ELCA Amaltea 2 User manual

This manual contains very important instructions for the installation, and use of this control board mod.

Do not install prior to reading this manual, the best results depends upon the correct application , installation.

We the manufactures of this product declines any responsibility in the case of an incorrect installation or improper use ,

And should be installed by a qualified person. This product has been created by keeping the strictest safety norms following

EC directives : CEE73/23, CEE89/336, CEE93/68, CEE89/106, CEE89/392.

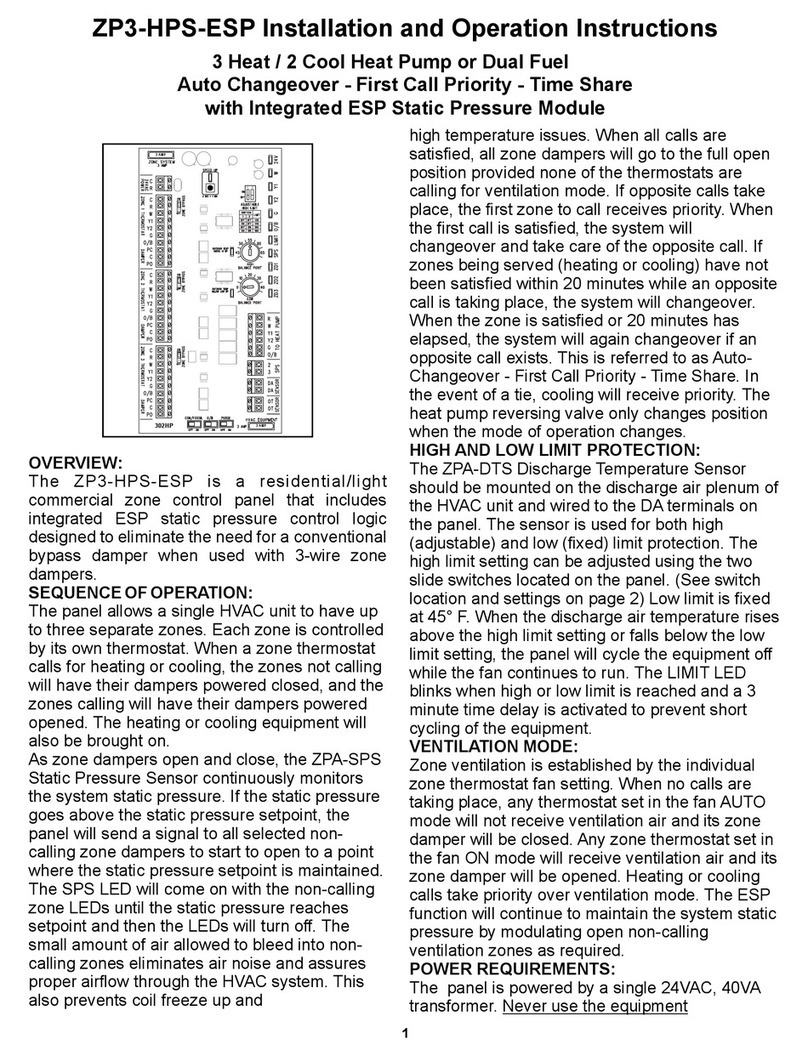

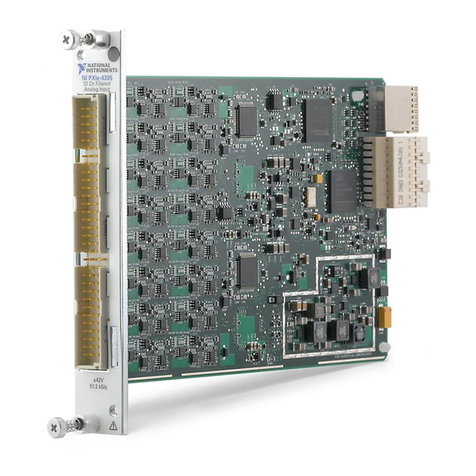

AMALTEA-2.

STOP

P1

Led ON

OK

RECEIVER

DIP

Led

ABC

Courtesy Light

Flashing light

Motor

Com

220Vac

Antenna

Stop

Button.

Start/Stop

C

B-

A

- Only rolling code

Theft proof’s function

- Tampering

Off ON

1 Pause

2 Times

omnipolar

230V 50Hz

4512345

TX

24 Vac

Photocell

Photocell

TERMINALS CONNECTION

1-2

3-5

4-5

6-5

7-8

9-10

11-12-13

14-15 power supply 230 Vac - 50 Hz )

11-14

ANTENNA terminal n.1=RF

STOPcontact, normally close.

