EIK AMPHIBIOUS EXCAVATOR Series User manual

www.eikengineering.com

EIK Engineering Sdn. Bhd.

Address : No. 10 (PTD 5749), Jalan SiLC ¼, Kawasan Perindustrian SiLC, 79200 Nusajaya, Johor, Malaysia.

Tel : +607-531 9922

Fax : +607-531 9919

www.eikengineering.com

VER.1.09

Copyright © 2010 by EIK Engineering Sdn Bhd All right reserved

OPERATION MANUAL

AMPHIBIOUS EXCAVATOR SERIES

THIS SHOULD BE KEPT IN MACHINE AT ALL TIMES

www.eikengineering.com

THANK YOU FOR CHOOSING EIK AMPHIBIOUS UNDERCARRIAGE/EXCAVATOR

You are now the owner of an amphibious excavator that is designed and manufactured

by EIK Engineering Sdn. Bhd. that allowed you to carry out excavation activities in soft

terrain, swampy and muddy area. The unique feature of our amphibious excavator is the

undercarriage that has a patented pending technology that leads the industry. The

pontoon is designed with appropriate for variant excavator sizes to ensure that it is able

to float on water as a safety feature.

It is IMPORTANT that you read and observe the information and instruction contained in

this operation manual before using your amphibious undercarriage/excavator for the

first time. It will quickly enable you to become familiar with your excavator and help you

to assess potential hazard to yourself and to the machine while operating the EIK

amphibious undercarriage/excavator.

Failure to observe or adhere to operation safety notes and procedure may result in

accident and injury and breakdown that may incur loss of costly productive hours.

EIK is not responsible for any damage cause by ignorance of warning sign and failure to

observe and adhere to operation safety. This machine must be operated by qualified

operator with normal excavator license certified by local government.

The warranty term and condition or claims can be referred to EIK Engineering Product

Warranty Certificate.

We trust you derive great return on your investment with EIK amphibious

undercarriage/excavator.

Thank You

EIK ENGINEERING SDN BHD

www.eikengineering.com

CONTENT

1 SAFETY OPERATION

Understand Machine Operation 1

Wear Protective Clothing 1

Prepare Safety Equipment 2

Inspect the Machine 2

Inspection and Maintenance 3

Park Machine Safely 3

Operate the Machine with Wider Undercarriage 5

Launching Machine into Open Water 6

Landing the Machine from Open Water 7

Travelling the Machine in Open Water 8

Avoid Water Travelling During Bad Weather Condition 9

Avoid Digging Job in Floatation Mode 10

Digging at Recommended Water Depth 11

Operates the Boom, Stick and Bucket Carefully 13

Avoid Abuse Operation 13

Avoid Hammering Operation 14

Beware of Power Line 14

Travelling the Machine 15

General 15

Land 15

2 UNDERCARRIAGE MAINTENANCE

Track Tension 17

Track Rollers Lubrication 20

Greasing 20

Axle Bearing 20

Hydraulic Cylinder Pin & Bushing 22

Hydraulic Cylinder 23

Hydraulic Travel Motor Gear Oil 24

Spud Pile Winch Hydraulic Motor Gear Oil 25

Wearing Plates 28

Track Parts 29

Pontoon 31

Hydraulic Line 34

3 APPENDIX

Amphibious Undercarriage Maintenance Check List Table 36

www.eikengineering.com

1) SAFETY OPERATION

1.1 Understand Machine Operation

1.1.1 Only qualified operator with understanding and experience should operate the

amphibious excavator. This operation manual must be read carefully and operators

must understand all the contents before operate the amphibious excavator.

1.1.2 Operator must hold normal excavator license certified by local government. Training

must be conducted to inexperience operator before operating the machine.

1.1.3 Learn and remember the location and purpose of all controls, instruments, buttons,

indicator lamps and caution signs.

1.2 Wear Protective Clothing

1.2.1 Wear protective clothing and other safety equipment during machine installation,

operation and maintenance.

Figure 1.1

1.2.2 Prepare lifebelt inside the operator cabin before operating the machine in open water.

Safety life jacket must be worn for safety purpose.

Figure 1.2

1

www.eikengineering.com

1.3 Prepare Safety Equipment

1.3.1 Affix any provided safety sign stickers at the glass panel inside the operator cabin. The

stickers must be in the position where the operator can clearly read.

1.3.2 Fasten a complete first-aid kit and fully charged fire extinguisher at the amphibious

excavator and learn how to use them correctly.

Figure 1.3

1.4 Inspect the Machine

1.4.1 Inspect your machine carefully every time before you use it. Check the base of the

pontoons for damage or cracks. Repair any damage or cracks prior to operation in open

water or swampy area.

1.4.2 Do not start or operate the amphibious excavator before you are in the operator’s seat.

1.4.3 When you are going to operate the machine, ensure that all personnel are away from

the machine.

2

www.eikengineering.com

1.5 Inspection and Maintenance

1.5.1 Stop the engine before inspection or maintenance work.

1.5.2 Use safety sign “under inspection and maintenance” in order to warn the others not to

operate and keep away from the amphibious excavator.

Figure 1.4

1.6 Park Machine Safely

1.6.1 Ensure that you lower the bucket and stop the engine when you are going to park the

machine. Put the control lever in neutral position before you leave the cab.

