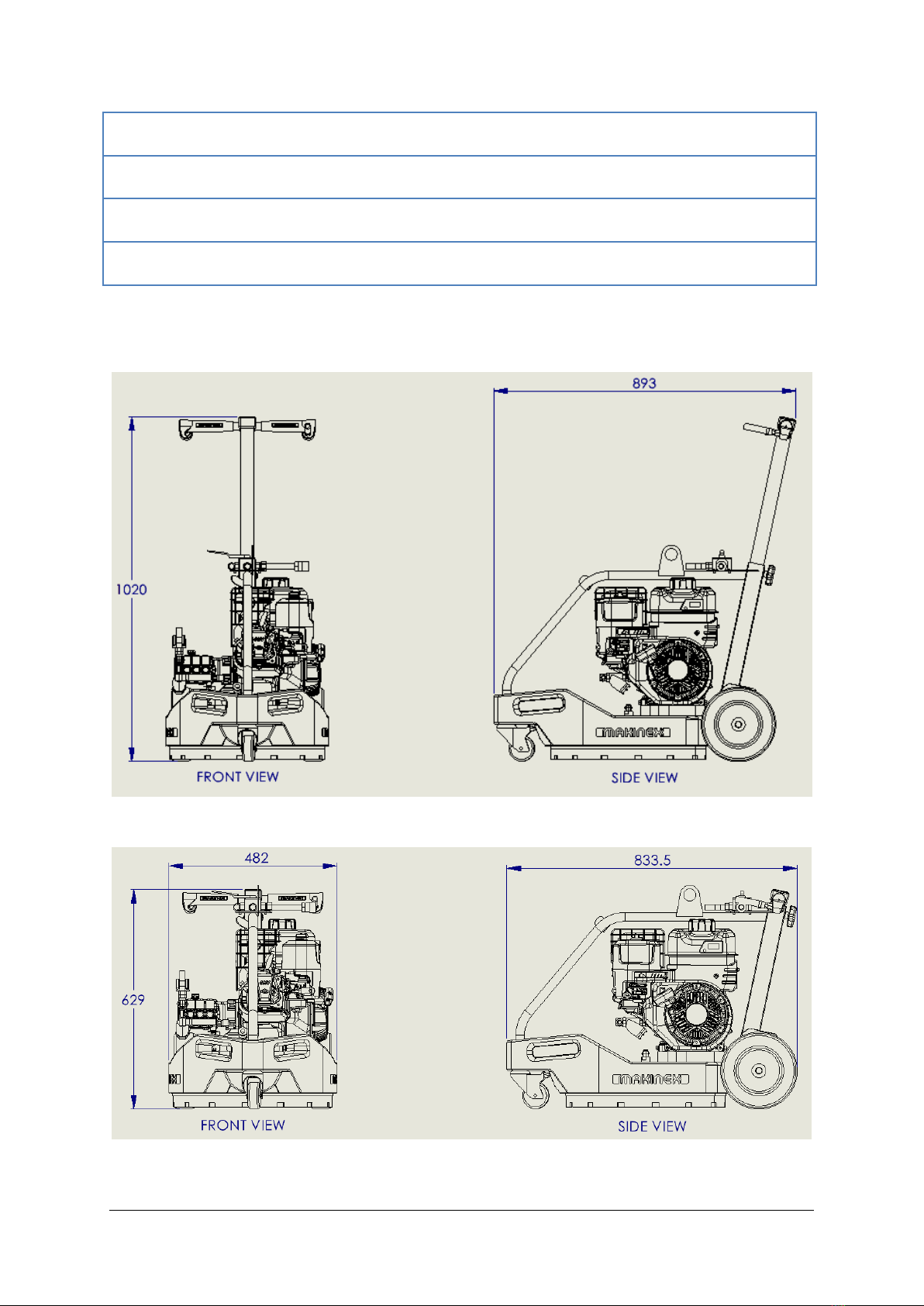

OVERALL MACHINE SPECIFICATIONS

MODEL

DPC-2200

OVERALL WEIGHT

40kg/88.2lb

OVERALL WIDTH

482mm/19.0inch

HANDLE FOLDED HEIGHT

629mm/24.8inch

HANDLE EXTENDED HEIGHT

1020mm/40.2inch

HANDLE FOLDED LENGTH

833.5mm/32.8inch

HANDLE EXTENDED LENGTH

893mm/35.2inch

HOSE LENGTH

10m/32.8ft

PRESSURE OUTPUT

2200psi/152bar

FLOW RATE

11L/min

(3.0 gal/min)

ENGINE

5.5HP BRIGGS AND STRATTON XR 950 pull start

GEAR BOX

NONE

NOISE LEVEL @ HANDLE

92dBA

NOISE LEVEL @ 7m

88dBA

SOUND POWER LEVEL (LWA)

