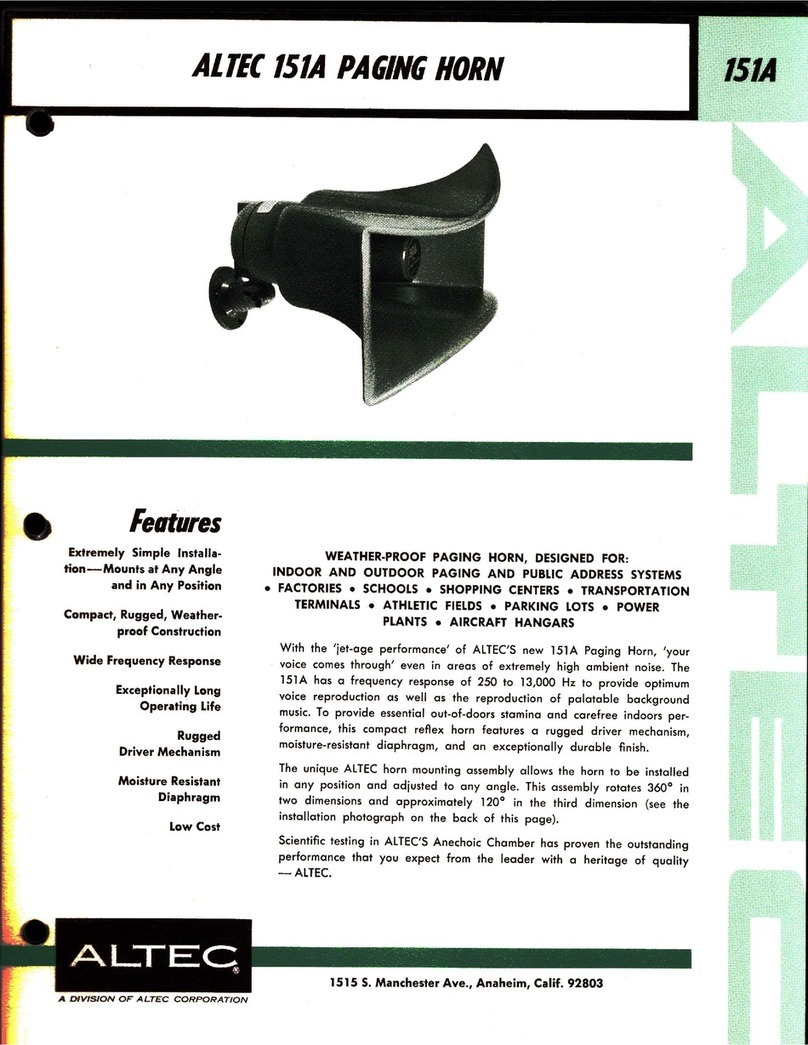

MH6040AC Coaxial Constant-Directivity Manifold TechnologyHorn System

2

MH6040AC Coaxial Constant-Directivity Manifold TechnologyHorn System

flange to aid electrical box mounting.

If the MH6040AC is suspended, it is recom-

mended that the unit be inspected at least

once a year. If any sign of weakness is de-

tected, remedial action should be taken im-

mediately.

Equalization and Subpassband

Protection

The MH6040AC’s mid-bass section exhib-

its typical constant-directivity horn charac-

teristics, i.e., roll-off at the frequency ex-

tremes.Athigher frequencies, the roll-offap-

proximately matches the power-response of

the DL10X-SH (6 dB per octave). At lower

frequencies, directivity is lost when the

mouth is no longer large enough to maintain

directional control. These two consequences

can be observed in the “humped” response

in Figure 3. Equalization can be easily ap-

plied with a graphic equalizer to give a flat

response.

The high-frequency compression driver can

be equalized with a graphic equalizer or an

EQ module inserted into the Electro-Voice

XEQ-2 (two-way) or XEQ-3 (two-way or

three-way) active crossover/equalizer. The

EQ module should be selected to suit the

particularcompressiondriverand the HP640

horn (see relevant data sheet). Because of

its use in large arenas, where air loss can be

significant, it is recommended that the sys-

tem be equalized “on site” for optimum re-

sults.TheXEQ-3andthemid-bassEQmod-

ule from the EQMT-2 can be used to pro-

vide a good starting point for the equaliza-

tion.

Electro-Voice strongly recommends the use

of a 100-Hz high-pass filter to protect the

driversfromunnecessary excursion and ther-

mal stress.

Directivity

The axial directivity factor Rqof the

MH6040AC was computed at each of the

one-third-octave center frequencies over the

frequency range noted from the horizontal/

vertical polars shown in Figure 7. Directiv-

ity index (Di) was taken over the same fre-

quency range.

