Elekta Neuromag NM21283A User manual

Sensor Tuner

User’s Guide

Software Version 3.0 for

Elekta Neuromag

March 2005

NM21283A-A

This document contains copyrighted and possibly confidential information and is intended for the exclusive use of

customers having Neuromag products and authorized representatives of Elekta Neuromag Oy. Disclosure to others or

other use is strictly prohibited without the express written authorization of Elekta Neuromag Oy.

Elekta Neuromag Oy reserves the right to make changes in the specifications or data shown herein at any time with-

out notice or obligation.

Elekta Neuromag Oy makes no warranty of any kind with regard to this document and the related software, including

but not limited to, the implied warranties of merchantability and fitness for a particular purpose. Elekta Neuromag Oy

shall not be liable for errors contained herein or direct, indirect, incidental or consequential damages in connection

with the furnishing, performance, or use of this material and software.

Elekta Neuromag, Vectorview and Neuromag System are trade marks of Elekta Neuromag Oy, UNIX is a trademark

of UNIX System Laboratories, Inc., and Motif is a trademark of Open Software Foundation, Inc.

Editor: Matti Kajola

© 2001-2005 Elekta Neuromag Oy. All rights reserved.

Printed in Finland.

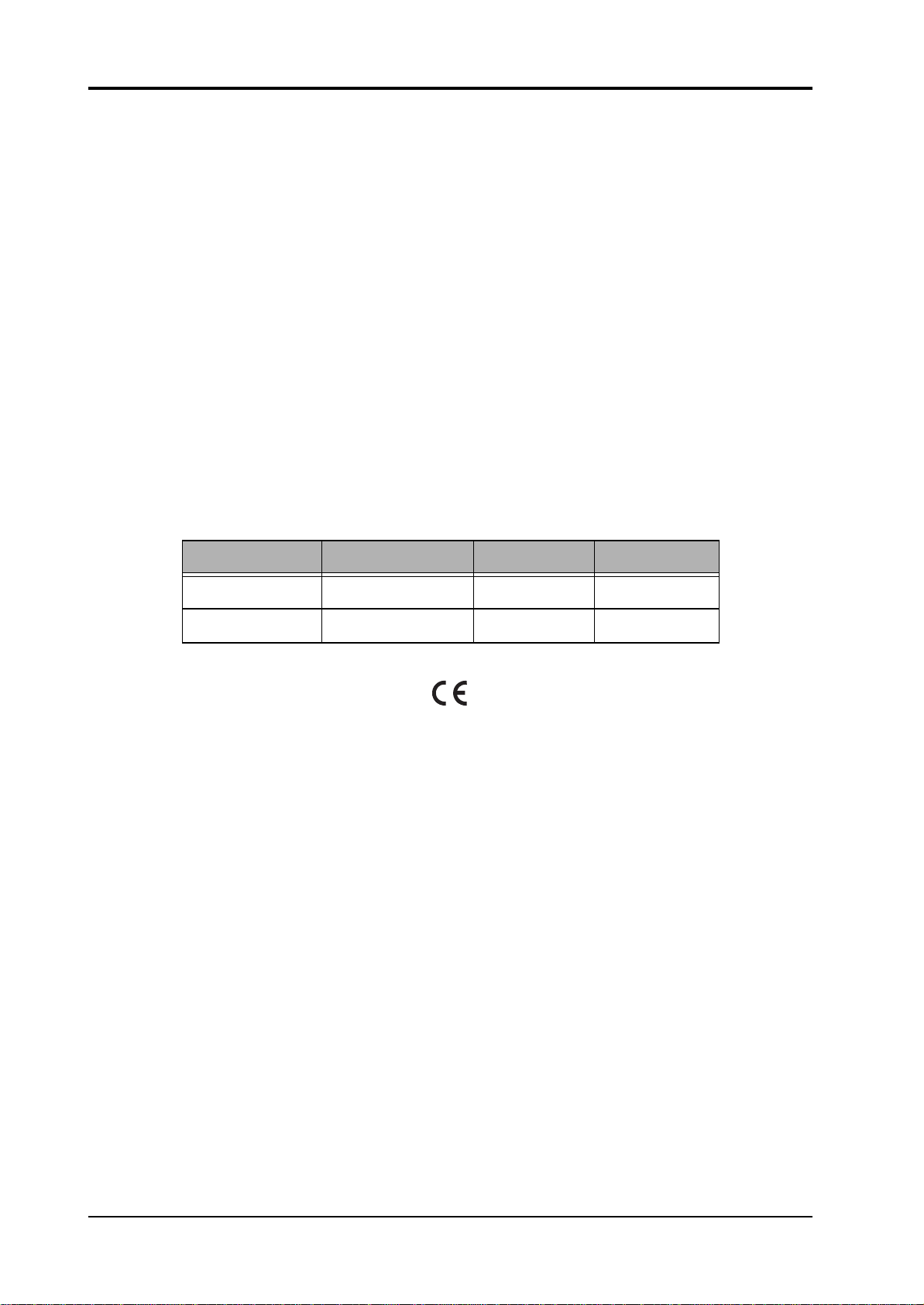

Printing History Neuromag p/n Software Date

1st edition NM21283A tune_vv 3.0.x 2001-12-27

2st edition NM21283A-A tune_vv 3.0.x 2005-03-13

0537

NM21283A-A i

Contents

Introduction 1

Part 1 Basic Usage

Chapter 1 User interface basics 5

1.1 Using menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Using text fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Using file selection boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2 Getting started 9

2.1 Beginning a session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Using online HELP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Ending a session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 3 Basic tuning operations 11

3.1 Measuring the sensor noise level . . . . . . . . . . . . . . . . . . . . . 11

3.2 Fine tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Resetting channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Heating sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 About saving and loading settings . . . . . . . . . . . . . . . . . . . . 14

3.6 Noise display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 4 Troubleshooting 17

4.1 Basic checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Viewing noise history of a channel . . . . . . . . . . . . . . . . . . . . 17

4.3 Tuning selected channels . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 5 Description of the menus 21

5.1 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Parameters Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Commands Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Search Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.6 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ii NM21283A-A

Part 2 Sensor operation principles

Chapter 6 Principles of SQUID operation 27

6.1 Operation of a SQUID magnetometer . . . . . . . . . . . . . . . . . . 27

6.2 SQUID electronics of Vectorview . . . . . . . . . . . . . . . . . . . . . . 29