Figure 1.5

3

www.eikengineering.com

1.6.2 Placed the blocks againt the track if you park the machine on a slope and do not park

the machine with the front attachment pointed the downhill.

Figure 1.6

1.6.3 Remove the engine and cab key with you before leaving the machine.

1.6.4 Do not park your machine on water.

Figure 1.7

4

www.eikengineering.com

1.7 Operate the Machine with Wider Undercarriage

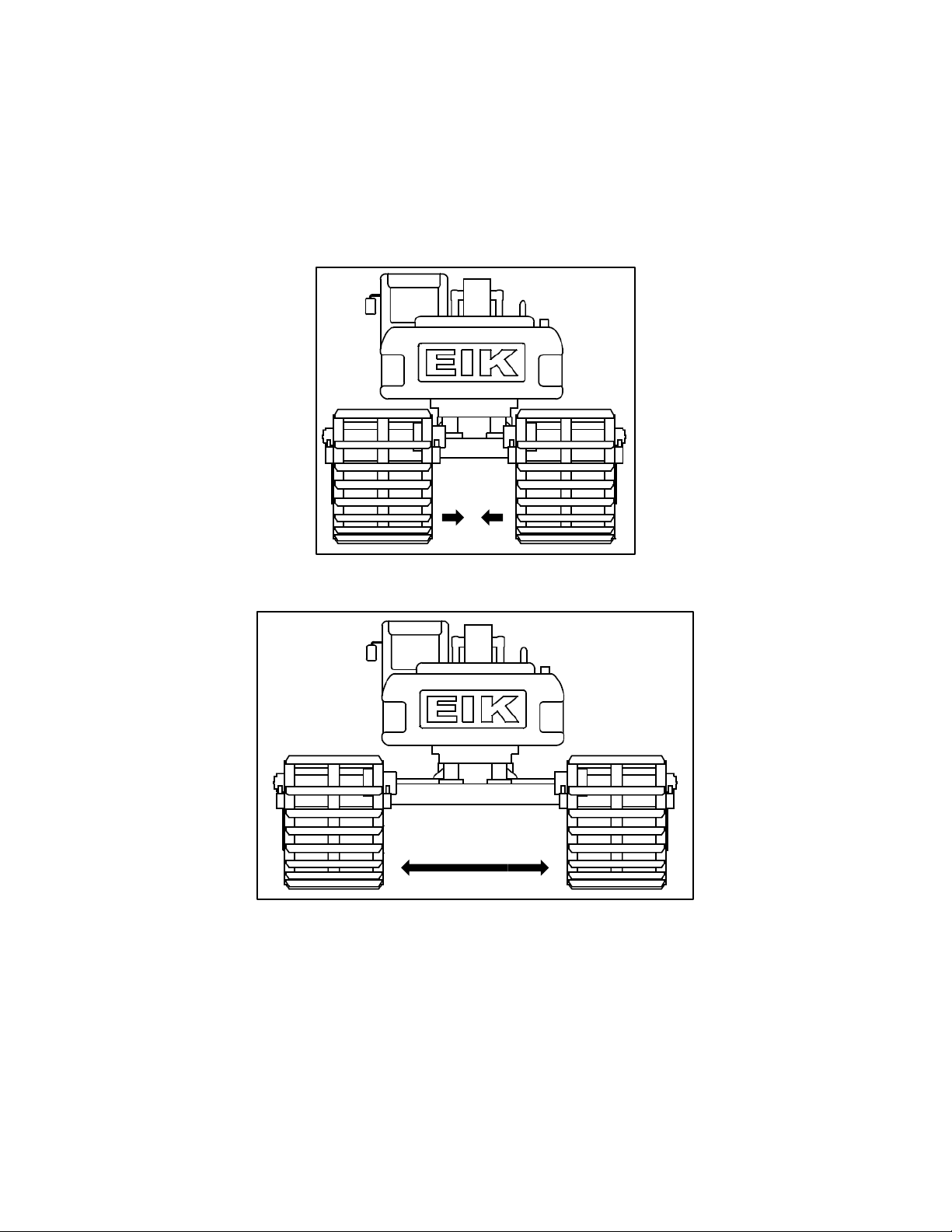

The undercarriage of the amphibious excavator can be set to narrow position as per figure 1.8

and wide position as per figure 1.9, it is compulsory to operate the machine with wider

undercarriage. The undercarriage must be adjusted to the maximum width either manually or

hydraulically before operation. Narrow undercarriage is only applicable for non-operation

application or transportation by trailer.

Figure 1.8

Figure 1.9

5

www.eikengineering.com

1.8 Launching Machine into Open Water

1.7.1 Steep or sudden step or uneven water bed contour may result in machine instability

which could be hazardous during launching.

Figure 1.10

1.7.2 Before launching:

Always examine the water depth and the contour of the water bed to ensure it is

gentle, and with sufficient surface area to accommodate the entire foot print of the

pontoons (undercarriage).

Figure 1.11

6

www.eikengineering.com

Choose a land with slope approximately 10° or less continues down to the the water

until the machine can floats. Prepare the slope if there is no such landscape at your

site.

Lower the front attachment to create a low centre of gravity for the machine which

could stabilze the machine during launching.

