Electronics Research, Inc. 100A Series User manual

100A Series Low Power FM Antenna

Types 100A-1M, 100A-2F, 100A-2F-HW

20100326001_AEN Revision 03

Electronics Research, Inc. | 7777 Gardner Road, Chandler, IN 47610 USA | www.eriinc.com | +1 (812) 925-60000

Installation Instructions

Notice

The installation, maintenance, or removal of antenna systems requires qualied, experienced personnel.

ERI installation instructions are written for such personnel. Antenna systems should be inspected once a

year by qualied personnel to verify proper installation, maintenance, and condition of equipment. ERI

disclaims any liability or responsibility for the results of improper installation practices.

READ THE INSTRUCTIONS THOROUGHLY BEFORE ASSEMBLY

Preparation

Before beginning the assembly and installation of

the 100A Series antenna system, make sure all parts

are present.

Tools Required (not included):

5/32 Inch Allen wrench•

9/16 Inch Open-end wrench•

Adjustable wrench (15/16 Inch Capacity)•

Ruler or Tape Measure accurate to 1/16 inch (0.15•

cm)

NOTE: A torque wrench adaptable to tools

mentioned above will be helpful in the installation

process.

Parts*

Element Boom Assembly (qty 1)1.

Element Arm Assembly (qty 2)2.

Arm Extender Kit (qty 4)3.

Universal Mounting Clamps (qty 2)4.

Cable Ties (qty 10)5.

* The parts listed are for the 100A-1M. For type numbers 100A-2F

and 100A-2F-HW, an additional 100A element (as described

above) and a PD100A power divider are included.

1

2

3

4

5

2

Step 1: Secure the Feed Grounding Ring

to the Element Arm

To ensure a good electrical connection between1.

the Grounding Ring and the Element Arm,

temporarily remove the 5/16 wing-nut, lock-

washer and at-washers from the grounding

set-screw.

Next, locate your frequency range and antenna2.

type number in the table below and nd the

corresponding grounding ring position (1, 2, 3,

or 4).

Now slide the Grounding Ring over the spot3.

that corresponds to the correct grounding ring

position.

Using a 5/32 inch Allen wrench, tighten the set-4.

screw to 11 lbf·ft (15 N·m) torque imbedding the

screw into the Element Arm.

Repeat Step 1 for the remaining Element Arm5.

assemblies.

Step 2: Install Arm Extenders

Loosen the 15/16 inch End Fastener (brass nut1.

found at each end of both element arms) to the

point where the Arm Extenders can be freely

inserted. NOTE: As shipped, the element arm’s

15/16 inch end fasteners are pre-tightened

in order to trap the assemblies’internal

compression ring. Caution should be exercised

while performing this operation. Removing

the nut could result in the loss of the internal

compression ring.

Insert an Arm Extender into each end of the2.

Element Arms.

Locate your frequency range and antenna type3.

number in the Tip Length table (right) and

nd the corresponding Tip Length "L". NOTE:

Be certain that you are using the length that

corresponds both to your antenna frequency

and type number.

Position each Arm Extender so that the exposed4.

length is "L" (from the table). This Length is

measured from the top of the 15/16 inch

clamping nut to the tip of arm extender. NOTE:

The extender tip length is critical and must be

set correctly.

Once the Arm Extender is set, secure the5.

connection with an adjustable wrench and

torque to 15 lbf·ft (21 N·m) .

5/16 wing-nut, lock-washer

and at-washers

1

2

3

Step 1

4

Step 2

L

15/16 End Fastener

Type

Number

Grounding Ring Position

1 2 3 4

100A-1M 96.5 - 108.0 — 92.5 - 96.4 87.5 - 92.4

100A-2F 96.5 - 108.0 — 92.5 - 96.4 87.5 - 92.4

100A-2F-HW 97.5 - 108.0 87.5 - 89.4 89.5 - 97.4 —

3

Step 3: Mount the Element Arms to the

Element Boom

Remove the mounting hardware (stainless steel1.