6.3 Optimal point of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 7 Manual tuning 33

7.1 Need for manual tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2 Tools for manual tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.3 Measuring flux to current curves using Squiddler . . . . . . . . 34

7.4 Measuring flux to current curves using Tuner . . . . . . . . . . . 34

7.5 Measuring noise level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.6 Manual tuning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.7 Typical sensor problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Part 3 Advanced features

Chapter 8 Basic measurements 43

8.1 Setting the expert level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.2 Selecting and running jobs . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.3 Measurement parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.4 View modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.5 I-Phi measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.6 Noise measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.7 FFT measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.8 Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Chapter 9 Tuning procedures 51

9.1 Noise level based tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.2 Tuning based on characteristics . . . . . . . . . . . . . . . . . . . . . . 52

9.3 Manual tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Chapter 10 Measuring characteristics 53

10.1 Operating point parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.2 Measuring derivative information . . . . . . . . . . . . . . . . . . . . . 54

10.3 Measuring and using current-voltage characteristics . . . . . 54

10.4 Measuring gate curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 11 Miscellaneous 56

11.1 Searching channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

NM21283A-A iii

11.2 Loading and saving in special cases . . . . . . . . . . . . . . . . . . 56

11.3 Marking broken channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.4 Reverting operating points . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.5 Creating start-up files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.6 Updating the power-up settings . . . . . . . . . . . . . . . . . . . . . . 58

11.7 Synchronizing Janitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11.8 Using SSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 12 Description of the menus 61

12.1 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

12.2 Job Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

12.3 Parameters Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

12.4 Commands Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

12.5 Search Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

12.6 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

12.7 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Appendix A Command line options 68

Appendix B Parameters 69

Appendix C Revision history 76

iv NM21283A-A

NM21283A-A 1

Introduction

This manual has two functions. It is at the same time the user’s manual of

the sensor tuning program and also a manual describing the operation

principles of Vectorview™ sensor hardware. Detailed descriptions about

the SQUID sensor system, electronics, and tuning principles, are given in

addition to the description of the tuning program.