109dB

DPC-2200 USER MANUAL Page 11 of 38

SURFACE-CLEANER

460mm (18inch)

BALL VALVE

500bar/ 7252psi rated 3-way ball valve

TRIGGER GUN

358.5bar/ 5200psi rated

WAND LENGTH

900mm/35.4inch

OVERALL MACHINE DIMENSIONS

DPC-2200 USER MANUAL Page 12 of 38

PUMP SPECIFICATIONS

MODEL

DPC-2200 (With JRV3G30)

PRESSURE OUTPUT MAX

2200 psi/152 bar

FLOW RATE MAX

11L/min (3.0 gal/min)

OIL TYPE

10W30

RPM

2600

WEIGHT

4kg/8.8lbs

ENGINE SPECIFICATIONS

ENGINE TYPE

Briggs and Stratton XR950

Air-cooled 4-stroke OHV

BORE x STROKE

68.3 x 55.9mm/2.7 x 2.2inch

DISPLACEMENT

208cm³/12.7inch³

MAX POWER OUTPUT

6.5HP (4.8kW) @ 2600 rpm

GROSS TORQUE

9.5 lb-ft (12.88Nm) @ 2600 rpm

PTO SHAFT ROTATION

Counter-clockwise (from PTO shaft side)

COMPRESSION RATIO

8.5:1

CARBURATOR

Gravity Feed, Needle and Seat Float

IGNITION SYSTEM

Electronic Magnetron Ignition Module

STARTING SYSTEM

Recoil Starter

LUBRICATION SYSTEM

Splash

GOVERNOR SYSTEM

Mechanical

OIL CAPACITY

0.6L (0.63 US qt)

FUEL TANK CAPACITY

3.1L (3.1 U.S. qts)

FUEL

Unleaded 86 Octane or higher

DRY WEIGHT

16kg (35lbs)

RUN TIME (Full tank)