3/8 at-washer, lock-washer and nut) from both

Boom Cradle Brackets. (Step 3 a)

Place one Element Arm into each Boom Cradle2.

Bracket with the Feed Strap Stud pointing up.

(Step 3 b)

Secure the arm to the threaded post using the3.

mounting hardware (stainless steel 3/8 at-

washer, lock-washer and nut).

Tighten the cradle nut until the cradle’s sharp4.

grounding point is rmly seated into the Element

Arm material and the lock washer is compressed,

approximately 12 lbf·ft (16 N·m) torque.

Step 3b

Step 3a

Boom Cradle Brackets

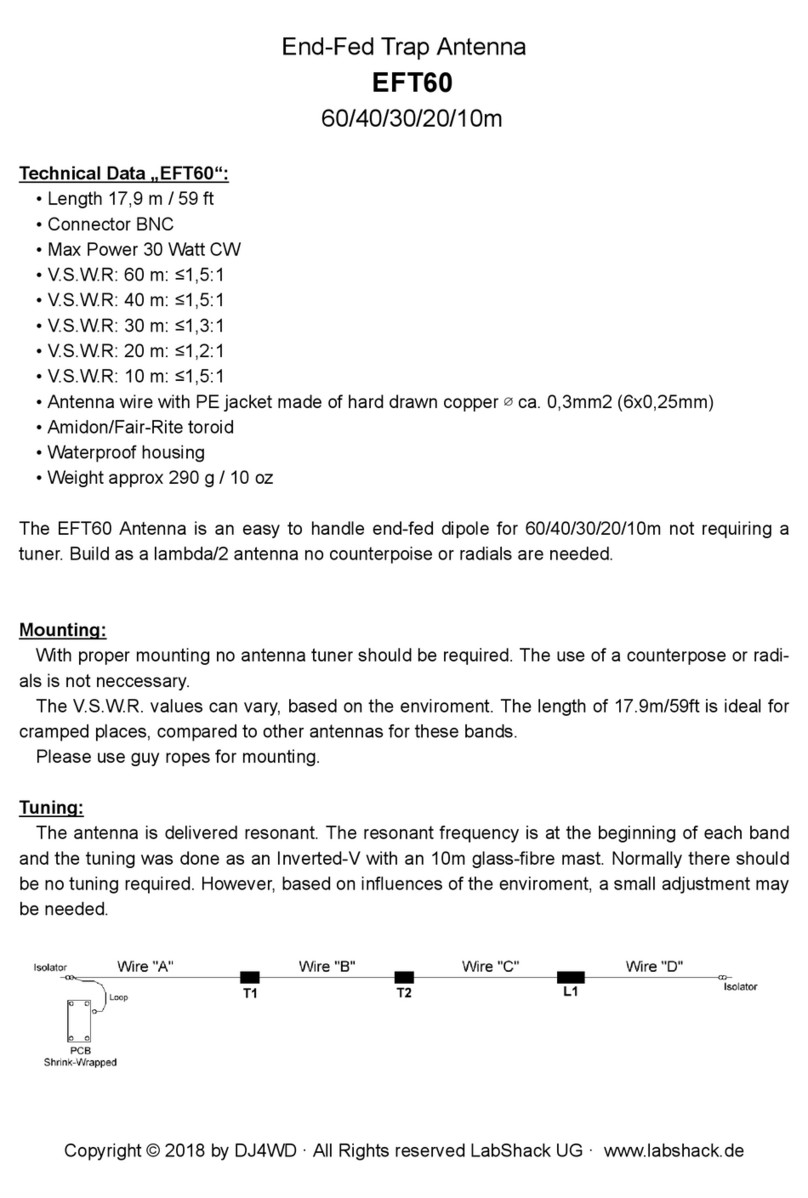

Tip Length, ‘L’