The SQUID tuner program tune_vv, is a versatile tool that can be used in

maintenance of Vectorview™ measurement system. It facilitates the tun-

ing and monitoring of the performance of the sensor electronics.

The key features provided by the program are:

• Measuring white noise level.

• Automatic fine tuning of the noise level.

• Adjusting sensor operating point manually.

• Measuring several characteristic curves of the sensors.

• Manual heating of single or all sensors.

The functionality of the program depends on the expert level being used.

The lowest level 0 allows noise measurements and automatic fine tuning

of the system. The expert level 1 allows more complicated measurements

and setting of various parameters affecting the program. Using the fea-

tures in level 1 requires understanding of the operation of the sensor sys-

tem, and is intended to be used by service personnel.

This manual is divided in three parts. The first one describes how to tune

the system automatically using the SQUID tuning program. This is a

everyday operation, and reading of this part is recommended for all users.

All expert level 0 operations are explained.

The second part explains the operating principles of a SQUID sensor and

electronics. It also contains a detailed description how the sensors are

tuned manually. This information is essential for the maintenance person-

nel and for understanding advanced features of the tuning program.

The third part describes advanced features of the tuning program. These

are available when the expert level is set to 1, and are normally used only

by the maintenance personnel.

2 NM21283A-A

NM21283A-A 3

PART 1

Basic Usage

This part describes the basic usage of the SQUID tuning program. It

contains information about the functionality available in the lowest

expert level 0. This allows measuring white noise level of all channels

and automatic fine tuning. Reading of this part is recommended for all

users of a Vectorview system.

4 NM21283A-A

NM21283A-A 5

1

CHAPTER 1 User interface basics

This chapter explains the notation conventions used in this manual and the

basics of the user interface manipulation. If you are familiar with the

Motif interface, you may want to skip the rest of this chapter. The descrip-

tion of the interface given here is not intended to be complete, but rather

to give enough of information to let a novice user to operate the program.

For more information about the general manipulation of the operating sys-

tem interface, refer to “User’s Guide” of Common Desktop Environment.

1.1 Using menus

On the top of the main window of the program lies a horizontal bar con-

taining so called menus. Each one is represented by its name. When the

name is clicked with the mouse button 1 (usually the leftmost button), a

stack of buttons appears. This stack of buttons is called a menu. You can

initiate different kinds of operations by clicking corresponding button in a

menu. When a button within the menu is pressed, and the mouse button is

released, the corresponding action will be executed, and the menu disap-

pears.

You may also activate a menu button by pressing the mouse button on the

name of the menu, holding the button down and dragging it on top of the

desired button. The action is now executed when the button is released on

the menu item. If you pop up a menu accidentally, you can cancel the

operation by releasing the mouse button when cursor is outside the menu,

or if you clicked the name, by clicking somewhere outside the menu.

Some menus contain so called submenus. They are connected to menu

buttons whose activation pops up yet another menu. The submenu itself is

used just similar fashion as a normal menu. Submenus are denoted by a

small triangle on the left edge of a menu button.

1.2 Using text fields

Several user interface elements use so called text fields, or text boxes.

This is a rectangle that contains some editable text inside.

1User interface basics

6 NM21283A-A

To enter some new text into an empty field, click the rectangle to get the

active text insertion point (so called text focus) into the desired text field.

Then use keyboard to enter whatever text that is needed. If the text editor

has multiple lines, use return key to start a new line. Notice that in single

line text fields, pressing the return key may case some execution to occur.