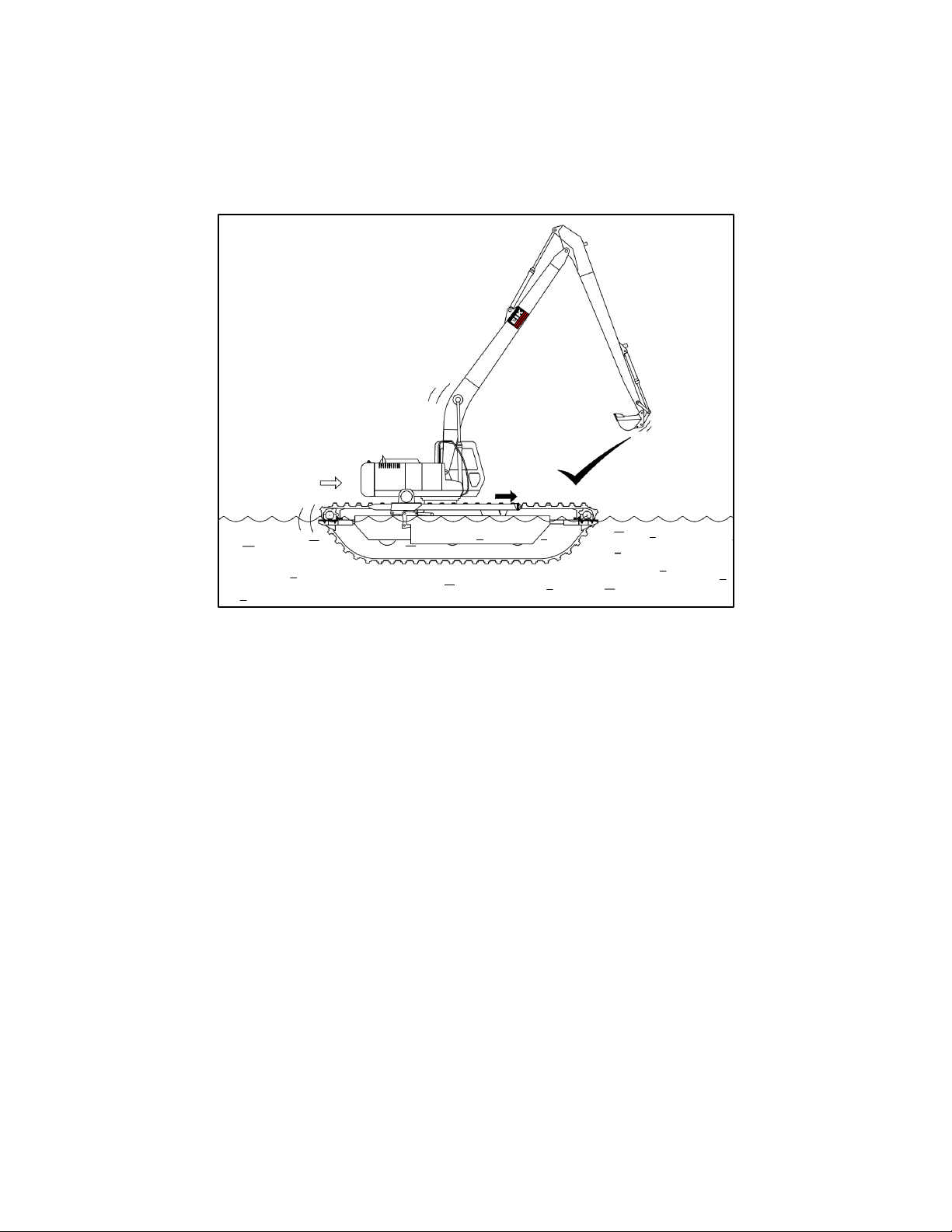

Launch the machine tailforemost at a slow speed. Refer to the arrow direction at the

pontoon before launching.

Figure 1.12

1.9 Landing the Machine from Open Water

Lower the front attachment once the front track catches the land during landing. If the track

slips during landing, use the bucket to help your machine escape from water.

Ensure that the front machine is facing to the land during landing.

Figure 1.13

7

www.eikengineering.com

1.10 Travelling the Machine in Open Water

Check and determine that there are no bubles evolving from the pontoons after launching

and before travelling. Ensure that the machine is not abnormally tipping to one side before

proceed with operation.

Figure 1.14

Travel the machine in the direction of arrow at the pontoon and smoothly adjust the front

attachments position, up or down when you want to keep your machine horizontal and

balance.

