Ekotape 212 User manual

PHoToFACT* FolJ"t EKOTAPE

MODET 2t2

JACK VOTUME

CONTROL

CONTROT -tINE

CORD

RECEPTACAL

CONTROL

KNOB

REMOTE

CONTROT

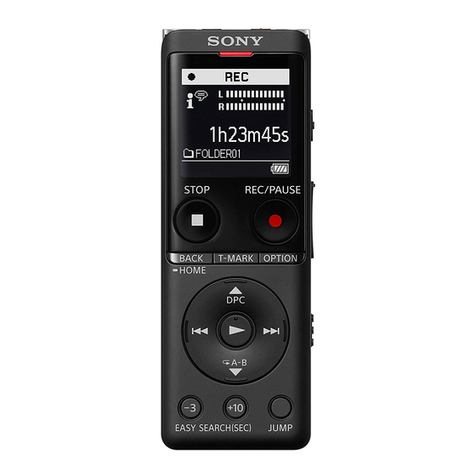

Figure 1

GENERAL INFORMATION

The Webster Electric Ekotape Recorder Model?LZ is for custom installation and has no

cabinet, orcarryingcase. TheModel2l2isdesignedto record and ptay back two tracks of mate-

rialonstandardwidthrecordingtape, which doubles the playing time of a standard 5'* or ?t'reel

of tapewithnolossoffrequency response or quality. Recording can be made from a radio, tele-

vision receiver or phonograph, in addition to those made directly from the microphone.

The Model 2t2 has two tape speeds, 3 3/4" and 7 112" per second. Using both tracks of

the taperrecording time is as follows:

MIKE

INPUT RECORD

tISTEN

CONTROT ON.OFF

swlTcr-l

SPEAKER

ON.OFF

SWITCH

J

ol

lll p

ce{

3-

5H

rg

Ex

H9

Fi

)o!

I lll

t\'

Size Reel

5tt

7"

3 3/4"Speed

t hour

2 hours

? 1/2"Speed

1/2 hour

t hour

Thisunitisdesignedto operate on 60 cycle, 115 volts, AC supply only. Before connecting

to your line supply, be absolutely certain that it agrees with the above specifications.

Manufactured by:

Webster Electric Company

Racine, Wisconsin

Fhis moteriol compiled ond published by

sAils & co., lNc., INDIANAPOLIS, INDIANA

Copyright 1915 . All Rights Reserved

DATE 12 - 55 $rT 301 TOTDER 1

HOWAR.D lf.

1e1;;;1r1e:1yi1+1.1;y1=;* ffi

. . :, : i:l;:i,::, .:::.I:::i:::a::i.i:::#

I

t;

r1 *{i?

$il

Figure 2

OPERATING INSTRUCTIONS

Preparing The Ekotape For Recording-

1. InserttheAC power cord into the receptacle

on the right side of the unit.

2. Plug t h e AC cord into a convenient wall re-

ceptacle of the proper rating.

3. Place a reel of tape on the left hand or "sup-

ply" spindle (9) in a manner so that the tape will un-

wind in a clockwise direction.

NOTE: The Ekotape isdesigned touse Type "A"wound

tape, i. e. the dull magnetic coated side faces

inward on the reel. If t h e tape used i s Type

"8" (coated side facing outward) the recording

will be made at a very low sound level and the

playback will be almost inaudible.

4. Place an empty reel on the right hand or

"take-up" spindle.

5. Unwind approximately 10" of tape and, while

holding a section of tape straight with both hands, in-

sert the tape in the tape slot making sure the dull

coated side of the tape faces the front of the recorder.

Page 2

6. Insert the free end of the tape through to the

hub of the "take-up" reel, f orcing it into one of the

three radial slots. While holding the tape in this po-

sition, turn the reel several turns (clockwise) until

the tape is secured to the r e e I and all slack is taken

up between reels.

To Make A Recording-

1. After the recording tape has been properiy

threaded, turn the "On-Off" control to the "On" po-

sition.

2. Turn the mechanism control knob (2) to "For-

ward".

3. Turn the "Record-Listen" selector knob to

the "Record" position.

NOTE: The "Record-Listen" selector knob will stay

in the "Record" position only when the mech-

anism control knob (2) is in the "Forward" po-

sition.

4. Turn the "Volume" control clockwise until the

incoming signal causes the "Record Indicator" to

flicker occasionally. A recording is now being made

on the tape.

To Record From Microphone-

1. Insert the microphone plug into the "Mic. "

jack, located on the left side of the top panel.

2. Followthe instructions under the heading of ,

"To Make A Recording",

3. Best results will be obtained if the micro-

phone is kept closer to the source of sound than to any

walls in the recording area to prevent echos of the

sounds as they rebound off the walls.

NOTE: The microphone should be kept at least three

feet away from the loudspeakerduringrecord-

ing unless the "Speaker " control knob is in "Off "

position.

