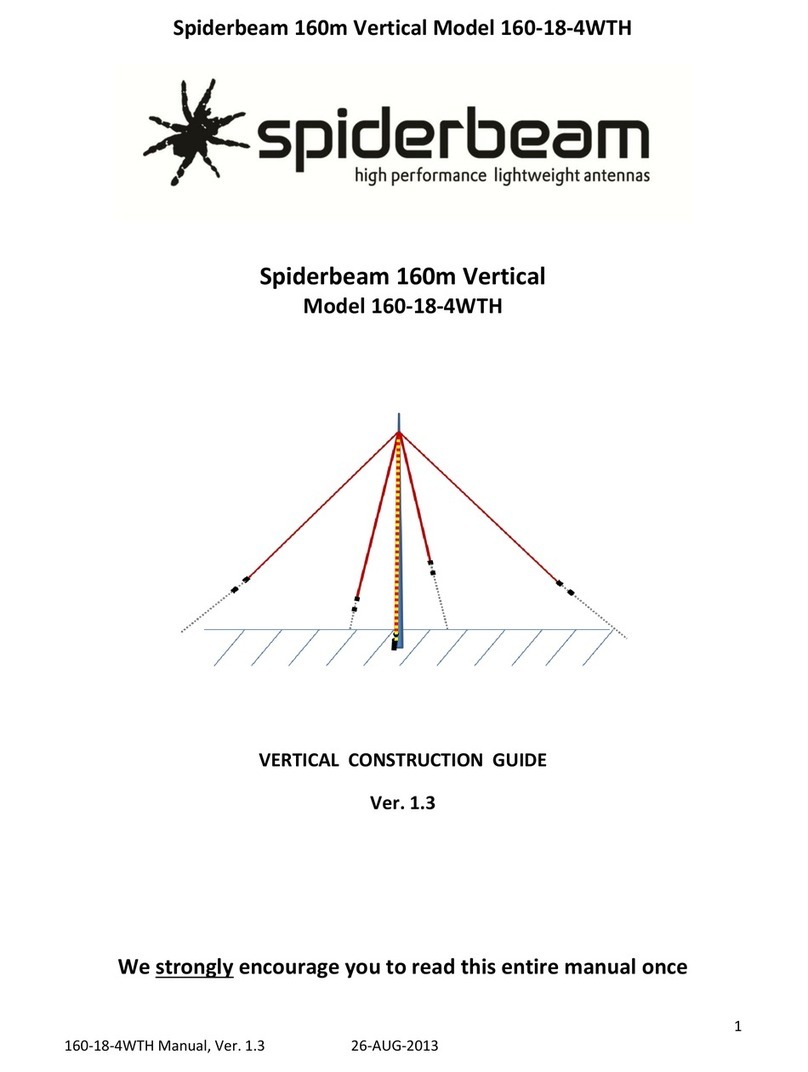

Spiderbeam 160m Vertical Model 160-18-4WTH

5160-18-4WTH Manual, Ver. 1.7 17-JULY-2021

1.0 Description and Theory

1.1 Antenna Description

The Spiderbeam Model 160-18-4WTH is a base-fed, [electrical] quarter wavelength vertical

antenna built on a Spiderbeam 18 meter-high telescoping fiberglass pole. It uses 4 top-hat

loading wires to reduce the antenna’s physical height by electrically lengthening the antenna.

This antenna is very easy to build, but does require tuning after it has been erected. It is not

plug and play. Tuning is accomplished by adjusting wire lengths.

Despite being less than 1/8 wavelength in overall height, the Spiderbeam 160-18-4WTH delivers

performance that is very close to that of a full-size vertical antenna on 160m –provided you

have adequate space for proper installation of the top-hat wires and radial network.

