Contents

SERVICE MANUAL ................................................... 1

Contents ........................................................................ 2

Safety Instructions......................................................... 3

Safety Precautions ..........................................................3

Product Safety Notice .....................................................3

Service Personnel Warning.............................................3

Specifications ................................................................ 5

Circuit Protections ....................................................... 10

Fuses (F601, F602, F603).............................................10

Thermal fuses (SW903, SW904, SW905, SW906)....... 11

Temperature sensors, wind sensors .............................12

Power failure, fan lock and filter error detection ............ 13

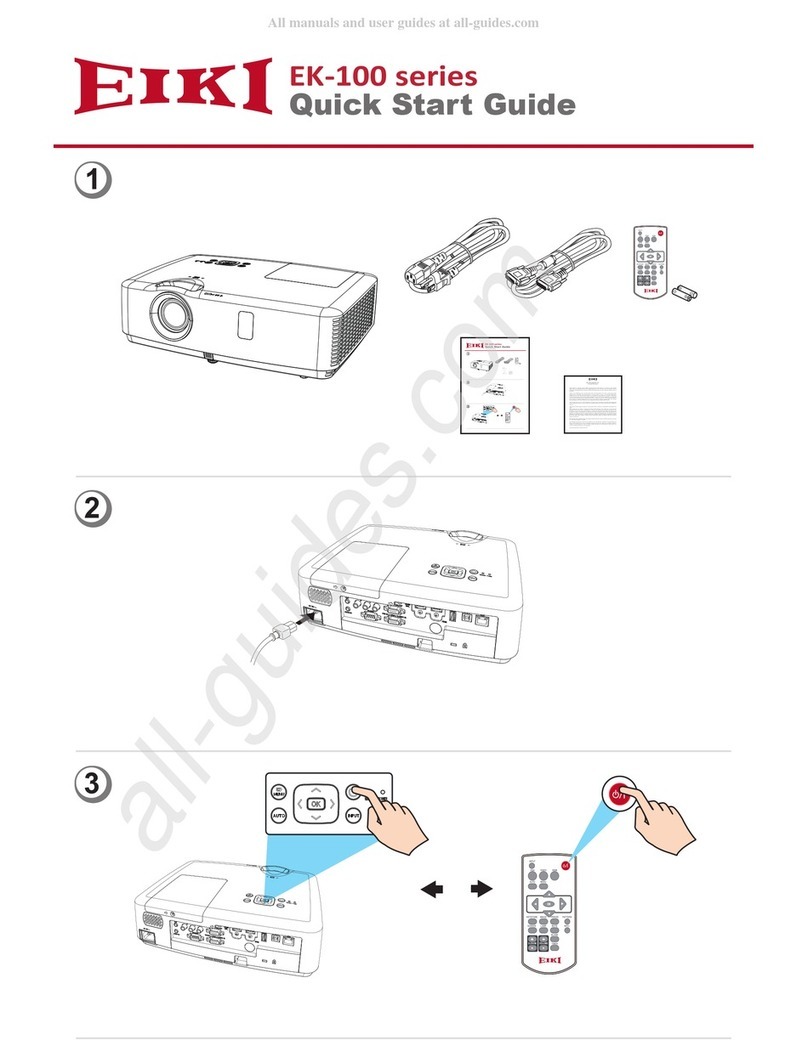

Maintenance................................................................ 14

Maintenance.................................................................. 14

Replacing the unit.......................................................... 14

Air filter unit ................................................................... 14

Lamp unit....................................................................... 17

Quick maintenance .......................................................21

Cleaning the optical parts..............................................22

Security Function Notice ............................................. 23

Lens Mounting............................................................. 24

Mechanical Disassembly............................................. 32

Order of mechanical disassembly.................................32

Optical Parts Disassembly .......................................... 51

Order of optical parts disassembly................................ 51

Servicing Notice .......................................................... 65

Note on main board replacement..................................65

Adjustment data setting.................................................65

Serial number setting ....................................................65

Model no. setting...........................................................65

Adjustments................................................................. 66

Adjustments after parts replacement ............................66

Optical Adjustments .................................................... 67

Optical adjustment location...........................................67

Before adjustment .........................................................68

1. Optical center adjustment..........................................70

2. PBS adjustment......................................................... 74

3. Contrast adjustment .................................................. 75

4. Back focus adjustment .............................................. 76

5. Convergence adjustment ..........................................77

Adjustment tool installation ...........................................78

Adjustment tool removal................................................79

Adjustment ....................................................................80

Electrical Adjustments................................................. 81

Service adjustment menu operation .............................81

Circuit adjustments........................................................82

Test points and locations...............................................86

Service adjustment data................................................87

Chassis Description .................................................. 158

Chassis over view........................................................158

Boards connection ...................................................... 159

Troubleshooting......................................................... 160

No picture .................................................................... 160

No Power.....................................................................164

Power supplies to boards ............................................ 165

AC filter, AC-DC power board...................................... 166

DC power board .......................................................... 167

PFC-1 & PFC-2 board .................................................168

Power supply and power failure detection................... 169

Power drive and power failure signals......................... 172

Fan control system ...................................................... 173

Motor control system ................................................... 174

Temperature abnormality ............................................ 175

Lamp abnormality........................................................ 176

Lamp control system ................................................... 177

Power failure detection system ................................... 178

Error history log ........................................................... 179

Diagnosis of power failure with serial port...................180

Indicators and projector condition ............................... 181

Serial Control............................................................. 185

Serial control interfaces...............................................185

Control Port Functions............................................... 188

IC Block Diagrams..................................................... 191

Exploded Views & Parts List ..................................SPL-1

Exploded Views..................................................... SPL-2

Mechanical Parts List .......................................... SPL-20

Electrical Parts List...............................................SPL-23

Schematic Diagram & Circuit Board Diagram........ DIA-1

Pin description of diode, transistor and IC ...............DIA-2

Schematic Diagram ................................................DIA-3

Circuit Board Diagram .......................................... DIA-15