Frequency

Range

100A-1M 100A-2F 100A-2F-HW

inch cm inch cm inch cm

107.5 - 108.0 2 5/16 5.87 2 1/4 5.72 1 7/8 4.76

106.5 - 107.4 2 3/4 6.99 2 5/8 6.67 2 1/8 5.40

105.5 - 106.4 3 7.62 3 7.62 2 1/2 6.35

104.5 - 105.4 3 5/16 8.41 3 3/8 8.57 2 29/32 7.38

103.5 - 104.4 3 11/16 9.37 3 3/4 9.53 3 5/16 8.41

102.5 - 103.4 4 10.16 4 1/8 10.48 3 11/16 9.37

101.5 - 102.4 4 3/8 11.11 4 9/16 11.59 4 1/16 10.32

100.5 - 101.4 4 5/8 11.75 4 7/8 12.38 4 1/2 11.43

99.5 - 100.4 5 12.7 5 3/16 13.18 4 7/8 12.38

98.5 - 99.4 5 5/16 13.49 5 9/16 14.13 5 3/16 13.18

97.5 - 98.4 5 5/8 14.29 5 7/8 14.92 5 19/32 14.21

96.5 - 97.4 6 1/16 15.4 6 1/4 15.88 5 11/16 14.45

95.5 - 96.4 6 3/16 15.72 6 5/16 16.03 6 1/16 15.40

94.5 - 95.4 6 9/16 16.67 6 5/8 16.83 6 7/16 16.35

93.5 - 94.4 7 1/8 18.1 7 17.78 6 13/16 17.30

92.5 - 93.4 7 5/16 18.57 7 3/8 18.73 7 3/16 18.26

91.5 - 92.4 7 1/2 19.05 7 1/2 19.05 7 3/16 18.26

90.5 - 91.4 7 7/8 20 7 7/8 20 8 1/16 20.48

89.5 - 90.4 8 5/16 21.11 8 5/16 21.11 8 1/2 21.59

88.5 - 89.4 8 3/4 22.23 8 3/4 22.23 9 1/8 23.18

87.5 - 88.4 9 3/16 23.34 9 3/16 23.34 9 5/8 24.45

4

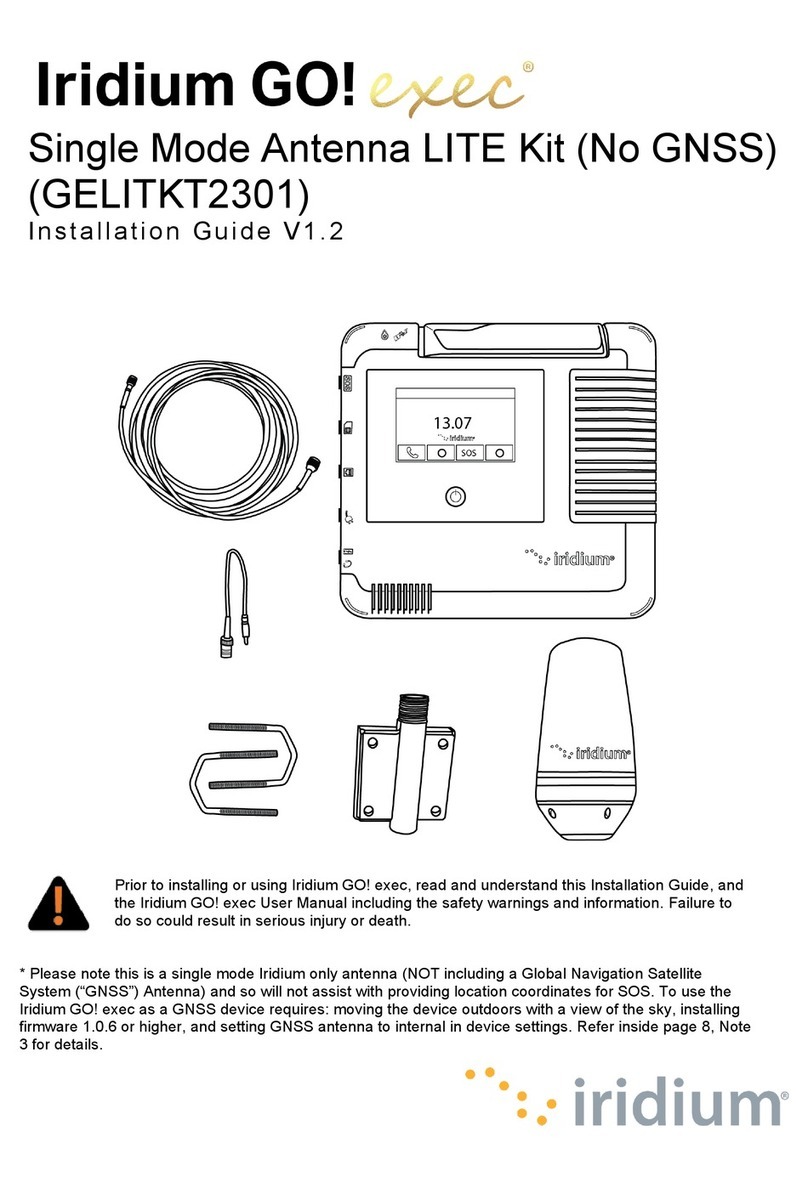

Step 5: Secure the Antenna to its

support structure

A Universal Mounting Clamp Kit is included with

the antenna for ease of mounting to the tower

leg. The kit generally eliminates the need for any

additional brackets, however chain and“J” bolts can

