Elektor EPROM User manual

MICROPROCESSOR

12 Elektor Electronics 11/2002

An EPROM emulator is a useful if not indis-

pensable tool if you are into developing soft-

ware for a system employing an EPROM for

storage of executable code or fixed data. Such

a ‘programmable imitation EPROM’ obviates

the need to erase an EPROM after any pro-

gramming cycle, before the new (and hope-

fully improved) program may be loaded into

the chip. Erasing an EPROM with

the aid of UV light usually takes

about 20 minutes, which, many of

you will agree, is an annoyingly long

time. If you want to test a new ver-

sion of the software during those 20

(long) minutes, a second EPROM

may be useful, but the entire opera-

tion is still cumbersome and tedious.

Over time, many different EPROM

emulators have appeared on the

market. Elektor Electronics, too, has

published a fair number of designs.

In most, if not all, cases, these emu-

lators are connected to the target cir-

cuit (sometimes also called host cir-

cuit) by way of a length of flatcable

terminated in a DIP-style plug that

can be inserted in an EPROM socket.

The length of the ‘umbilical cord’ is

limited to prevent a too high capaci-

tive load on the data and address

bus of the target system, or timing

problems caused by pulse reflection

on the cable. In practice, the con-

nection between the EPROM emula-

tor and the target circuit is often a

source of headaches.

A second, often neglected, disad-

vantage of the traditional EPROM

emulator is that it can not be pro-

grammed using a normal EPROM

programmer. Usually, programming

such units requires a special pro-

gram contained in the emulator soft-

ware (and hopefully supplied with

the kit).

The emulator presented in this

article goes off the beaten track and

is not hindered by any of the above

disadvantages. It can be pro-

grammed in any old EPROM pro-

grammer, and the complete unit may

be plugged into the EPROM socket

in the target circuit without any

problems.

EPROM Emulator

a perfect imitation-EPROM

Design by P. Goossens

As opposed to most other EPROM emulators, the design discussed in this

article provides a virtually perfect imitation of a ‘real-life’ 27C256 device,

which may be programmed in any programmer as well as inserted into

the target system.

MICROPROCESSOR

1311/2002 Elektor Electronics

select) input of the chip allows the signals

applied to the datalines to be programmed at

the location (address) pointed to by the

address bus. A Low input level applied to the

OE (output enable) input enables the con-

tents of the current address to be read out.

This is usually done immediately after pro-

gramming a byte, to make sure the program-

The EPROM

An EPROM is normally programmed

in a general-purpose EPROM pro-

grammer. Most of these units first

run a blank check on the chip you’ve

inserted. This is done by reading all

bytes in the EPROM to see if they

are at FF. If one or more bytes are

found with a different value, the

EPROM is not empty and a suitable

error report is produced. In many

cases, no further action is possible

until the entire chip is blank. Some

programmers are capable of detect-

ing the EPROM brand and type

inserted into the programming

socket. Once this information is

(automatically) established, the rel-

evant programming voltage(s) and

programming algorithm are set up.

Device recognition (if supported by

the chip manufacturer) is effected by

applying +12 V to the A9 pin and

then reading certain addresses from

the EPROM.

Once the programmer has estab-

lished that the EPROM is empty, the

actual programming sequence is

allowed to begin. First, the EPROM

is switched to programming mode

by applying a relatively high voltage

to the Vpp pin on the device. The

level of the programming voltage

depends on the EPROM type used,

and lies between 12.5 V and 21 V.

At the same time, the EPROM sup-

ply voltage (at the Vcc pin) is raised

from +5 V to +6 V. If you are curi-

ous to know how that is done in

practice, look ahead at the top part

of Figure 4.

With the EPROM in programming

mode, a logic Low at the CS(chip

62256

IC3

A10

A11

A12

RAM

A13

A14

10

A0

A1

A2

A3

A4

A5

A6

A7 25

A8 24

A9 21

23

1422

OE

20 CS

28

11 D0

12 D1

13 D2

15 D3

16 D4

17 D5

18 D6

19 D7

27

WR

26

9

8

7

6

5

4

3

2

1

74HCT245

IC5

3EN2

3EN1

11

12

13

14

15

16

17

18

19 G3

2

3

4

7

8

9

5

6

1

1

2

8x 10k1

23456789

R9

+5V +5V

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A0

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

16V8

IC4

GAL

19

20

10

I0

I1

I2

I3

I4

I5

I6

I7

I8

F7

11 I9

12

F0 13

F1 14

F2 15

F3 16

F4 17

F5 18

F6

1

2

3

6

7

8

4

5

9

+5V

C3

100n

S1

R6

10k

S2

R5

10k

+5V

D2

4V7

R4

100

½

A9

D5 D4

R8

1k2

R7

1k2

+5V

D3

4V7

R3

33

½

D1

7V5

R1

10k

R2

10k

T1

BS170

+5V

K1 C1

100n

C2

100n

78L05

IC1

+5V

IC5

20

10

C4

100n

+5V

024066 - 11

RAMWRL

RAMOEL

RAMCSL

LED2L

LED1L

BUDIR

BUGATEL

EPOEL

EPCSL

EPVPPL

EPSV

HEADER

27256

EPROM

IC2

A10

A11

A12

VPP

A13

A14

10 A0

A1

A2

A3

A4

A5

A6

A7

25 A8

24 A9

21

23

1422

OE

20

CS

28

11

D0 12

D1 13

D2 15

D3 16

D4 17

D5 18

D6 19

D7

26

27

9

8

7

6

5

4

3

2

1

+9VDC

Figure 1. The circuit diagram of the EPROM emulator — exquisite simplicity.

Features

–Emulates 27C256 EPROM

–Suitable for programming with any pro-

grammer supporting the 27C256

–Electrical protection against reading of

DEVICE-ID

– Easy to erase

–Compact

– Easy to use

ming operation was successful. If the verify

returns ‘ok’ the next byte is programmed.