8

www.eikengineering.com

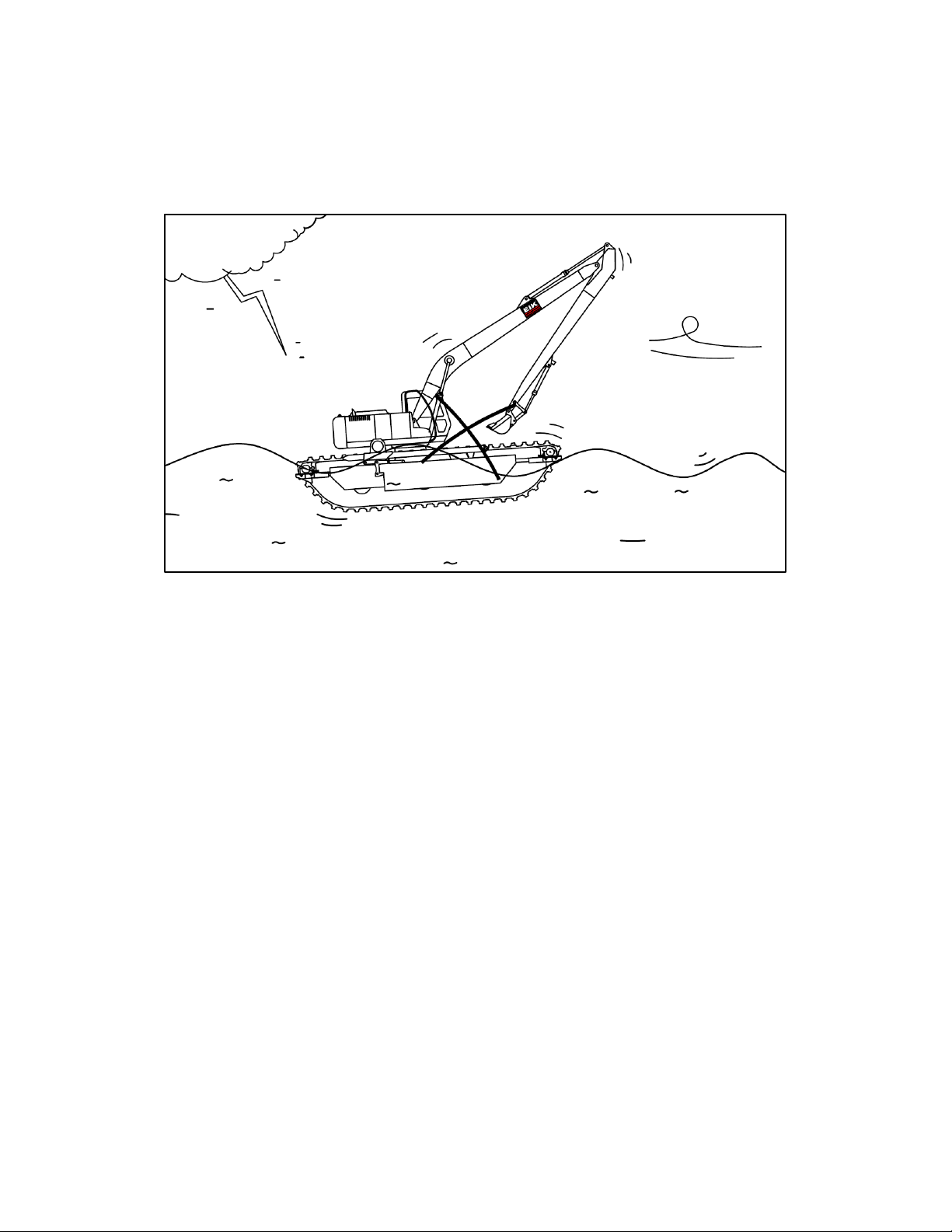

1.11 Avoid Water Travelling During Bad Weather Condition

Travelling in open water is limited to still water only. Do not travel the machine at the area with

the present of water current, or running stream of water, or the wind is blowing over than

4m/s.

