EIS AWT6-V6-SW User manual

Heat Pump

DC Inverter Air to Water

Before operating this product, please read the

instructions carefully and keep this manual for future use.

User’s manual

User’s manual

AWT -V6-SW6/9/11/13

AWT6/9/11/13-MBW

2

5

Catalogue

1.Introduction

1.1.Preliminary Information

1.2.Safety Precautions

1.3.Functioning Principles

1.5.Product Component Diagram

1.6.Technical Specifications

2.Overview of the Units

2.1.Functional Diagrams

2.2.Outlines and Dimensions

2.3.Exploded Views

3.Assembly Configurations

Assembly Configuration Selection Flowchart

Assembly Drawings, Wiring, and Software

4.Installation Walkthrough

4.1.Sanitary Hot Water Applications

4.2.Heating and Cooling Circuits

4.3.Indoor Unit Installation

4.4.Outdoor Unit Installation

4.10.Attention

4.11.Electric heating

4.12.Test Run

5.Appendix

A. Wiring

5

3

1.4.Water pump

4.5.Refrigerant pipe connection

4.6.Refrigerant Pipework

4.7.Water pipe connection

4.8.Installation of the kits in the accessories

4.9.Wiring

B. Wiring Diagrams

6

8

9

12

13

15

15

19

28

33

33

34

49

49

50

53

54

56

57

60

61

63

73

74

77

78

78

80

Installation

Manual

User’s

Manual

Below are the accessories that are included with your purchase.

Please check to ensure that none are missing or damaged.

If so,please contact your local distributor.

Included Accessories

1 2

13 14

X1 X1

X1 X1

4

7

X1

Mixing Circuit 2

Temperature Sensor

Extension cable for

15

X1

Power cable for outdoor unit

E-heater (for monoblock unit only)

Sensor Cable for

Water Inlet Temperature

(for monblock only)

Sensor Cable for

Water Outlet Temperature

(for monblock only)

Safety

Valve Kit

346

X1 X1

X1

Mixing Circuit 1

Temperature Sensor

Mixing Circuit 2

Temperature Sensor

5

X1

Mixing Circuit 1

Temperature Sensor

Extension cable for

89

X1 X1

TR-Room

Temperature Sensor

Extension cable for

Temperature Sensor

Room

11

X1

Cable for Flow Switch

(for monblock only)

13

12

X1

Sensor Cable for

Water Inlet

Temperature

(for monblock only)

10

X1

Communication

Cable between

Indoor and

Outdoor Unit

1. Introduction

1.1 Preliminary Information

Thank you for your purchase of our quality heat pump.

This manual is intended to provide detailed instructions for the successful installation of your newly

purchased heat pump product. Please ensure that this manual, along with the User’s and Service

manuals, are kept in an easy-to-access location for your reference later on.

DISCLAIMER

Proper adherence to the directions provided herein is vital for both the smooth operation of this

system, as well as for your safety and the safety of those around you. Amitime Electric Co., Ltd. is not

responsible or liable for any losses incurred due to misuse or mishandling of this product, which

includes, but is not limited to:

• Purchasing, installing, and/or operating this product with the intention of using it outside of

its established, technical purpose.

• Carrying out improper work upon the unit, or any of its components, that has not been given

explicit, prior consent in the form of writing.

• Installation attempts of this system by anyone other than a properly trained and licensed

professional.

• Negligence of properly-worn personal protection (safety glasses, gloves, etc.) while performing

installation, maintenance, or servicing of this product.

SAFETY

• The operation of this system during ambient temperatures which are below or beyond the

temperature range intended (-25°C to 43°C)

If unsure of what installation procedures to use, please contact your local distributor for information

and/or advisement. Any accessories used with this product must be official only. Any electrical work

must be carried out by certified electricians only. The manufacturer is not responsible for any alter-

ations or modifications that are made without explicit, written approval. The design of this unit com-

plies and conforms to all necessary and relevant safety regulations, and is otherwise safe to operate for

its intended use.

Please pay attention to the following pages, which detail important precautions that should be closely

followed, to ensure safe installation and operation .