be ordered for larger pole installations.

Step 5

Step 4: Attach the Feed Strap

Loosen the feed insulator wing-nut and1.

swing the strap from the shipped position

(perpendicular to the Boom) to where the

strap engages the Grounding Ring’s protruding

threaded studs (set-screws).

Fasten the strap to the two threaded studs; a2.

proper connection is obtained when the strap

is sandwiched between the two stainless-steel

at washers, lock washer and 5/16 inch wing-nut

removed in Step 1. The Grounding Ring Wing-

Nut is secured using 8 lbf·ft (11 N·m) of torque

applied to the wing-nut.

Hand tighten the Insulator wing nut taking care3.

not to exceed the 3 lbf·ft (4 N·m) torque rating.

Step 4

Feed insulator wing-nut

Grounding Ring Wing-nut

5

Step 6: Connect the antenna feed to the

transmission Feed

Connect the antenna feed pigtail to the1.

transmission feed.

To prevent water and other contaminants from2.

seeping into the joint, wrap the connection with

a good quality rubber electrical tape.

To prevent cable strain, excess cable should be3.

spooled and tied down. The 11’pigtail feed of

the 100A Series Antenna can be coiled into a 5 in.

diameter, however never exceed the maximum

1-3/4 in. bending radius of the cable. NOTE:

Failure to properly install and secure the cable

might allow wind vibration to destroy antenna

connections. Use the 10 furnished Cable Ties to

spool and tie the cable to the tower.

