6

CCoonntteennttss

A WARNING AND SAFETY INFORMATION ..................................................................................................7

A.1 General information ......................................................................................................................7

A.2 Personal protection equipment ........................................................................................................8

A.3 General safety .............................................................................................................................8

A.4 General safety rules ......................................................................................................................9

A.5 Technical data ........................................................................................................................... 12

A.6 Transport, handling and storage .................................................................................................... 12

A.7 Installation and assembly ............................................................................................................. 13

A.8 Product loading and unloading ...................................................................................................... 15

A.9 Machine cleaning and maintenance................................................................................................ 15

A.10 Machine disposal........................................................................................................................ 16

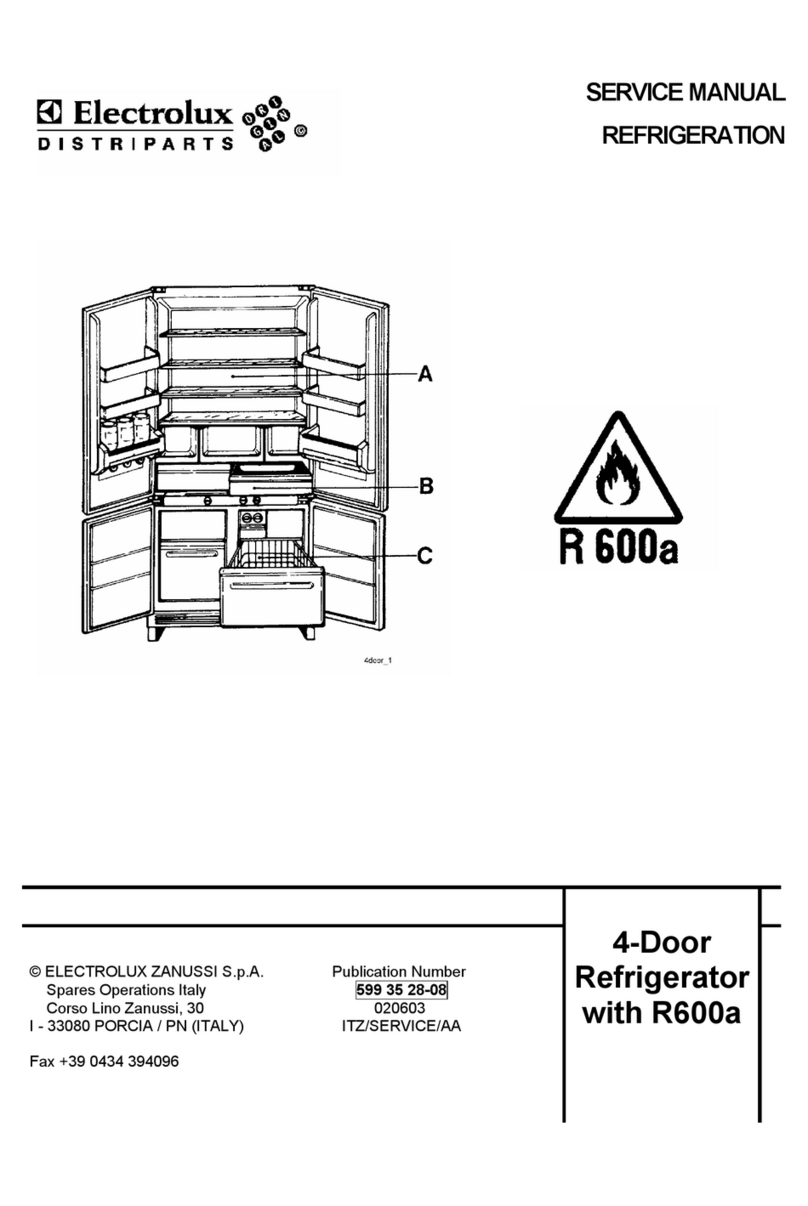

B APPLIANCE AND MANUFACTURER'S IDENTIFICATION DATA .................................................................. 17

C GENERAL INFORMATION .................................................................................................................... 17

C.1 Introduction ............................................................................................................................... 17

C.2 Additional indications................................................................................................................... 17

C.3 Intended use and restrictions ........................................................................................................ 17

C.4 Testing and inspection................................................................................................................. 17

C.5 Copyright.................................................................................................................................. 17

C.6 Keeping the manual .................................................................................................................... 17

C.7 Recipients of the manual .............................................................................................................. 17

C.8 Definitions................................................................................................................................. 18

C.9 Responsibility ............................................................................................................................ 18

D TRANSPORT, HANDLING AND STORAGE .............................................................................................. 18

D.1 Handling................................................................................................................................... 18

D.1.1 Procedures for handling operations....................................................................................... 18

D.1.2 Placing the load ................................................................................................................ 18

D.2 Unpacking ................................................................................................................................ 18

D.2.1 Disposal of packing ........................................................................................................... 19

D.3 Storage .................................................................................................................................... 19

E TECHNICAL DATA .............................................................................................................................. 19

E.1 Materials and fluids used.............................................................................................................. 19

E.2 Main technical characteristics........................................................................................................ 19

F INSTALLATION AND ASSEMBLY........................................................................................................... 19

F.1 Introduction............................................................................................................................... 19

F.2 The customer's responsibilities ...................................................................................................... 19

F.3 Machine space limits................................................................................................................... 19

F.4 Positioning................................................................................................................................ 19

F.5 Defrost..................................................................................................................................... 20

G NORMAL MACHINE USE...................................................................................................................... 20

G.1 Characteristics of personnel trained for normal machine use ................................................................ 20

G.2 Characteristics of personnel enabled to operate on the machine ........................................................... 20

G.3 Operator qualified for normal machine use ....................................................................................... 20

H OPERATION ...................................................................................................................................... 21

H.1 Thermometer............................................................................................................................. 21

H.2 Temperature adjustment and inside lighting of refrigerated models with fully insulated door and glass

door......................................................................................................................................... 21

H.3 Loading food ............................................................................................................................. 21

I MACHINE CLEANING AND MAINTENANCE............................................................................................. 21

I.1 Ordinary maintenance ................................................................................................................. 21

I.1.1 Informations for maintenance............................................................................................... 21

I.1.2 Cleaning the cabinet and accessories.................................................................................... 21

I.1.3 Compartment cleaning ....................................................................................................... 22

I.1.4 Precautions in case of long idle periods ................................................................................. 22

I.1.5 Quick troubleshooting guide ................................................................................................ 22

I.2 Repair and extraordinary maintenance ............................................................................................ 22

I.2.1 Periodical condenser cleaning ............................................................................................. 22

I.2.2 Maintenance intervals ........................................................................................................ 22

J MACHINE DISPOSAL........................................................................................................................... 23

J.1 Waste storage ........................................................................................................................... 23

J.2 Procedure regarding appliance dismantling macro operations .............................................................. 23