ELCA Eclipce 2 User manual

1

ATTENZIONE

A correct ground connection is mandatory

during the installation it is important to have

a switch a contact opening of at least 3 mm

that assures an omnipolar disconnection of

the board to the current network

Control board for swing gates.

FOLLOW THIS INSTRUCTIONS CAREFULLY

This manual contains important instructions for installation and use of this control board mod.

ECLIPSE2. Don’t install before reading this manual, the security of the product depends on a correct

installation. The producing company declines any responsability in case of a not correct instalment or

improper use. This product has been created by keeping the strictest safety norms following EC

directives : CEE 73/23, CEE 89/336, CEE 93/68, CEE 89/106, CEE 89/392.

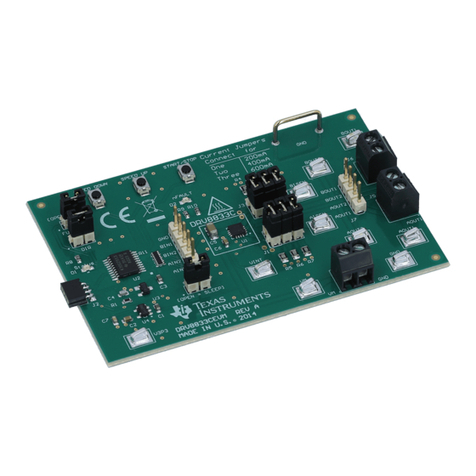

Electric-lock

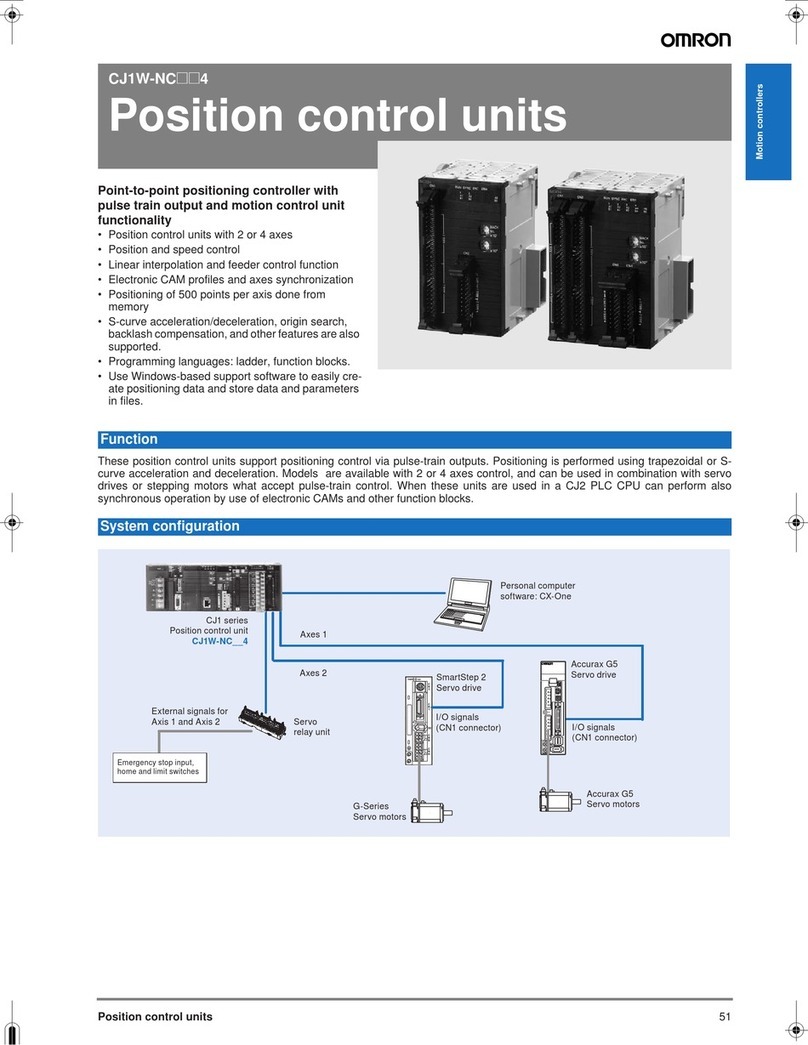

19 18 17 16 15 14 13 12 11 10 9 8 7 654321

20

2122

23

24

25

26

27

2829

30

31

32 33

35 34

FUSE 315m A

FUSE 6A

FUSE 2,5A

Led ON

Led OK

FOR ZA FR ENO

DIP A

DIP B

RE CEI VER

++

Com

Com

Pha s e

Neutra l

24Vac

Gn d

E lectri- loc k

Pedestrian

Start/stop

Com

Stop

Phot oc 1

Phot oc 2

Com

Op en

Close

Fa1

Fc1

Com

Int ercom -

Int ercom +

Ant. RF

An t . G n d

Motor 1

delaye d

in ope ni ng

Moto r 2

delayed

in clo si ng

STOP

An te nna

Court ec y

lam p

Flashin glight

23 0Va c

24Vac

Disconnection

omn i po l are

23 0V 50 H z

24 Va c

12345

Ph oto c ell 1 Ph oto cel l 1

45 12345

Ph oto cel l 2 Ph oto cel l 2

45

Fc1

Fa1

Limit swi tch

Motors 1 and 2

Pus hbutton

Ope n and Close

Sto p

Key switch

Puhbu t ton

wa lk-w ay

Outside

photoc. Active

only in closing

Inside p hotoc.

Active both in opening

and closing

Pe d

St a rt

St o p

Fot1

Fo t 2

Ap re

Fc 1

Fa 1

Ch i ud e

M1

M1 rev

M2 r ev

M2

Elett

FOT30 RX FOT30 TX

Sta rt Pe d

FOT30 RX FOT30 TX

Magnetic Detect

Via Malintoppi, 32

63025 FERMO (AP) ITALY

Tel/Fax: (0039) 0734 605080

Web: www.elcasnc.com

REV. 3