To Record From Radio Or

Television Receiver-

Recordings can be made from a radio or tele-

vision receiver by placing the microphone near the lou&

speakerl however, this type of recording may not be

satisfactory as other sounds may be picked up by the

microphone which as a result may be recorded on the

tape. A superior quality recording can be made by use

of Radio Cord Attachment. Connect attachment cord

as follows:

1. Connect the cord clips across the voice coil

terminals on the radio or television speaker,

2. A terminal strip marked Rad-Pho- Input is

provided on the bottom of the chassis, and the other

end of cord should be connected here.

3. Set the radio or television receiver for soft

playing, then operate the Ekotapecontrols as

described under "To Make A Recording".

To Record From Phonograph-

1" Connect the alligator clips of the Radio Cord

Attachmenttotheendsof thepickup leads of the phono-

graph and then connect the other end to the terminal

marked Radio-Pho-Input. Proceed with the recording

as described under "To Make A Recording.'.

NOTE: Shoulda hum develope from the above connec-

tions, reverse the cord clips on the pickup

leads.

To Rewind-

Turn the mechanism control knob (2) counter-

clockwise into the "Rewind" position. When the re-

winding is completed move the mechanism control

knob (2)into"Stop" positionand allow the tapeto come

to a complete stop before moving the mechanism control

knob to any other function.

Twin Track Operation-

Model212 is a twin-track unit, whichrecordson

approximately half the width of tie tape at one time .

1. To record a secondprogram onthe same tape ,

lift the full reel from the right hand spindle,

turn it over, and place itonthelefthandspindle.

2. Place the empty reel on the right hand spindle ;

properly thread the tape, and continue your re-

cording as describedunder "To MakeARecord -

ing".

NOTE: Since it is impossible to edit and splice one

"track" without affecting the other, recordings

which are to be edited should be limited to one

track only.

To Play A Recording-

1. With the tape properly threaded, turn the

mechanism control knob (2) to the "Forward" position .

2. Actjust the "Volume" and "Tone" controls to

suit.

3. Besure thespeaker "On-Off" switch, located

on the right side of the top panel, is in the "On" po-

sition.

Fast Forward-

If it is desired to reach a recording near the

endof atape ina few seconds, turn rrreehanismcontrol

knob (2) to the "Fast Forward" position. In the "Fast

Forward" position the tape moves ahead approximately

15 times normallistening speedof 3 3/4 or 7 L/2inches

per second. The most rapid fast f orward speed is

therefore obtained with the speed control set at 7 L/2 .

REMOVING UNIT FROM MOUNTING BOARD

All service work with the exception of cleaning

the head assembly, adjustment or replacement of brake

lever assemblies (45 and 54), remote lever assembly

(51), pinch roller and lever assemblies (22), (23) and

(18), pressure padassembly (28), will require removal

of unit from the mounting board.

1. To remove the back cover (5) for cleaning of

the head remove all control knobs, and remove two

screws located under mechanism control knob (2). Move

back cover (5) about 1/16 inch toward the front of the

unit and lift straight up and off.

2. Toremove recordhead cover (?), remove one

attaching screw and li-ft off.

3. For removal of the top panel assembly (13),

followtheabove instructionsand remove seven screws

on panel and two under back cover (5). Lift panel

straight up and off.

4. To remove recorder from mounting board,

omitparagraph 1, 2and 3, detachtheAC line cord, re-

movetwoscrewslocatedon each side of the top panel.

Carefully lift unit straight up and out, detaching all

leads, and other connections to the amplifier . Make

sure unit is completely free of the amplifier,

5. When reassemblingthe unit, reverse the above

procedurel plug the amplifier leads into the unit as

marked on the bottom of the unit. Be sure that all leads

clear all moving parts before lowering into place.

6x

H9

F>

Nr!

rm

19

Page 3

Fig.ure 3

TRoUBLES AND REMEDIES 3. Arr,plifier troubte.

Motor Or Amplifier Inoperafive When On-Off Control

Switch Is Turned On- 4. Worn or dirty pressure pad, See "Pressure

Pad And Lever Adjustments".

1' check to see if power is reaching recorder' b. pressure pad spring (2g) roose or missing.

2.Damaged power cord. (a) The pressure pad lever assembly (28)

@Repair or replace. should apply pressure against the tape, thus

holding the tape f i r m against the recording

3. Damaged "On-Off" control switch. head. If this is not true, check the pressure

@Replace "On-Off" control switch assembly. padspring (29); if looseor missing, replace.

4.Defectivepowertransformer, orrectifiertubg Erasing Incomplete Or No Erase-

will cause the amplifier to be inoperative.

@Replac"po*e"transformer. or rectifier tube. 1. Dirt on face of play-record head.

(a) Clean with soft cloth and carbon tetrachlo-

Sound Is Fuzzy, Faint, Distorted, ride.

or No sound- z. oscillatorcoilassemblyortubenotoperating.