In several dialogs it is equivalent of pressing the default button of the dia-

log.

If you need to alter all or some text in a text field, select first the text to be

altered by pressing the mouse button 1 on the starting point of the text to

be replaced, and dragging the cursor to the end point of the text to be

selected, and then releasing the button. The selected text should now have

different background color that rest of the text. Then simply type in the

new text. When you press the first character of the new text, the old

selected text will disappear.

Some text can be removed from a text field by first selecting it as

described above, and then pressing delete key. Note that the last selected

piece of text is also copied into the clipboard of the program. The current

selection in the clipboard can be “pasted” in any text field by clicking the

insertion point with mouse button 2. Selecting some text by button 1 and

pasting it in some other place by pressing button 2 saves often a lot of

time compared to entering the same text from keyboard. Copying long

numbers is usually also more reliable that entering them manually.

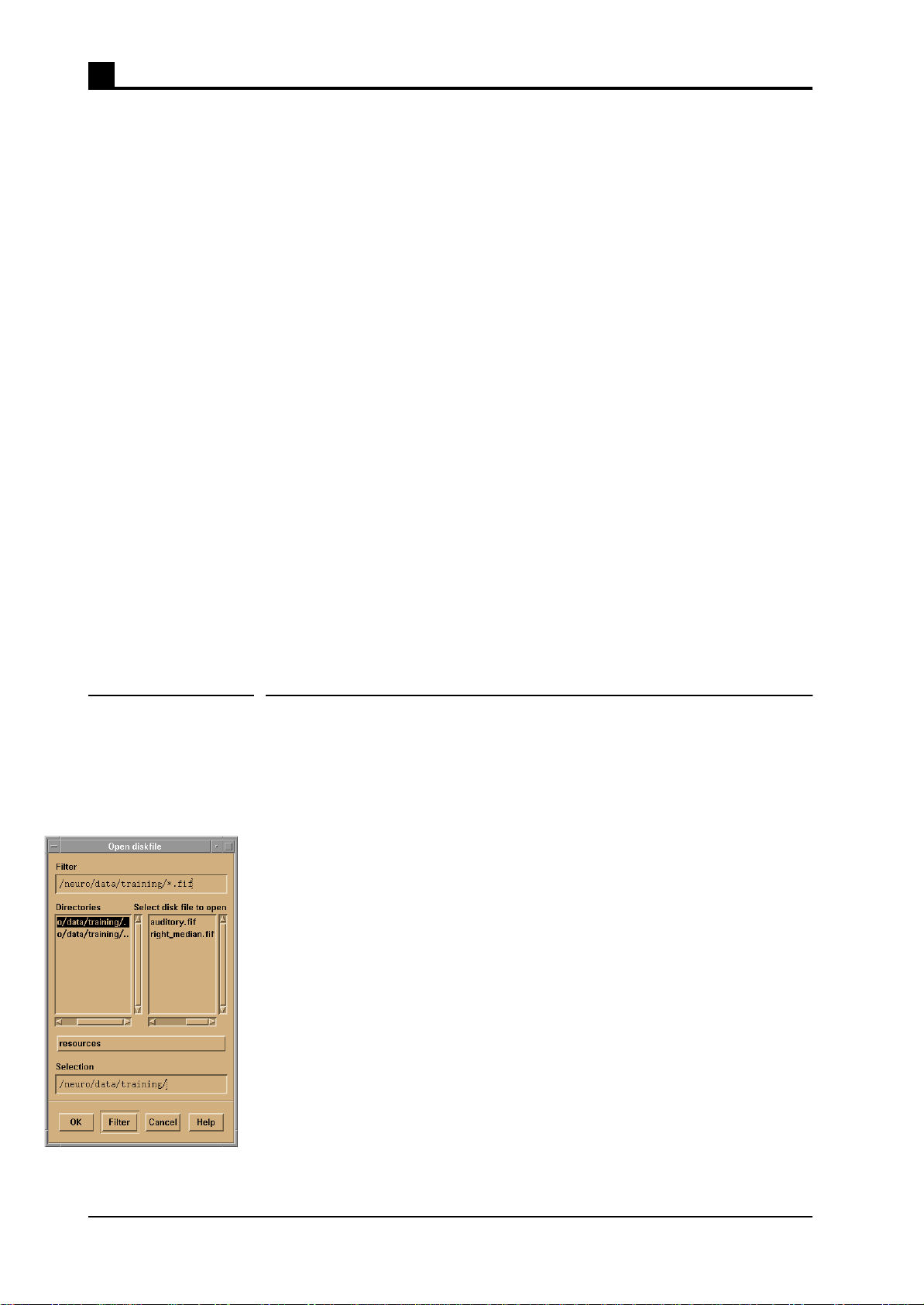

1.3 Using file selection boxes

In several phases of the analysis one must select a file to be loaded or pro-

cessed. In most cases user can do this selection using a file selection box

dialog. The figure on the left shows an example dialog.

On the top there is a field that contains a directory specification along with

a file mask. This specification defines the directory from which a file can

be selected, and the subset of files within this directory that are shown as

possible choices. If the mask part after the last slash in specification is

character *, all files in the directory are shown. If the mask contains other

characters, the file names show must contain the same pattern. For exam-

ple specification /neuro/dacq/tuning/*.tnp would select all files in direc-

tory /neuro/newdata/test that end to string “.tnp”.

Below the directory specification there are two selection boxes. The left

one lists all subdirectories to the directory specified above. You can

change the currently viewed directory easily by double clicking a direc-

tory name in this list. The right list contains all the files matching the

directory specification. Note that the parent directory is noted by filename

“..” (two dots) in these lists.

User interface basics 1

NM21283A-A 7

Below the lists there is a text field that shows the currently selected file. If

you must create a new file that does not exist yet, you can enter the new

