-2-

Contents

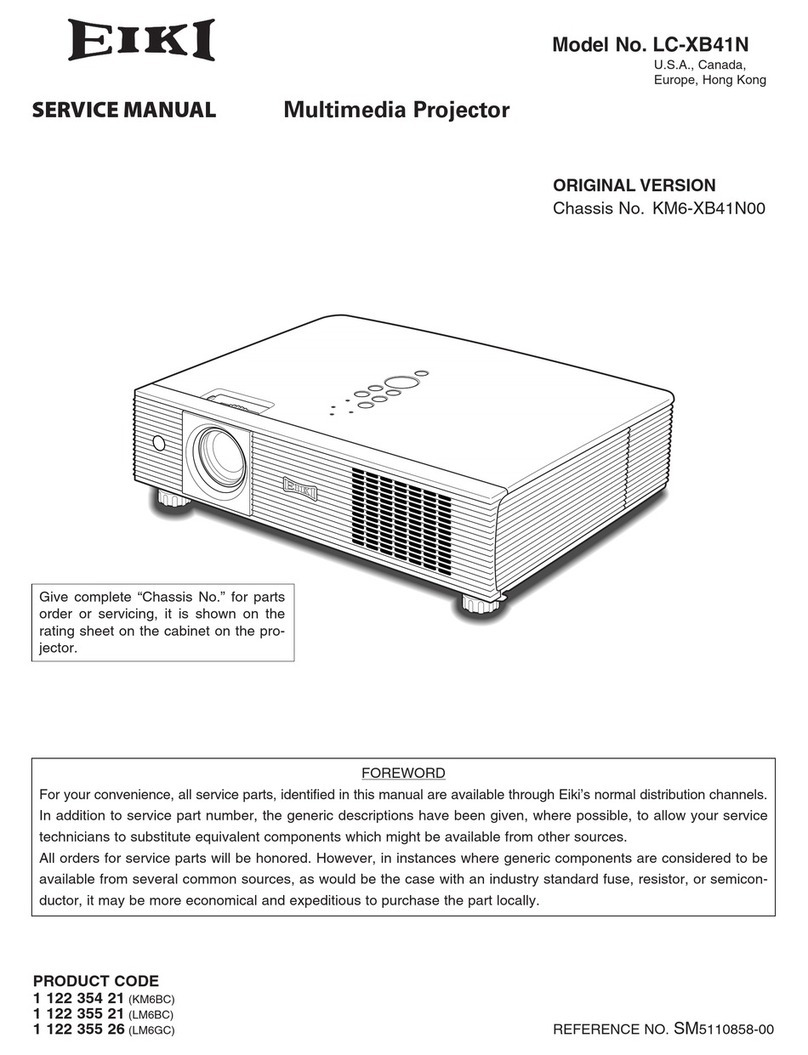

SERVICE MANUAL........................................................ 1

Contents........................................................................ 2

Safety Instructions......................................................... 3

Safety Precautions...................................................... 3

Product Safety Notice................................................. 3

Service Personnel Warning......................................... 3

Specifications ................................................................ 4

Circuit Protections ......................................................... 5

Thermal switch ........................................................... 5

Lamp cover switch...................................................... 5

Fuse ............................................................................ 5

Warning temperature and power failure protection.... 6

Maintenance.................................................................. 7

Cleaning the Air Filter ................................................. 7

Resetting the Filter Counter........................................ 7

Attaching the Lens Cover............................................ 8

Cleaning the Projection Lens ...................................... 8

Cleaning the Projector Cabinet ................................... 8

Lamp replacement...................................................... 9

How to check Lamp Used Time ................................ 10

Warning Message on the non-standard lamp used .. 10

Security Function Notice ..............................................11

Resetting procedure ..................................................11

Standby mode Notice.................................................. 12

Mechanical Disassembly ............................................. 13

Optical Parts Disassembly........................................... 18

Adjustments ................................................................ 25

Adjustments after Parts Replacement...................... 25

Optical Adjustments .................................................... 26

Contrast adjustment ................................................. 26

Integrator lens adjustment ....................................... 27

Relay lens-Out adjustment ....................................... 28

Electrical Adjustments................................................. 29

Service Adjustment Menu Operation ....................... 29

Memory IC (IC1371) Replacement ........................... 29

Circuit Adjustments .................................................. 30

Test Points and Locations ......................................... 35

Service Adjustment Data Table ................................. 36

Chassis Block Diagrams .............................................. 53

Chassis over view..................................................... 53

System control.......................................................... 54

Lamp control............................................................. 55

Audio circuit .............................................................. 56

Power supply & protection circuit............................. 57

Fan control circuit ..................................................... 58

IIC bus Control circuit ............................................... 59

Troubleshooting ........................................................... 60

Indicators and Projector Condition............................ 60

No Power .................................................................. 61

No Picture ................................................................. 62

No Sound.................................................................. 63

Control Port Functions ................................................. 64

Scaler I/O Port Functions (PW190)............................ 64

Electrical Parts List ...................................................... 71

Electrical Parts Location............................................ 72

Electrical Parts List ................................................... 73

Mechanical Parts List................................................... 94

Cabinet Parts Location.............................................. 94

Optical Parts Location............................................... 95

Mechanical Parts List.............................................. 100

Diagrams & Drawings..................................................A1

Parts description and reading in schematic diagram ...A2

Schematic Diagrams....................................................A3

Printed Wiring Board Diagrams.................................. A11

Pin description of diode, transistor and IC.................A15

Note on Soldering...................................................... A16