Figure 1.15

9

www.eikengineering.com

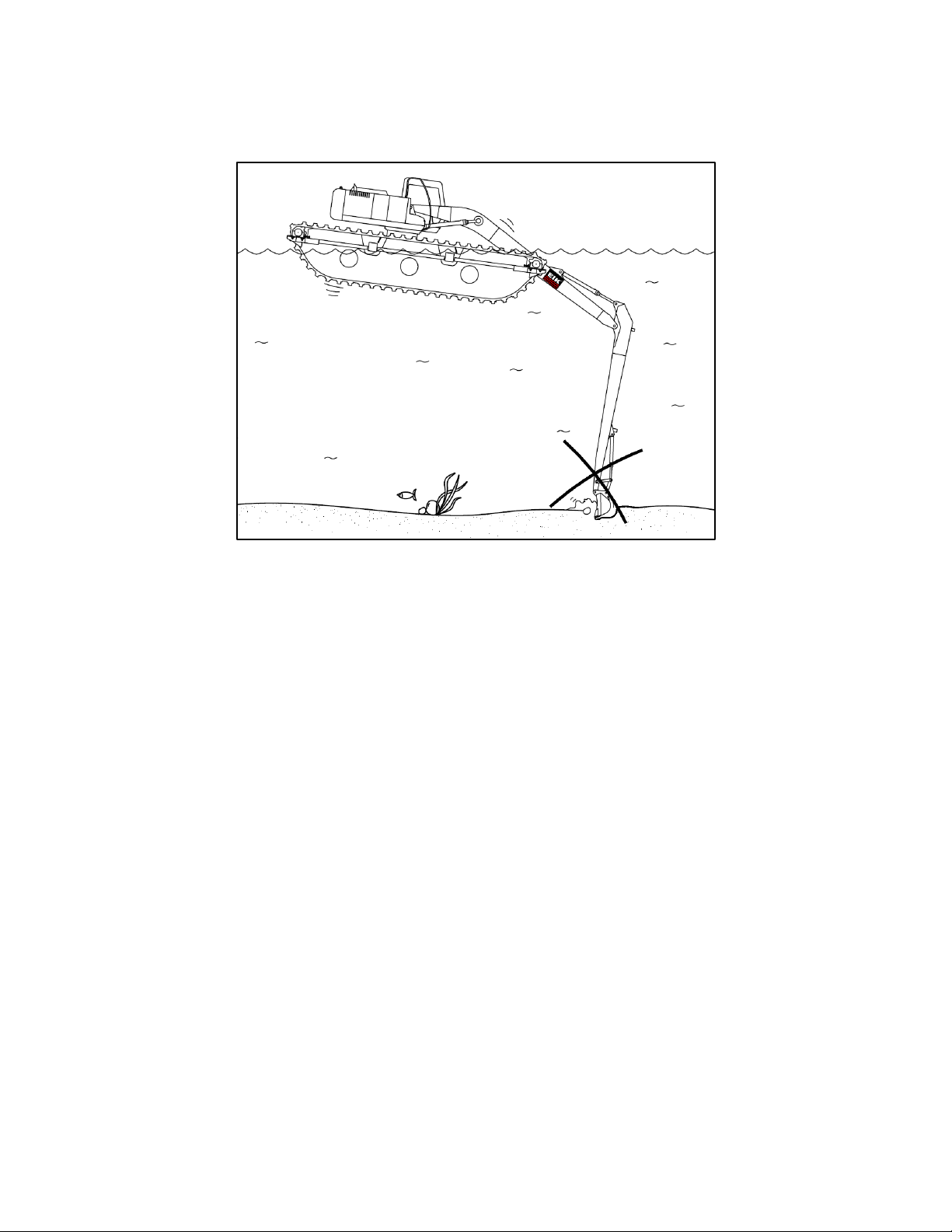

1.12 Avoid Digging Job in Floatation Mode

Amphibious excavator is prohibited to work in floatation mode.

Figure 1.16

10

www.eikengineering.com

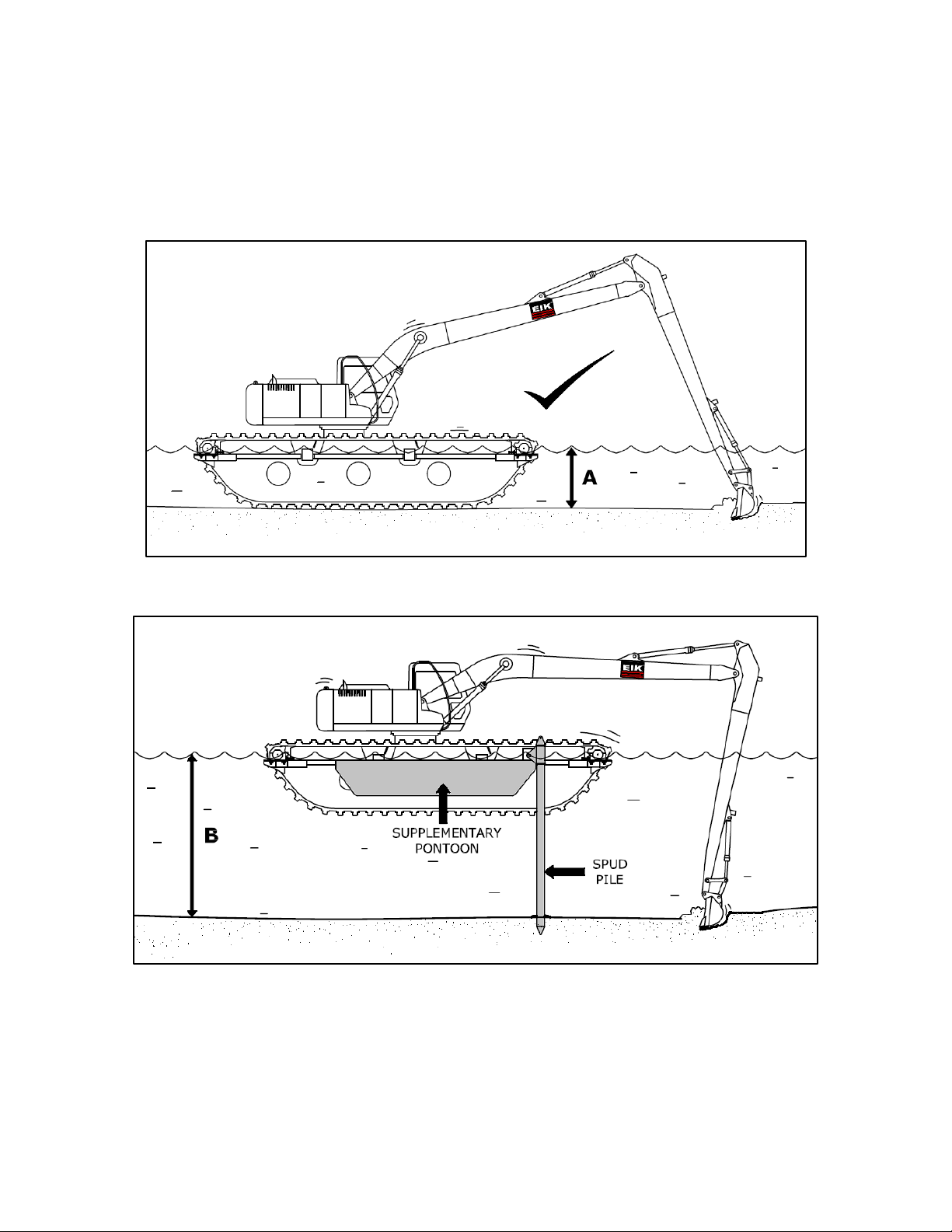

1.13 Digging at Recommended Water Depth

For safety reason, digging jobs at watery area can only be performed at limited water depth.

