Eisen HT3300 User manual

INSTRUCTION MANUAL

Hydraulic

Floor Jack 3 Ton

Double Pump

Mechanism

Quick start technology

ensures that after

the 1st stroke, the

hydraulic floor

jack moves up 3

times more than the

standard jack

Robust and durable

steel body provides

rigidity and stability

Swivel saddle for

convenient positioning

under the vehicle

Heavy-duty swivel rear

castors for smooth

movement and

positioning

Cushion on handle

prevents damage to

the vehicle

Rubber cushion on

the saddle prevents

marring of the lift

points of the vehicle

Built-in safety valve

protects against

overloading of jack at

120% of capacity

Hydraulic oil by-pass

system protects

ram from being over

extended

Complete with long

two piece handle for

ease of operation and

reduced operator

fatigue

Dimensions: (27×

13-1/2× 6-1/8) inches/

(686×330×152) mm

CAPACITY

SADDLE LIFTS

SADDLE DIAMETER

SADDLE SWIVEL

OVERALL DIMENSIONS

FRONT WHEEL DIAMETER

REAR WHEEL DIAMETER

SPECIFICATIONS

Cushion on

handle prevents

damage

Rubber cushion on

saddle prevents

marring

Double Pump Technology

ensures fast rising action

HT3300

www.P65Warnings.ca.gov

Cancer and Reproductive Harm-WARNING:

Complies with ASME PASE/2014 Safety Standard

1

2

SAFETY INFORMATION

•Follow workshop health & safety rules,

regulations and conditions whenusing the

floor jack.

•This is alifting device only. Do not useit for

anything other than its intended purpose.

Load must be supported by proper rated

capacity jack stands underthe vehicle before

starting inspection or work. Do not overload.

Jack capacity is 3 tons.

•Use only on hard level surfaces.

•Never stand or place your body beneath the

load being lifted.

•Never attempt to exceed thelimits of the

floor jack. Applying excessive force to the tool

can overload the jack, decrease thelife and

increase the wear onthe jack.

•Lift only onareas of the vehicle as specified by

the vehicle manufacturer.

•Do not move or dolly the vehiclewhileit is on

the jack.

•Use genuine parts only. Unauthorized parts

may be dangerous and will void the warranty.

•Keep the floor jack cleanand in good working

order for best and safest performance.

•DO NOT use the floor jack for a task it is not

designed to perform.

•DO NOT use for aircraft purposes.

•DO NOT overreach. Keep proper footing and

balance at all times. Do not reach over or

across the product.

•DO NOT drop, throw or abuse the floor jack.

•Failure to heed these markings may result

in serious personal injury and/or property

damage.

WARNING!

•DO NOT use the floor jack if damaged or

thought to be faulty. Contact yourlocal service

agent.

PACKAGING CONTENT

DESCRIPTION QTY.

Floor Jack 1

Lower Handle 1

Upper Handle 1

O.I.P.M. 1

TOOLS NEEDED

•10 mm spanner / 3/8” spanner

•18 mm spanner / 11/16” spanner

•8mm hex key/ 5/16” hex key

BEFORE INSTALLATION

•Make sure all equipment is rated to the

appropriate capacity.

•Check damaged parts.Before using the tool,

any part that appears damaged should be

carefully checked to determine that it will

operate properly and perform its intended

function. Check for alignment and binding of

moving parts, any broken parts ormounting

fixtures; and any other condition that may

damaged should be properly repaired or

replaced by a qualified technician.

•Always use good quality hydraulic jack oil

when adding or replacing the oil in your

together. When filling theFloor Jack with oil,

do not permit dirt or any other substance to

enter the hydraulic system. (Refer Maintenance

of Page 3 for more details.)

•Make sure that all connections are secure.

•Consult the vehicle owner’s manual to

determine thelocation of lift points.

WARNING!

•Defective accessories can lead to personal

injury and material damage

INSTALLATION

(Refer “EXPLODED VIEW”)

CAUTION

· The Floor jack is heavy. Usecaution when

lifting out of box.

Assembly

•In the two piece handle assembly (37)

provided, assembletheupper sectioninto

the lower section, line up the holes, insert and

tighten the screw (38). Use a 10mm spanner /

3/8” spanner to tighten thescrew.

