7

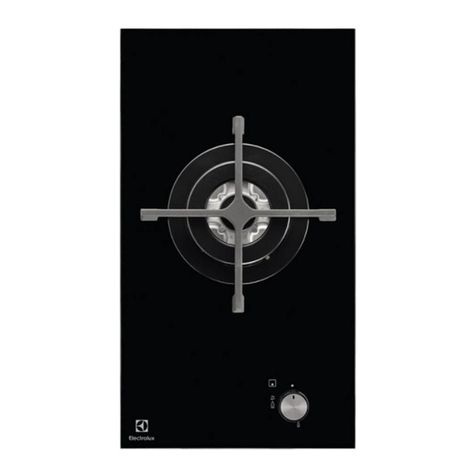

Installation

A) End of shaft with nut

B) Washer

C) Elbow

Important

This appliance must be installed by qualified

personnel.

The installer shall verify the satisfactory operation

of the i nition system on all burners both

individually and in combination.

The manufacturer will not accept liability, should

the above instructions or any of the other safety

instructions incorporated in this book be i nored.

Regulations

This appliance shall be installed in accordance with the

manufacturers installation instructions, local as fittin

re ulations, municipal buildin codes, AS5601 (AG601)

and any other relevant statutory re ulations.

Data label

The data label is located on the bottom of the appliance.

This appliance is suitable for Natural or Universal LPG.

Ensure that the as supply matches the data label. A

duplicate of the data label is supplied in the packa in of

the user manual and must be attached to readily

accessible adjacent surfaces of the appliances.

Connection to the gas supply

Gas connection must be carried out in conformity with

the re ulations in force. The appliance leaves the factory

tested and re ulated for the type of as indicated on the

plate which is situated in the lower position near the as

connection tube. Ascertain that the type of as with which

the appliance will be supplied is the same as that indicated

on the plate.

If different carry out all the operations accordin to the

indications cited in the para raph adaption to different

types of as.

For a maximum output and minimum consumption

ascertain that the pressure of the as used has the values

indicated in the table of burner characteristics.

The joint is mounted on the intake area of the pipe, fitted

with a filleted nut G 1/2", between the sealin

components. Screw the parts without forcin , turn the

joint in the direction required and then ti hten everythin .

Connection

Carry out the connection to the as plant only by means

of a rigid metallic pipe conformin to the re ulations

in force. This appliance is not suitable for connection

with a hose assembly. The joint for the entry of as into

the appliance is threaded R 1/2" (male thread).

Carry out the connection avoidin any type of stress on

the appliance.

It is important to install the elbow correctly, with

the shoulder on the end of the thread, fitted to the

hob connectin pipe. Failure to ensure the

correct assembly will cause leakage of gas.

FO 0814

FO 0264

Natural as appliances must be fitted with a pressure

re ulator and be installed at the inlet connection. The

as pressure must then be set as a part of the

commissionin procedures.

For U-LPG the pressure adjustment is made via the

re ulator fitted at the domestic cylinder.

The natural as re ulator and U-LPG pressure test point

must be accessible with the appliance installed.

Important

Upon completion of installation, always check:

lthat all the joints are completely sealed by usin a

soapy solution, never a flame;

lthat the as pressure has been re ulated to 1.00kPa

for Natural Gas and 2.75kPa for Universal-LPG. The

pressure test point is located on the re ulator. The

pressure should be measured and adjusted with the

Wok burner on hi h flame;

lthat the automatic i nition system is operatin

satisfactory on all burners, both individually and in

combination;

lthat the burners operate correctly, are stable, without

yellow tippin or excessive noise on hi h and low

flame.

Then demonstrate to the customer the appliance

operation and leave these instructions.