EHV Kanuk 3 User manual

Kanuk® 3 & 4 Classic/with hotplate

und Turbo 1 & 2

Manual

Brilliantly simple – simply brilliant.

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde

2

1. Construction manual

1.1 General requirements

1.2 Weight

1.3 General requirements

1.3.1 Construction manual/accessories

1.4 Combustion air supply

1.5 Couplers

1.6 Distance to combustible components and furniture/ Fire protection

1.7 Chimneys

2. Directions for use

2.1 Safe combustibles

2.2 Use of Kanuk® hot-air kilns

2.3 Buttery control valve

2.4 Combustion air regulation

2.5 Heating up

2.6 Chimney re

2.7 Procedures during incidents - safe decommissioning

2.8 Relling

2.9 Bed of ashes

2.10 Cleaning

3. Guarantee

3.1 Guarantee/Warranty

4. Kanuk® Turbo additional information

Thank you for choosing a Kanuk® hot-air kiln. We wish you lots of fun

trying out your new Kanuk®. Please read this manual carefully before

rst use. It contains important notes and information on installation,

operation, and safe use.

1. Construction manual

Please take into account that combustion installations may only be put into ser-

vice after a district master chimneysweeper has veried functionality and safety

of the exhaust system (chimney) and the heating appliance.This also applies to

the case of changes.

TABLE OF CONTENTS

3

4

4

4

5

5

6

6

8

8

8

9

9

10

10

10

11

11

11

12

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde 3

STRUCTURE AND COMPONENTS OF THE KANUK®

Kanuk®Classic Kanuk®with hotplate Kanuk®Turbo

4

8

7

1

2

3

6

5

1.1. General requirements

Structure and components of the Kanuk®

Kiln shell 1

Door with special Schott Robax® glass 2

Door locking mechanism 3

Gas ue pipe 4

Ash catch plate 5

Primary air regulation 6

Supply air controller for secondary air regulation 7

Secondary air regulation 8

4

8

2

3

67

5

11

2

3

4

56

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde

4

CONSTRUCTION MANUAL

1.3. General requirements

Please adhere to the respective prescriptions governed by public law when

installing your Kanuk®, especially those set by the state building code and the

corresponding ring directives.

