080505-NIN-SQ-EN 16/24 EN

Operating the unit on short cycle

The compressor is starting

but its thermal protection is

operating incorrectly.

-Too much or too little refrigerant,

incondensable air or gas in the circuit.

-Defective compressor capacitor (single

phase models).

-Voltage too low or too high.

-Flare connections are crushed or

compressed.

- Valve capillaries or nozzle obstructed

(damp).

-Insufficient air circulation.

-Inversion valve damaged or blocked

mid-way (reversible models).

-Empty the installation, repair the

leaks, create a vacuum and refill.

-Determine the exact cause and

change the compressor.

-Change the capacitor.

-Fix the power supply problem.

-Locate and fix the crushed sections.

- Empty the installation, create a

vacuum and refill.

-Clean the coils and the filters, check

that the fan motors are functioning

correctly.

-Change the inversion valve.

Indoor coil iced up

Evaporation pressure too

weak.

- Lack of cooling fluid, leakage.

-Insufficient air circulation.

- Lowest temperature limit in cooling

mode exceeded.

-Empty the installation, repair the

leaks, create a vacuum and refill.

-Clean the coils and the filters,

check the fan motors are

functioning correctly, position the air

vents correctly.

-Install a low temperature kit.

Unit noisy

Faulty installation -Check that anti-vibration blocks are

installed and tubes are correctly fixed

into place.

-Re-tighten the fixings and fit anti-

vibration blocks if absent.

Compressor noisy -Check whether the compressor is

leaking oil.

-Excess of refrigerant.

-Repair leak and top up the oil.

-Remove excess refrigerant.

Insufficient or excessive condensation pressure

Excessive high pressure -Coil is clogged.

-Indoor unit fan (heating mode) or

outdoor unit fan (cooling mode) faulty.

-Too much refrigerant

-Presence of air or non-condensable

gas.

-Liquid side blocked or crushed.

-Clean the coil.

-Change the ventilator.

- Remove excess refrigerant.

- Empty the installation, create a

vacuum and refill.

- Fix the blockage or crushed

section.

Insufficiently high pressure -Too little refrigerant, leaks.

-Compressor valves are worn.

-Empty the installation, repair the

leaks, create a vacuum and refill.

-Replace the compressor.

Excessive or insufficient evaporation pressure

Excessive evaporation

pressure

-Too much refrigerant

-Cycle inversion valve is faulty or

leaking (reversible product).

-Remove the excess fluid.

-Change the valve.

- Insufficient evaporation

pressure

-Too little refrigerant, leaks.

-Indoor unit coil (cooling mode) or

outdoor unit coil (heating mode) iced

up.

-Insufficient airflow in indoor unit

(cooling mode) or in outdoor unit

(heating mode).

-Liquid side blocked or crushed.

- Valve capillaries or nozzle obstructed

-Empty the installation, repair the

leaks if necessary, create a vacuum

and refill.

- Find the cause and fix it.

-Check that the ventilator is working

correctly.

-Remove the blockage or fix the

crushed section.