Step 6

6

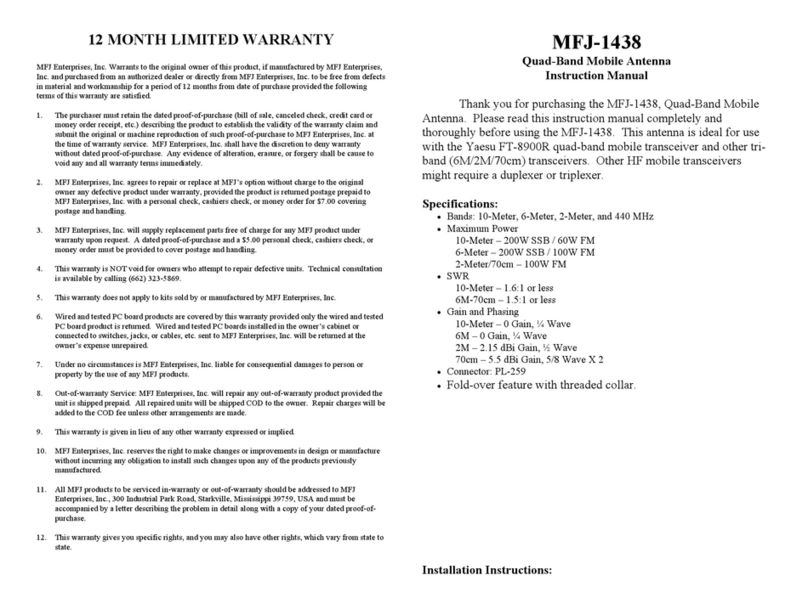

Bay Spacing

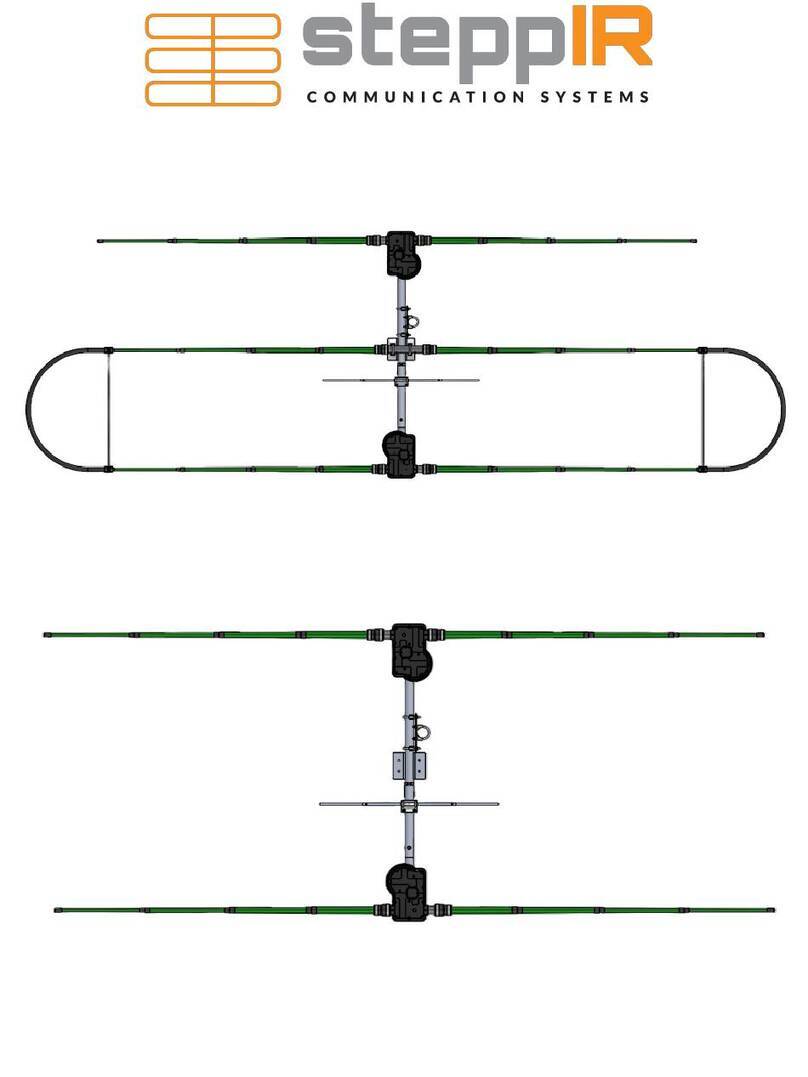

For Antenna Type Numbers 100A-2F and

100A-2F-HW

Use the Bay Spacing table (right) and repeat steps

1 through 6 for the additional element. Install the

PD100A power divider according to the diagrams

above and the Bay Spacing table (right).

The Power Divider is secured to the tower using

stainless steel hose clamps furnished with the

Power Divider. Seal power divider connections with

electrical tape.