Full Load

75% Load

50% Load

1.5 hours

2.25 hours

2.75 hours

DPC-2200 USER MANUAL Page 13 of 38

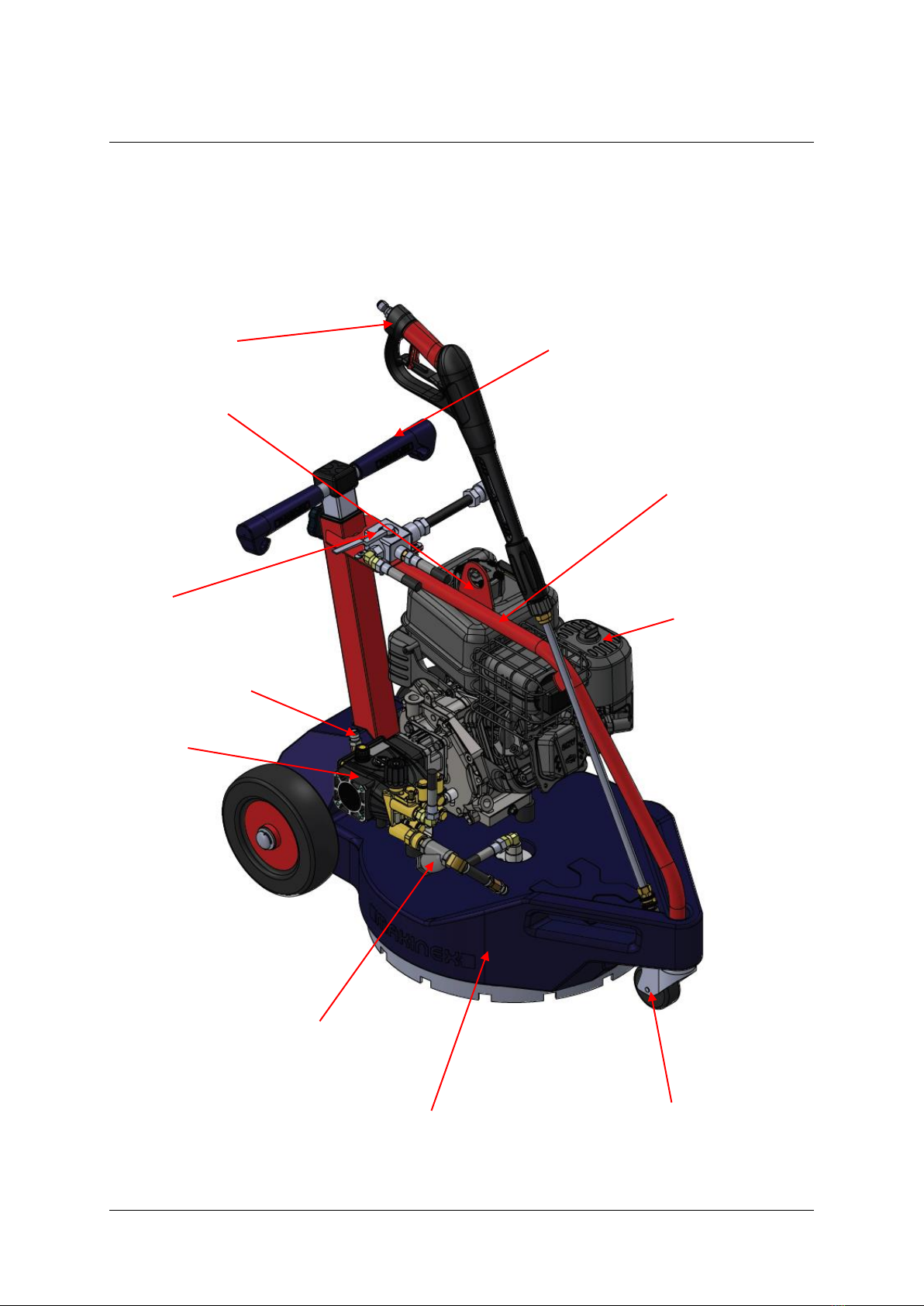

CONTROLS AND FEATURES

SPRAY GUN

LIFTING EYE

CASTOR WITH

BRAKE

3-WAY VALVE

POWDER COAT

FRAME

RETRACTABLE

HANDLE

AR PUMP

ROTOMOULD BASE

BRIGGS AND STRATTON

PULL START ENGINE

GARDEN HOSE CONNECTOR

INLET WATER FILTER

DPC-2200 USER MANUAL Page 14 of 38

FEATURES

Valve for switching between surface cleaner and wand

Durable powder coated frame

Easily manoeuvrable with front swivel castor

Internal Bypass Valve to protect seals from overheating

Thermal dump valve for over heat discharge

Multi cushion isolators for vibration reduction

Detachable 10m high pressure hose

Spray gun included and mounted on frame

Built in 2200 psi Surface-Cleaner

Compact design for easy storage and transport

Lifting point for transportation

DPC-2200 USER MANUAL Page 15 of 38

OPERATION

OIL LEVEL CHECK

CAUTION

Check the engine oil level with the engine stopped and in a

levelled position

1. Clean area around oil fill and remove oil cap.

2. Check the dipstick to ensure there is enough

oil.

3. If there is not enough oil, using oil funnel

(optional), slowly pour contents into oil fill

opening.

4. Replace oil fill cap and tighten.

5. For pump oil, see ‘CHECKING PUMP OIL

LEVEL’ in maintenance section of this manual.

NOTE: Refer to XR 950 Manual for more in-depth instructions

NOTE: New machines will be pre-oiled from MAKINEX with:

Power Equipment Engine Oil –SAE 10W-30, API SJ

NOTE: IMPROPER treatment of pressure

cleaner can damage it and shorten its life.

DO NOT attempt to start the engine before it

has been properly serviced with the

recommended oil. This may result in an

engine failure.

DPC-2200 USER MANUAL Page 16 of 38

REFUELING

WARNING

FAILURE TO USE FUEL AS RECOMMENDED IN THIS

MANUAL WILL VOID WARRANTY

DO NOT use unapproved gasoline such as ethanol-based fuel.

DO NOT mix oil with gasoline.

DO NOT modify engine to run on alternate fuels.

WARNING

Fuel and fuel vapour are extremely flammable

and explosive. Fire or explosion from misuse

of fuel can cause severe burns and even death.

FIRE

HAZARD

WARNING

Always ensure that fuel tanks are filled outdoors.

1. Turn engine OFF and let it cool for at least two minutes before removing fuel

cap.

2. Loosen fuel cap slowly to release pressure.

3. Slowly add unleaded gasoline to fuel tank. DO NOT fill fuel above baffle to allow

for appropriate space fuel expansion.

4. Wait for spilled fuel to evaporate before starting the engine.

WARNING

Keep fuel away from sparks, open flames, pilot lights,

heat and other ignition sources.

DO NOT light a cigarette or smoke near open fuel tank

or container.

DPC-2200 USER MANUAL Page 17 of 38

OPERATING YOUR PRESSURE CLEANER

1. HOW TO PRE-START PRESSURE CLEANER

To start your pressure cleaner for the first time, follow these instructions. This

information also applies if you let the pressure cleaner sit idle for at least a day.

1.1 Place pressure cleaner near an outside water source capable of supplying

water at a flow rate at least 5 gallons/19L per minute and no less than 20 psi at

pressure cleaner end of garden hose.

1.2 Check all high-pressure hose connections are tightly connected to the pump,

valve, spray gun and Surface-Cleaner.