This manual has to stay with the equipment at all time, must not remove!

2

FOR SAFETY REASON A SAFETY DEVICE MUST BE USE WHEN USING THIS REMOTE CONTROL !!!

TERMINALS CONNECTIONS :

1-2 Antenna, terminal n°2 = RF 15-14 “Start/Stop” push button (n.o. contact)

3-4 Input from intercom 12Vac see <T> 16-14 SS2 push button motor n 2 command

5-6 Closing limit switch (n.c. contact)

see <D> 17-18 Electric - lock 12vac-15w

7-5 Opening limit switch (n.c. contact)

see <D> 18-19 24Vac output (max 3 pairs of photocell)

8-5 ‘’open’’ push button (n.o. contact)

or Magnetic Detect 20-21 POWER SUPPLY 230V-50Hz

9-10 ‘’close’ ’push button (n.o contact) 22-23 Flashing light 230V -25w

11-10 Photocell n 2 (n.c. contact) or

rubber see logic <H> 24-25 Courtesy light contact ( free voltage)

12-10 Photocell n 1 (n.c. contact) 26-27-28 Motor n 1 (terminal N.27 = com.)

13-14 “Stop” push button (n.c. contact) 29-30-31 Motor n.2 (terminal. N.30 = com.)

LED FUNCTIONS

ON Normally ON POWER ON BOARD

OK 1 flashing when a radio code is

received and recognized

During programming

1 flashing when a code is

memorized

3flashing = error, the code

received is already in memory

or memory is full

ON, during motor timing

programming

ON, during pause timing

programming

ON, during RESET

Flashing when the RESET has

been execute

M1 ON, when motor n 1 is activated

M1rev Show the direction of motor n 1

M2rev Show the direction of motor n 2

M2 ON, when motor n 2 is activated

Elett ON, when electric-lock is activated

Ped ON, when SS2 button is pushed

Start ON, when START button is pushed

Stop Normally ON it turns OFF when STOP

button is pushed

Fot1 Normally ON it turns OFF when the

photocell n 1 ray is interrupt

Fot2 Normally ON it turns OFF when the

photocell n 2 ray is interrupt

Apre ON, when OPEN button is pushed

Chiude ON, when CLOSE button is pushed

Fa1 Normally ON it turns OFF when the

open limit switch is activated

Fc1 Normally ON it turns OFF when the

close limit switch is activated

DIPS SWITCH:

DIP SWITCH ‘’A’’ DIP SWITCH ‘’B’’