name in this field and press ok button. For details of editing text fields see

“Using text fields” on page 5.

To select a file that already exists, double click the name of the file in the

right selection box. You may also select the file name by clicking it once,

and then pressing the ok button.

If you need to cancel the ongoing selection, press the cancel button on the

bottom of the dialog.

1User interface basics

8 NM21283A-A

NM21283A-A 9

2

CHAPTER 2 Getting started

This chapter gives you an overview of the program, explains how to start

and stop it and provides some basic aspects that you need to know.

2.1 Beginning a session

The tuner program can be started in three ways:

• Selecting the Tuner... button in the Tools menu of the acquisition pro-

gram. Measurements using acquisition program should be stopped

before starting the tuner. See “Data acquisition User’s Manual” for

details of the acquisition program.

• Using the graphical user interface of the operating system by double

clicking the tuner icon in “Maintenance” toolbox under the “MEG

analysis” toolbox.

• Giving a suitable command in UNIX shell. For the proper command

and options, refer to Appendix A.

Only one tuning program should be running at any time. If the tuning pro-

gram is already running on the same system, the new starting program

shows an question dialog warning about the already running program. In

such a case you should answer OK to stop the new one and find out who is

running the program. It is possible that you get this message even if there

is no other instance of the program running, for example if the program

was killed or it died unexpectedly. If you are sure that there is no other

copy running you can go on using the program by responding with Can-

cel button.

After starting the program, a user interface similar to Figure 2.1 appears.

On the top of the window is a menu bar that allows access to several oper-

ations and parameter settings. Major part of the window area is taken by a

graphics area which is used to show the results of current operation. On

the left are controls to show and alter manually the SQUID working point

parameters and two large buttons that are used to initiate and stop opera-

tions. These buttons will be called “start button” and “stop button”

throughout the manual. The labels on these buttons change depending on

the situation. In the bottom of the window is a status display area and con-

trols to alter graphics display scales.

2Getting started

10 NM21283A-A

The status display area is divided in four regions described here from left

to right:

• The leftmost small icons show the state of the acquisition.