Beamwidth

Plots of the MH6040AC’s 6-dB-down total

includedbeamwidth angles are shown inFig-

ure 6 for each of the one-third-octave center

frequencies noted.

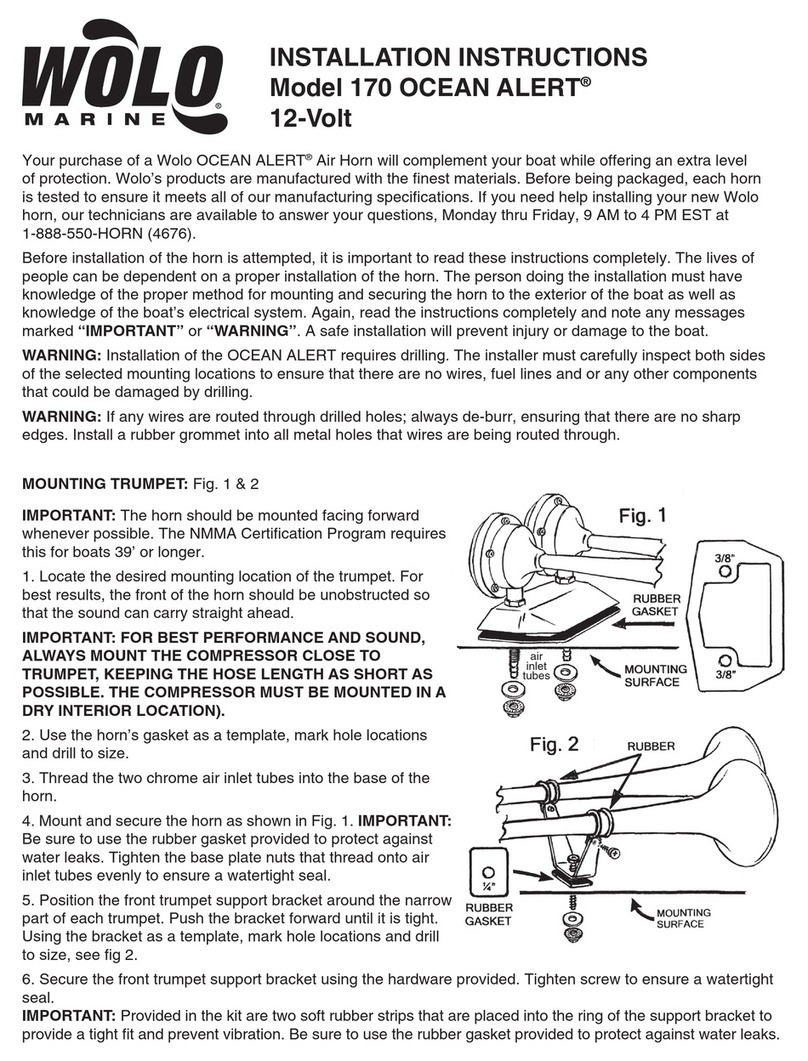

Polar Response

The directional characteristics of the

MH6040AC were obtained by selecting the

horizontal and vertical details from a full set

of polar data measured in EV’s large

anechoic chamber. The measurement micro-

phone was placed 6.1 m (20 ft) from the cen-

ter of rotation of the horn which, in turn, is

0.94m (3.08 ft) behind themouthof the horn.

See Figure 1.

Polarity of the DL10X-SH Drivers

For Manifold Technology®to operate cor-

rectly, the drivers must be operated “in

phase.” In other words, for parallel connec-

tion, the DL10X-SH’s must be connected so

the negative terminals of the drivers are con-

nected together, and the positive terminals

are connected together.

Service

In the unlikely event the MH6040AC re-

quires service, each DL10X-SH easily can

bereplaced or serviced byremovingthe back

cover and then removing the driver. A ser-

vice data sheet is available from Electro-

Voice.