1.3.1 Construction manual / accessories

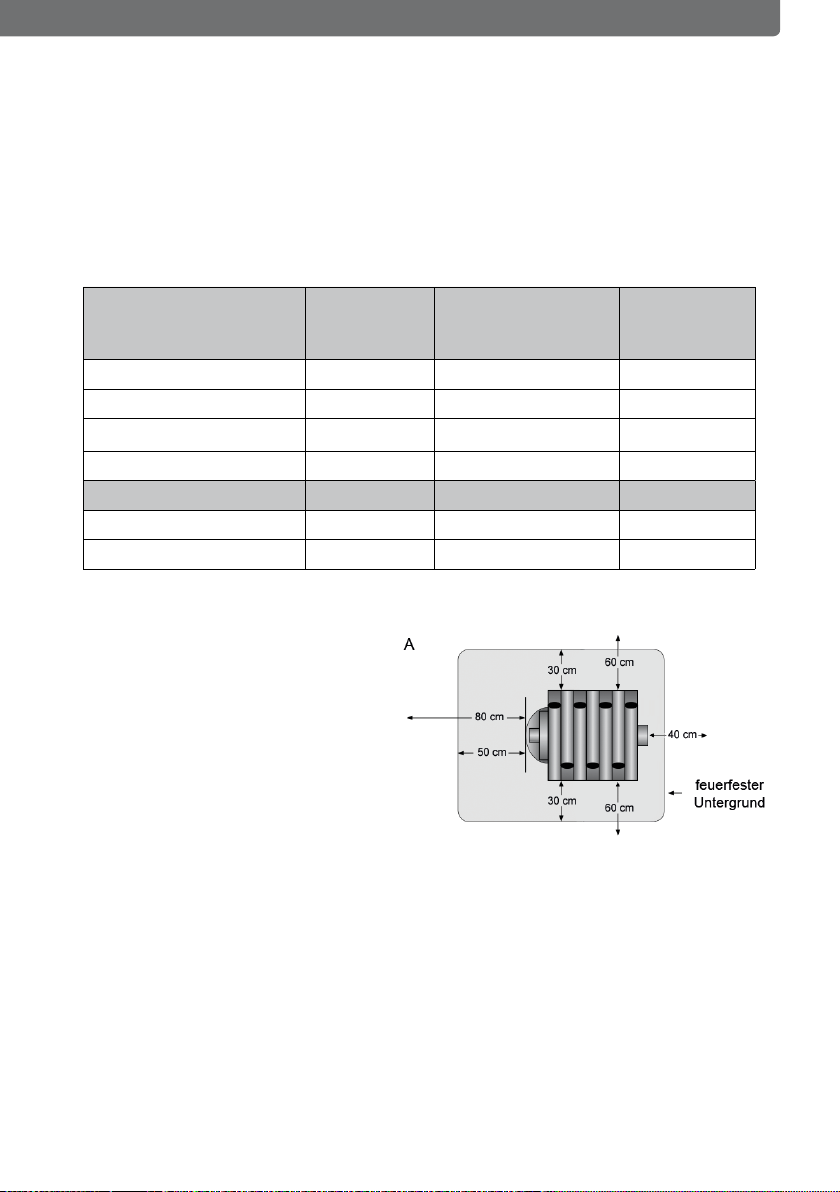

Ash catch plate

Remove the ash catch plate from its

packaging and clip it into the bolt underneath

the door from the top.

Kiln shell of the Kanuk® Classic

Step I

Push the hangers at the top and bottom

into the rst and last radiation tube. The

side panels will be clipped into the bottom

hangers.

Step II

Fix the side panels with the accompanying

screws at the top hangers.