A1 Pre-flashing -- L -- B1 Electric-lock -- N --

A2 Walk-way 45° -- M -- B2 Motor phase reverse – G --

A3 Logic 0 -- H -- B3 In ON position = motor delay erased

A4 Logic 1 -- H -- B4 In ON position = slow-down erased

A5 Pause time activated B5 In ON position = locking for wind – P -

A6 Pause time program – E -- B6 Open gate signal – Q --

A7 M1 timing program – B -- B7 Courtesy lamp = 2 seconds – R --

A8 M2 timing program – B -- B8 Courtesy lamp code program – A4 --

A9 Start code program – A1 -- B9 Soft motor Start – S --

A10 ERASE – I -- B10 Walk-way code program – A7 --

YOU CAN USE WITHOUT PROGRAMMING…… ! -

The control board is supplied with a BASI PROGRAM that give you the following functions :

¾Motors timing : 20 seconds –slow-down excluded

¾Pause time : 30 seconds

¾Delay time : 5 seconds in closing and 2 seconds in opening

¾Courtesy lamp time : 3 minutes

¾Radio code in memory: channel n 1 ASTER with dips 1,3,5,7,9 = ON = BASIC CODE.

3

>>>> AT ANY TIME YOU CAN FETCH THE BASIC PROGRAM BY THE RESET FUNCTION <<<<

.

RESET

•Turn OFF the power.

•Set the dips A7, A8, A10.in ON position

•Turn ON the power, the led OK goes ON

,then start to flashing, the reset is finish

•Set the dips A7, A8, A10 in OFF position,

the led OK goes off

On during

RESET

Flashing

at the end

7

8

10

RESET

- ATTENTION !!! – during normal function the dips: A6, A7, A8, A9, A10, B2, B8, B10, MUST

BE IN OFF POSITION.

<A> CODE RADIO PROGRAMMING.

--- as soon the first code is memorized the ‘’basic code’’ will be erased

--- max code in memory : 160 standard code or 53 rolling code

--- if the first code memorized is a rolling code then the board accept only rolling code, to accept again

the standard code, RESET must be done

Code Start/Stop

A1. set the DIP A9.in ON position

A2. send a code with transmitter ( about 50 cm far ) the

OK led give you a confirm with 1 flashing, if the led

make 3 flashing that means that the code is already

in memory or the memory is full

A3. set the DIP A9.in OFF position

60 cm

9

Code courtesy lamp

A4. set the DIP B8.in ON position

A5. send a code with transmitter as step A2

A6. set the DIP B8.in OFF position

60 cm

1 Flash

8

Code walk-way SS2

A7. set the DIP B10.in ON position

A8. send a code with transmitter as step A2

A9. set the DIP B10.in OFF position

60 cm

1 Flash

10

4

Code Stop

A10. set the DIP A9 in ON position and open the contact

between terminals n 13-14.

A11. send a code with transmitter as step A2

A12. set the dip A9 in OFF position and close the contact

on terminals n 13-14.

14 13

Com

Stop

60 cm

1 Flash

9

A13. Code Open: Set the DIP A9 in ON position and close the contact between terminals n 8 – 5. Send a code

with transmitter. Set the dip A9 in OFF position and open the contact on terminals n 8 - 5.

A14. Code Close: Set the DIP A9 in ON position and close the contact between terminals n 9 – 10. Send a code

with transmitter. Set the dip A9 in OFF position and open the contact on terminals n 9 - 10.

!!!! TO ERASE A CODE SEE STEP - I -.

<B> MOTORS TIMING PROGRAMMING ,WITH SLOW-DOWN

-- set and leave the DIP B4 in OFF position.

-- set the trimmer Forza to “+”.

-- set the trimmer Freno to mid range.

ATTENTION:for a correct function it is necessary that the gate have a physical stop in opening

and in closing

ATTENTION:if YOU HAVE ONLY ONE MOTOR YOU MUST CONNECT AS MOTOR N 2

(terminals n 29-30-31 ) AND YOU MUST SET AND LEAVE THE DIP B3 in ON.position.

- Time motor n°2 -

B1. by hand close swing n 2.

Turn OFF the power.

Turn ON the power

Gate to

program

Motor2 Motor1

B2. set the DIP A8 in ON position, the led OK

goes on.

8

4

Fixed

on

B3. send a command with transmitter or by start

push button, if the motor does not move in

opening the phase inversion <G> must be

done.

Motor2

Give the 1st impulse

to start the motor

Max force

for 1,5 sec

Normal

speed

B4. when slowing down is required send a second

command at this point the motor move at the

speed set by the trimmer FRENO.

Motor2

Give the 2nd

impulse to

start slowing

down

Slowing

down

5

B5. After 2 seconds that the gate is

completely opened send a third command

for stopping.

Motor2

A

fter 2 sec give

the 3th impulse

to stop the motor

B6. repeat steps B3, B4, B5 for closing time programming.

