X-Array InstallTM Xi-1153/64 Loudspeaker System

X-Array Install

TM

Xi-1153/64 Loudspeaker System

2

The ISP-100 digital electronic unit was used

toprovidethenecessary crossover filters and

equalization during power testing. Specifi-

cally, the Xi-1153/64 passes the ANSI/EIA

RS426-A power test with the follwing test

parameters:

Low-Frequency Section:

PE(MAX): 600 watts

Test Voltages: 58.7 volts rms

117.4 volt speak

RSR(1.15 RE): 5.75 ohms

Mid-bass Section:

PE(MAX): 300 watts

Test Voltages: 45.5 volts rms

91 volts peak

RSR(1.15 RE): 6.9 ohms

High-Frequency Section:

PE(MAX): 75 watts

Test Voltages: 30.1 volts rms

60.2 volts peak

RSR(1.15 RE): 12.1 ohms

Crossover, Equalization And Time-

Delay Controller

The Xi-1153/64 speaker system and variants

are designed as an integrated package that

utilizes the Merlin ISP100, Klark Teknik

DN8000 or Electro-Voice Dx34A digital

crossover system. Optimal performance of

the Xi-1153/64 speaker system can only be

assured when using the above controllers.

For the three-way, non-overlap crossover

configuration, either the merlin ISP-100,

DN8000 or Dx34A may be used. For the

two-element-line-array configuration, how-

ever, only the Merlin ISP-100 may be used.