The length of the programming pulse

depends on the programming algorithm

applied. The same goes for repetition of the

programming cycle if the relevant byte was

not successfully programmed.

During normal use of the EPROM (Vpp and

Vcc at 5 V), the device will respond ‘nor-

mally’ to signals applied to the CSand OE

pins. Only with both inputs activated (i.e., at

logic Low) will the EPROM supply the data

belonging with the address placed on the

address bus.

Practical Circuit

The circuit diagram shown in Figure 1 com-

prises relatively few components — three

ICs, a voltage regulator, one FET and two

indicator LEDs do the job. IC2 is not an inte-

grated circuit but an assembly of two 14-way

pinheaders that form the connections of the

EPROM being emulated by the circuit.

IC3, a RAM type 62C256, forms the heart

of the circuit. Although a 70-ns version is

specified in the parts list, a faster chip is, of

course, also allowed. Slower versions, how-

ever, are not recommended for use in this cir-

cuit.

IC4 is a GAL type 16V8 which has been

programmed to supply a fair amount of (invis-

ible) logic circuitry that ‘translates’ external

signals to the ones required by IC3. This

translation process requires the GAL to be

connected to the EPROM socket via a few

logic links, as well as to be provided with

information as to the presence of an external

voltage at the Vcc pin, and a voltage greater

than 12 V at the Vpp pin.

The combination R3-D3 affords protection

of the GAL against higher voltages at the

EPROM Vcc pin. That is necessary because

this voltage is usually raised to +6 V during

programming. The circuit around transistor

T1 detects the programming voltage at the

Vpp connection of the EPROM socket. Zener

diode D1 starts to conduct if the program-

ming voltage is present. The voltage at the

gate of T1 is then high enough for the FET to

be switched on. In combination with resistor

R1, zener diode D1 lowers the voltage to

about 7.5 V, thus ensuring that the FET

remains securely switched off at a voltage of

5Vat the Vpp terminal.

IC5, then, acts as a buffer device between the

MICROPROCESSOR

14 Elektor Electronics 11/2002

*IDENTIFICATION

024066;

*TYPE

GAL16V8;

*PINS

% Pin-assignment for input signals %

EPVP = 8, % Detection of 5V supply %

/EPVPP = 3, % Low active detection of VPP > 12V %

/EPOE = 1, % Input for /OE from EPROM-socket %

/EPCS = 2, % Input for /CS form EPROM-socket %

/SW1 = 9, % Input for switch S1 %

/SW2 = 11, % Input for switch S2 %

% Pin-assignment for output signals %

/RAMCS.t = 15, % output for /CS of RAM IC3 %

/RAMOE.t = 14, % output for /OE of RAM IC3 %

/RAMWR.t = 13, % output for /WR of RAM IC3 %

/BLANK.t = 16, % BLANK-state output for LED D5 %

/PROGRAM.t = 17, % PROGRAM-detect output for LED D4 %

/BUGATE.t = 19, % output for /G of buffer IC 5 %

BUDIR.t = 18; % output for DIR of buffer IC 5 %

*BOOLEAN-EQUATIONS

RAMCS.e = VCC; % These lines make sure that all used %

RAMOE.e = VCC; % output-lines of the GAL are %

RAMWR.e = VCC; % constantly driven %

BLANK.e = VCC;

PROGRAM.e = VCC;

BUGATE.e = VCC;

BUDIR.e = VCC;

% Switch to BLANK-state is S1 is pressed and hold this state %

% Until the EPROM programmer wishes to program the EPROM %

% OR the user wishes to switch to normal operation by pressing %

% S2 %

% This signal also drives LED D5 to indicate the BLANK-mode %

BLANK = BLANK*/PROGRAM*/SW2+SW1 ;

% Detection of a programming pulse to drive LED D4 %

PROGRAM = EPVPP*EPCS*/EPOE;

% CS for the RAM : Continuous during programming, else equal %

% to CS on the ROM %

% Only active during presence of external power to save the %

% battery %

RAMCS= EPVPP*EPVP+/EPVPP*EPCS*EPVP;

% OE for the RAM : During programming if OE on the ROM is %

% active AND Cs of the ROM is inactive %

RAMOE= EPVPP*EPOE*/EPCS + /EPVPP*EPOE*/BLANK;

% WR for the RAM : During programming if ROM-OE is inactive %

% AND ROM-CS is inactive, else if in BLANK-mode AND ROM-OE %

% is active. This means that reading while in blank-mode %

% causes the RAM to be written. Pull-ups make sure that the %

% code 0xFF will be written %

RAMWR= EPVPP*EPCS*/EPOE + /EPVPP*BLANK*EPOE;

% The DIR-signal for the 74HCT245. When this pin is active, %

% Data is transferred from the socket to the RAM-IC %

% Otherwise, the datapath is FROM the RAM to the socket %

BUDIR = EPVPP*/EPOE;

% The GATE-signal for the 74HCT245. If it is active (low) %

% the drivers are active, otherwise the A and B pins are %

% in High-Z state %

% It has to be active even in the BLANK-mode, so it wil force%

% 0xFF on the external databus during blank-check! %

% BUGATE is only active when external power is supplied to %

% save power from the battery whenever the device is not %

% required to be active %

BUGATE=EPVP*EPVPP*EPOE + EPVP*EPVPP*EPCS + EPVP*/EPVPP*EPOE;

*END

Figure 2. JEDEC file listing of the GAL contents.

Blank mode

This mode actually has two functions: mimic

an empty (blank) EPROM and clearing the

RAM IC. The signals used during Blank mode

are shown in Figure 3. Most EPROM pro-

grammers will check if the device is empty

before programming it. The conclusion that

the entire EPROM is empty is also employed

to speed up the programming process.