- Empty the installation, create a

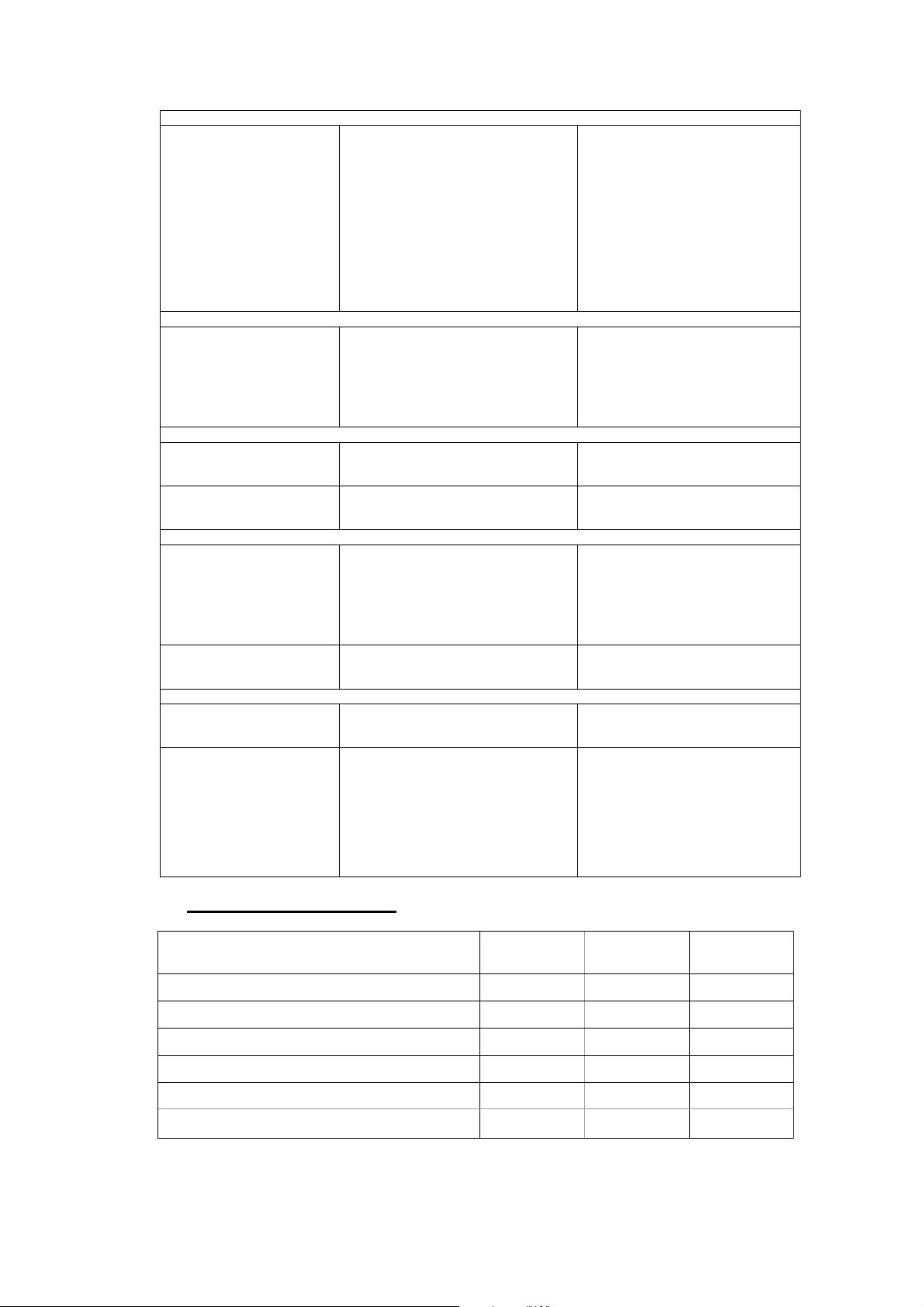

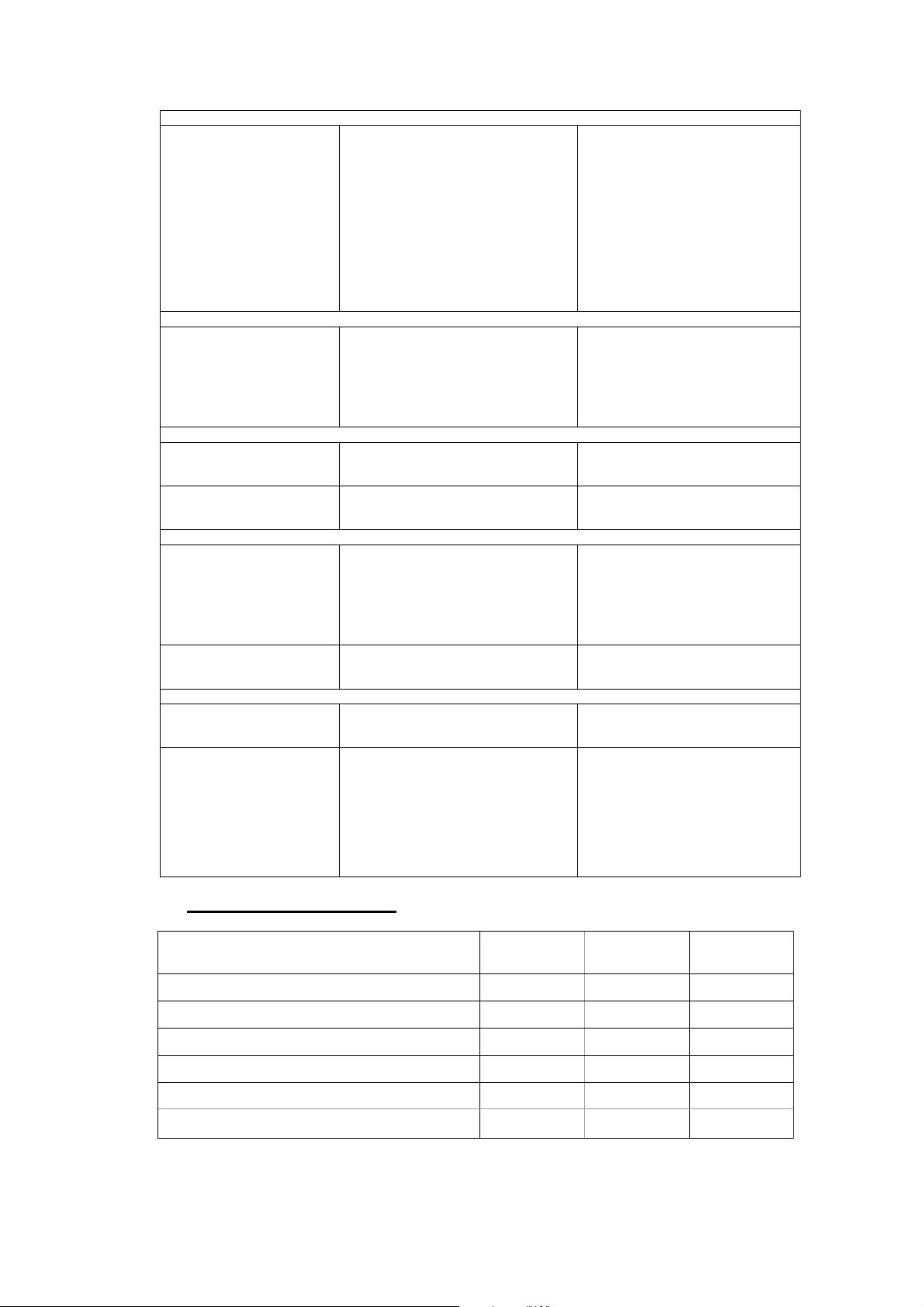

8- DIAGNOSIS (flashing LED s)

Error indication OPERATION

LAMP

TIMER

LAMP

DEFROSTING

LAMP

Indoor fan can’t start after 1 minutes

Evaporator temp sensor fault

Over current on the compressor more than 4 times

EEPROM fault ON

Indoor main PCB fault

Room temperature sensor fault

Flashing at 0.5s / 0.5s

Switched off

ON LED is light