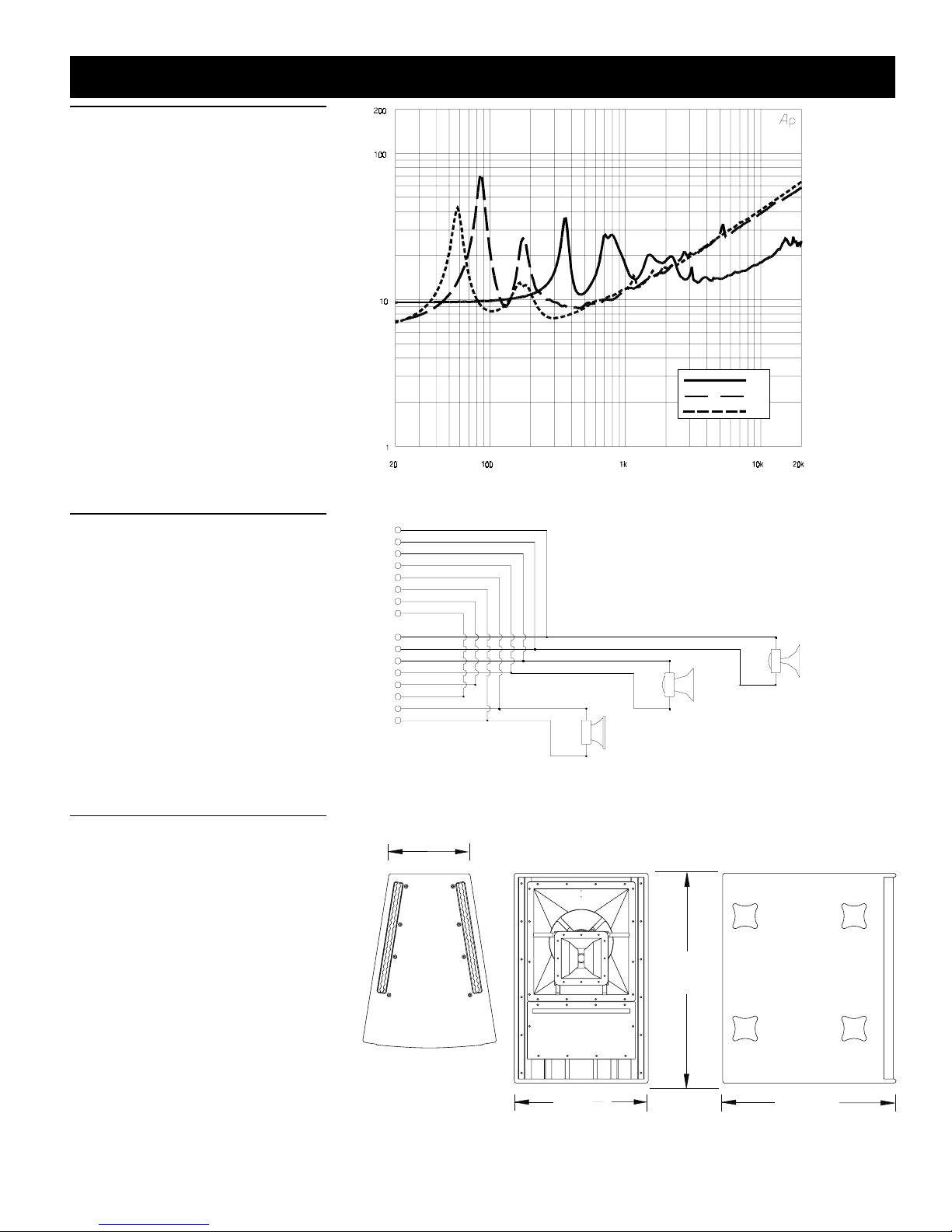

Electrical Connection And System

Wiring

Electrical connections to the Xi-1153/64 are

made on the back of the enclosure via a

8-pin connector. There are two connectors

on the input panel to allow paralleling of

other Xi-1153/64 systems. The Neutrik

Speakon®

NL8MPR is used for both connec-

tions. The pin assignments are as follows:

HF: Pin 4 In / Pins 4 Out

MB: Pin 3 In / Pins 3 Out

LF: Pin 1 In / Pins 2 Out

The wiring diagram of the loudspeaker

system is shown in figure 7. The electrical

impedance is shown in Figure 6.

Amplifier Recommendations

Power amplfiers with the following rat-

ings are recommended for use with the

Xi-1153/64 speaker systems:

LF: 600-800 watts continous into 8 ohms.

MB: 300-600 watts continous into 8 ohms.

HF: 125-250 watts continous into 8 ohms.

Xi-1153/64 speakers may be paralleled only

with other Xi-1153/64 speakers if the am-

plifier is capable of delivering full power at

the lower impedances. The use of amplifi-

ers with lower power ratings is acceptable;

however, the full-power capabilities of the

Xi speakers will to be realized. The use of

amplifiers with significantly higher power

ratings will generate maximum dynamic

range and fidelity, but care must be utilized

forlongerduration signals as mechanical and

thermal damage is possible in the system.

Flying the Xi Systems

A manual entitled the X-Array Install™ Fly-

ing Manual is available from Electro-Voice,

and is included with each flying Xi loud-

speaker system. A breif introductory over-

view is included here. The X-Array-Install™

Flying Manual should be consulted for com-

pletestructuralspecifications and detailed in-

formationonsafely suspending and using the

Xi systems.

The Xi systems incorporate a unique two-

pointflying system that permits a wide range

ofverticalangle adjustment, and offersmaxi-

mumflexibility in array design for both tour-

ing sound and permanent installations. The

quick-release, aircraft-rated heavy-duty

L-track-type hardware design allows arrays

of loudspeakers to be assembled (and disas-

sembled) very quickly, and offers such flex-

ibility in the vertical angling of cabinets that

pull-up points are usually unnecessary. Fur-

thermore, all of the flying Xi loudspeaker

models include the same rigging hardware,

allowing different models to be mixed as

necessary throughout an array.

Theworking-loadlimit (for an 8:1 safety fac-

tor) for each rigging point on the Xi loud-

speaker enclosure is 227 kg (500 lb) for a 0°

pull angle and 170 kg (375 lb) for a 90° pull

angle when used with the New Haven

NH32101-2 double-stud fitting, and 113 kg

(250lb)at any angle when used with theNew

Haven NH8192-2S or Ancra 42546-10

single-stud fittings with locking pins. The

working-load limit (for an 8:1 safety fac-

tor) for the overall enclosure is 453 kg

(1,000 lb). (Consult the X-Array Install™

Flying Manual for specific structural ratings

and limitations.) The enclosures may be ori-

ented with the rigging track on the sides of

the enclosure, or on the top and bottom, and

may be daisy-chained together as long as the

safety factor is 8:1 or greater, and local regu-

lations are met. For fire safety and additional

structuralstrengthin both flying orientations,

top-to-bottom and side-to-side metal straps

link the rigging track inside the enclosure.

All associated rigging is the responsibility

of others.

CAUTION: The Xi loudspeaker system

should be suspended overhead only in ac-

cordance with the procedures and limita-

tions specified in the X-Array Install Fly-

ing Manual and manual updates notices.

Field Replacment

Normal service for the Xi requires only a #2

Phillipsscrewdriveranda 3/16-inch hex-key

wrench. The drivers may be accessed as fol-

lows:

HF: First remove the grille, the remove the

screws securing the front flange of the high-

frequency horn. Peel the hook and loop

fastner strips from the four corners of the

foam shroud and remove the four sides of

the shroud. Lift the horn and driver out of

the wood assembly. In the event of failure,

thediaphragmassembly can be replaced with

the driver attached to the horn.

MB: Remove the screws securing the hatch

onthebackof the enclosure and lift the hatch

out.Remove the screws securing the 12-inch

woofer and lift the driver out of the enclo-

sure.In the event of failure, the entire woofer

must be replaced.

LF: First remove the grille, the remove the

screws securing the hatch on the front of the

enclosure. Remove the screws securing the

15-inch woofer and lift the driver out of the