Because the programmer ‘knows’ that every

address reads FF, it may safely skip all

addresses that have to contain FF. This cuts

down on programming time, although it does

require the EPROM emulator to be ‘empty’

before it is programmed.

The normal procedure to check if an

EPROM is empty is to read all addresses and

compare the resultant data against the value

FF. To do so, your programmer will generate

all possible addresses and generate a read

pulse at each of them. These pulses may be

used to clear the EPROM emulator memory.

Each address is programmed by converting

the read pulse from the programmer into a

write pulse for the RAM IC. All datalines

being pulled to +5 V via resistor array R9,

IC3 is then filled with the value FF at all

memory locations.

At this point, the programmer has issued

a read command and expects device data

(preferably FF) to be placed on to the data-

bus. This is arranged by buffer IC5. The DIR

inputs remain Low, so the A signals are con-

figured as outputs and the B signals, as

inputs. The B signals, too, are connected to

+5 V via resistor array R9, so the buffer IC

will faithfully place the desired data (FF) on

to the databus.

Program mode

The GAL monitors the signal EPVpp to detect

the presence of a programming voltage

(≥12.5 mming mode. An EPROM being pro-

grammed responds differently to the signals

at CSand OE. Actually, in this state, these

signals may be renamed to WR and RD. Also,

there is no longer an additional signal avail-

able to enable the EPROM to be selected. For-

tunately, that is not necessary during pro-

gramming, because there is no need for the

EPROM to share the data bus and address

bus with other memory devices. In this state,

therefore, it appears as if the EPROM is per-

manently selected — see also Figure 4.

During a programming pulse, the buffer IC

has to transfer the data from the programmer

to the RAM (IC3). This is achieved by pulling

the DIR signal logic High. During a read pulse

(OE activated), the HC245 device has to

buffer the data in the opposite direction. This

EPROM and the databus. This IC is

necessary while the emulator is in

‘Blank’ mode when it is exptected to

supply the value FF at all times dur-

ing a read command. The GAL

arranges for the driver to be acti-

vated in the direction BA and the

EPROM is not read (actually, a write

command is given to the RAM IC,

more about this further on). Because

of the pull-up resistors inside R9, IC5

sees only logic Ones at the B inputs,

and faithfully copies these to the

external databus.

Some EPROM programmers are

equipped with pull-down resistors.

That is why IC5 is included in the

circuit, since without it the resis-

tance value of R9, depending on the

programmer, would have to be

selected low enough to prevent the

emulator acting as a significant (but

unwanted) voltage source in the tar-

get circuit.

Switch S1 allows you to switch

the EPROM emulator into Blank

mode, while S2 needs to be actuated

to manually leave this mode.

Finally, there are the components

around voltage regulator IC1. This is

a standard 5-volt regulator that steps

down the 9-V input voltage to 5

volts required by the logic circuitry.

The GAL

Apart from IC3, the most important

part of the circuit is the GAL chip.

As already mentioned, it contains all

logic circuitry we need to translate

and format external signals so that

they can be understood by the RAM

chip.

The JEDEC source file listing for

the GAL is shown in Figure 2.

Although an uncomplicated and

modest bit of programming, the

equivalent logic function of the GAL

is the same as that offered by a

rather more than a handful of ICs…

which if used would make the pro-

ject unwieldy.

The GAL will operate in one of

three modes: Blank, Normal and Pro-

gram. Each of these modes requires

the GAL to work in a different man-

ner. The Blank and Normal modes

may be selected manually by the

user. By pressing S1 once, the GAL

is configured for Blank mode. The

contents of the emulator may then

be erased by means of a blank check

run by the programmer. This state is

held until the user presses S2, or the

programmer starts to program the

emulator.

Normal mode is selected by

pressing S2 once. The emulator unit

will hen behave like an ordinary

27C256 EPROM.

Program mode is automatically

selected as soon as the programmer

starts to program the emulator (Vpp

raised to >12.5 volts). Once the pro-

gramming is finished (Vpp dropped

to +5 V), the emulator automatically

returns to Normal mode.

MICROPROCESSOR

1511/2002 Elektor Electronics

EPROM

CS

OE

RAM

BUFFER

CS

RD

WR

024066- 13

DIR

G

024066- 14

EPROM

CS

OE

RAM

BUFFER

CS

RD

WR

DIR

G

Figure 3. Signals in Blank mode.

Figure 4. Signals in Program mode.

is arranged by the GAL pulling the DIR input

logic Low.

Normal mode

The major signals with the circuit in Normal

mode are shown in Figure 5. From the dia-

gram it is clear that in this mode the GAL

does not have to perform particularly difficult

functions.

The GAL is also responsible for automatic

power reduction when the emulator is not in

use. By means of R3 and D3, IC4 is able to

detect the presence of an external supply

voltage. If no external supply voltage is

detected, IC5 and IC3 may be switched off.

IC4 prevents the signals G and CSfrom being

activated, effectively reducing the current

consumption of the RAM and the buffer when

the circuit is not used. A very useful feature

indeed because our EPROM emulator is bat-

tery-powered!

MICROPROCESSOR

16 Elektor Electronics 11/2002

CS

VPP

OE

Data Data outunknown

WR

CS

RD

G

DIR

EPROM

RAM

BUFFER

Data in unknown

024066- 15

Figure 5. Signals in Normal mode.

(C) ELEKTOR

024066-1

C1

C2

C3

C4

D1

D2

D3

D4

D5

IC1

IC2 IC3

IC4IC5

K1

R1

R2

R3

R4

R5

R6 R7

R8

R9

S1 S2

T1

0

+

024066-1

(C) ELEKTOR

024066-1

Figure 6 The unit is compact thanks to IC3 being mounted above IC4 and IC5.