PD100A

(Power Divider)

Hose

Clamps

Weep

Hole

7

Bay Spacing

Frequency

Range

100A-2F 100A-2F-HW

inch cm inch cm

107.5 - 108.0 109 1/4 277.5 54 5/8 138.75

106.5 - 107.4 110 5/16 280.19 55 5/32 140.10

105.5 - 106.4 111 3/8 282.89 55 11/16 141.45

104.5 - 105.4 112 3/8 285.43 56 3/16 142.72

103.5 - 104.4 113 1/2 288.29 56 3/4 144.15

102.5 - 103.4 114 9/16 290.99 57 9/32 145.49

101.5 - 102.4 115 3/4 294.01 57 7/8 147.00

100.5 - 101.4 116 7/8 296.86 58 7/16 148.43

99.5 - 100.4 118 299.72 59 149.86

98.5 - 99.4 119 1/4 302.9 59 5/8 151.45

97.5 - 98.4 120 7/16 305.91 60 7/32 152.96

96.5 - 97.4 122 5/8 311.47 61 5/16 155.73

95.5 - 96.4 122 15/16 312.26 61 15/32 156.13

94.5 - 95.4 124 1/4 315.6 62 1/8 157.80

93.5 - 94.4 125 1/2 318.77 62 3/4 159.39

92.5 - 93.4 126 7/8 322.26 63 7/16 161.13

91.5 - 92.4 128 1/4 325.76 64 1/8 162.88

90.5 - 91.4 129 11/16 329.41 64 27/32 164.70

89.5 - 90.4 131 1/8 333.06 65 9/16 166.53

88.5 - 89.4 132 5/8 336.87 66 5/16 168.43

87.5 - 88.4 134 1/8 340.64 67 1/16 170.34

Pre-Deployment Checklist

[ ] The mounting hardware ts the diameter of the

tower leg.

[ ] The Grounding Ring is installed properly

according to the table.

[ ] All components are securely connected..

[ ] The feed cable rated capacity is not exceeded and

is correctly paired to the rating of the Antenna.

[ ] Electrical tape is used at the connection point

between the feed pigtail (antenna feed lead-in)

and the feed-line connector.

[ ] If a feed cable adapter is required, the gender is

correct.

[ ] Inspect the element’s feed pigtail (antenna feed

lead-in) for connector damage, cable kinks,

or pinching. Do not install if damaged; call

Electronics Research Inc for assistance.

Attention Installer

Do not install the Antenna near other tower1.

mounted Antennas. Always mount the Antenna’s

Boom pointing in the direction of desired

coverage.

Always mount the antenna with the Strap2.

Insulator pointing up.

Ensure the feed pigtail stays coiled until you3.

reach the tower location to mount the antenna.

If a 2-Bay* conguration is being installed,4.

mount the elements directly above one another

using the bay spacing distance furnished in the

Bay Spacing table.

Always tie down loose cable to the tower using5.

quality tie-down material.

The length of certain horizontal and diagonal6.

tower members can create resonant conditions

that may impact antenna VSWR performance.

If possible, avoid 30”to 60”dimensions

corresponding to ¼ and ½ wavelengths.

* PD100A power divider and second 100A element is

required for the 2-Bay arrangement. The Power Divider

is secured to the tower using stainless steel hose clamps

furnished with the Power Divider. Seal power divider

connections with electrical tape.

Electronics Research, Inc. | 7777 Gardner Road, Chandler, IN 47610 USA | www.eriinc.com | +1 (812) 925-60000

All designs, specications, and availabilities

of products and services presented in this

publication are subject to change without notice.

Publication 20100326001_AEN Revision 03

(2011-02-04) Copyright © 2011 Electronics

Research, Inc. Chandler, IN 47610 USA

For Technical Support call 877 ERI-LINE or +1 812 925-6000,

or visit our website at www.eriinc.com

This manual suits for next models

3

Table of contents