•Insert the bottom end of handleinto the top

of handle Socket (28) and securely tighten the

handle bolt (27) and washer. Ensure the handle

can turn freely. Usean18 mm spanner /11/16”

spanner to tighten the bolt.

•Turn the handle/release valve clockwise to the

closed position. Do not over tighten.

•Your floor jack is ready for use.

OPERATING INSTRUCTIONS

(Refer “EXPLODED VIEW”)

CAUTION

•Chock vehicle’s wheels to prevent rolling while

lifting.

•Use jack stands to support vehicle. Never work

around or under a vehicle supported only by

the Floor Jack.

•Watch for movement of vehicle or jack stands

as vehicle is lowered. If any movement occurs,

jack vehicle up and adjust jack stands properly.

•When not in use, make sure pressure is

released by turning HandleAssembly fully

counterclockwise. This will prolong the life of

the jack.

Lifting

•Twist the handle assembly clockwise to close

the pressure release valve.

•Position the jack underthespecified lift point.

3

•Begin lifting by pumping the handleup and

down.

•Lift Handle Assembly as high as clearance

allows.

•Repeat Steps 3-4 until vehicle is at desired

height. Do not over-extend thejack.

•Place jack stands underneath vehicle at

specified points. Refer to the vehicle’s

instruction manual for properjack stand

placement locations.

•Slowly twist Handle Assembly counterclockwise.

This will lower the vehicleonto the jack stands.

•Completely lower the FloorJack and remove

from underneath the vehicle.

•To make sure vehicle is stable, stand away and

attempt to rock the vehicle. If movement is

detected, jack up the vehicleand adjust jack

stands properly. Test again.

Lowering

•Turn the handle/release valve clockwise to the

closed position. Do not over tighten.

·

jack stands.

•Remove the jack stands.Do not get under or let

anyone get under the vehicle whilelowering.

•Turn the handle/release valve slowly

counterclockwise to lower the vehicleonto the

ground.

MAINTENANCE

(Refer “EXPLODED VIEW”)

CAUTION

•Usehigh grade hydraulic oil only.

•Never use brake fluid, motor oil, transmission

fluid, turbine oil or any other fluids.

•ISO-VG22 or equivalent hydraulic oil is

recommended.

Check and Refill Oil

•With the jack in the fully lowered,level position,

remove unit cover (25), then remove oil filler

plug (42). Use an8mm / 5/16” hex key to open

the oil filler plug.

•Proper oil level should bejust covering inner

cylinder as seen from the oil fillerplug hole.

•Do not overfill. Always fill with new, clean

hydraulic jack oil as recommended above.

•Reinstall oil filler plug, then reinstall unit cover.

Lubrication and Cleaning

•Periodically clean and lubricate all moving parts

and pivot points.

Air Venting Procedures

•With the jack in the fully lowered position,

handle in open position, remove oil filler plug.

•Pump the handle rapidly several times. Reinstall

oil filler plug.

•Turn the handle/release valve clockwise to the

closed position.

•Pump the handle until the lift arm (8) reaches

maximum height and continue to pump

several times to remove trapped air inthe

system.

•Turn the handle/release valve

counterclockwisein one full turn and lower lift

arm to the lowest position. Use force onsaddle

if necessary.

•Carefully and slowly loosen oil filler plug to

release pressurized air.

•Repeat above steps until trapped air is

completely vented.

Damaged Equipment

•Any jack that appears to bedamaged in

any way, is found to be worn, or operates

abnormally SHALL BE REMOVED FROM

SERVICEUNTIL REPAIRED.

Alterations

•Becauseof potential hazards associated with

this type of equipment, no alterations shall be

made to theproduct.

Attachments and Adapters

•Only attachments and/or adapters supplied

Inspection

•Visual inspectionshall bemade before each

use of thedevice by checking for abnormal

conditions,such as cracked welds, leaks,and

damaged, loose, or missing parts.

•Other inspections shall be made perproduct

operating instructions.

•This device shall be inspected immediately

if the device is believed to have been

subjected to anabnormal load or shock. It is

recommended that this inspectionbemade by

a TH authorized repair facility.

•Owners and/or operators should be aware

that repair of this equipment may require

specialized knowledge and facilities. It is

recommended that an annual inspection of the

product be made by a TH authorized repair

facility and that any defective parts,decals, or

safety labels orsigns be replaced with TH

specified parts.