COMPONENTS LIST

Resistors:

R1,R2,R5,R6 = 10kΩ

R3 = 33Ω

R4 = 100Ω

R7,R8 = 1kΩ2

R9 = 8-way SIL array 10kΩ

Capacitors:

C1-C4 = 100nF

Semiconductors:

D1 = zener diode 7.5V

D2,D3 = zener diode 4.7V

D4 = LED, high-efficiency, yellow

D5 = LED, high-efficiency, red

T1 = BS170 or BS107

IC1 = 78L05

IC3 = 62256-70CP

IC4 = GAL 16V89, programmed, order

code 024066-31 (see Readers Services

page)

IC5 = 74HCT245

Miscellaneous:

IC2 = 2 ? 14-way pinheader

S1,S2 = pushbutton

K1 = 9V battery clip with leads

PCB, order code 024066-1 (see Readers

Services page)

Disk, GAL JEDEC listing, order code

024066-11

PCB design and GAL listing also available as

files from Free Downloads at

www.elektor-electronics.co.uk

on the programmer’s ZIF socket. In practice,

however, we found that the lever had to be

lifted ever so slightly to enable the circuit to

be inserted into the socket. The above tip,

may, therefore, not be applicable in all cases.

Finally…

With the board fully stuffed and the battery

connected, the emulator is, in principle, ready

for use. First, however, we recommend run-

ning a few function tests.

The operation of the GAL may be checked

by pressing S1. LED D5 should light and go

out again when S2 is pressed once more.

Now insert the EPOM emulator into the IF

socket of your programmer and then press S1.

Run a Blank Check on the programmer. If

everything works as it should, the program-

mer should report an empty (blank) EPROM.

Now press S2 to force the emulator into Nor-

mal mode. Next, run another Blank Check on

your programmer. This test should also be

completed without problems, proving that

each and every mem-

ory location in the

emulator RAM (IC3)

contains the value FF.

As a final test, we

can check the pro-

gramming. Choose an

arbitrary programming

file on the programmer

and ‘burn’ it into (emu-

lated) EPROM. LED D4

should light. Next, run

a Verify operation to

see if the program-

ming operation was

successful.

If a problem is

encountered, carefully

inspect the construc-

tion of your emulator.

Check the orientation

of the ICs, diodes, etc.,

as well as the value of

all components. Also

inspect the solder

joints for short-circuits

and/or dry joints.

One more tip: temporarily install a ZIF

socket in the EPROM socket of the target cir-

cuit. This allows the emulator unit to be

inserted and removed as many times as nec-

essary without the risk of bad contacts

between target circuit and emulator. The

cheaper brands of IC sockets which prolifer-

ate in the hobby circuit these days are prone

to developing contact problems when used

more than two or three times.

(024066-1)

Power supply

The complete circuit is powered by

a 9-volt battery. Purposely no provi-

sion is made for the circuit to be

powered from the +5-V supply pin of

the EPROM. After all, the voltage at

this pin may become +6 V during

programming, which is not a healthy

level for the ICs in the emulator. If

you do want to employ this voltage,

measures should be taken for it to be

stabilised at +5 V. A DC-DC con-

verter could be used for this pur-

pose, but the disadvantages will

always outweigh the benefits,

mainly because the circuit becomes

bulky and difficult to work with in

practice. The battery can be elimi-

nated anyway because the circuit is

not permanently connected to an

external power supply which would

guarantee that the RAM contents

are not lost or corrupted the instant

the emulator is removed from the

programmer and taken to the

EPROM socket of the target system.

Construction

The artwork of the printed circuit

board designed for the EPROM emu-

lator is shown in Figure 6. The

board allows the unit to be compact

and easy to handle. Construction is

easy by almost any standard. As

customary, it is best to start with the

lower profile components (in this

case, the horizontally mounted resis-

tors). Then follow the other discrete

parts, the integrated circuits and the

pushbuttons. Two points are worth

noting. The first concerns the emu-

lator connections marked ‘IC2’.

These consist of two rows of 14-way

pinheaders whose pins have to pro-

trude downwards, requiring the

headers themselves to be soldered

at the underside of the PCB, too.

This is best done with the ICs

already mounted. A further pint to

note is that IC3 is mounted above

IC4 and IC5. The latter two have to

be soldered on to the board first,

while IC3 is fitted with a raised

socket. This is conveniently made

from two 14-way pinheaders. As a

matter of course, IC4 and IC5 are

mounted without sockets, else IC3

would require a second socket! By

the way, note the position of IC3:

viewed from above, it should be at

the right-hand side of connectors for

‘IC2’.

Here are some more practical

details. The holder for the 9-V bat-

tery may be secured to IC3 using

two-sided sticky tape to make the

unit sturdy and compact. It may also

be a good idea to file a away a small

piece of PCB material to the left of

diode D1 to make room for the lever

MICROPROCESSOR

1711/2002 Elektor Electronics

GENERALINTEREST

18 Elektor Electronics 11/2002

(which is still used in modern

microwave ovens).

The first practical application of

this system was for Radio Detection

And Ranging, better known as its

acronym RADAR. The operation of

radar is based on the transmission of

a series of SHF waves at regular

intervals. When these waves hit an

object of sufficient mass then part of

them will be reflected back to the

transmitter, where an aerial can

detect them.

In the original systems the start of

the horizontal sweep in the cathode-

ray tube was synchronised with the

transmission of the signal burst and

the return signal received by the aer-

ial was fed to the vertical deflection

amplifier. When the aerial received a

return signal (the waves reflected

back by an object) a spike could be

seen further to the right of the tube,

the position depending on the dis-

tance of the object (see Figure 1).