B7. set the DIP A8 in OFF position ,the led

OK goes off.

8

4

OFF

- Time motor n 1 -

B8. by hand close the swing n 1, leave swing

n 2 open

Turn OFF the power.

Turn ON the power.

Gate to

program

Motor2 Motor1

B9. set the DIP A7 in ON position ,the led

OK goes on.

7

4

Fixed

ON

B10. send a command with transmitter or by

start push button, if the motor does not

move in opening the phase inversion <G>

must be done

Motor 1

Give the 1s t impul se

to sta rt the motor

Max f orce

for 1,5 sec

No rm a

speed

B11. when slowing down is required send a

second command at this point the motor

move at the speed set by the trimmer

FRENO.

Mo tor1

Give the 2nd

impulse t o

start slowing

down

Slowing

down

B12. after 2 seconds that the gate is

completely opened send a third command

for stopping.

Mot or1

After 2 sec give

the 3th impu lse

tostop the motor

B13. repeat steps B10, B11, B12 for closing time programming.

6

B14. set the DIP A7 in OFF position the led

OK goes off.

7

4

OFF

NOTE : you can make several movement in opening and in closing, only the last will be memorized !!!!.

<C>MOTORS TIME PROGRAMMING WITHOUT SLOWING DOWN.

-- set and leave the DIP B4 in ON position.

-- set the trimmer Forza to +” .

ATTENTION:for a correct function it is necessary that the gate have a physical stop in opening

and in closing.

ATTENTION:if you have only one motor you have to connect has motor n 2 ,terminals

n 29-30-31,and you must set the DIP B3 in ON position.

- time Motor n°2 -

C1.place the gate n 2 in closing position

Turn OFF the power.

Turn ON the power.

Gate to

program

Motor2 Motor1

C2.set the DIP A8 in ON position, the led OK

goes on

8

4

Fixed

ON

C3.send a command with transmitter or by

start push button, if the motor does not

move in opening the phase inversion <G>

must be done.

Motor2

Give the 1st impulse

to start the motor

Max force

for 1,5 sec

Normal

speed

C4.after 2 seconds that the gate is

completely opened send a second

command for stopping.

Motor2

A

fter 2 sec give

the 2nd impulse

to stop the motor

C5.repeat steps C3, C4 for closing time programming

C6.set the DIP A8 in OFF position, the led

OK goes off.

8

4

OFF

7

- time Motor n°1 -

C7.place the gate n 2 open and the gate n 1

to close position.

Turn OFF the power.

Turn ON the power

Gate to

program

Motor2 Motor1

C8.set the DIP A7 in ON position, the led OK

goes on.

7

4

Fixed

ON

C9.send a command with transmitter or by

start push button, if the motor does not

move in opening the phase inversion

<G> must be done.

Motor 1

Give the 1s t impul se

to sta rt the motor

Max f orce

for 1,5 sec

Norm al

spe ed

C10. after 2 seconds that the gate is

completely opened send a second

command for stopping.

Mo tor1

After 2 sec give

the 2nd impulse

to stop the motor

C11. repeat steps C9, C10 for closing time programming.

C12. set the DIP A7 in OFF position, the led

OK goes off.

7

4

OFF

<E> PAUSE TIME PROGRAMMING

NOTE : to enable pause time set and leave the DIP A5 in ON position.

ATTENTION:before start with pause time program check that the DIP B3 is in OFF position.

E1. set the DIP A6 in ON position, the led

OK goes on, leaving for as long as

pause is required ( from 1 second up 20

minutes )

E2. set the DIP A6 in OFF position the led

OK goes off.

Fixed

ON

6

5

.

E1

8

<F> CHANGE DELAY CLOSING TIME

F1. set the DIP B3 in ON. position

F2. set the DIP A6 in ON position, the led

OK goes on, leaving for the time

required, then set it in OFF position.

F3. set the DIP B3.in OFF position

NOTE: if the dip B3 is leave in ON position

the time delay is = 0 second that mean

booth motor start in closing at the same

time

3

6

Fixed

ON

F1 F2

<G> REVERSE MOTOR PHASE

this function automatically change the phase motor, in this way does not need to change the

motor wire connections

Reverse phase motor n 1

G1.set the DIP B2.in ON position

G2.set the DIP A7 in ON position, the led

OK make a flash to indicate that the

reverse is done

G3.set the dips A7 and B2 in OFF position,

the led OK goes off.