1. Dirty head. (a) Check erase voltage with an AC vacuum

(a) Check the record head (30) to see if it is tube voltmeter. There should be a reading

dirty. The recording head is subject to an of approximately 45 volts.

accumulation of tape coating residue, which

is worn off the tape as it passes the head. 3. Defective erase coil in head.

This should be periodically removed since it (a) Check erase head continuity.

may cause faint recordings and poor playback .

Wipe off the record and erase head contact 4. Pressurepadsworn ornot properlyadjusted.

surfaces carefully with a clean cloth. If dirt See "Pressure Pad And Lever Adjustments".

is caked or hard and will not come off with a

dry cloth, dampen the cloth slightly with Failure To Record-

carbon tetrachloride. 1. Record coil open.

NOTE: Do not use a brush or excessive amount of (a) Replace play-record head (30).

solvent on the head surfaces. 2. Insufficient bias voltage.

2. Over recorded or under recorded tape. (a) Check bias voltage across play-record

(a) Correctrecording volume is very impor- head w ith an AC vacuum tube voltmeter.

tant. Too weaka signal, whichdoesnotcause There should be a reading of approximately

the recordlevel indicator to flicker, will re- 100 volts.

sult in weak playback and high background

noise. Too strong a signal, causing the in- 3. Dirt on face of play-record head.

dicator to g I o w continuously, will result in (a) Clean with soft cloth and carbon tetrachlo-

distortion during playback. ride.

Page 4

I

4.

adjusted.

WiIl Not

Figure

Pressurepad worn, defective ornot properly

(a) Adjust pressure pador replace. See

"Pressure Pad And Lever Adjustments".

PIay Back-

4(a) Replace or readjust. See "Adjusting

Brake Lever Assembly".

Take-Up Or Fast Forward Inoperative,

1. Iake-up clutch worn or out of adjustment.

(a) Adjust or replace. See "CorrectingTake-

Up And Fast-Forward Troubles".

2. Drive pin (67) missing.

(a) Replace.

3. Brakes dragging on supply reel.

(a)Adjust brakes. See "Adjusting Brake

Lever Assembly".

4. Take-upreel supportplate (62) dirtyor dam-

aged, (a) Clean, Iubricate or replace. S e e "Cor-

recting Take-Up And Fast-Forward Trou-

bles",

5. Noisy, take-up or fast forward.

(a) Clean, Iubricate or replace.

6. Defective idler wtreels (?6 or 86).

(a) Replace. See "Correcting Take-Up And

Fast-Forward Troubles". (Paragraph 4).

?.. Reel take-up support plate spring (61) broken.

(a) Replace.

Tape Overruns From Fast Forward

To Forward Position-

1. Supply reel brakes not functioning properly,

worn or out of adjustment.

(a) Replace or readjust. See "Adjusting

Brake Lever Assembly".

2. Pinch roller (18) damaged or out of adjust-

ment.

tx

H9

Fi

!H

1\'

1. Open coil in play-record head.

(a) Replace head.

2. Open input circuit.

(a) Check circuit.

Howl Or Ringing Sound-

1. Microphonic tube.

(a) Replace defective tube.

Trouble Common To Radio Receivers-

1. Defective cornponents.

(a) Check and replace in accordance with

standard practice.

Rewind Inoperative, Noisy Or lrregular-

1. Defective motor pulley assembly (94).

(a) Replace.

2. Supplyreel shaft supportassembly (55), dirty

or defective.

(a) Clean, Iubricate or replace.

3. Supply reel support spring (60) is broken.

(a) Replace.

4. Brake (45) dragging on take-up reel.

(a) Adjust brakes. See "Adjusting Brake

Lever Assembly".

Tape Overruns From Rewind To Stop-

1. Take-up reel brakes (45) not functioning pro-

perly, worn or improperly adjusted.

Page 5

dl I

I

I

A PHOTOFACT 'EXPLODED" VIEW

@ Howard W. Sams & Co., lnc. 1955

Page 6

Figure 5A. Exploded View Of Parts Above Baseplate.

-l

A PHOTOFACT "EXPLODED" VIE\(/

@ Howard W. Sams & Co., lnc. 1955

Figure 58 , E>rploded View Of Parts Below Baseplate.

Ex

H9

Ft

hr!

dm

N'

Page 7

Adjustment".

Noisy Running In Stop And

Forward Positions-

1. Defective idlers, dry bearings or flat spots

on idlers.(a) Clean, Iubricate or replace. See "Cor-

bles".

Tape Spills Out Of Supply Reel n-

1. Dirty or defective pinch roller (18).

(a) Clean, Iubricate or replace. See "Cor-

recting Take-Up And Fast-Forward Trou-

bles".

2. Pinchroller lever assemblies(22 and 23) out

of adjustment or damaged.

Page 8

Figure 6

(a) Repair or replace" See "Pinch Roller (a) Adjust or replace. See "Pinch Roller

Adjustment".