Kanuk® model 3 Classic 4 Classic 3 HP* 4 HP Turbo 1 Turbo 2

Weight in kg 145 175 145 175 165 210

* HP = with hotplate

1.2. Weight

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde 5

CONSTRUCTION MANUAL

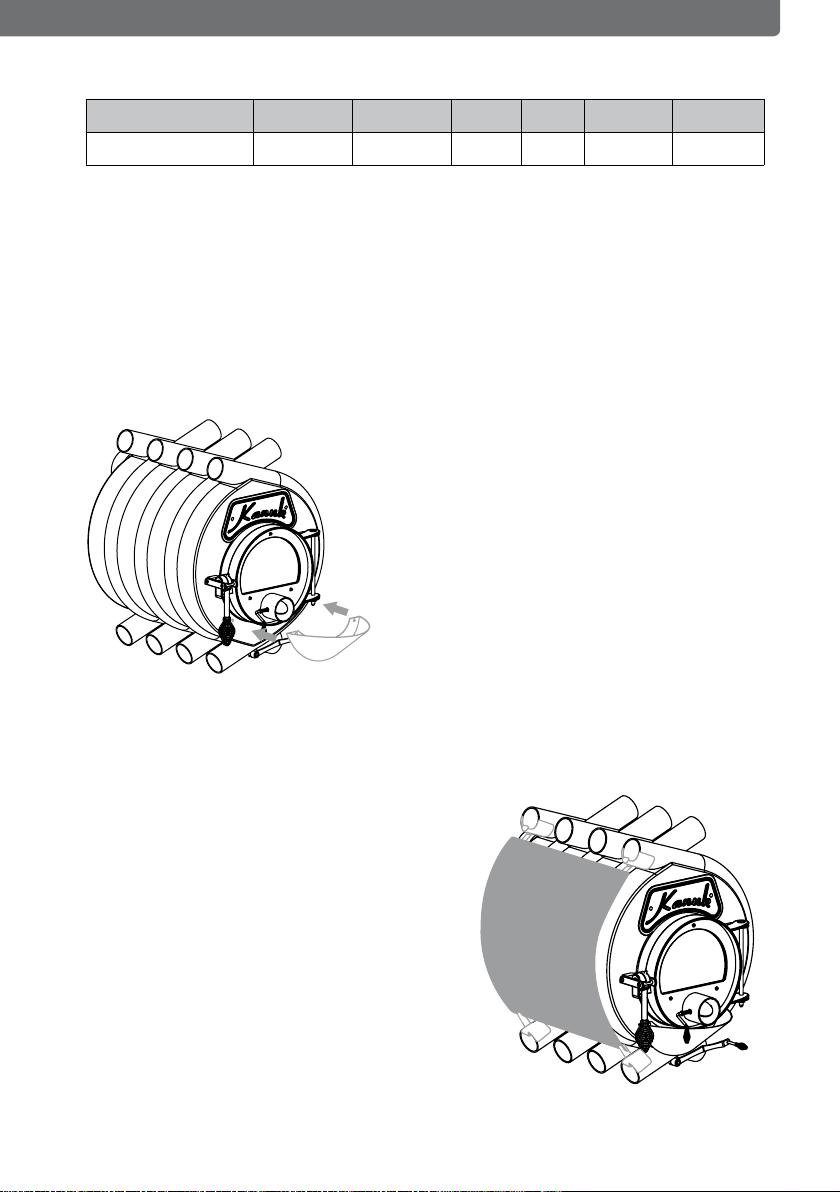

Kiln shell of the Kanuk® with hotplate

Step I

Push the hangers at the top and bottom

into the rst and last radiation tube.

The side panels will be clipped into the

bottom hangers.

Step II

Fix the side panels with the accompanying

screws at the top hangers.

Self-closing door layout I

Remove the circlip of the door-xing bolt. Now pull the bolt

to the top and push it into the torsion spring. The medium

hanger of the spring will be xed on the doorframe. The ends

of the springs are to be xed behind the door suspension.

Now return the bolt to the primary position and x it with the

circlip. Please make sure to x the door additionally during

the entire process.

1.4. 1.4. Combustion air supply

The combustion air supply is sucient for Kanuk® hot-air kilns up to a nominal

heating capacity of 27 kW, provided there is at least one door or

window to be opened. Furthermore, the room needs a cross-section of

at least 150 cm². The room must not fall below 4 m³ per kW of nominal

heating capacity.

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde

6

1.5. Couplers

The coupler between the heat system and the exhaust system (chimney) ought

to be as short as possible, straight and needs to be installed in rising position.

You may need to caulk the links. For cleaning the couplers, there ought to be at

least one opening left free.The material density must not fall below 2 mm.

1.6. Fire protection – distance to combustible components and furniture

forward

from the side

with side plate /

without side plate

back

Kanuk® 3 Classic 80 cm 50 cm / 80 cm 40 cm

Kanuk® 4 Classic 80 cm 55 cm / 90 cm 40 cm

Kanuk® 3 with hotplate 80 cm 50 cm / 80 cm 40 cm

Kanuk® 4 with hotplate 80 cm 55 cm / 90 cm 40 cm

forward from the side back

Kanuk® Turbo 1 80 cm 80 cm 40 cm

Kanuk® Turbo 2 80 cm 90 cm 40 cm

CONSTRUCTION MANUAL

Flammable oor coverings

have to be protected by re-

resistant material.

In addition the material needs

to be placed also at least 50

cm in front of the stove and

30 cm next to it.

1.7. Chimneys

Kanuk® hot-air kilns don’t require a chimney of their own if the door

spring was tted for layout 1.The combustion measurements were

carried out according to the norm DIN 13384 parts 1, 2 and 3 with the value

triplet given in table 1.

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde 7

Table 1: Value triplet for measurements of chimneys according to DIN

13384 parts 1, 2 and 3:

Kanuk® model 3 Classic 4 Classic 3 HP* 4 HP Turbo 1 Turbo 2

Nominal heat output in kW 22 27 22 27 20 30

Eciency in % 83 82,4 83 82,4 83,7 82,4

Emission temperature in °C 238 238 238 238 238 238

CO2in % 9,89 9,89 9,89 9,89 9,89 9,89

CO in mg/m³ 1094 1196 1094 1196 992 1196

Exhaust ow rate in g/s 19,5 24,8 19,5 24,8 14,2 24,8

Dust in mg/m³ 29 36 29 36 22 36

Minimal chimney draft in Pa 12 12 12 12 12 12

* HP = with hotplate

Table 2: Combustion chamber performance data:

Kanuk® model 3 Classic 4 Classic 3 HP** 4 HP Turbo 1 Turbo 2

fuel consumption in kg/h 7 8,6 7 8,6 6,9 8,9

maximum log length in cm 65 80 65 80 65 80

maximum heatable volume

in m³ *

700 1000 700 1000 650 1000

maximum quantity of com-

bustible in kg

7 8,6 7 8,6 6,9 8,9

* depending on building structure, insulation, etc.

** HP = with hotplate

CONSTRUCTION MANUAL

Note: We can only guarantee the operational safety and the nominal heat

outputs of our Kanuk® hot-air kilns as long as the combustion measurements

of the chimneys were carried out according to the norm DIN 13384 part 1, 2

and 3 and was attested by a district master chimneysweeper.