PHOTOCELL contact, normally close

START/STOP contact, normally open

output 24 Vac max feeding 2 photocells

courtesy lamp contact (max 5A-230V) free voltage contact

connection for monophase motor 500W max (terminal n.11=common)

flashing light connection 230V-25W

(TERMINAL 14=NEUTRAL

!

FOLLOW THESE INSTRUCTION CAREFULLY !!!

!ATTENTION !!

During the installation it’s important to have a switch with

contact opening of at least 3mm that assurse an omnipolar

disconnection of the board to the current network . Procede

with a correct motor grounding.

Control board for

rolling-shutters and

blinds’ automation with:

-rolling code

-cortecy lamp contact

Amaltea 2

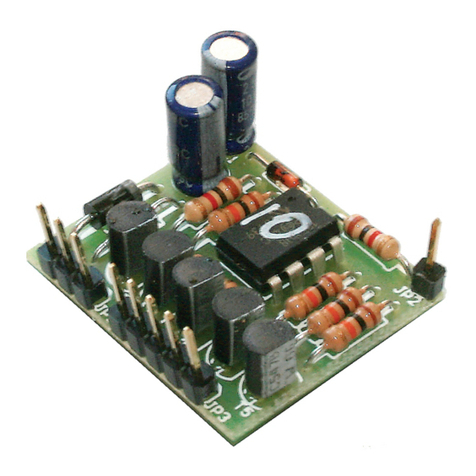

Soldering bridges

RX

1

Switch

ELCA snc Tel. 0039 0734 608484

Via Malintoppi, 32 Fax 0039 0734 605080

ITALY web: www.elcasnc.com

This manual has to stay with the equipment at all time, must not remove!