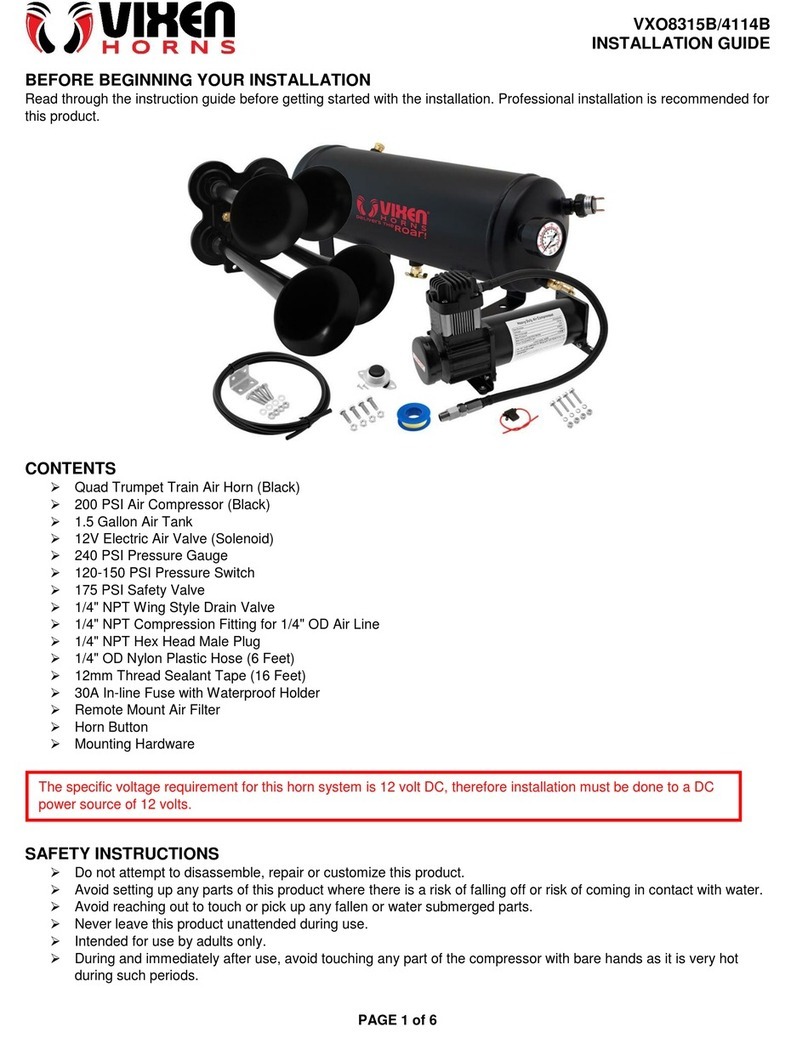

Power Handling Capacity

To our knowledge, Electro-Voice was the

first U.S. manufacturer to develop and pub-

lish a power test closely related to real-life

conditions. A random-noise input signal is

used because it contains many frequencies

simultaneously, just like real voice or instru-

ment program. The signal contains more

energy at extremely high and low frequen-

cies than typical actual program, adding an

extramarginof reliability. The test combines

not only the overall “long-term average” or

“continuous”level—whichour ears interpret

as loudness—but also short-duration peaks

which are many times higher than average,

just like actual program. The long-term av-

erage level stresses the speaker thermally

(heat).The instantaneous peaks testmechani-

cal reliability (cone excursion). Note that the

sine-wave test signals sometimes used have

a much less demanding peak value relative

to their average level. In actual use, long-

term average levels exist from several sec-

ondsonup.The test performed lasts for eight

hours, adding another extra level of confi-

dence.

Specifically, the MH6040AC mid-band sec-

tion is designed to withstand the power test

described in EIA Standard RS-426A. The

EIA test spectrum is applied for eight hours.

The spectrum is obtained by filtering white

noise (a particular type of random noise with

equal energy per bandwidth). The filter ap-

plies 6-dB-per-octave slopes below 40 Hz

and above 318 Hz. When measured with a

one-third-octave constant-percentage ana-

lyzer, this filter produces a spectrum whose

3-dB-down points are at 100 Hz and 1,200

Hzwith a 3-dB-per-octave slope above1,200

Hz.Thisshapedsignal is then further filtered

with an 80-Hz, 12-dB-per-octave high-pass

filter to prevent out-of-passband displace-

ment. The amplifier is set to provide 600

watts into the 3.45-ohm EIA equivalent im-

pedance (45.5 volts). Amplifier clipping sets

instantaneous peaks at 6 dB above the con-

tinuous power or 2,400 watts peak (91.0

volts). During this test, the mid-band sec-

tionisnothigh passed at 1,250 Hz. The high-

frequencysection’spowerhandling is depen-

dent on the selected driver combination.

Please refer to the relevant engineering data

sheet.

Architects’ and Engineers’

Specifications

The horn shall be of the constant-directivity

type.Itshall produce a horizontal beamwidth

(6-dB-down angle) of -60°, deviating no

more than +10° or –20° from this angle over

the range of 400 Hz to 20 kHz. It shall pro-

duce a vertical beamwidth of 40°, deviating

no more than +20° or –15° over the fre-

quency range of 325 Hz to 20 kHz. In addi-

tion, it shall provide an acoustic load to be-

low 100 Hz.

The MH6040AC mid-bass section shall op-

erate over the range of 100 Hz to 4,000 Hz,

with a recommended crossover frequency of