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde

8

2. Directions of use

2.1. Safe combustibles

Only air-dried, natural logs of wood measuring between 25-80 cm in

length and 35 cm in diameter with less than 20% water content may be

used as combustibles. In case you use wood remainders, make sure it was

stored in a dry place for at least two years before using it as rewood.

Never use more than the given amount in table 2 at a time to prevent

overheating of the Kanuk® hot-air kiln. Don’t use treated or plastic-coated

wood, chip trays, sawdust, coal, coke, or similar combustibles!

2.2. Use of Kanuk®

Kanuk® hot-air kilns may only be used with combustion chamber door

closed. All Kanuk® hot-air kilns can be tted with a self-closing door

mechanism (layout 1).

2.3. Buttery control valve

Remember to open the buttery control valve in

the exhaust gas stub when using the Kanuk®

hotair kiln (position 0). The hand knob must be

pointing in the direction of the exhaust gas stub.

In case of a high draught of the chimney (see ta-

ble 1, feed pressure), the control valve in the ex-

haust gas stub can be partially closed (position

Z).

Note: Overheating and/or improper combustibles can result in

damage of the combustion chamber! See table 2: maximal combustible

amounts (given in kilograms per hour).

DIRECTIONS OF USE

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde 9

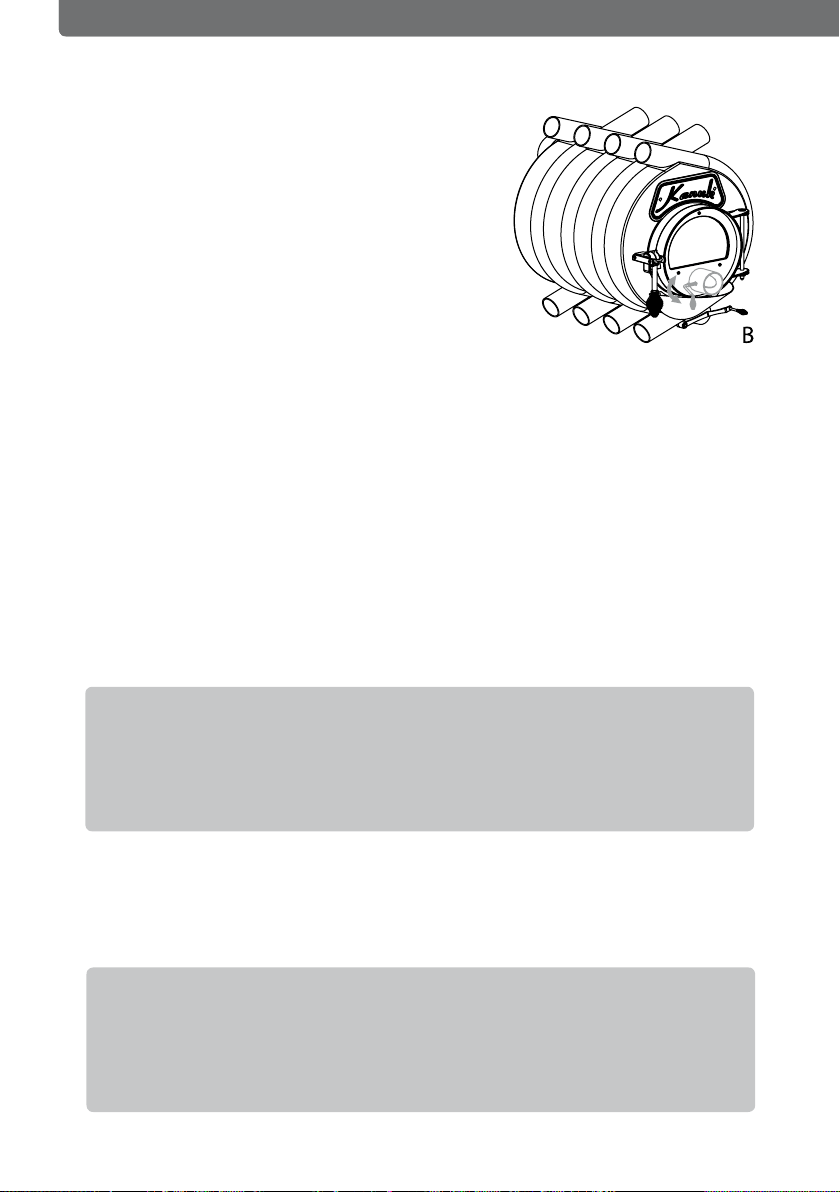

2.4. Combustion air regulation

Kanuk® hot-air kilns are tted with primary

(image B) and secondary (image A) air vents

for combustion air supply. During heating up

and use with nominal heat output, the primary

and secondary air vent in the rear wall must be

opened. The primary air vent (imageB) is prima-

rily meant for pane ventilation and ought to be

closed partially or fully only for incandescence.