This system could not only be

used to detect the presence of every

object (aeroplane) that was in its

field of ‘view’, but it could also deter-

mine the distance accurately

between the aerial and the object,

since the propagation speed of the

waves and the rate of horizontal

deflection (time base) were known.

This is how R.A.D.A.R. came about,

an acronym that soon turned into an

everyday word.

Subsequently the radar was

improved to cover all of the sur-

rounding area rather than just a

small section directly in front of the

aerial. This was done by mounting

Everything you always wanted to know about

Speed Cameras

but were afraid to ask…

By: B. Bouchez

Feared by many motorists (let those who have never driven too fast cast

the first stone), the speed camera, usually containing a radar, is an

electronic device whose workings are still a mystery to most electronics

hobbyists. In this article we take the covers of these curious devices and

describe their operation in detail, also considering a few ideas to guard

against their actions.

A little bit of history

Many, many years ago, the investigations car-

ried out on electromagnetic radiation in the

thirties revealed that RF waves appeared to

be reflected back from some objects. This

property became more discernible as the fre-

quency was increased (above 100 MHz). It

wasn’t until the end of the thirties that SHF (f

>1GHz) waves could be generated easily,

thanks to the introduction of the magnetron

(Source: Applied Concepts, Inc. / Stalker Radar)

GENERALINTEREST

1911/2002 Elektor Electronics

sure the speed of vehicles, we’ll take a look

at the commercial applications that are found

at the side of the road.

The basis of every speed camera (let’s call

it a radar) is a SHF generator, which can

transmit a beam in a specific direction. From

the previous section we have learnt that the

sensitivity of the device is directly propor-

tional to the frequency of the beam. The exact

frequency used depends on the manufacturer,

but is generally between 2 GHz and 15 GHz.

The device can either have a SHF oscillator

based on a Gunn diode and a resonant cav-

ity, or a transistor oscillator followed by a

power amplifier. The power of these oscilla-

tors is not very high (usually less than 10

mW), but the effective power output is

increased through the use of a directional aer-

ial.

The receiver for the reflected signal is

often based on a Schottky diode, situated at

the focal point of the aerial (usually the same

aerial is used for transmission and reception),

which functions as a mixer of the transmitted

and reflected signals.

The output signal of the receiver is ampli-

fied, conditioned by an analogue circuit and

then passed on to the measurement section,

which is nothing more than a frequency

counter.

the aerial assembly on top of a

turntable (the cathode-ray tubes

were now given deflections in two

directions).

Introducing the Doppler

effect

The device just described is not

capable of determining the speed of

the detected object; this was limited

to measuring the movement of the

echo on the screen, which gave a

rather inaccurate result.

As an example, consider a car

that makes a sound with a fixed fre-

quency (a car that is driven with

fixed revs for example). When you

are in the car you won’t notice any

variation in the frequency of the

engine sound.

If however you stand at the side

of the road and listen to the car

when it drives past under identical

conditions you will notice that the

frequency of the engine sound

increases as the car comes nearer

and then decreases as the car trav-

els past you. (This effect is also

noticeable in F1 Grand Prix races

when the cars roar past the camera.)

This phenomenon works the other

way round as well: when you drive

your car past somebody who is

shouting on the pavement, you

should notice that the frequency of

the shouting increases as you go

towards the person, and then

decreases as you move away.

When the distance between the

sound source and the receiver

remains constant then the frequency

of the received signal won’t vary

either.

The Doppler effect (named after

the physicist who discovered it) is

nothing more than that described by

the formula in Figure 2:

fM= 2 vf

Ecos (α/c)

where

fMis the frequency of the received

signal.

v is the speed of the vehicle.

fEis the frequency of the transmitted

signal.

αis the angle between the transmit-

ter and the path along which the

vehicle travels.

cis the propagation speed of the sig-

nal in air (300,000 km/s for radio

waves, 340 m/s for sound

waves).

From this we can deduce that

sending a fixed frequency signal

towards the car and then measuring

the frequency of the returning signal

will give you the speed of a car.

This is the principle used for

radars in speed cameras, although

they have little in common with the

systems described in the first part of

this article.

It should be mentioned that the

sensitivity of the radar increases as

the angle between the beam and the

path of the vehicle decreases. For

this reason the aerials of speed cam-

eras are positioned parallel to the

roads rather than across them! This

is also the reason why few types of

radar can work along bends, since

the angle between the beam and the

vehicle continually changes, creating

errors in the measurements.

From theory to practice!

Now that we’ve seen how the

Doppler effect can be used to mea-

frequency

generator

controlled

SHF

oscillator

synchronised

sawtooth

generator

switch

TX/RX antenna

transmitted

burst

received

burst

020165 - 11

return

signal

amplifier

horizontal

amplifier

vertical

amplifier

Figure 1: Principle of operation of first generation radars (1940).

Figure 2: The Doppler effect.

020165 - 12

V

fE

fM

direction of vehicle M

Speed check

TX/RX

M

α

The signal from the frequency counter

goes to a microprocessor that calculates the

speed and sends it to a display. It also checks

if the measured speed exceeds a preset value

and warns the police officers who are nearby

that an offender has just passed, or it acti-

vates a camera and flashgun.

In short, the basic principles behind a high

frequency speed detector (Figure 3) are not

very complex. (Note that we’re talking about

the principles, a practical implementation is

something else altogether, especially the high

frequency section.)

How well does it work?

Now that we know how it all works we may

wonder how reliable the measurements made

by these devices are. Let’s keep one thing

clear: we have no intention of encouraging

any of our readers to break the speed limit or

behave irresponsibly. We just want to look at

the problem from a technical viewpoint to dis-

cover what the limits are of SHF speed cam-

eras. In this way we can distinguish between

proven facts and ‘rumours’ that are doing the

rounds, made by people with little knowledge

of electronics. Instead of straying into difficult

technical considerations we’ll just answer the

most common questions.