Figure 1.17 below illustrates a standard amphibious excavator operates at water depth A and

figure 1.18 illustrates an amphibious excavator operates at water depth B with supplementary

pontoon and spud piles. Refer to Table 1.1 on next page.

Figure 1.17

Figure 1.18

11

www.eikengineering.com

Table 1.1 below shows the recommended water depth for digging purpose for each model of

amphibious excavator produced by EIK®.

MODEL

A, MAX. (METER)

B, MAX. (METER)

AM80

1.1

2.5

AM140

1.2

4.0

AM200, AM250, AM300, AM350

1.5

4.0

Table 1.1

“Supplementary Pontoons (also known as Side Pontoons) and Spud Pile do not eliminate any risk or

operation mishap”.

“Operator is solely responsible for the safe operation of the machine.”

12

www.eikengineering.com

1.14 Operate the Boom, Stick and Bucket Carefully

Carefully operates the machine if a long reach is used as front attachment. Begin and end the

operation with slowly and smoothly. The attachment may collide with the pontoons and cause

severe damage to the structure and will affect the safe operation of the machine.

Figure 1.19

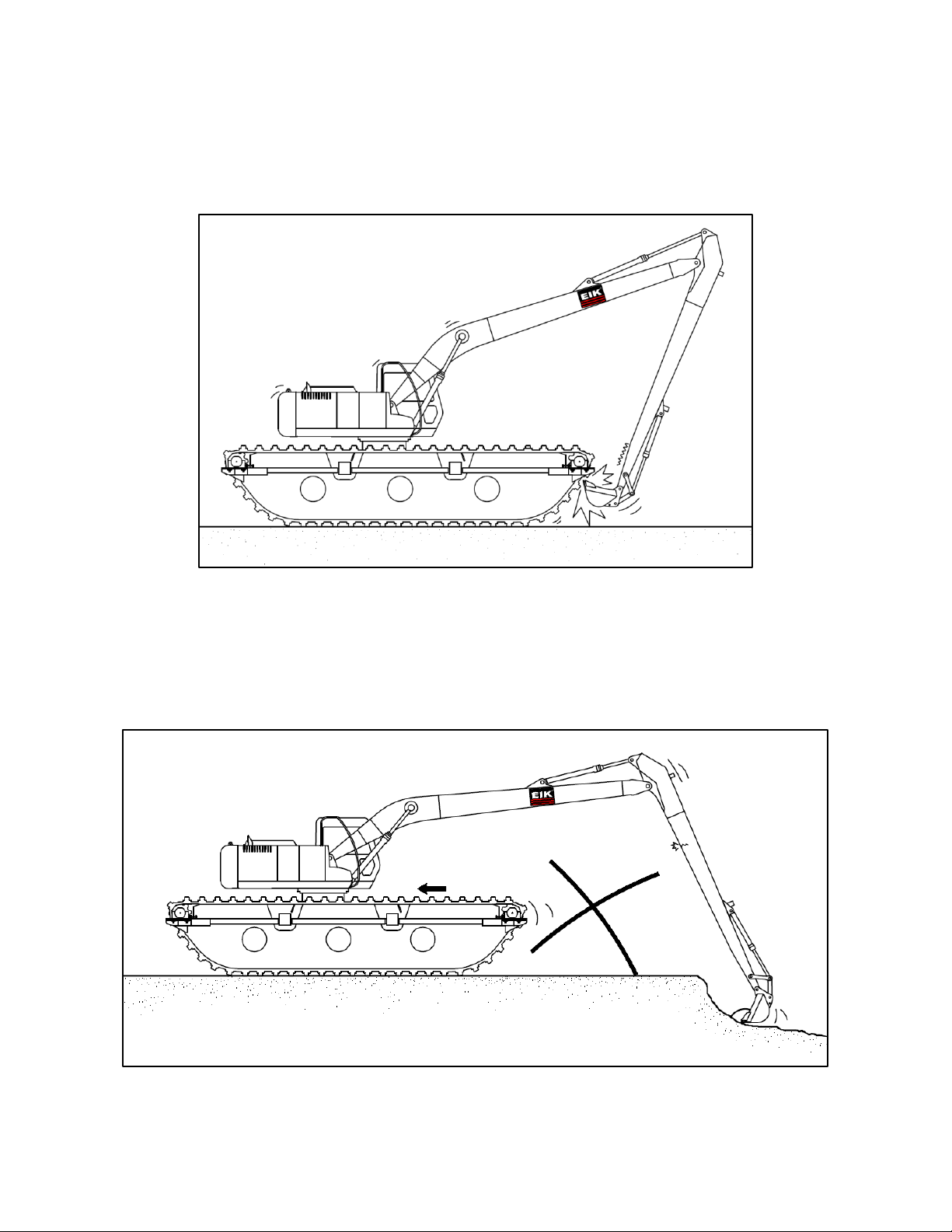

1.15 Avoid Abuse Operation

Do not use travel force as additional digging technique. This operation will exert excessive force

upon the machine structure especially to the front attachments and severe damage may result.