!FOR SAFETY REASON A SAFETY DEVICE

MUST BE USE WHEN USING THIS REMOTE CONTROL

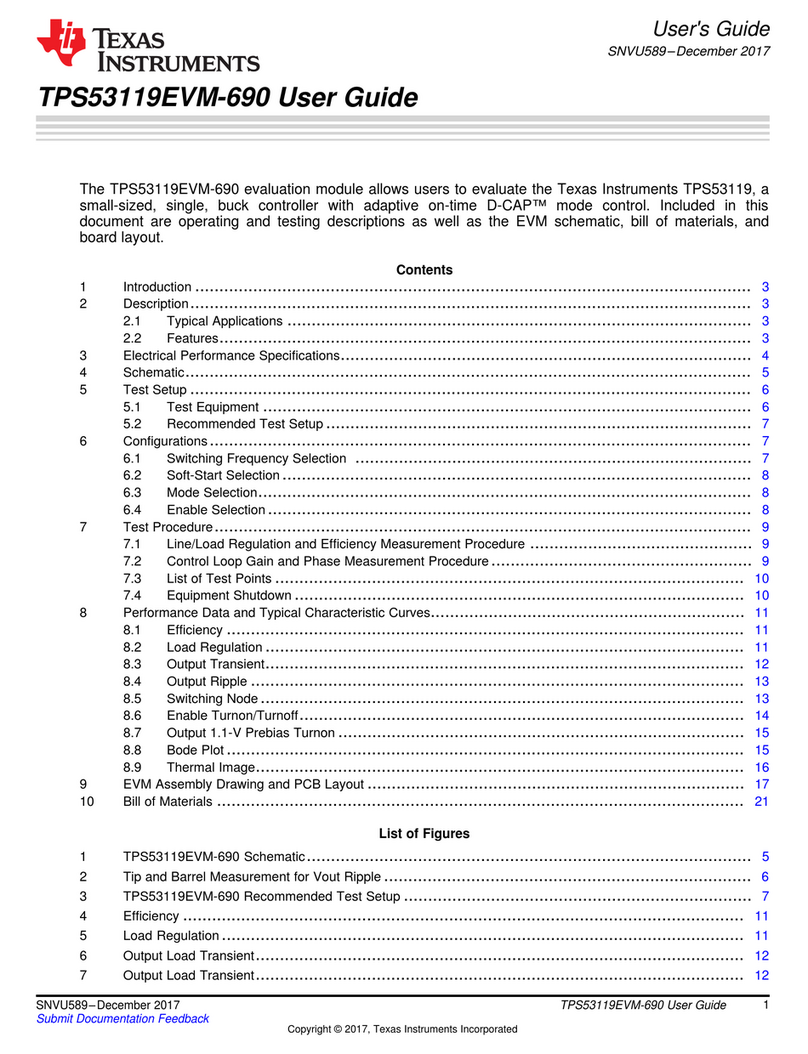

FUNCTIONS

Switch

omnipolar

230V 50Hz

R2

Off On

1 Pause

2 Times

Dip

P1

R1

P1 Off On

1 Pause

2 Times

Dip

R3

2

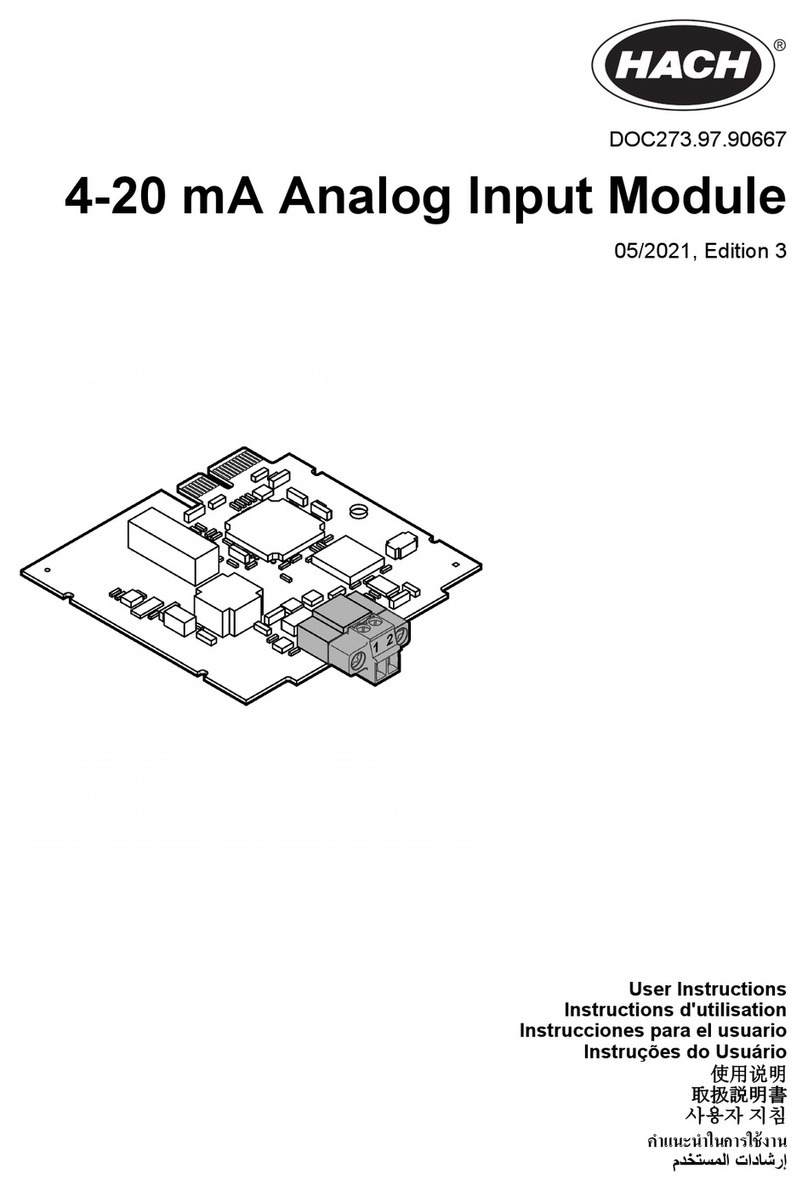

A - RADIO CODE PROGRAMMING (A code different from basic code)

possible to program different standard codes or

It’s

A1 - Set a new code in hand set

A2 - Push the white button on the main PCB ONCE THE should

come on.

A3 - Send an impulse or signal from hand set from a minimum distance of 0,5

meter the OK led should go out for about 0,5 second, indicating the

memory has accepted the new code. It’s possible to store more codes in the

memory, when the memory becomes full the OK led will falsh 2 times to

indicate the memory is full.