Operation during rain or mist: in contrast to

widespread opinion, radar works perfectly

well during rain or mist (after all, radar is

used extensively to help with the landing of

aeroplanes in bad weather!). In general,

when it rains it comes down vertically (at

least it does here!), which is at right angles

to the radar beam, bringing about a Doppler

effect of zero (cos 90° = 0, so fM= 0). Heavy

rain that comes down at an angle due to

strong gusts of wind can affect the signal-to-

noise ratio of the receiver and prevent its cor-

rect operation. In this case the processor will

simply reject the measurements.

Since mist doesn’t move with respect to

the radar beam (or only very slowly) it will be

practically invisible to the receiver and the

measurements are completely unaffected.

Measurement range: the distance from which

a radar can measure the speed of a vehicle

depends on two factors: the power of the SHF

oscillator and the sensitivity of the detector.

We already knew that the oscillator power is

generally low and that the use of a directional

aerial increased the transmitted power. The

biggest problem for the detector is the signal-

to-noise ratio, which doesn’t get any better

with Schottky diodes. In this section the sen-

sitivity can also be improved through the use

of aerials. Whilst the first radars could only

take measurements up to twenty

meters, the newer models with their

ultra-sensitive detectors are capable

of taking measurements over several

hundred meters, so well before they

can be seen from the car!

Reaction time: just as with any other

equipment that use frequency coun-

ters, these speed cameras also

require a certain time to take a mea-

surement. Furthermore, most

devices now take several measure-

ments rapidly, making it possible to

reject any possibly erroneous mea-

surements. Older models required

about half a second to take a reliable

measurement. Current models react

within a tenth of a second, so any

motorist who ignores the speed limit

will have very little chance of avoid-

ing a fine after noticing a speed

camera. Sometimes the radar equip-

ment also contains a DSP (Digital

Signal Processor), which uses a spe-

cial algorithm with a very short pull-

in time, making extremely fast read-

ings possible.

Continuous transmission: in contrast

to what you may have thought after

reading the theoretical part of this

article, a radar does not need to have

its oscillator functioning continu-

ously. It only needs to be active long

enough to stabilise and take a mea-

surement. Actual radar equipment

works on a random basis or is acti-

vated only when a vehicle comes

nearby.

Discrimination: when several vehi-

cles travelling at different speeds

encounter a radar beam, the result-

ing Doppler signal contains a mix-

ture of signals at different frequen-

cies. The majority of current devices

can’t separate these components

and reject the measurement as

faulty. There are however newer sys-

tems that contain a DSP (the author

has worked on one of these sys-

tems), which can measure the speed

of several cars simultaneously. So

now only those cars that happen to

be in the ‘shadow’ of others can

escape the speed cameras.

The long and short of it is that

speed cameras have become so

accurate and reliable (which can be

confirmed by drivers who don’t keep

to the speed limit), that it has

become extremely difficult to evade

them!

On the wrong side

of the law

Mankind, and especially homo auto-

mobilis, behaves in such a way that

when he comes across an obstacle

he will try everything to get round

GENERALINTEREST

20 Elektor Electronics 11/2002

cult by the fact that very narrow beams are

used, making for a small ‘detection area’.

Some users of radar detectors have noticed

that the beam can also be detected when it

is reflected off other cars ahead and have

gladly made use of this property.

And now for the final problem: most radar

equipment can take measurements of

approaching (from the front) or receding (from

the rear) vehicles. But the sensitivity of most

detectors is limited to just one direction. To

be prepared for any eventuality the vehicle

should therefore have a detector at both the

front and rear!

And finally...

As the saying goes, if you play with fire you

may get burned. As we have seen in this arti-

cle, speed cameras have become reliable

instruments that are difficult to locate or

interfere with.

Knowing how to detect a SHF beam is one

thing; to disrupt a speed measurement is

another story. In short, although most in-car

radar detectors sold at the moment do work

and show the presence of speed cameras,

they are of little use because the speed cam-

era is likely to be triggered before the driver

can slow down.

Even though speed cameras are some-

times situated in places where they aren’t

justified (which has given rise to the name

‘euro-pump` on the continent), in our opin-

ion it shows more sense to respect the speed

limits (also out of respect for other road

users), rather than attempt to get round the

law at all costs.

(020165-1)

it. Speed cameras are no exception

to this, and numerous boffins

(whether competent or not) have

contributed to the development of

counter measures.

Before we continue we would like

to make one thing perfectly clear: in

the majority of European countries

the possession, and even more so,

the use of equipment intended to

disrupt the operation of speed cam-

eras is illegal. Indifference in this

area is not recommended, since the

consequences can be dire (handing

in of the driver’s licence, confiscation

of the vehicle, prosecutions, etc.).

In spite of this, some drivers think

it is worth the risk and don’t shrink

back from using these devices.

Loosely speaking, there are two

types of ‘anti-radars`: jamming

devices and detectors.

The jamming devices are simply

small SHF oscillators, which are

used to send a ‘fake’ signal back to

the speed camera, causing the mea-

surement to fail and preventing the

logical analysis of the frequency.

Besides the fact that these devices

are relatively ineffective (in most

radars the circuits are less sensitive

to interference signals: the frequency

of the jamming signal therefore has

to be as close as possible to that of

the speed camera, and every device

has its own frequency), the elec-

tronic circuits in the radar can detect

such jamming signals and notify the

police. A jamming device is therefore

a sure-fire way to get caught!

A detector on the other hand con-

sists of a simple SHF receiver, and

by definition these can’t be

detected. In the USA (where their

use is permitted) they are sold in

large quantities. On the Internet

they are readily available and in

some European countries they are

also freely available (their sale is

permitted but their use isn’t!). These

are usually relatively simple circuits

containing a microwave detector

and a comparator that drives an

alarm. In short, simplicity itself

(although their price seems to sug-

gest the opposite is true!).