1 fash

then fixed

ON

27

2

G1 G2

Riverse phase motor n 2

G4.set the DIP B2.in ON position

G5.set the dip A8 in ON position, the led

OK make a flash to indicate that the

reverse is done.

G6.set the dips A8 and B2 in OFF position,

the led OK goes off.

1 flash

then fixed

ON

8

2

G4 G5

<H> LOGIC

--- set and leave the dips A3 and A4 as you need.

DIP A Logic

3

4

Logic step by step

The first command open, the second make a stop, the

third start closing and so on…..

3

4

No step by step logic

One command open, during the open other command

does not make effect, during the closure one command

invert to open.

3

4

Immediate close after cross photocell n1 and n 2.

9

3

4

No step by step logic for pneumatic bar

If on terminals n 10-11 you connect a pneumatic bar,

when the bar is pressed the gate reverse the movement

for 1,5 second then stop.

<I> RADIO CODE ERASING

- erasing all code.

I1. if you make the RESET function, all code are erasing and the BASIC CODE come back in

memory.

Erasing Start/Stop code

I2. set the DIP A9 in ON position

I3. set the DIP A10 in ON position, the Led OK make a

flash.

I4. set the dips A9 and A10 in OFF position

1 Flash

9

10

Erasing courtesy lamp code

I5. set the DIP B8 in ON position

I6. set the DIP A10 in ON position, the Led OK make a

flash

I7. set the dips DIP B8 and A10 in OFF position

1 Flash

10

8

Erasing walk-way code SS2

I8. set the DIP B10 in ON position

I9. set the DIP A10 in ON position, the Led OK make a

flash.

I10.set the dips B10 and A10 in OFF position

1 Flash

10

10

Erasing stop code

I11.open the contact on terminals n 13-14.

I12.set the dip A10 in ON position, the Led OK make a

flash.

I13.close the contact on terminals n 13-14.

14 13

Com

Stop

1 Flash

10

Erasing just one code.

.

-- set the DIP A10.in ON position

-- send a code already in memory, this code will be erasing

the Led OK make a flash.

-- set the DIP A10.in OFF position

1 Flash

10

<L> PRE-FLASHING DIP A1

-- Set and leave the DIP A1 in ON position, the pre-flashing is 3 seconds.

<M> 45° WALK-WAY DIP A2

-- set and leave the DIP A2 in ON position.

10

<N> NO ELECTRIC-LOCK COMMAND DIP B1

-- set and leave the DIP B1 in ON position

<O> NO DELAY IN CLOSING DIP B3

set and leave the DIP B3 in ON position, in this way booth gates close at the same time

<P> LOCKING FOR WIND + SECURE LOCK DIP B5

Note : this function can be activated only if the dip B1 is in OFF

position

-- set and leave the DIP B5 in ON position

When activated the motors make a short movement in

closing before start to open, in this way is more easy to

unlock the electric-lock even with bad wind condition

- !!! Pay attention on program motor n 2 in closing phase, after 3

seconds that the impulse for slowing down has been given the

motor n 2 automatically will start at max force to thrust and close

the electric-lock

Motor2

Slowing

down

3 sec

Max

force

Normal

speed

Max

force

<Q> OPEN GATE SIGNAL DIP B6

-- set and leave the DIP B6 in ON position, on terminals n 24-25 you have a closing contact until the

gate is opening.

<R> COURTESY LAMP CONTACT TIME = 2 SECONDS DIP B7

-- set and leave the DIP B7 in ON position , this may be useful if you want to command a lamp on a

network

<S> MOTOR SOFT START WHEN THE GATE IS NEAR THE PHYSICAL STOP DIP B9

note the dip B4 must be OFF

set and leave the DIP B9 in ON position, in this way the start up is eliminate ( 1,5 sec max force

and the gate does not make vibration when touch the physical stop

it is important to set the trimmer FRENO for the right speed

.

<T> INTERCOM INPUT

It is possible to feed 12vac on terminals n 3-4 , this give a command start SS or SS2 depend of the

jumper setting

If jumper CAR is insert Start/Stop.command will be execute

CAR PED

If jumper PED is insert WALK-WAY SS2 command will be execute

CAR PED

11

BOX 208 IP56 SIZE mm

WARRANTY

ELCA devices and accessories are guaranteed for a period of 24 months after production, whose date

is printed on each items. ELCA will replace or repair its devices, provided that they are returned to our

plant. In order to check the actual functioning of the returned pieces, they will remain the property of

manufacturer. The warranty does not include damages due to any incorrect use, such as : non

fulfilment of the instructions detailed for each device. Moreover, warranty does not cover damage due

to wrong tension supply and any other reason for wich the manufacturer cannot be made responsible.