Mechanism Control Knob (2) Inoperative-

1. Loose set screw in knob.

(a) Tighten.

2. Loose set screws in pinch roller cam assem-

(a) Adjust and tighten.

Speed Selector Not Functioning-

1. Broken springs (74 and 75) on drive idler

assemblies.

(a) Replace.

Speed Equalization Switch Not Functioning-

1. Switch carn assembly (52) Ioose or broken.

(a) Tighten or replace.

recting Take-Up And Fast-Forward Trou- bty (35).

\t

I

6

o

ii !,';d

S .i lPo

E BTE

4 t66 .

9 -Loo

. c du

q 9 Hoo.5

g E d o!

J d E:? i;

EJPS'E"

3iislrH

( b E (,;g

- oo A!- D

:o!-9Fo

.acYa->a

5!". te_k

xt 3 EI Es

iEslaE.i

--i O Oi c U

:n6: E bs

PsEPEl9

6Eo".5oc

ABEIEgs

oc:iots

E-iou;+l

oo;-'"oo

&'SeE;i a

:;! J > c:

5t.Y9ri.9

,.., o ;: e ! L

E;885; g

.i ciai3d

F

EUJ

5:H

o.<U}

ro

sg

<r: {l

<

-@

()

t:(!l

td>

cr. U)

e

@tRE E

@

|o

o

-E@

@

@

8*

rq=

-l [*]t'

@

6tr

o>

v>

JHI''

@

F

t

o

|o

g.-a\

E/

@tE

@

e.

Ld

=

o

J

J

P

r

6

o

<) F

('

N

z

an

€

/i

E/

A.

=

o

G

o

c>

d

E

G

=t

<(J

k€

=e

=3

ko

Ee

6

a-N

=@

s|o

U

e-\

"-(5)

'-- I

ex

H9

Ft

}\'!

dm

N'

Page 9

2. Switch contacts worn, dirty or broken.

(a) Clean contacts or replace. See "Speed

Equalization Switch Adjustment".

Machine Inoperative When Mechanism

1. Damaged or worn cam and shaJt assembly

(35A). (a) Replace.

ADJUSTMENTS

Pressure Pad And Lever Adjustments-

Cleaning, adjusting or replacing pressure pad

assembly and lever assemblies should be done in the

following manner;

1. Toadjustpressurepadassembly(28), remove

back cover (5) and top panel (13). To remove

assembly f or cleaning, repair or adjustment,

remove spring (29) and retaining ring (27). Ro-

tate the pressurepad assemblyslightly counter-

clockwise and lift off. Reassemble in reverse

orderand lubricate (see "Lubrication"). Adjust

byturning cam and shaft assembly (35A) to "For-

ward" position and check to be sure pressure

pads engage groove of head properly.

NOTE: Be sure flat of pad presses against the erase

and record p o I e pieces. To adjust properly ,

bend levers accordingly.

Improper Rewind Operation-

Ifthe unit doesnot perform therewind operation

properly, check as follows:

1. Adefective motorpulley(94) maybe the cause

of improper rewind. To replace a defective

motor pulleyassembly, remove the three mount-

ingscrews (103) from motor and plateassembly

(104). Carefully remove theassembly so as not

to damage the drive idler assemblies (?6 and 86).

Before removing the motor pulley measure and

note distance from hub to motor. Loosen the

twoAllen head set screws andremove themotor

pulley assembly, Reassemble with a new pulley

inreverse order, Be surepulley hub is correct

distance from motor as previously noted.

2. Adirty or defective supply reelshaft support

assembly (55) may be responsible for improper

rewind. To correctfaulty operation, clean, re-

pair or replace any damaged or worn parts.

Adjusting Brake Lever Assembly (45 and 54)-

If tape overruns from "Rewind" to "Stop" posi-

tion, adjust, clean or replace brake lever assembly

(45).

1. To ad just brake lever assembly (45), turn

camand shaft assembly (35A) to"Rewind" posi-

tion. Adjust either by bending the brake lever

assembly (45) or by slightly bending the stop on

mechanism panel just enough to clear the cup

disc on reel shaft (10). Clearance should not

exceed 1/64 inch. Adjust brake lever (45) so

that remote Iever (51) returns to "Stop" posi-

tion. Check to be sure brake lever (54) on the

supply reel (9) is being held in its stop position

Page 10

by the remote lever assembly (51). If not, turn

camand shaftassembly (35A) to "FastForward"

andadjust brake lever assembly(54) as outlined

above. Before reassembly of top panel, thread

recorder with tape and checkunit for any further

trouble.

2. If tape overruns from "Fast Forward" to

"Forward", check operation of brake lever (54)

as explained in above paragraph with this ex-

ception; turn cam and shaft assembly (35A) to

"Fast Forward" position and adjust brake lever

(54) on the supply reel (9). Check brake lever

(45) on the take-up reel to be sure it is held in

its stop position by the remote lever assembly

(51). f not, turn carn and sha"ft assembly (35A)

to "Rewind" and adjust brake lever as covered

in above paragraph.