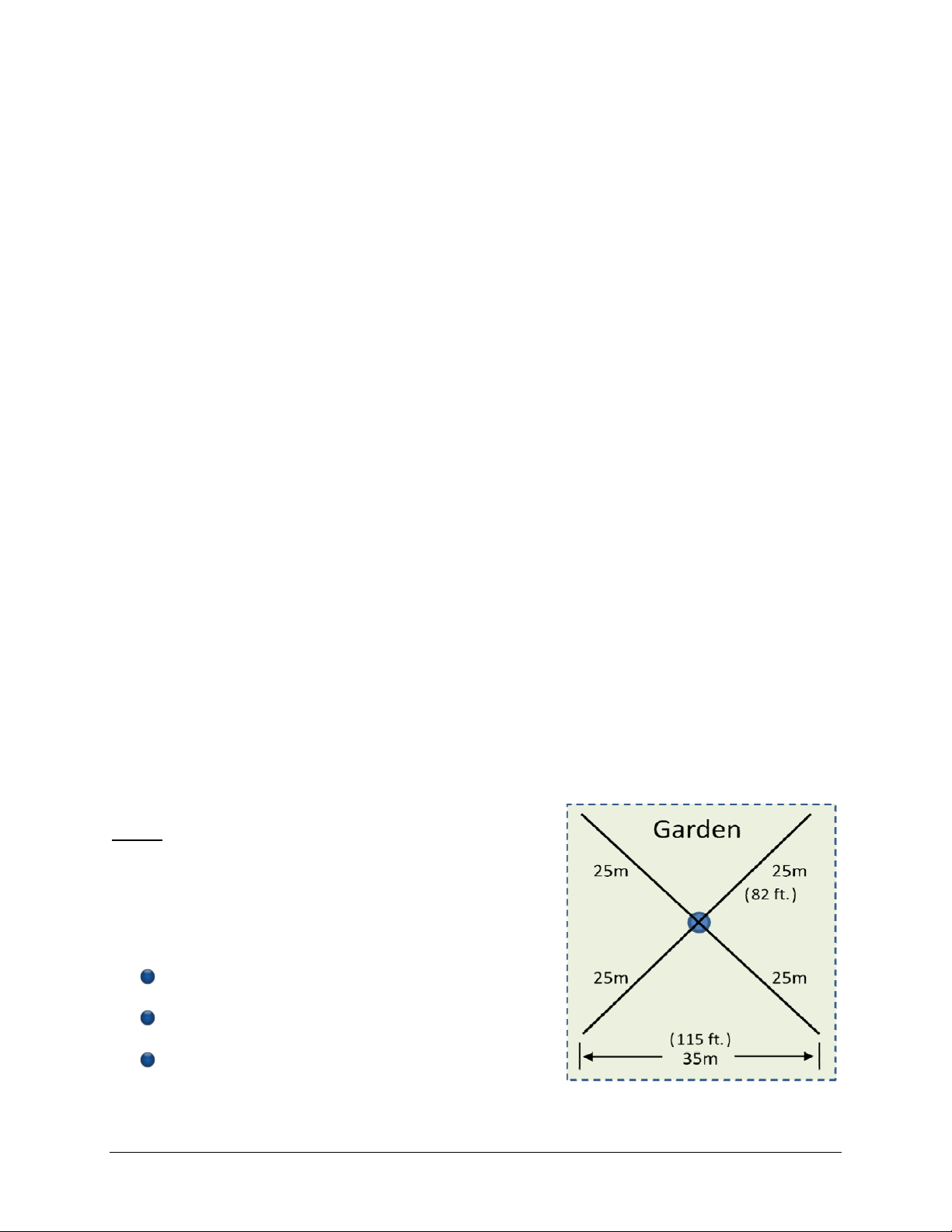

1.2 Required Space

The space required for this antenna is 35m (115’) by 35m, or 1225 sq. meters (~13,000 sq. ft.).

This area should be square, not rectangular. Minor deviations from this will not cause too much

loss in performance. If you have more space, take advantage of it by placing the ground stakes

supporting the top-hat wires farther away from the pole.

The perfect installation would have many wires used for the top hat, and they would all be

mounted in a horizontal plane at the top of the antenna. In real life installations, this is not

possible. A more practical installation will be one with 4 wires sloping to stakes in the ground at

some distant point away from the antenna (typically 25m).

The antenna itself consists of 3 electrical components: the vertical segment of the radiator; the

top-hat segment of the radiator; and a good set of ground-mounted radials. The physical length

of the vertical segment of the radiator is limited by the.

usablelength of the fiberglass pole, which is about 2.

meters less than its physical length. The top-hat wires.

must. always be the same length and equally spaced.

around the pole. Their physical length is determined by.

three factors:

The number of wires used in the top-hat.

The angle of the top-hat wire to the mast.

The ground characteristics at the location.