Storage

•This Jack should be stored ina dry location on

a level surface.

4

EXPLODED VIEW

3

18

20

23

33

24

42

26

27

31

30

29

28

35 36

34

33

32

25

22

21

19

18

17

16

17

16

15

15

14

13

12

11

10

9

8

7

6

5

4

3

21

38

37

39

40

41

5

REF NO. PARTS DESCRIPTION QTY.

1 ø18, C ring 2

2 ø18 Washer 2

3 Front Wheel 2

4 Left Shaft unit 1

5 Rod Link 2

6 SPINDLE 2

7 Right Shaft unit 1

8LIFT ARM 1

9ø16, C ring 2

10 Saddle 1

11 ø25, C ring 2

12 Return Spring 2

13 ø4x45 Coder Pin 1

14 Reinforce Axle 1

15 Reinforce Axle-Rod 2

16 ø8, lock washer 6

17 M8x20 Inner Hex Bolt 6

18 ø16, lock washer 4

19 ø16, Nut 2

20 ø16, thin Nut 2

21 Pin Link Rod 2

REF NO. PARTS DESCRIPTION QTY.

22 Screws M5*15 4

23 Pull-Rod 2

24 Safety Head 2

25 Cover 1

26 Power unit 1

27 M12 Handle Bolt 1

28 Handle Socket 1

29 Roller 1

30 ø25x18 Coder Pin 1

31 Plunger Pin 1

32 ø18 lock washer 2

33 M18 Short Bolt 2

34 Rear Wheel 2

35 "M10x20 Inner Hex Bolt" 4

36 ø10 lock washer 4

37 Handle Assemble 1

38 M6x35 Handle Bolt 1

39 Saddle Axle 1

40 Saddle pad 1

41 Handle Foam 1

42 Oil Filler Plug 1

PART LIST

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Jack will not lift the load. 1. Release valve not tightly closed.

2. Low oil level.

3. Defective or worn internal parts.

4. Load exceeds maximum

allowance.

1. Tighten release valve.

2. Check and add oil. Follow “Check and Refill Oil” instructions

on Page 3.

3. Discontinue use and contact a TH authorized repair center.

4. Use a higher capacity jack.

Jack will not hold the load. 1. Release valve not tightly closed.

2. Power unit malfunction.

1. Tighten release valve.

2. Discontinue use and contact a TH authorized repair center.

Jack will not descend to

minimum height, or will

not remain in lowered

position.

1. Air trapped in system.

2. Reservoir oil overfilled.

1. Vent air out of system. Follow “Air Venting Procedures” above.

2. Check and ensure proper oil level. Follow “Check and Refill

Oil” instruction on Pg.3.

Jack will not lift to max

height.

1. Low oil level. 1. Check and ensure proper oil level. Follow “Check and Refill

Oil” instructions above.

Jack will not function

properly after tried

solution.

1. Internal malfunction or structural

damage.

1. Stop usage and contact a TH authorized repair center.

TROUBLE SHOOTING

DISPOSAL

The components or the used product must be given to companies that specialize inthe disposal and

recycling of industrial waste.