Adjusting Brake Arm Assembly (113)-

If af ter completing adjustments as covered in

"Adjusting Brake Lever Assembly", the overrun on

"Rewind" and "Fast Forward" is not corrected, re-

move the unit from the case and check as follows:

1, Check "Rewind" position first and adjust or

replace brake arm assembly (113). First be

sure brake pad is still attached to arm. Turn

cam and shaft assembly (35A) to the "Rewind"

position and adjust the brake arm (113) so pad

just clears the reel pulley assembly (70) but by

no more than 1/64 inch.

2. Check "Fast Forward" position and adjust or

replace brake arm assembly (113). First be

sure brake pad is still attached to arm. Turn

cam and shaft assembly (35A) to "Fast For-

ward" position and ad just bral<e arm (113) so

thatthe pad clears reel pulley assembly (Ba) by

no more than 1/64 inch.

Correcting Take-Up And Fast

Forward Troubles-

If take-up and fast forward drive does not func-

tion properly, r e m o v e unit from case and check as

follows:

1. If the take-up or fast-forward drive is weak ,

screw the self-Iocking wing nut (?3) on the reel

shaft (10) s o spring (?2) will produce a greater

friction drive.

2. Ifafter adjustingthe self-locking wingnut

(?3) a weak drive still exists, then remove wing

nut, spring (?2), washer (?1) and reel pulley

assembly (?0) and check felt pad on pulley. If

pad is worn badly, replace assembly (70), but

if pad shows no excegsive wear, remove clutch

disc (68) and check to see i.f drive pin (6?) is in

place. Replace pin if missing and reassemble

in reverse order and adjust wing nut.

3. If unit i s noisy in "Forward" or "Fast-For-

ward" position, check to s e e if idler assembly

(110) isdirty or damaged, Or it may be the re-

sult of dirty bearings on the take-up shaft or

pulley assembly. To check, inspect idler

assembly (110) and determine if dirty or defec-

tive. Remove retainingring (112), fibre washer

(111), idler assembly (110), and fibr e washer

(111). Clean any dirt or oil from idler tire and

bearing. Clean flywheel and shaft assembly (89) ,

drive area only, also reel pulley(?0) drive area

witha suitable solvent, Relubricate idler bear-

ing and reassemble in reverse order.

4. If noise still exists in "Forward" or "Fast-

Forward"position check the reel shaft assembly

(10). Rem ove wing nut (?3) and spring (?2) ,

washer (71), reel pulley (?0), clutch disc (68),

pin (67), U-washer (66), washer (65), retaining

ring (64), fibre washer (63), reel pulley assem-

bty (10) and fibre washer (12). Clean and in-

spect all parts for wear or damage. Clean the

bearing in the reel support assembly (62) and

inspect bearing. Relubricate and replace any

defective parts and reassemble in order shown

on exploded view.

Pinch Roller Adjustment-

If pinch roller is damaged or out of adjustment,

clean and adjust in the following manner:

1. Toclean thefollower leverassembly (23) and

the pinch roller lever assembly (22), remove

springs (20 and 24), and retaining ring (21).

Remove both assemblies and shaf t attached to

mechanism plate. Clean thoroughly, removing

oldgrease and dirt, and relubricate. Reassem-

ble in reverse order. Adjust tab on follower

Leverassembly (23) so that pinchroller (22) en-

gages flywheel capstan just before lever (54)

releases supply reel pulley (9) from "Stop" po-

sition to "Forward". This prevents flare out of

thetape inthe supply reel, from "Stop"to "For-

ward" position.

MAINTENANCE

Cleaning The Play-Recor4 Head-

Theplay-recordhead is subject to anaccumula-

tion of tape coating residue which is worn off the tape

as it passes the head" This should beperiodically re-

moved since it may cause faint recordings and poor

playback. Wipe off the record and erase head contact

surfaces carefully with a clean cloth. If dirt is caked

orhard and willnot come off with a dry cloth, dampen

the cloth slightly with carbon tetrachloride.

NOTE: Donot use abrush or exeessiveamount of sol-

vent on the head surfaces,

Lubrication-

On normal use, the Ekotape requires a limited

amount of lubrication. Motor, flywheel shaf t, reel

spindles, pinch roller assembly and idlers operate in

oilite bearings. Whenever unit is disassembled for

repair, clean all bearings, cams, and levers, and

lubricate the following:

1. Lubricateall oilite bearings withSAE 20 oil .

2. Lubricate all cams and levers with Liqui-Moly

NV Grease or equivalent.

3. Appty a thin film of lubricant on the working

areas of parts.

NOTE: Do notuse cleaning solvent on oilite bearings.

Do not overlubricate, Ex

H9

Fi

}\t!

rl'l

19

EL AL PARTS LIST

Ref .