5

1. Introduction

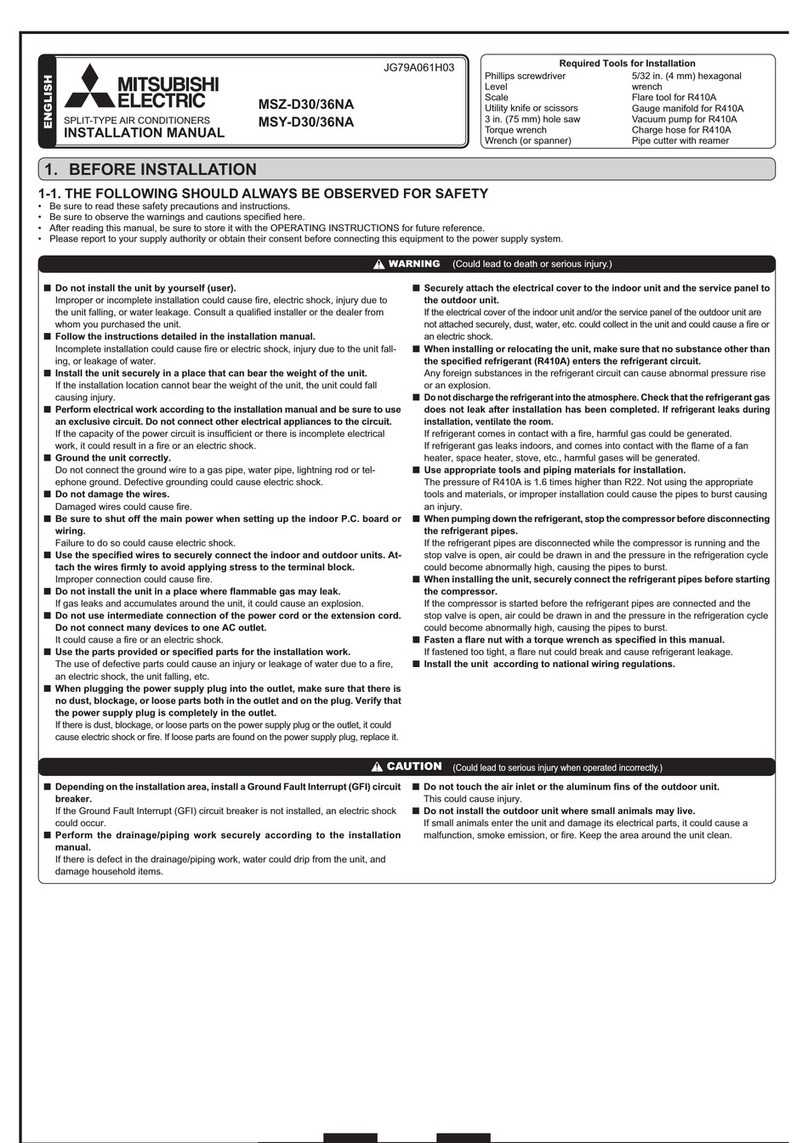

1.2.Safety Precautions

To ensure both your personal safety, as well as the safety of the product, note the symbols below and

be sure to understand their correlation to each of the precautions depicted.

CautionWarning Prohibition

The installation, dismantlement

and maintenance of the unit must

be performed by qualified

personnel. It is forbidden to do any

changes to the structure of the unit.

Otherwise injury of person or unit

damage might happen.

To avoid electrical shock, make

sure to disconnect the power

supply 1 minute or more before

servicing the electrical parts. Even

after 1 minute, always measure the

voltage at the terminals of main

circuit capacitors or electrical parts

and, before touching, make sure

that those voltages are lower

than the safety voltage.

User Manual

Be sure to read this manual before

use.

For sanitary hot water, please

always add a mixture valve before

water tap and set it to proper

temperature.

Ground wire

Use a dedicated socket for this

unit, otherwise malfunction may

occur.

The power supply to the unit must

be grounded.

Do not touch the air outlet grill

when fan motor is running.

Do not touch the power plug with

wet hands. Never pull out the plug

by pulling the power cable.

Water or any kind of liquid is

strictly forbidden to be poured into

the product, or may cause electric

creepage or breakdown of the

product.

This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not be made by

children without supervision.

6

Copper

Steel

Fuse

Main

Power Cable RCD

Indoor

unit

When the power cord gets loose

or damaged, always get a qualified

person to fix it.

It is mandatory to use a suitable

circuit breaker for the heat pump

and make sure the power supply to

the unit corresponds to the

specifications. Otherwise the unit

might be damaged.

Disposal of Scrap Batteries(if

there is).Please discard the

batteries as sorted municipal waste

at the accessible collection point.

Installation of a residual current

device (RCD) having a rated

residual operating current not

exceeding 30 mA is advisable.