1.3 Make sure there are no kinks on hoses

1.4 Make sure the unit is in a levelled position.

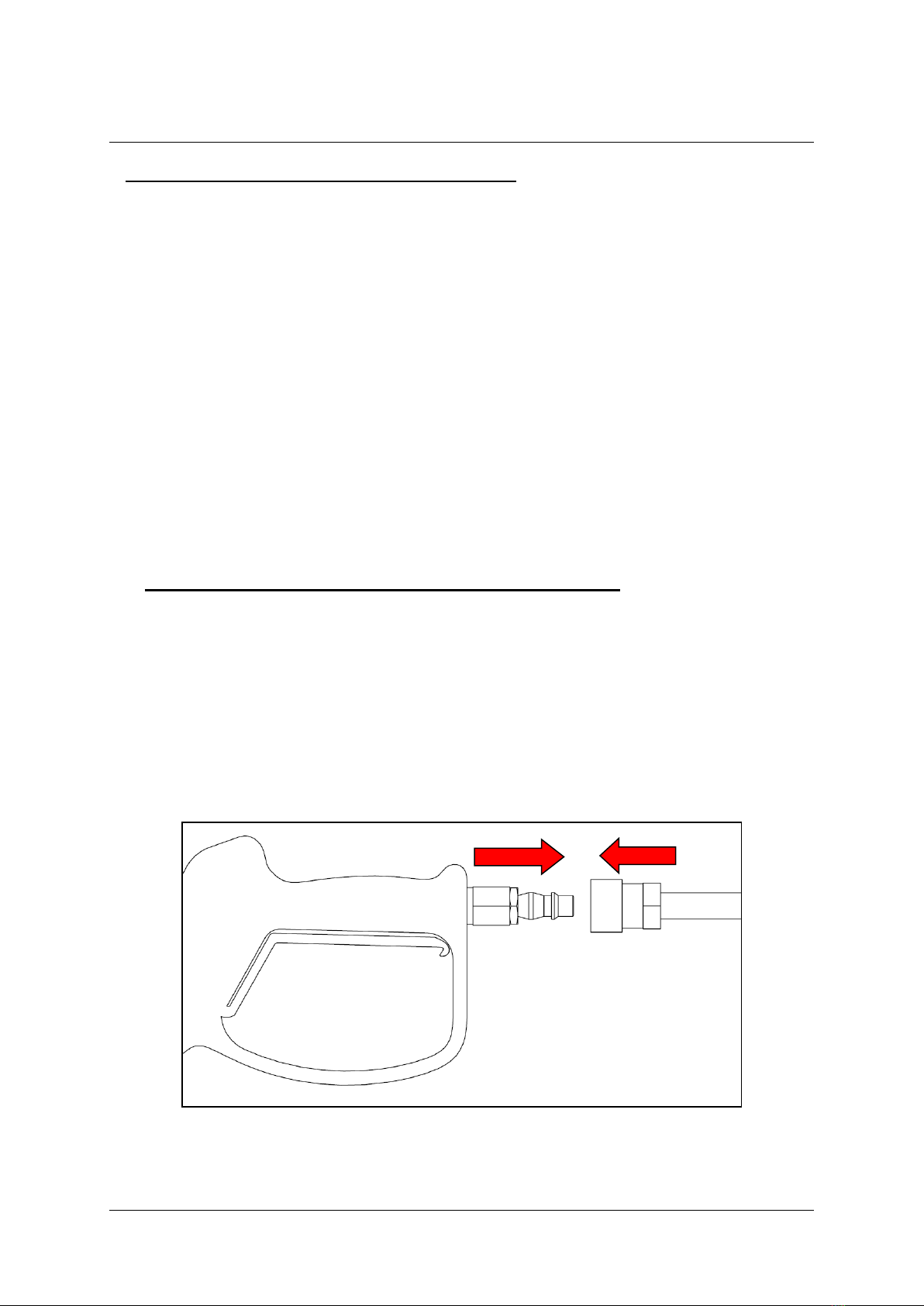

2. ATTACHING HIGH-PRESSURE HOSE TO SPRAY-GUN

2.1 The spray gun is preassembled to a swivel male quick-connect fitting.

2.2 Connect the Quick-Connect female fitting from the high-pressure hose to

the spray gun as shown by hand, make sure it’s a tight fit and the threads

are not cross threaded (the connection is a self-sealed one, hence no

plumbing is needed)

Table of contents

Other MAKINEX Pressure Washer manuals

Popular Pressure Washer manuals by other brands

A-iPower

A-iPower PWE2000 Owner's Manual and Operating Instructions

Jula

Jula MEEC TOOLS 009875 operating instructions

U-Line

U-Line H-8942 manual

Scheppach

Scheppach HCE1450 Translation of original operating manual

General Pump

General Pump 2100306 Operator's manual

Snapper

Snapper 580.752640 Operator's manual