No. Part

No- Description Ref.

No. Part

No. Description

v1

v2

v3

V4

v5

v6

c1A

c1B

clc

c2A

c2B

c2c

c3

C4

c5

c6

c7

CB

c9

c10

c11

c12

c13

c14

c15

c16

c1?

24 1 - 19367

24L-t4238

s6063

s6065-3

s3595

s4261

s3595

2tt-r49t2

211 -30639

21 1 - 15048

s4261

s6065 -9

s6065-9

s6065-3

s6065-3

24t-L2t67-t

s6065-3

58?9, Pre. Amp.

6C4, 1st A. F. Amp.

6C4,2nd A. F. Amp.

6SN?GT, Record Amp. & Cathode

Follower

6AQ5, Bias Osc.

5Y3GT, Rectifier

Elect. Cap., 40MFD @450V.

Elect. Cap., 40MFD@450V.

Elect. Cap., 40MFD @)450V.

Elect. Cap., 40MFD@450V.

Elect. Cap., 40MFD@450V.

Elect. Cap., 40MFD@ 25V.

Elect. Cap., 50MFD@)OV.

Cap. Ceramic, 200MMF@ 500V.

Cap. Molded Paper, . 1MID@400V.

Cap. Molded Paper, . 05MFD

@400v.

Cap. Molded Paper,

Cap. Molded Paper,

200v.

Cap. Molded Paper,

400v.

Cap. Molded Paper,

400v.

Cap. Molded Paper,

400v.

.1MFD@4oov.

.05MrD@

.02MrD@)

.04?MTD@

.05MFD@

Cap. Ceramic, 400MMF @ 500V.

Cap. Ceramic, 400MMF@ 500V.

Cap. Ceramic, 200MMF @ 500V.

Cap. Ceramic, 200MMF@ 500V.

Cap. Molded Paper, . 006Mm@

400v.

Cap. Ceramic, 200MMF@ 500V.

c18

c19

c20

c2L

c22

c23

c24

R1

R2

R3

R4

R5

R6

R?

R8

R9

R10

Rl1

R12

R13

R14

R15

R16

R1?

R18

R19

R20

R21

F"22

R23

P"24

R25

R26

s6065-3

zlt-t4492

211-18931

24L-14260-l

24L-t4260-t

s6065 -2

241-L4260-2

24L-L7940

29501 -53

29501 -29

29501 - 1 1

29501 -53

29501 -56

29501 -44

29501 -35

29501 -14

29501 -35

2950r-44

29501 -41

29501 -14

29501 -48

29501 -21

29501 -56

29501 -?5

29501 -35

29501 -95

29501-44

29501 -53

29501 -48

29501 -48

29501 -41

29501 -32

29501 -36

Cap. Ceramic, 200MMF@ 500V.

Cap. Molded Paper, . 2MFD@400V.

Cap. Molded Paper, .47MFD@)

200v.

Cap. Ceramic, 3000MMF@ 500V.

Cap. Ceramic, 3000MMF@ 500V.

Cap. Ceramic, 100MMF@ 500V.

Cap. Ceramic, 1?000MMF@ 500V.

Volume Control,500K, 1/2 W.

Resistor, 510K, 1/2 W.

Resistor, 22K, L/2 W.

Resistor, lK,L/2 W.

Resistor, 5t0K,l/2 W.

Resistor, 1MEG, l/2 W.

Resistor, 150K, 1/2 W.

Resistor, llK, L/2 W .

Resistor, 2K, t/2 W .

Resistor, ltK,l/2 W.

Resistor, llOK,l/2 W.

Resistor, 100K, 1/2 W.

Resistor, 2K, L/2 W .

Resistor, 240K,t/2 W.

Resistor, 5.lK,l/2 W.

Resistor, 1MEG, L/2 W.

Resistor, S. 1K, 1 W.

Resistor, llK,L/2 W.

Resistor, 2MEG, l/2 W.

Resistor, 150K, 1/2 W.

Resistor, 5L0K,l/2 W.

Resistor, 240K,L/2 W.

Resistor, 240K,I/2 W.

Resistor, 100K, 1/2 W.

Resistor, 30K, 1/2 W.

Resistor, 62K,1/2 W.

Page 11

P- uon

r('EI

No. Part

No. Descrintion Ref .

No. Part

No. Description

P-27

R28

R29

R30

R31

R32

R33

R34

R35

z9DUr -:to

29501 -14

29501 -35

29501 -53

29501 -29

29501 -53

29501 -17

29501 -41

29502-15

tteslstor, OZf\, L/Z W.

Resistor, 2K,L/2 W.

Resistor, llK,l/2 W.

Resistor, 510K, 1/2 W.

Resistor, 22K,1/2 W.

Resistor, 510K, 1/2 W.

Resistor, 3K,l/2 W.

Resistor, 10K, L/2 W.