6

Table of contents

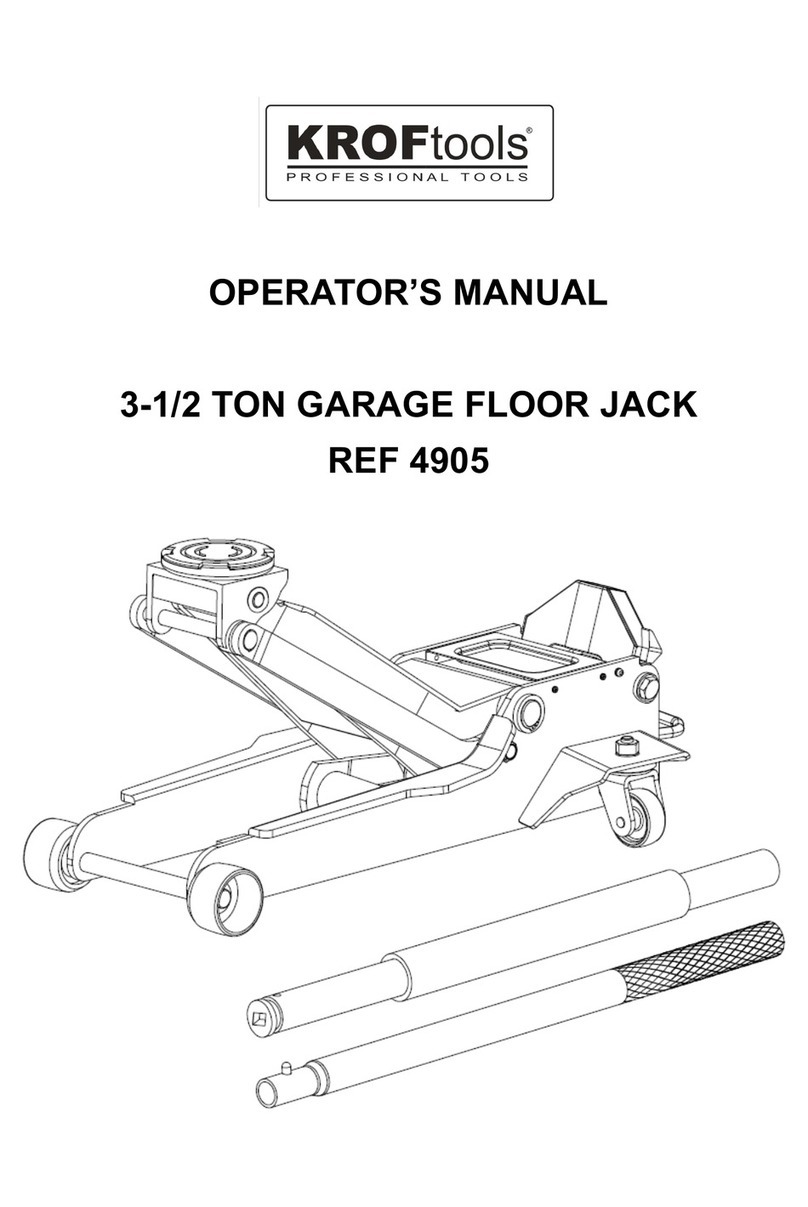

Popular Jack manuals by other brands

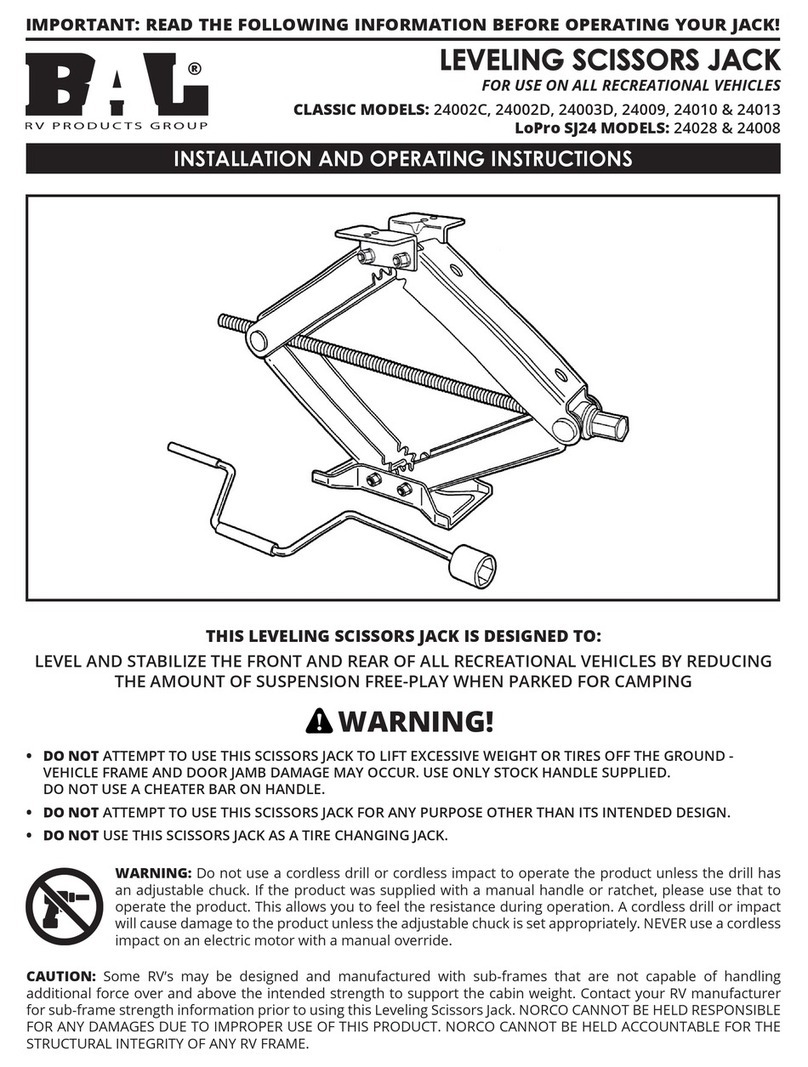

RV Products

RV Products BAL LoPro SJ24 Installation and operating instructions

Pittsburgh Automotive

Pittsburgh Automotive 60234 Owner's manual & safety instructions

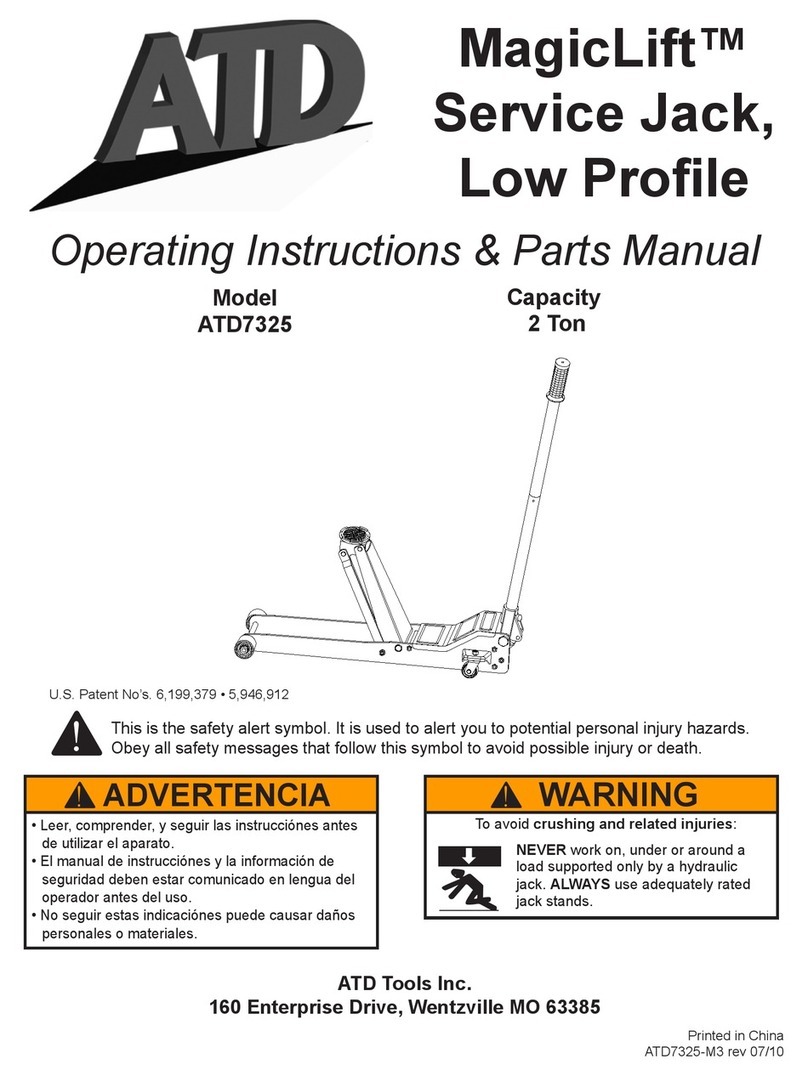

ATD Tools

ATD Tools MagicLift ATD7325 Operating instructions & parts manual

HAUL MASTER

HAUL MASTER 68761 Owner's manual & safety instructions

Torin

Torin BIG RED T83006 owner's manual

TMG

TMG TMG-AJA12 product manual

Pro-Lift

Pro-Lift Garage in a Box Operating instructions & parts manual

Sealey

Sealey 3040A.V2 Series quick start guide

EKKO

EKKO EP15SLI Series manual

ATD Tools

ATD Tools 7392 Operating instructions & parts manual

Simplex

Simplex Pow'r-Riser JA Series instruction sheet

Craftsman

Craftsman 50284 Operator's manual