By closing the secondary air vent in

the rear wall, the combustion air ven-

tilation will be choked. This can result in higher emission rate.

The secondary air vents cannot be closed fully for safety reasons.

2.5. Heating up

Fully open the control valve in the exhaust gas stub, the primary air vent in the

combustion chamber door, and the secondary air vent in the rear wall. For hea-

ting up, stack the rewood in a pyramid over screwed paper and cover it in thin

logs of wood.Then start the re. After heating up, ll up the Kanuk® hot-air kiln

with logs according to chapter 2.1.

Before the rst heating-up, make sure to check the correct installation of the vie-

wing window of the Kanuk® hot-air kiln. The screws for the hanger on the front

side of the combustion chamber door must be tightened to the degree that the

door remains movable (hand-tight).

Note: Kanuk® hot-air kilns are coated in high quality heat-resistant

paint. During the rst phase of heating up, the burn-in of the paint may

result in slight smoke development and odor nuisance. Make sure to

keep your windows and doors open when heating up the kiln for the

rst time.

DIRECTIONS OF USE

Note: For the protection of the stove you should pay attention to the

fact, that the stove is loaded moderately with rewood, so that the steel

can distend steadily. Because of the amazing temperature dierences

between the ambiant temperature and the temperature within the sto-

ve, there may be crackling noises withing the Kanuk®.

10

DIRECTIONS OF USE

2.6. Information in case of a chimney re

If you use the wrong combustible or if the combustible is still too wet, there is

the possibility of deposits in the chimney, which may cause a chimney re. The

air supply at the stove has to be closed immediately and of course you have to

contact the re brigade and your chimney sweeper as well. After the re is done,

the chimney needs to be checked by a specialist, to make sure that there are no

damages or leakinesses.

2.7. Procedure in case of incidences – safe shutdown

In some rare cases there is the possibility that there is no draught in the chimney

and that even a pilot re will not help. If that‘s the problem, you have to contact

a chimney sweeper, in no case try to light a bigger re. If there is smoke escaping

from the stove, of course the chimney sweeper has to be informed, too. Open

every window immediately, to make sure that there is enough fresh air available.

2.8. Relling

Open the primary air vent in the combustion chamber door and the se-

condary air vent in the rear wall and set the control valve in the exhaust

gas stub to position A. Then open the combustion chamber door and ll

with wooden logs until reaching the rear wall. Make sure to leave enough

space underneath the logs, as that will prevent the re from being hoked.

When close the combustion chamber door. Once the logs are well burnt,

you can consider curtailing the primary and secondary air vent to facilitate

a more regular burn-o. Make sure to leave the primary air vent open at all

times for the pane ventilation to function without interference.

2.9. Bed of ashes

Remember to leave a 5-10 cm layer of ashes on the ground of the combustion

chamber. The bed of ashes will protect the ground of the kiln from blowing.

Remove only excess ashes with a shovel every now and then. You can obtain

the required accessories from your Kanuk® co-contractor.

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde 11

DIRECTIONS OF USE

2.10. Cleaning

The gas leading parts of the Kanuk® hot-air kilns (bae plate, buttery

valve, etc.) and the connecting pieces need to be cleaned in case of de-

lement. Carry out a cleaning in all cases once during and after the heating

period. The sealing cord of the combustion chamber door needs to be re-

placed in case of damage.

3. Guarantee

3.1. Guarantee / Warranty

End consumers get a two-year guarantee. In case of commercial use, the gu-

arantee period is extended by 12 months. Viewing panes and ceramic sealing

cords are generally not included in the guarantee. In case of damage, please

contact your Kanuk® co-contractor in rst instance. Photos of the blemished

element and the location of installation as well as the exhaust system are requi-

red in general for handling cases of damage. Furthermore, please submit the

production number and a detailed description of damage. Ask your co-contrac-

tor for the required form sheet. Only original or spare parts accredited by the

manufacturer may be used. Wrong use and inobservance of this manual will

abrogate the warranty claim.