Resistor, 1K,5W.

rtJU

T1

L1

L2

M1

M2

M3

M4

M5

MA

242-t1935

241-14246-l

242-L1937

28755-7

P1 1139-1

242-LBl65

241-r7949

24t-t7942

29502-14Resistor,20K, 10W,

Power Transformer

Bias Osc. Coil

Filter Choke

Fuse,2Amp.

Lamp, #51

Selector Switch Assy.

Equalizer Switch

Speaker Switch

ELECTRICAL PARTS LIST - Con'

No.

ttel Part

No. Description tiel.

No. yarL

No, Description

1

21

3

4

5

6

7

I

I

10

11

t2

13

t4

15

16

t7

18

19

20

2l

22

23

24

25

26

27

28

29

30

31

32

33

34

35

35A

36

3?

38

39

40

4l

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

24L-t78t8-l

242-19844-r

241-15116

242-L78L5-l

24t-t7816-2

29529-t4

24t-t78r7 -L

29529-4L

242-t776t

242-1777t-L

24L-L7770

24L-L7770

24t-r7814-l

29529-40

29527 -4

29602-103

24t-t'1747

242-17744

24L-L7722

241 - 12138

29650- 1

242-t774r-2

242-L',t739-2

24L-17734

29650- 1

242-r7748-l

24t-t7801

242-L4r59

29527 -13

24t-t7154

241,17753

24t-L7152

242-t77tO-l

242-t7707 -l

242-t77t3-L

24 1 - 1?801

29651-1

241 -12059

29602-t24

241-L7134

242-L7683-3

29651 -1

244-L1758-t

24t-t7734

24t-12059

29602-L22

29651-1

24t-r7734

242-17755-L

242-t9345

242-t775

242-t7758-l

242-17695-l

29602-L24

24t-t2059

Control Knobs, Amplifier

Mechanism Control Knob Assy,

Socket Hd. Set Screw

Knob Assembly

Back Cover

Rec. Pan. Hd. Mach. Screw

Record Head Cover

Rec. Pan Hd. Mach. Screw

Reel Shaft Assembly (left)

Reel Shaft Assembly (right)

Washer, Fibre

Washer, Fibre

Top Panel

Mach"Screws Top Panel Mtg.

Screw

Washer, Steel

Washer, Fibre

Pinch Roller Assembly

Washer, Fibre

Spring

Retaining Ring

Pinch Roller Lever Assembly

Follower Lever Assembly

Spring

Screw, Record Head Mounting

Flat Washer Steel

Retaining Ring

Pressure Pad Assembly

Spring

Play-Record-Erase Head Assy.

Screw (2 Used)

Top Tape Guide (2 Used)

Tape Guide Spacer (2 Used)

Tape Guide Shelf

Pinch Roller Cam Assembly

Cam and Shaft Assembly

Index and Interlock Lever Assy.

Spring

Retaining Ring

Spring Tension Washer

Washer

Remote Lever Arm

Spring

Mechanism Plate Assembly

Retaining Ring

Brake Lever Assembly

Spring

Spring Tension Washer

Washer

Retaining Ring

Spring

Remote Lever Assembly

Switch Cam Assembly

Set Serew

Brake Lever Assembly

Reel Shaft Support Assy.

Washer

Spring Tension Washer

58 I

seI

60 I

61 I

62 I

63 1

64 1

65

66

67

68

69

?0

7l

12

73

74

75

76

77

?B

79

80

81

82

83

84

85

B6

8?

BB

89

90

91

92

93

94

95

96

9?

98

99

100

101

102

103

104

104A

105

106

10?

108

109

110

111

tt2

11?

24r-t7770

24t-L7770

241-1?801

241 -1?801

242-r7103-2

24t-t7770

29650-2

29602- 133

24L-r7775

24L-t7086-4

24t-17771

29650-2

242-r7773-t

29602 - 102

241-tI644

24L-21799-l

24r-r1802

241-t7802

242-L7136-r

29650-1

24t-t7723

242-t7724-1

242-r7739-2

24L-L77L7 -t

24L-t77L7 -L

242-r7737 -2

242-L7766-l

242-1773t-2

24L-t7723

29650-1

241-r7718-r

24r-13609

29650-1

24t-17723

242-t77BB-2

241-t7789-2

242-t7765-r

241-t7674

24L-t7786-r

24L-14t34

242-t77t6-l

24t-17723

29650-1

242-I77L9-3

241-17122

29650- 1

tat _11eea

Washer, Fibre

Washer, Fibre

Spring

Spring

Reel Shaft Support Assy.(right)

Washer, Fibre

Retaining Ring

Washer, Steel

U-Washer, Steel

Pin

Clutch Disc

Retaining Ring

Reel Pulley Assembly

Washer, Steel

Spring

Self Locking Wing Nut

Spring

Spring

Top Lever and Idler Assy,

Retaining Ring

Spring Tension Washer

Cam Shaft Assy.

