Contents

Contents

1 Introduction.........................................................................................................................................5

2 Installation ..........................................................................................................................................6

2.1 General safety information..........................................................................................................6

2.2 Symbols....................................................................................................................................6

2.3 Requirements............................................................................................................................7

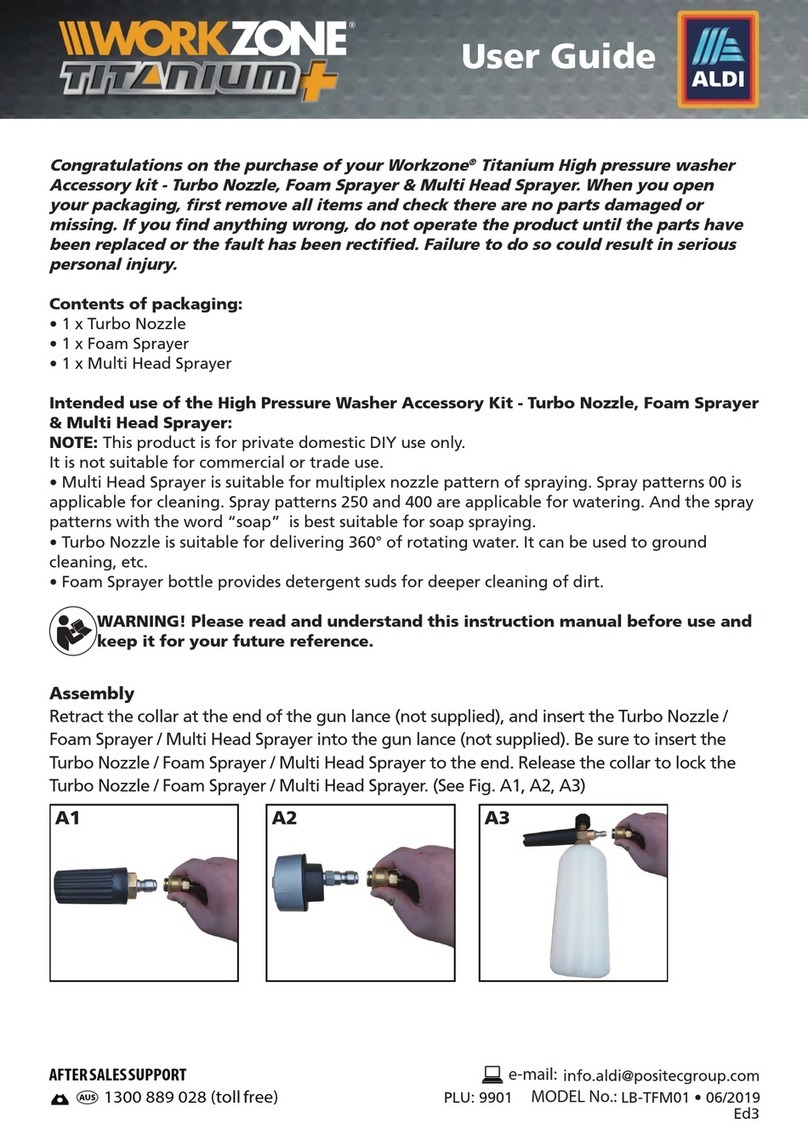

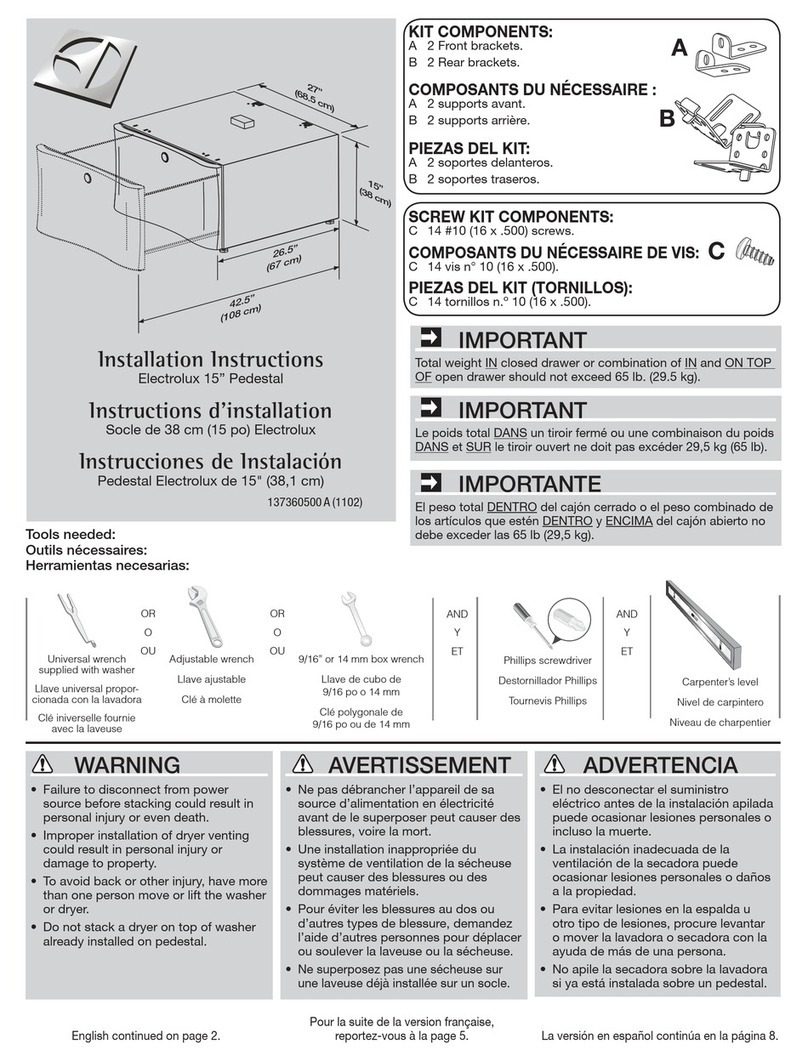

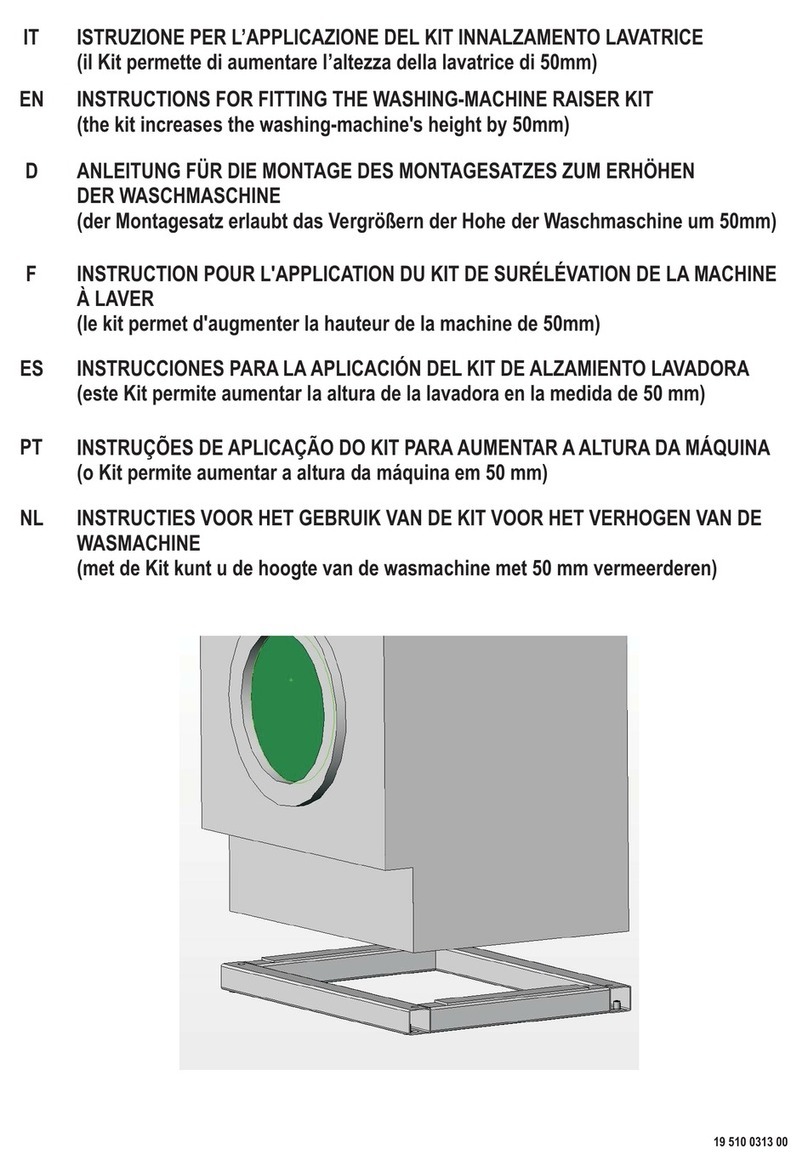

2.4 Installation of the pump-stand .....................................................................................................7

2.5 Installation of Flush manifold (option) ..........................................................................................9

2.6 Installation of the EDS controller ...............................................................................................10