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde

12

KANUK® TURBO ADDITIONAL INFORMATION

4. Kanuk® Turbo additional information

This supplement provides additional information concerning the wood-

burning stoves Kanuk® Turbo. Please read these information carefully be-

fore using the Kanuk® Turbo.

Combustion air supply

For the Kanuk® Turbo wood stoves with a heat output up to 30 kW the

combustion air intake is sucient:

• when the location has at least one door to the outside

• or a window that can be opened (cross section >200 cm²)

The location should have a cubage of not less than 4 m² per kW heat out-

put.

Chimneys

Kanuk® Turbo wood-burning stoves don‘t need an own chimney. The re

rating results from DIN 13384 part 1, 2 and 3 with the triplet shown in

table 1.

Kanuk® Turbo wood-burning stoves don‘t need an own chimney. The re

rating results from DIN 13384 part 1, 2 and 3 with the triplet shown in

table 1.

Kanuk® model Turbo 1 Turbo 2

Nominal heat output in kW 20 30

E ciency in % 83,7 82,4

Abgastemperatur in °C 238 238

CO2in % 9,89 9,89

CO in mg/m³ 992 1196

Exhaust ow rate in g/s 14,2 24,8

Dust in mg/m³ 22 36

Minimal chimney draft in Pa 12 12

Note: We only guarantee operating safety and heat outputs from

our Kanuk® Turbo wood stoves, when the adequate re rating of the

chimney is proven with a calculation via DIN 13384 part 1, 2 and 3 and

when it is certicated by a chimney sweep.

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde 13

KANUK® TURBO ADDITIONAL INFORMATION

Table 2: Combustion chamber - performance characteristics

Kanuk® model Turbo 1 Turbo 2

fuel consumption in kg/h 5,7 8,6

maximum log length in cm 65 80

maximum heatable volume in m³ * 650 1000

* depending on building structure, insulation, etc.

Operation instruction for Kanuk® Turbo wood-burning stoves

Ventilator

The ventilator is installed at the back of the Kanuk® Turbo and it turns bet-

ween 1600 and 2000 m³ an hour.

The ventilator‘s power can be regulated stageless and it is possbile to con-

trol it additionnaly with the thermostat at the front‘s right side of the sto-

ve. The temperature indicator is xed at the front‘s upper part. It meters

the temperature between covering and combustion chamber.

temperature indicator control

Ventilator and control are supplied with 230 V via a normal power outlet.

Note: It is generally forbidden to put objects into the opening of the air

inlet. This can inuence the operating or damage the ventilator com-

pletely.

On/O

speed governor

ventilator

thermostat

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde

14

Connecting pieces - air ducts

The wood-burning stoves Kanuk® Turbo 1 and 2 oer connecting pieces

for forwarding/distribution of the warm air into air ducts above the stove‘s

dome. For the connection it is possible to use a normal aerating pipe (fol-

ded spiral-seam pipe). There is also the possibility to use pipe bends, T-

pieces, Y-pieces or similar connection pieces to forward the warm air.

Connection diameter:

Kanuk® Turbo 1 - 315 mm diameter

Kanuk® Turbo 1 - 315 mm diameter

The xation is made with self-tapping screws directly into the connecting

piece. Additionally you may use heat-resistant sealant.Warranty and eci-

ency of the Kanuk® Turbo wood-burning stoves can only be guaranteed

under consideration of the operating instruction.

KANUK® TURBO ADDITIONAL INFORMATION

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde 15

EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde

16 EHV GmbH • Entwicklung | Herstellung | Vertrieb • Hauptstraße 131 • 01744 Dippoldiswalde

EHV GmbH

Hauptstraße 131

01744 Dippoldiswalde

This manual suits for next models

6

Table of contents

Other EHV Stove manuals

Popular Stove manuals by other brands

Vermont Castings

Vermont Castings Resolute Installation planning guide

Stanley

Stanley ARGON F650 INSTALLATION, SERVICING AND USER OPERATING INSTRUCTIONS

EIRECO

EIRECO 740 Designed and manufactured in ireland

ACR Electronics

ACR Electronics Tenbury T5500 instruction manual

klover

klover BI-FIRE manual

Vermont Castings

Vermont Castings Jefferson 2822 Homeowner's installation and operating manual