• Area showing current helium level in the dewar.

• Status message area which shows information about ongoing activities.

• Information area showing variable user data like cursor position.

• Scale controls of the graphics display.

2.2 Using online HELP

The Help menu contains currently only a button which shows the version

information about the program. No online help is currently available.

2.3 Ending a session

To exit the program, select Exit from the File menu. This menu is inactive

(gray) during active measurements, so if the menu is unavailable you must

stop the ongoing measurement by pressing the “stop button”. It is recom-

mended that you exit the program after checking the noise levels or tuning

before starting a new acquisition.

Figure 2.1 Main window of the SQUID tuning program

Menu bar

Working point

View channel

Start button

Stop button

State icons

Helium level Status text area Graphics controls

Graphics area

Information area

controls

NM21283A-A 11

3

CHAPTER 3 Basic tuning operations

This chapter explains how to measure white noise level of the sensors,

automatic fine tuning, and heating of the sensors.

3.1 Measuring the sensor noise level

The tuner program can be used to check the white noise level of all the

sensors. This can be done before the measurements to check that all chan-

nels are working properly.

To measure white noise levels using Tuner:

1. Stop any ongoing acquisition by pressing stop button of the acquisition

program, and wait for the measurement to stop.

2. Start the tuning program (if not running yet). See “Beginning a ses-

sion” on page 9.

3. Press the large “Measure noise” button on the left.

Warning: If there was a measurement running when the tuner was

started, the start button is gray, and no tuner measurements can be initi-

ated. In this case, one must exit the tuner, stop the normal acquisition

measurement, and then restart the tuner again.

Warning: Acquisition program can not perform measurements if the

tuner is accessing the measurement system. To enable measurements,

press stop button to stop current operation, and then another time to

release the collector (software part responsible for delivering the magne-

tometer data). It is recommended that you then exit the tuning program,

even though that is not necessary to perform normal acquisition.

The program now starts measuring the noise level of the system. The

noise level of all channels is shown on a bar display in the display area.

Normally all bars should be red and display value between 2 to 5

( for gradiometers). Small negative bars indicate channels

that are saturated and probably are not operating in flux locked mode (not

functioning properly). Note that the colors can be adjusted personally. The

above description refers to default colors.

fT Hz⁄

fT cm Hz()⁄

3Basic tuning operations

12 NM21283A-A

If the noise values look good you can press the “stop button”, exit the pro-

gram, and go on measuring with the acquisition program. If not, proceed

to tune the channels. This is explained in the next section.

3.2 Fine tuning

Normally the program is used to tune slight offsets from a good operating

point that is set after the installation of the system or thermal cycling. This

is referred as fine tuning.

Before tuning one should measure the noise level. See “Measuring the

sensor noise level” on page 11. If it is abnormally high, check that the

door of the shielded room is closed. If the noise still looks very high, or

some channels are saturated (small black bars appear in the display), try

heating the noisy channels. See “Heating sensors” on page 13. If the over-

all noise level is very high, you probably need to load suitable tuning set-

tings from a file before doing the fine tuning. See “About saving and

loading settings” on page 14. Contact your administrator to find out the

correct tuning file.

When the channels seem to work properly, but the noise level is higher

than normally, running the auto-tuning routine of the tuning program

should be able to fine tune the noise levels to normal.

To tune sensors automatically:

1. Start a noise level measurement.

2. Press the “start button” again (the same button that was used to start the

noise measurement). The button should now have text Tune on it.

3. Wait until the tuning has obtained good noise values. (Or, hopefully

not, failed to tune the noise.) The tuning does not stop automatically. It

continues until it is explicitly stopped.

4. Press Stop tuning button.

5. Press Stop collector button (the same stop button as before which now

has different text on it), to release the acquisition system for normal

measurements.

Warning: All measurements should be made with the doors of the

shielded room closed.

Warning: Heat single noisy channels before tuning. Tuning may success

even with flux trapped SQUID but then the tuning is off when the sensor

is later returned to its normal state.