ON

OFF

Please select the correct fuse or

breaker as per recommended. Steel

wire or copper wire cannot be

taken as substitute for fuse or

breaker. Otherwise, damages

maybe caused.

Be aware fingers might be hurt by

the fin of the coil.

7

This marking indicates that this product should not be disposed with

other household wastes throughout the EU. To prevent possible harm to

the environment or human health from uncontrolled waste disposal,

recycle it responsibly to promote the sustainable reuse of material

resources. To return your used device, please use the return and

collection systems or contact the retailer where the product was

purchased. They can take this product for environmental safe recycling.

System water filling T/P valve

Connect to heating/cooling system

Buffer tank

Connect to heat pump

One way valve

Filter

City water inlet

1. It's suggested to use pure water for filling the system.

2. If use city water for filling, please soften the water and add a filter.

Note: After filling, the system of water system should be 0.15~0.6MPa.

1. Introduction

1.2.Safety Precautions

Water inlet

Water Outlet

Outdoor unitIndoor unit

Filter

Water pump

Heat

exchanger

Power supply

Four-way vavle

Compressor

Three-way valve

Refrigerant Filter T-connector

Fan motor

Pressure

check valve

Evaporator

Heating

Cooling

8

1. Introduction

1.3.Functioning Principles

Outdoor Unit

Expansion

Valve

Filter

Refrigerant

Three-Way Valve

Pressure Check

Valve

Power Supply

Compressor

Four-Way Vale

Fan Motor

Evaporator

AWT6/9/11/13-V6-SW

AWT6/9/11/13-V6-MBW

9

1. Introduction

1.4.Water Pump

3

Q [m h]

[m]

H

[kPa]

p

Pump curves:

UPM3 xx-75

UPM3 xx-70

UPM3 xx-60

UPM3 xx-50

UPM3 xx-40

The pump speed can be selected on the pump.The default setting is highest speed.If the water flow

in the system is too high(e.g.noise of running water in the installation) the speed can be lowered.

Setting the pump speed

80

70

60

50

40

30

20

10

0

8

7

6

5

4

3

2

1

0

Q [I/S]

User interface

The user interface is designed with a single push

button, one red/green LED and four yellow LEDs.

Push button LEDs

User interface with one push button and five LEDs

The user interface shows:

performance view (during operation)

operation status

alarm status

settings view (after pressing the button).

During operation,the display shows the performance

view. If you press the button, the user interface

switches the view or runs in the setting selection

mode.

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6

1.00.9 type

0.8

0.70.60.50.4

0.30.20.1

0.0

During operation,the display shows the performance

view. If you press the button, the user interface

switches the view or runs in the setting selection

mode.

The user interface shows:

performance view (during operation)

operation status

alarm status

settings view (after pressing the button).

Performance view

The performance view shows either the operation

status or the alarm status.

Operation area

25%

50%

75%

100%

Fig. 1 Operation area according to performance load

10

1. Introduction

1.4.Water Pump

Operation status

When the circulator is running, LED 1 is green. The

four yellow LEDs indicate the current power

consumption (P1) as shown in the table below. See fig.

1. When the operation mode is active, all active LEDs

are constantly on in order to differenti ate this mode

from the select setting mode. If the circulator is

stopped by an external signal, LED 1 flashes green.

Alarm status

If the circulator has detected one or more alarms, the

bi- colored LED 1 switches from green to r ed. When

an alarm is active, the LEDs indicate the alarm type as

defined in the table below. If multiple alarms are active

at the same time, the LEDs only show the error with

the highest priority. The priority is defined by the

sequence of the table.

When there is no active alarm anymore, the user

interface switches back to operation mode.

Display Indication Pump operation Counter action

One red LED +

one yellow LED

(LED 5)

One red LED +

one yellow LED

(LED 4)

One red LED +

one yellow LED

(LED 3)

Rotor is

blocked.

Supply

voltage too

low.

Electrical

error.

Trying to start

again every 1.33

seconds.

Wait or block

the shaft.

Only warning,

pump runs.

Pump is stopped

because of low

supply voltage or

serious failure.

Control the

supply voltage.

Control the

supply voltage /

Exchange the

pump.

Display Indication Performance in % of

P1 MAX

One green

LED (flashing) Standby (only externally

controlled) 0

One green

LED + one Low performance 0-25

yellow LED

One green

LED + two Medium low performance 25-50

yellow LED

One green

LED + three Medium high performance 50-75

yellow LED

One green

LED + four High perf ormance 75-100

yellow LED

Navigation

Key lock function

The purpose of the key lock function is to avoid

accidental change of settings and misuse.