Any device returned must be delivered to ELCA with carriage paid and will be sent back with freight

collect.

Warranty validity ceases in case of the customer’s non fulfilment of payment.

ELCA declines all responsibility for the non observance of the safety rules by part of the installer.

Table of contents

Other ELCA Control Unit manuals

Popular Control Unit manuals by other brands

Polycom

Polycom RMX 1500 Administrator's guide

Logitech

Logitech HARMONY EXPRESS Setup guide

Fireye

Fireye MBCE-110FR manual

Sennheiser

Sennheiser ADN CU1 instruction manual

Grundfos

Grundfos CIM 150 Functional profile and user manual

Feig Electronic

Feig Electronic OBID i-scan ID ISC.PRH102-B installation manual

ICP CON

ICP CON ET-2251 quick start

Emerson

Emerson KTM 2-WAY Installation, operation and maintenance instructions

Grundfos

Grundfos CIM 2 Series Installation and operating instructions

Omron

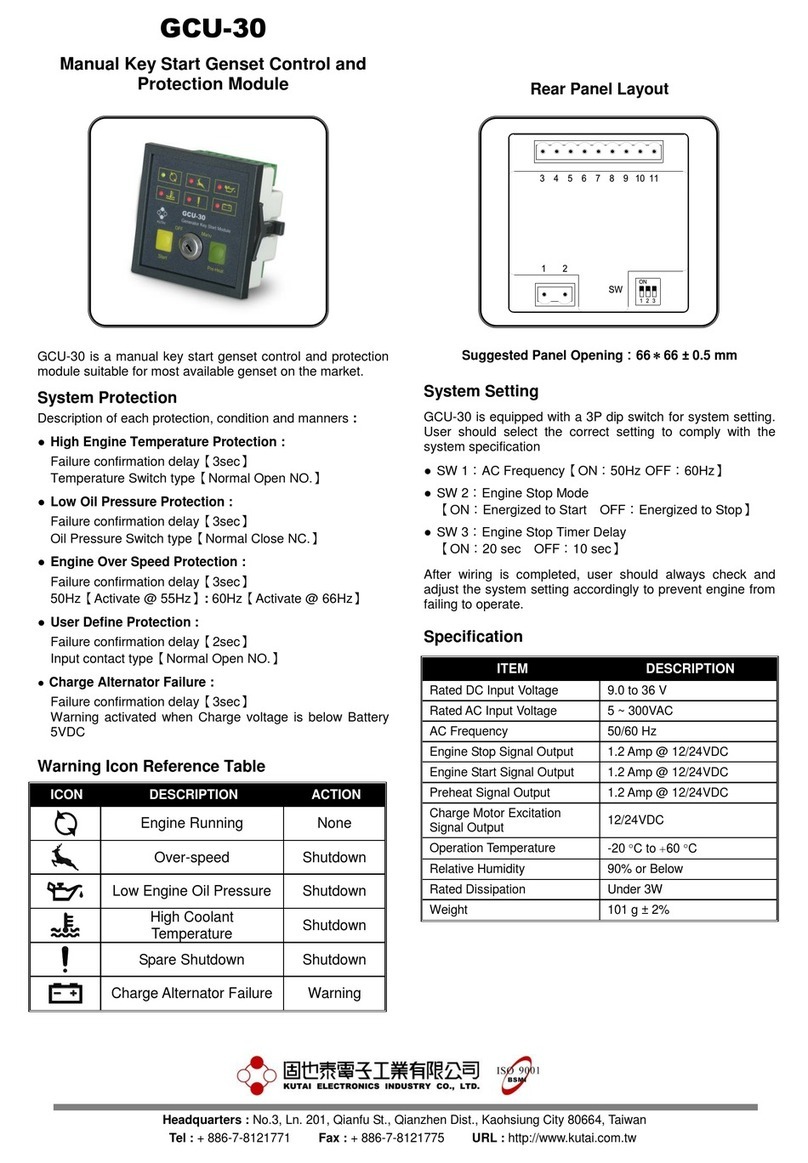

Omron CJ1W-NC214 - datasheet

Kutai electronics

Kutai electronics GCU-30 quick start guide

Triax

Triax CSE 816 Assembly instruction