Follower Lever Assembly

Idler Link Assembly

Idler Link Assembly

Follower Lever Assembly

Reel Pulley Assembly

Set Screw Allen

Lower Lever and IdlerAssy.

Spring Tension Washer

Retaining Ring

Flvwheel and Shaft Assy.

Steel Ball

Retaining Ring

Keyed Washer

Spring Tension Washer

Motor Pulley Assembly(Includes

items 95, 96 and 9?)

Motor Pulley Clutch Washer

Motor Pulley

Allen Set Screw

Lockwasher

Support Plate Mounting Screw

Support Plate Assembly

Washer Steel

Lockwasher

Motor Mounting Screw

Motor

Motor Mounting Plate

Fan

Set Screw

Idler Link Assembly

Spring Tension Washer

Retaining Ring

Idler Assembly

Washer Fibre

Retaining Ring

Brake Arm Assemblv

Page 12

Table of contents

Popular Voice Recorder manuals by other brands

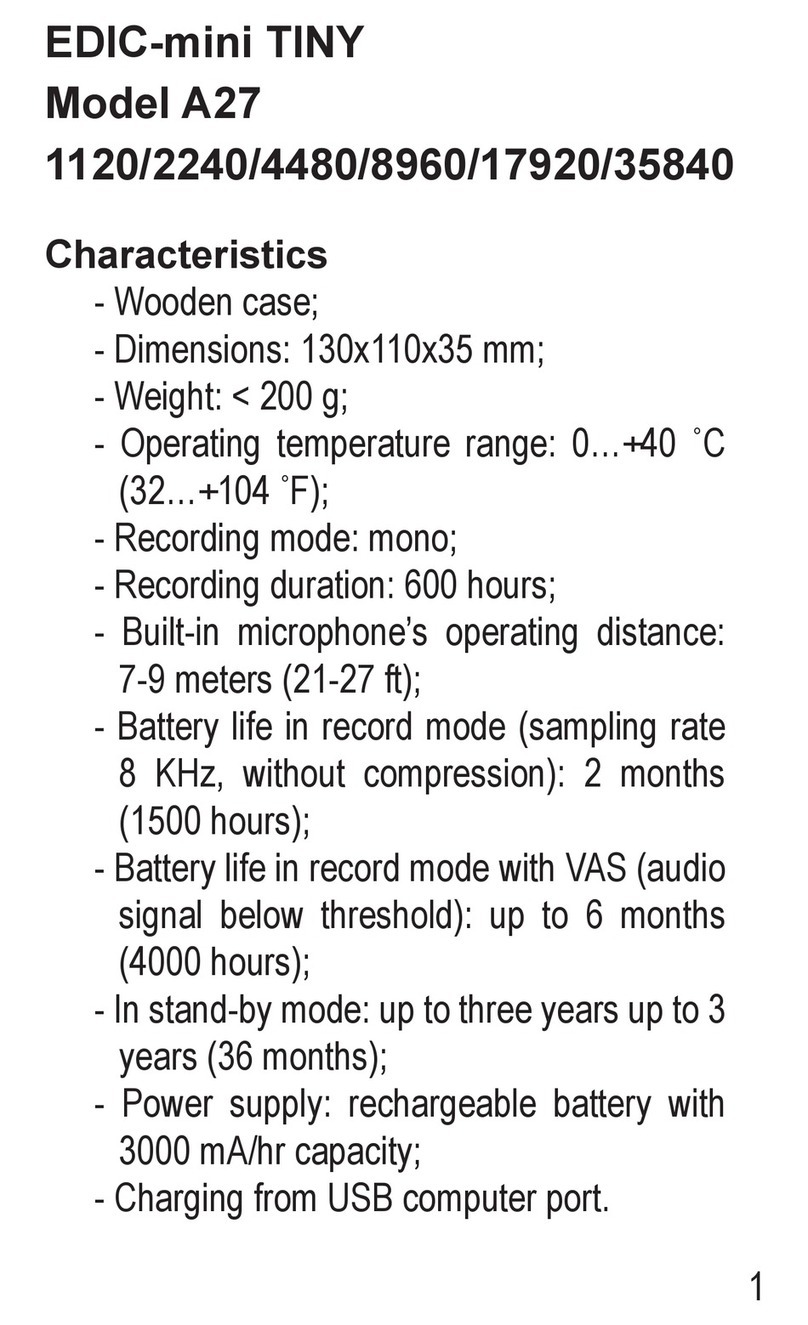

EDIC-mini

EDIC-mini TINY A27 1120 Short operating instructions

Yamaha

Yamaha POCKETRAK 2G - 2 GB Digital Player Brochure & specs

Safa Media

Safa Media R200 instruction manual

Sony

Sony ICD-P210 Digital Voice Editor 2 Specifications

Sony

Sony ICD-UX300 - Digital Flash Voice Recorder Specifications

Olympus

Olympus VN 4100 - 256 MB Digital Voice Recorder instructions