When the key lock function is enabled, all long key

presses will be ignored. This prevents the user from

entering the "select setting mode" area and allows the

user to see the "show setting mode" area.

If you press the key lock for more than 10 seconds,

you can toggle between enabling/disabling the key

lock function. When doing so, all LEDs, except for the

red LED, will fl ash for a second indicating that lock is

toggled.

User interface control modes for

UPM3 HYBRID variants

You can manage all UPM3 HYBRID variants with a

single push button and a LED interface.

You can select the following operation modes with the

push button.

The user interface shows the flashing LEDs in the

combination which is described in the tables below.

UPM3 FLEX AS

This circulator is for either external PWM profile A

signal control or speed selection.

You can define the maximum curve of the pump

operation range. With PWM signal, the circulator runs

at the corr esponding speed. Without PWM signal, the

circulator runs at maximum speed.

PWM profile A (heating)

* The circulator is factory-set to start in this control mode.

UPM3 xx-70 LED1 LED2 LED3 LED4 LED5

[m] red yellow yellow yellow yellow

4

5

6

7*

10S.

11

1. Introduction

1.4.Water Pump

Factory presetting

The circulator starts at the factory preset.

• For standard UPM3 HYBRID, UPM3 AUTO, UPM3

AUTO L this is proportional pressure, curve 3

For UPM3 FLEX AC and UPM3 FLEX AS this is

PWM profile A, curve 4.

In the "select setting" mode the circulator starts at this

control mode.The preset mode is marked with this

symbol * in the tables below.

Setting selection

You can choose between the performance view and

settings view.

If you press the button for 2 to 10 seconds, the user

interface switches to "setting selection" if the user

interface is unlocked. You can change the settings as

they appear. The settings appear in a particular order

in a closed loop. When you release the button, the

user inter face switches back to the performance view

and the last setting is stored.

Setting selection

PERFORMANCE SETTING MENU

SELECTED SETTING

10S.

1. Introduction

1.5.Product Components Diagram

12

Below is a general system application of the heat pump. Any specific configurations should be a

variation of this “master” system drawing. All suggested assembly variations are given in Chapter 3.

Name Symbol Name Symbol

Temp.Sensor

Safety valve Kit

Ball valve

Water filter

Air purging valve

Water pump

Mixing valve

Motorized valve

Expansion tank

Note:Dotted lines mean〝able to be controlled by the Heat Pump〞.

Middle temperature hot water

High temperature hot water

13

1. Introduction

1.6.Technical Specifications

Model

Power Supply-Refrigerant V/Hz/Ph 220-240/50/1-R410A

Max. Heating Capacity (1)

C.O.P (1)

Heating Capacity Min./Max.(1)

Heating Power Input Min./Max.(1)

C.O.P Min./Max.(1)

Max. Heating Capacity(2)

C.O.P (2)

Heating Capacity Min./Max.(2)

Heating power input Min./Max.(2)

C.O.P Min./Max.(2)

Max. Cooling Capacity(3)

E.E.R (3)

Cooling Capacity Min./Max.(3)

Cooling Power Input Min./Max.(3)

E.E.R Min./Max.(3)

Max. Cooling Capacity(4)

E.E.R(4)

Cooling Capacity Min./Max.(4)

Cooling Power Input Min./Max.(4)

E.E.R Min./Max.(4)

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

11.5

10.10

3.82

4.03

4.67/11.5

4.33/10.10

915/3029

975/2153

3.82/5.054.02/4.65

10.7

9.53

2.95

3.17

4.14/10.74.19/9.53

1218/3624

1230/2990

2.95/3.56

3.12/3.55

9.2

6.84

2.68

2.09

4.33/9.2

4.10/6.84

993/3465

1230/3280

2.685/4.11

2.09/3.32

6.74

5.05

2.15

1.58

2.17/6.74

2.34/5.05

924/3132

1080/3200

2.15/3.0

1.58/2.40

Compressor Type-Quantity/System Twin Rotary/1

Fan

Quantity

Airflow

Rated Power

m³/h

W

3100

3000

76

1

1

Type of Product DC Inverter Air to Water Heat Pump Unit

Noise Level Indoor/Outdoor 35/56

dB(A)