Basic tuning operations 3

NM21283A-A 13

Warning: Tuning for excessively long times (>5 min.) does not make the

tuning better. Instead, if the noise level is limited by something else than

SQUID noise, the tuning settings may drift to unstable values.

3.3 Resetting channels

The SQUID sensors are operated in so called flux locked mode. See

“SQUID electronics of Vectorview” on page 29. In some situations the

electronics is not capable following the signal and the output gets satu-

rated. This can be due to very strong signals (e.g. environmental low fre-

quency drift) or sharp transients. To get the sensor working again, the

integrator in the feed back loop and the zeroing mechanism (high pass fil-

ter), need to be reset. Saturated channels that need to be reset are repre-

sented as small negative bars in the noise display.

To reset all channels:

1. Select Commands > Reset electronics from the menus.

3.4 Heating sensors

The coils and the SQUIDs in a sensor unit contain very thin superconduct-

ing film. Sometimes when the sensor is exposed to strong (relative to the

signals measured) magnetic field, these films “trap” magnetic flux. Strong

magnetic field can penetrate the film destroying the superconductivity

from a small patch of the film so that the field can go through it. Typically

the impurities in the films cause these “holes” to stick at some fixed posi-

tion, thus this phenomenon is often called “flux trapping”.

The flux trapping in the sensor coils is not problematic if the flux really

stays in place. Unfortunately it is quite common that the trapped flux

moves between e.g. two points. Since the flux pinned into the film is

always strong, even a very small movement cause severe jumping in the

sensor signal.

If the flux trapping occurs so that the flux penetrates the Josephson junc-

tions in the SQUID, the sensor ceases to work. If the pinning point is in

near neighborhood of the junctions, the extra field leaking through the

junctions cause the modulation depth of the SQUID to diminish. This can

manifest itself as increased noise or, if the effect is reasonably small, as

moving of the optimal operating point (bias, offset, and gate voltages) to

somewhat different values.

The magnetic flux in the thin films of the sensor can be removed by heat-

ing the sensor above the critical temperature of the films, and then letting

it cool down again. The sensors in Vectorview are equipped with small

3Basic tuning operations

14 NM21283A-A

hearing resistors, so that this can be easily achieved by feeding a suitable

current pulse into the resistor. Note that each sensor unit contains three

SQUIDs, so three channels are always heated together.

To heat a single sensor that contains a particular channel:

1. Select the view channel by entering the channel name to the selection

box of the working point controls at the left side of the display area.

Press return and check that the name of the channel appear on the top

of the display.

2. Select Command > Heat sensor from the menus.

To heat all the sensors:

1. Select Command > Heat all sensors from the menus.

If you are making a noise measurement, you need also reset the electron-

ics after heating. See “Resetting channels” on page 13.

3.5 About saving and loading settings

Tuning settings can be saved on disk and loaded back to magnetometer

later on. Recommended practice is that there should be two or three stan-

dard settings files that contain carefully made good values for normal

usage and some special situations like using the device just after helium

filling or when the helium level is very low. In normal conditions one

good setting file should be enough.

If the automatic fine tuning of the system does not succeed, one should try

first to heat bad channels and if that is not enough, load a well known tun-

ing setting file. If this tuning still fails, contact your system administrator

to find out what has changed.

It is not recommended that the tuning settings are saved after each fine

tuning and then reloaded when tuning is needed next time, since then the

tuning settings files tend to “drift” and nobody really knows how the sys-

tem should perform when some particular file is used. It is usually better

to have fixed files that are saved only by the administrative personnel so

that the expected performance is known and possible changes in the sys-

tem can be detected.

To load tuning settings into tuner and magnetometer:

1. Select File > Load tunings from the menu. A dialog will pop up.

2. If the file suggested by the dialog is the one you want to load, press OK

to load the file. Otherwise press Load other to pop up an ordinary file

selection box and use it to select the file you want to load. See “Using

file selection boxes” on page 6.

This manual suits for next models

1

Table of contents