It isn’t difficult to design a broad-

band detector that reacts to fre-

quencies between 2 and 10 GHz,

which is the range where most mod-

ern devices operate. However, if the

oscillator of a speed camera is set to

a frequency that is outside the range

covered by the detector, or it uses an

optical laser, then you’re bound to

get caught.

The second problem is that in

order to detect something, there first

has to be something to detect (obvi-

ous, isn’t it?). Older radar equipment

transmitted continuously, which

made the task simpler, but newer

models only transmit intermittently,

either randomly or in short bursts,

reducing the chance of detecting

these devices. Some models (such as

the Mesta 208 sold in France where

the author lives) are even more cun-

ning and only come into action when

a car comes within their range.

These ‘green bullets’, as they are

known because of their shape and

colour, have an optical detector on

top that literally sees the vehicles

coming.

As soon as there is some move-

ment in front of the device it springs

into action.

This brings us to the third prob-

lem: a radar detector will sense the

beam at that instant. But at the

same time the speed camera is

already doing its work. From this it

follows that in the time taken by the

driver (a typical reaction time for

people is about half a second) to

take appropriate action (to brake or

disrupt the measurement), the radar

will already have taken four or five

measurements.

The detection is made more diffi-

GENERALINTEREST

2111/2002 Elektor Electronics

020165 - 13

SHF

oscillator

(2 – 10 GHz)

command

processor amplifier/

shaper analyser

display

TX/RX

parabolic antenna

Receiver/mixer

Figure 3: Basic principle of a high-frequency speed camera.

TEST&MEASUREMENT

24 Elektor Electronics 11/2002

We can thank an EU direc-

tive dating from 1998 for

the introduction and stan-

dardisation of the OBD-2

vehicle diagnostic connec-

tor. The connector is stan-

dard on all spark-ignition

engined vehicles from

2000 and should be fitted

to diesel engined variants

by 2003. The communica-

tion protocols used can

come in three different

varieties. In Europe the

most common protocol is

the ISO standard. All of

these protocols rely on

serial data transfer

but the

Vehicle Diagnostics

Adapter

Interface between an OBD-2 vehicle diagnostic

connector and a serial PC port

Design by G. Müller

In last month’s article we took a look at the background and specification

of the OBD-2 diagnostic connector fitted to new cars. Now, as promised

we present an interface adapter that allows your car to confess its

innermost secrets to your computer.

TEST&MEASUREMENT

2511/2002 Elektor Electronics

XT1 (Pin 2) and XT2 (Pin 3)

Connect a 3.579545 MHz crystal (NTSC TV

colour burst) between these two pins. A

capacitor (typically 27 pF) is fitted to each of

these pins down to Vss.

LFmode (Pin 4)

This input selects the default linefeed mode

after a reset or at power-up. A high-level on

this pin will mean that each line sent by the

ELM323 will be terminated by a carriage

return (CR) and line feed (LF) character. A

Low level on this input will mean that each

line sent will be terminated by a carriage

return only. The mode can also be changed in

software by issuing the ATL0 or ATL1 com-

mand from the AT command set.

RS232Rx (Pin 5)

The RS232 transmit signal can be connected

directly to this pin providing that a current

limiting resistor (typically about 47 kΩ)is con-

nected in series. On-chip diodes ensure that

signal levels and message format are

not compatible with the serial com-

munications port of a Personal Com-

puter.

The interface adapter described

here contains a pre-programmed

microcontroller produced by the

company Elm Electronics of Canada.

This controller together with a few

external components allows the OBD

vehicle connector to communicate

with the serial port of a PC, laptop or

PDA running a terminal emulation

program. Alternatively a more

sophisticated program can be devel-

oped for the PC to provide a better

user-interface and allow interpreta-

tion and resetting of failure codes,

together with real-time display of

actual sensor information. In a fol-

low-up article we will look at the

development of just such a program

and describe in detail the steps nec-

essary to produce the finished pro-

gram. The source code for this pro-

gram is written in C and can be

ported to any of the common operat-

ing systems such as Linux, BeOS, or

QNX using the freely available gcc

compiler program. The source code

together with a version of the pro-

gram compiled to run under Win-

dows will be available to download.

The interpreter chip

The ELM323 was specifically

designed as a low-cost solution for

interfacing a PC or PDA to a vehicle

diagnostics connector. To keep things

simple it communicates at a fixed

baud rate of 9600 baud and does not

offer a handshaking option for the

RS232 interface. In addition it is only

able to communicate using the

10.4 kHz ISO 9141 Protocol. This stan-

dard is the most common used by the

majority of European and Asian man-

ufacturers. Vehicles built in the US

use VPW and PWM protocols and

suitable interpreter chips are also

available from Elm Electronics.