A4 - To leave the programing procedure press twice, the OK led goes out

A5 - If you need to cancel codes from the memory :

Press and hold down turn power off and after a few seconds still

holding down switch power back on the PCB is now back to

factory setting

61 15 rolling codes

P1 OK LED

P1

P1

P1

P1 Led OK

A2

Led OK

50 cm

Turn off

0,5 sec

A3

P1

Led OK

2 impulses

A4

P1

Switch

omnipolar

230V 50Hz

A5

B- STOP CODE PROGRAMMING

<<< not available at the moment >>>

P1 Led OK

B1

Led OK

STOPSTOP

3

5

B2

P1

Led OK

2 impulses

B3

AMALTEA2 is the appropriate control board to operate motors with incorporated limit switch,

you’ll find it ready having a BASIC PROGRAM given from the factory :

> working time = 30 seconds

> radio code in memory = dips 1-3-5-7-9 ON channel n.1

( transmitter’s base code )

> without automatic closing

( courtesy lamp timing = 3 min.)

R-

It is possible to return to the BASIC CODE or PROGRAM :

R1 - Switch ELECTRICAL supply off turn dip switches 1 and 2 ON

R2 - While holding P1 down turn power on

R3 - The OK LED goes off for about 1 second at this time release P1 and

turn dip switches n.1 and n.2 off

( the program is back to basic code)

RESET

B1 - Push the button The OK led goes on.

B2- Open the stop contact (terminals 3-5) send a code from the

hand set, the OK led goes off for 1 sec.

B3 - For came out of programming push 2 times the button

P1.

P1.

3

C- COURTESY LAMP CODE PROGRAMMING

(if you need to switch the lamp by the transmitter)

C1- push two times the button the led flash

C2- send a code (not yet in memory) from the transmitter, the led stop

flashing for 0,5 seconds.

It’s possible to memorizing more codes.

- To erase the lamp codes follow the step

P1 OK

A-5 or a RESET

NOTE : Programming the code to command the courtecy lamp doesn't exclude its lighting

for 3 min at every movement.

P1

2 impulses

Led OK

Flashing

C1

Led OK

Turn off for

0,5 sec

C2

D- WORKING TIME PROGRAMMING

Off On

1 Pause

2 Times

Dip

Led OK

2° impulse

1° impulse

Start/stop

5

6

D2

Off On

1 Pause

2 Times

Dip

Led OK

E- PAUSE TIME PROGRAMMING (only required on automatic closing)

Off On

1 Pause

2 Times

Dip

Led OK

Off On

1 Pause

2 Times

Dip

E1

(Only use if the door takes longer than 30 seconds

--- place the door in closed position ---

D1 - turn dip switch n.2 on the board to on the

OK led should be on

D2- Send an impulse from hand set or by a switch with the

connected on 5-6 on the PCB, the door should start to open if not,

swap wires n.12 and n.13,and try again, the door should open, when

the door is fully opened give a signal again from hand set, or press the

switch to stop door,then turn off dip switch n.2 off on the PCB.

(Max time = 4 minutes)

D3- set the dip n.2 in OFF position

E1- turn on dip switch n.1 in ON (the OK led comes on) leave it on

for the desired time, max 4 minutes, turn off dip n.1 photocells

should be used when using this function.

Replace dip n.1 in OFF position.

OTE : If you want the door to stay open for a longer period in this mode, send a signal

from hand set the door will stay open untill you send another signal.

N

D3

D1

To open)