12.6

3.89

4.2/12.6

926/3072

3.89/4.77

11.5

3.08

3.76/11.5

1267/3723

2.97/3.28

10.3

3.29

4.29/10.37

957/3156

3.29/4.63

7.9

2.63

2.34/7.91

1000/3012

2.33/3.12

4200

150

2

35/59

6.21

4.05

2.19/6.21

540/1530

4.05/5.87

5.8

3.22

2.05/5.8

640/1810

3.22/4.12

5.81

3.51

2.05/5.81

768/2105

3.15/4.71

4.5

2.52

1.59/4.5

614/1740

2.52/4.32

2700

1

7665

35/5635/52

Water Side Heat

Exchanger

Type

Water Pressure Drop

Piping Connection

30

G1”

Kpa

Inch

Plate Heat Exchanger

30 30

20

AWT6-V6-SW/MBW AWT9-V6-SW/MBW AWT11-V6-SW/MBW AWT13-V6-SW/MBW

14

1. Introduction

1.6.Technical Specifications

Model

Water Pump

Water Volume

Range of setting temperature**

Hot water capacity*

Range of working temperature

Water pipe connection

Max. Pressure of Water

Inbuilt Electric Heater

Control of 2KW electric heater

Inbuilt Electric Heater

Control of 6KW electric heater

Refrigerant pipe connection

m

L

℃

Kg/h

inch

Map

KW

300

240

0.7

0.7

Type of Product DC Inverter Air to Water Heat Pump Unit

360

0.7

7.5

250

30-52-75**

140

-25~45

0.7

Manual

Auto/Manual

AWT6-V6-SW/MBW AWT9-V6-SW/MBW AWT11-V6-SW/MBW AWT13-V6-SW/MBW

Max Water Head 7.5 7.5 7.5

250 250 250

30-52-75** 30-52-75** 30-52-75**

℃-25~45 -25~45 -25~45

G1” G1” G1” G1”

2(220-240V/50Hz/1PH)

Manual Manual Manual

KW 6(400/50Hz/3PH)

inch

Auto/Manual Auto/Manual Auto/Manual

1/4”、1 /2” 3/8”、1/2” 3/8”、1/2” 3/8”、3/4”

Note: (1) Heating condition: Water inlet/outlet temperature: 30℃/35℃, Ambient temperature: DB 7℃/WB 6℃;

Heating condition: Water inlet/outlet temperature: 40℃/45℃, Ambient temperature: DB 7℃/WB 6℃;

Cooling condition: Water inlet/outlet temperature: 23℃/18℃, Ambient temperature: 35℃;

Cooling condition: Water inlet/outlet temperature: 12℃/7℃, Ambient temperature: 35℃.

Marked with "*" means: Hot water capacity is based on testing condition: DB/WB 20℃/15℃, target

water temperature 50℃.

Marked with "**" means: water temperature can reach 52 ℃ by heat pump, and reach 75℃ by using electric

heater simultaneously.

The specifications are subject to change without prior notice. For actual specifications of unit, please refer to

the stickers on the unit.

Performance tested as per EN14511-2007.

(2)

(3)

(4)

(5)

(6)

(7)

(8)

【 】 Indoor unit

Inside

Top

Outside

35

36

37

38

AWT6/ -V6-SW9/11/13

Handle

Touch screen operation panel

Decorative panel

Front panel

Digital thermostat

Automatic air purging valve

T/P valve

Water pressure gauge

Four-way safety valve kit

L type decorative panel in back side 1

L type decorative panel in back side 2

Middle temperature hot water outlet

Filling water to coil

Filling water to water tank

High temperature hot water outlet

(G1’’male)

(G1’’male)

(G3/4’’male)

(G1’’male)

Water expansion tank

Emergency Switch for 9KW electric heater

Thermostat knob

Plate heat exchanger

Water pump

Drainage

Electric box

Overheating protector for 500W electric heater

Temperature sensor for 500W electric heater

500W electric heater 230V/50Hz/1Ph

Water flow switch

9KW electric heater 400V/50Hz/1Ph

Anode Rod

Temperature sensor for hot water mode

Motorized three-way valve

Water tank

Rubber absorber feet

Service valve

Water to heating/cooling system(G1’’male)

39

40

5L Expansion Tank

1.5L refrigerant expansion tank (6/9/11kW)

2. Overview of the Units

2.1.Functional Diagrams

15

1

40 9

7

68

3

4

2

5

10

11

12

13

14

15

17

16

18

20

19

38

6

21

22

23

24

25

26

27

28

29 30

31

32

33

34

35

36

37

39

40

Water from heating/cooling system(G1’’male)