2.6.1 General .........................................................................................................................10

2.6.2 Installation on Compass Control and Compass Pro........................................................... 11

2.6.3 Installation on Clarus Control...........................................................................................16

2.6.4 Dual controller................................................................................................................18

3 Programming ....................................................................................................................................19

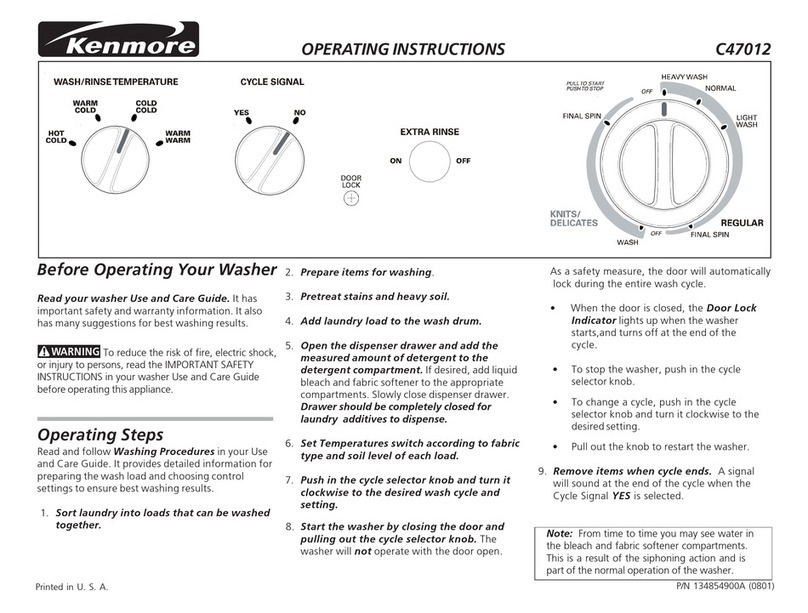

3.1 Operating panel.......................................................................................................................19

3.2 Language settings ...................................................................................................................19

3.3 Time and date settings .............................................................................................................19

3.4 Priming the pumps ...................................................................................................................19

3.5 Calibrating the pumps ..............................................................................................................20

3.6 Basic settings in the EDS controller ...........................................................................................23

3.7 Wash program set up ...............................................................................................................25

3.8 Download reports to a USB stick ...............................................................................................27

3.9 Electrolux wash program allocation ...........................................................................................28

3.10 Selection of operation mode .....................................................................................................29

4 Test run ............................................................................................................................................32

5 Technical specification.......................................................................................................................32

6 Trouble shooting and service..............................................................................................................33

The manufacturer reserves the right to make changes to design and component specifications.