4

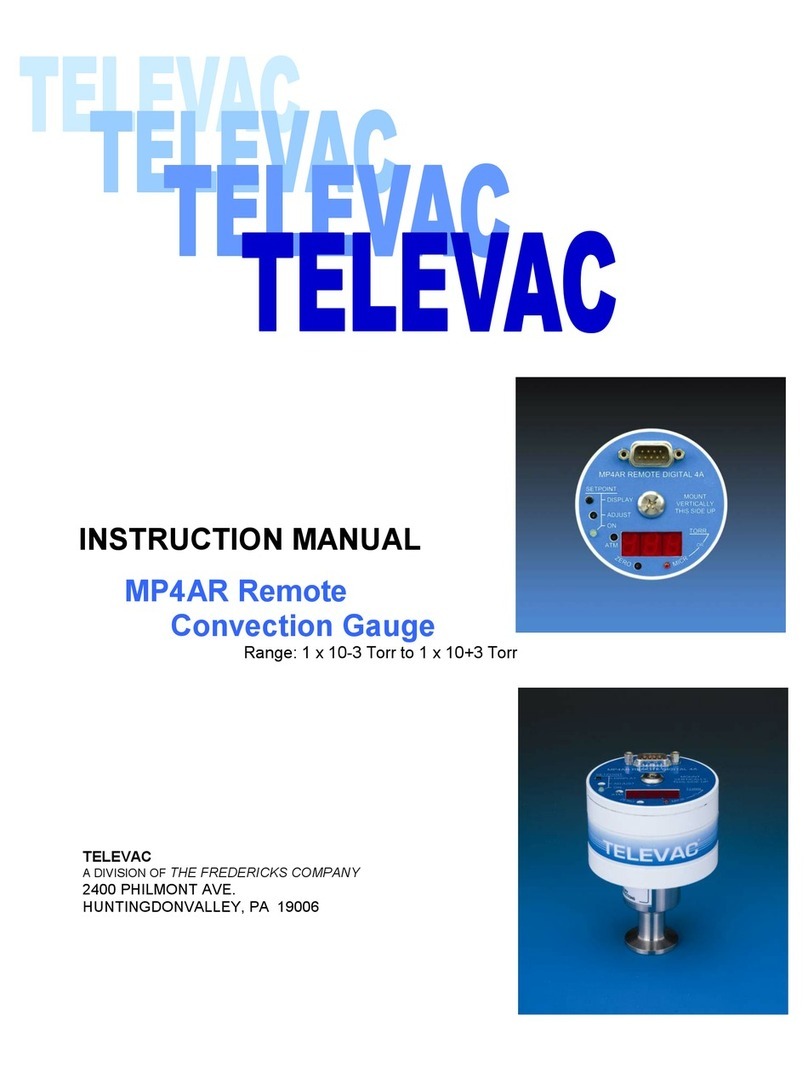

F- SPECIAL FUNCTIONS

ABC

F1

ABC

F3

FEATURES

> power supply = 230vac >output for single phase motor 500w max

> low tension input 12V > output 24 vac (power for 2 couple of photocells)

> extractable self-learning receiver, frequencies 434mhz

> ABS autoextinguishing box with closing screws Ip54 SIZE: 130-45-70 mm

ABC

F2

F1- if a solder bridge is across point “C” the control board will operate a

Rolling code, but this should only be done by a qualified person.

F2- to set

Solder a bridge across position “B” as shown in diagram again this should

be done by a qualified person, the customer may use a code to that blocks

any function,the first code memorized will have the theft proof function,the

OK led flashes twice.The board will only accept the theft proof code if the

door is in the closed position.

THEFT PROOF.

When a signal is recived the door will open for a few seconds and then close, this proves that

the theft proof function is activated.

When using the hand set again with the theft proof code the door will operate in the normal way.

- If a rest or code change is attempted while in THEFT PROOF the board will shut

down for its own protection, to start and go back to base code, the bridge on “B” must be

desoldered by a qualified person.

To come out of the theft proof function :

switch off power remove the bridge on “B” with a soldering iron, again

this can only be done by a qualified person, power back on and go

through the set up procedure.

ATTENTION !!!

F3 - TAMPER PROOF

If a bridge is soldered across “A” the tamper proof fuction is activated.

The installer has installed the board to memorize a code that lets you operate the door in a normal

way, but you can not change to another programe without removing bridge “A” again this should be

carried out by a qualified person.

this sets the modul

back to work as normal. This must be carried out by a qualified person.

: If both bridges are in operation, the first code takes preference the tamper proof takes

priority over theft proof, first code and then the second code will activate the board in this order.

A”,

NOTE A-B

- the first code programed will have the function, the OK led will flash 3 times.

- when you send a new code, this function is aborted the OK led will flash 4 times

>> to remove the function:

Switch the power off, remove board from box, remove solder on bridge “

TAMPERING

TAMPER PROOF

WARRANTY

ELCA devices and accessories are guaranteed for a period 24 months after production, whose date is printed

on each items. ELCA will replace or repair its devices, provided that they are returned to our plant.

In order to check the actual functioning of the returned pieces, they will remain the property of the manufacturer.

The warranty does not include damages due to any incorrect use such as : non fulfilment of the instructions detailed

for each device. Moreover, warranty dpes not cover any damage due wrong tension supply and any other reason

for wich the manufacturer cannot be made responsible. Any device returned must be delivered to ELCA with carriage

paid will be back with freight collect. Warranty validity ceases in case of the customer’s non fulfilment of payment.

Rev. 01 Issued by Baglioni Simone 27/10/04

Table of contents

Other ELCA Control Unit manuals