Cable gland

Fixing plate for refrigerant connector

6kW Refrigerant connector(1/4’’~1/ 2’’)

9/11kW Refrigerant connector(3/8’’~1/ 2’’)

13kW Refrigerant connector(3/8’’~5/ 8 ’’)

【 】 Indoor unit

AWT6/ -V6-SW9/11/13

2. Overview of the Units

2.1.Functional Diagrams

16

6kW Refrigerant connector:1/4”

13kW Refrigerant connector:3/8’’

9/11/kW Refrigerant connector:1/2’’

13kW Refrigerant connector:5/8’’

Automatic air purging valve

Service valve

High temperature hot water outlet(G1’’male)

Filling water to water tank(G3/4’’male)

9/11kW Refrigerant connector:3/8’’

6/kW Refrigerant connector:1/2’’

Filling water to coil(G1’’male)

Middle temperature hot water outlet(G1’’male)

Safety valve kit

Water from heating/cooling system(G1’’male)

Water to heating/cooling system(G1’’male)

Electric box

Electric heater

Water pump

21

22

23

25

26

27

28

29 30

31

32

33

34

35

36

37

24

11

12

13

14

15

17

16

18

20

19

6

【 】 Indoor unit

Inside

Top

Outside

35

36

37

AWT6/ -V6-MBW9/11/13

Handle

Touch screen operation panel

Decorative panel

Front panel

Digital thermostat

Automatic air purging valve

T/P valve

Water pressure gauge

Four-way safety valve kit

L type decorative panel in back side 1

L type decorative panel in back side 2

Middle temperature hot water outlet

Filling water to coil

Filling water to water tank

High temperature hot water outlet

(G1’’male)

(G1’’male)

(G3/4’’male)

(G1’’male)

Water expansion tank

Emergency Switch for 9KW electric heater

Thermostat knob

Water pump

Drainage

Electric box

Overheating protector for 500W electric heater

Temperature sensor for 500W electric heater

500W electric heater 230V/50Hz/1Ph

Water flow switch

9KW electric heater 400V/50Hz/1Ph

Anode Rod

Temperature sensor for hot water mode

Motorized three-way valve

Water tank

Rubber absorber feet

5L Expansion Tank

Water to heating/cooling system(G1’’male)

2. Overview of the Units

2.1.Functional Diagrams

17

Water from heating/cooling system(G1’’male)

Cable gland

9

7

68

3

4

2

5

10

1

40

Water outlet(G1’’male)

Water Inlet(G1’’male)

【 】 Indoor unit

AWT6/ -V6-MBW9/11/13

2. Overview of the Units

2.1.Functional Diagrams

18

Water pump

Water to heating/cooling system(G1’’male)

Electric box

Electric heater

Filling water to coil(G1’’male)

Middle temperature hot water outlet(G1’’male)

Safety valve kit

Water from heating/cooling system(G1’’male)

Automatic air purging valve

High temperature hot water outlet(G1’’male)

Filling water to water tank(G3/4’’male)

Water oulet (G1’’)

Water inlet (G1’’)

2. Overview of the Units

2.2.Outlines and Dimensions

19

【 】 Indoor unit

Unit:mm

AWT6/9/11/13-V6-SW

1600

1720

1688

1202

1310

600

675

660

2. Overview of the Units

2.2.Outlines and Dimensions

20

【 】 Indoor unit

Unit:mm

AWT6/9/11/13-V6-MBW

600

675

660

1720

1688

1202

1310

1600

This manual suits for next models

7

Table of contents

Popular Air Conditioner manuals by other brands

DeLonghi

DeLonghi CLIMAVENETA HED HCAT 0011 SE Installation and service manual

Fujitsu

Fujitsu AOU9RLF installation manual

Mitsubishi Electric

Mitsubishi Electric Mr. Slim MXZ-3A30NA installation manual

Daikin

Daikin FVXS25FV1A Operation manual

LU-VE

LU-VE FHD Series Installation and maintenance instruction

Samsung

Samsung ND022QHXEA user manual

Dometic GROUP

Dometic GROUP WAECO VAS 581 001 operating manual

Trane

Trane Precedent RT-PRC005 user manual

LG

LG AKWW0243AA0 owner's manual

American Standard

American Standard YSC036A Installation, operation and maintenance

Whirlpool

Whirlpool W7WCC085XB0 Use & care guide

Mitsubishi Electric

Mitsubishi Electric MSZ-D30NA installation manual