Figure 1.20

13

www.eikengineering.com

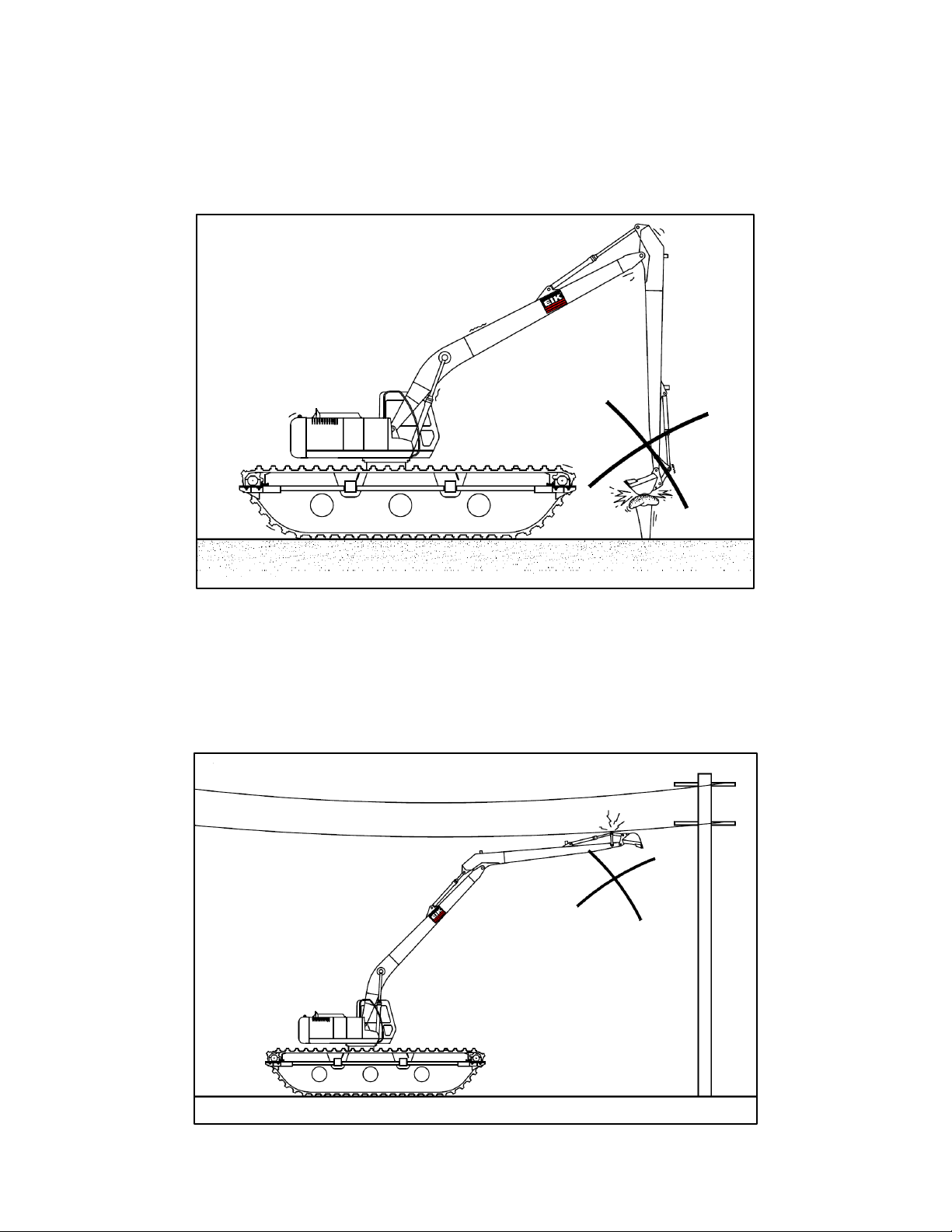

1.16 Avoid Hammering Operation

Do not perform hammering and pilling operations using bucket which could cause damage to

the bucket and the front attachments of the machine. Such operations are dangerous and

should be avoided at all circumstances.

Figure 1.21

1.17 Beware of Power Line

Beware of power lines when travelling on land. Lower the long reach attachment if you need to

pass over. Serious injury or death can result from contact with power lines.

Figure 1.22

14

www.eikengineering.com

1.18 Travelling the Machine

1.18.1 General

Check the track chain tension before start the work. Slack track chain may jump

track during steering. Adjust the track chain tension but do not excessively tighten

that would give rise to high travel resistance to the machine.

Before operating the travel levers inside the operator cabin, confirm which direction

the tracks and travel motor are facing. Yellow arrows at the pontoons are directed to

the front side.

1.18.2 Land

Use a flagman when travelling on the shoulder of a road or in confined area.

Travel on flat ground an in straight lines (turn with large angles) as much as possible.

When turning the machine, use alternating forward and reverse movement as much

as possible instead of making one sharp turn.

Avoid a hard travel on land with many stones, rocks and stub as much as possible

that may shorten the track shoes life.

When travelling on rough ground, use low (1st) gear with low engine speed to reduce

the shock to the pontoons and machine.

When ascending or descending slopes, keep the bucket 12 inches (30cm) above the

ground which give you enough time to lower the bucket to the ground immediately

if the machine start to slip.

Figure 1.23

15

www.eikengineering.com

Avoid changing directions on a slope. Otherwise the machine may turn over or

slide sideways.

Figure 1.24

“Operator is solely responsible for the safe operation of the machine.”

“Manufacturer shall not be responsible for any negligence or breach of safety operation procedures.”

16

www.eikengineering.com

2) UNDERCARRIAGE MAINTENANCE

Regular, intervals of proper lubrication and maintenance are essential for long life of the parts and

provide safe operation without drastically loss performance.

This chapter provides correct procedures for lubrication and maintenance for the undercarriage.

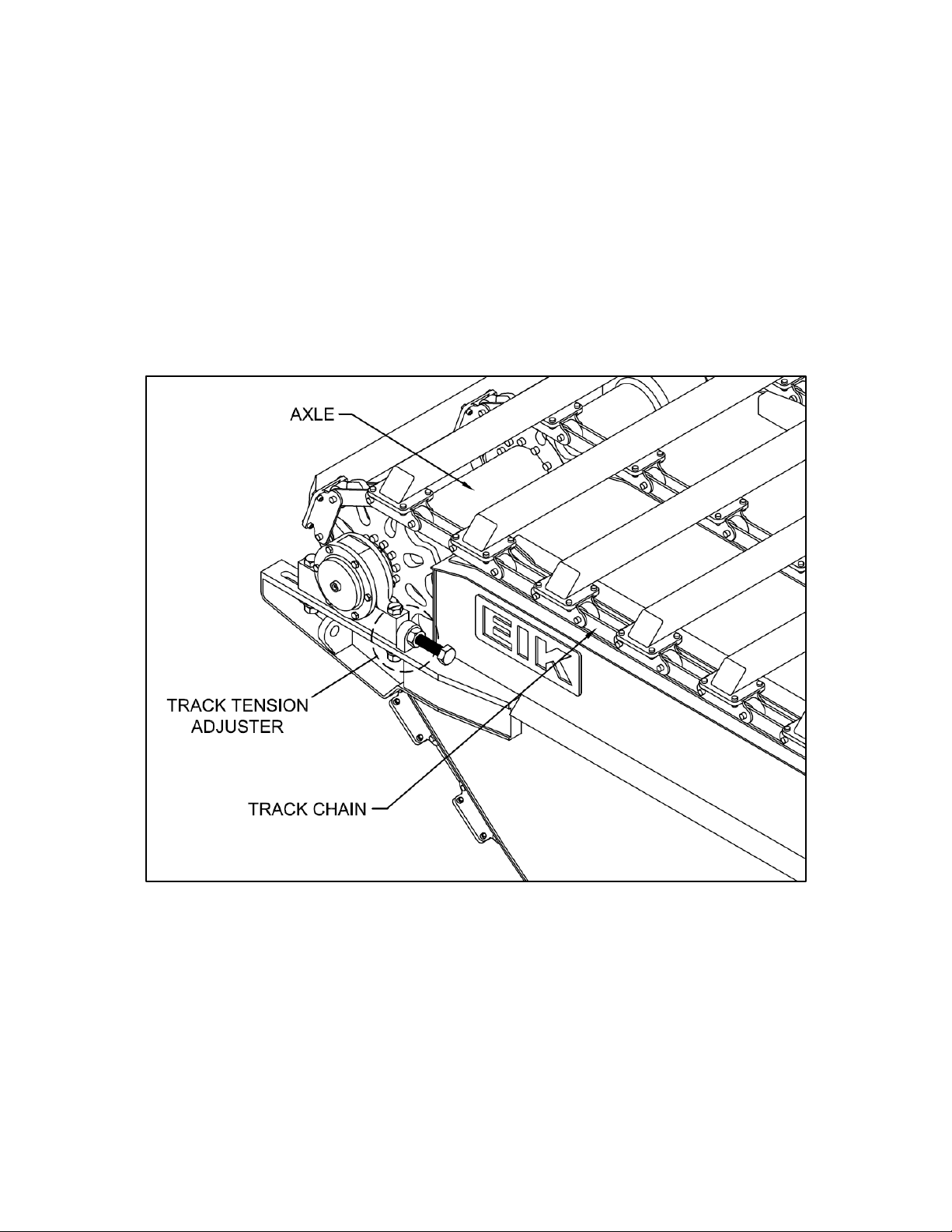

2.1 Track Tension

2.1.1 Check the track chain condition before and after travelling the machine. The chain may

come off from the track if it is too slack or loose during steering. Use bolts at track

tension adjuster to adjust the track chain tension but do not over tight the track chain

that would give high travel resistance to the machine.

Figure 2.1

2.1.2 Before the track chain can be adjusted, the mechanic must examine how slack the track

is and what is the suitable tension must be set.

2.1.3 Firstly, ensure that the bottom and the top track chains of the pontoon are in tension or

flat. Use the axle tracking force to get the flat chain on top of the pontoon (turn the

sprockets).

17

This manual suits for next models

6

Table of contents