The most important technical

specifications of the ELM323chip are

listed under the heading ‘Technical

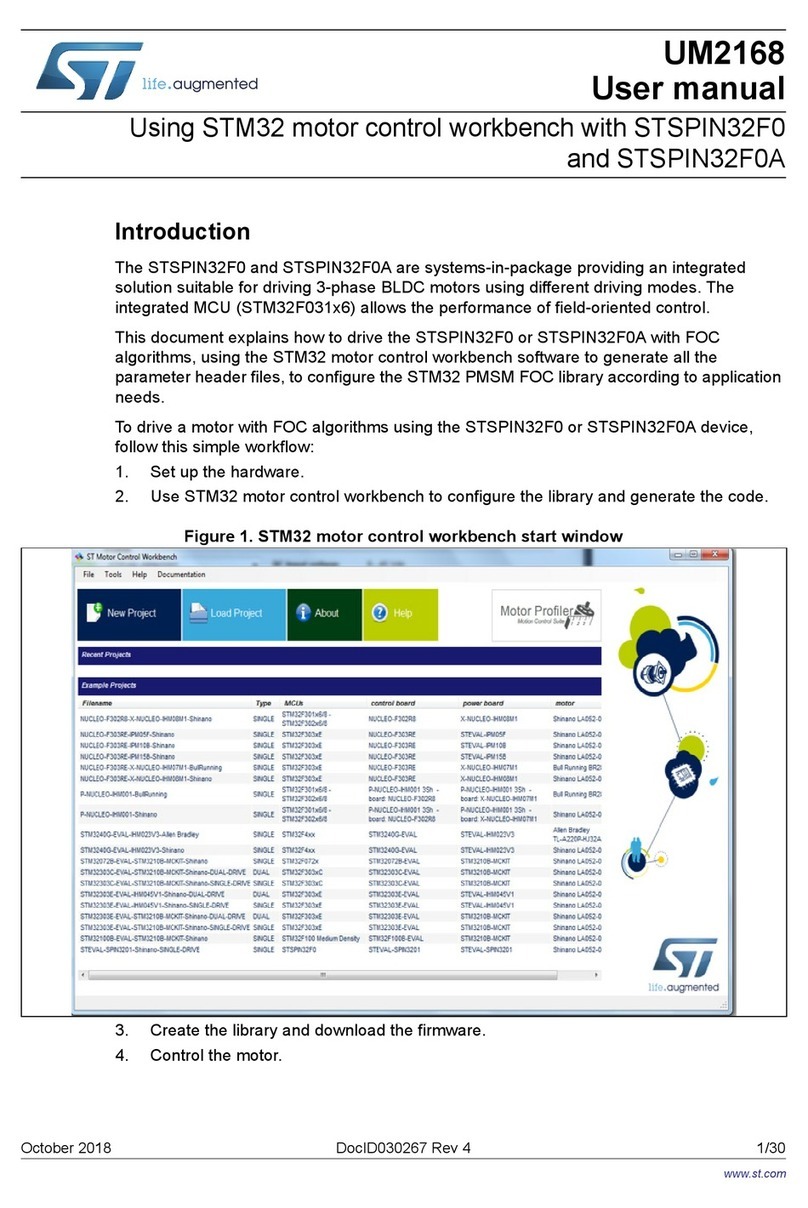

Data’ The pinouts are shown in Fig-

ure 1 and the internal block diagram

is in Figure 2. The pin descriptions

now follow:

VDD (Pin 1)

This pin is the positive supply pin

and should be the most positive

point in the circuit (see the technical

specifications). An internal power-on

reset is derived from this pin to ini-

tialise the microcontroller.

Figure 1. The ELM323 pin-outs.

ELM323 Technical Data

Absolute maximum ratings:

Storage temperature –65 °C to +150 °C

Ambient temperature with power applied –40 °C to +85 °C

Voltage on VDD with respect to VSS 0 to +7.0 V

Voltage on any other pin with respect to VSS –0.6 V to (VDD + 0.6 V)

Electrical characteristics

All values assume operation at 25 °C and 5 V supply unless otherwise stated. For further details refer to note 1 below.

Characteristic Minimum Typical Maximum Units Conditions

Operating voltage VDD 4.5 5.0 5.5 V

VDD rate of rise 0.05 V/ms See note 2

Average supply current IDD 1.0 2.4 mA See note 3

Input low voltage VSS 0.15 VDD V

Input high voltage 0.85 VDD VDD V

Output low voltage 0.6 V Current (Sink) = 8.7 mA

Output high voltage VDD – 0.7 V Current (source) = 5.4 mA

RS232Rx Pin input current 0.5 0.5 mA See note 4

RS232 Baud rate 9600 Baud See note 5

Notes:

1) This chip has a PIC16C505 from Microchip Technology as a core embedded micro-

controller.

2) This spec must be met to ensure that a correct power-on-reset occurs. If the supply

rises too slowly problems with the internal reset occur.

3) Device only. Without any load current.

4) This value represents the current flowing through the input protection diodes when

applying large voltages to the RS232Rx input (pin 5) through a current limiting resistor.

Values given are the maximum that should be allowed to flow continuously.

5) Nominal data transfer rate when the recommended 3.579 MHz crystal is used as the

frequency reference. Data is transferred to and from the ELM323 with 8 data bits, no

parity and 1 stop bit (8 N 1).

inputs to the ELM323 are protected against

overvoltage while Schmitt triggers reduce the

effects of noise on the inputs.

RS232Tx (Pin 6)

The ELM323 transmits data from this output.

The signal level is compatible with most

interface driver IC’s and there is even enough

current to use a single PNP transistor as a

line driver.

LED Drive outputs (Pin 7, 8, 9 and 10)

These four pins are low when the ELM323 is

transmitting or receiving RS232 or OBD data.

Providing that a suitable series current limit-

ing resistor is fitted, the outputs can source

or sink sufficient current to directly drive an

LED.

OBDIn (Pin 11)

The serial OBD-Data is input on this pin. A

logic high represents the active state of the

OBD K line. There is no Schmitt trigger fitted

to this input so an external input buffer

should be employed to reduce the input sig-

nal transition times.

OBDL (Pin 12) and OBDK (Pin 13)

These active-high output signals are used to

drive the OBD bus using external NPN driver

transistors. Data transfer normally occurs

over the K line but the standards specify that

the driver for the L line be implemented also

to ensure the bus is properly initialised. More

on this later.

VSS (Pin 14)

The common ground pin. (The most negative

point in the circuit).

The Interface circuit

The SAE Standard J1962 stipulates

that all OBD compliant vehicles must

provide a standard connector close

to the driver’s seat. The shape and

pinouts of the 16-pin connector has

already been described in the previ-

ous article (Card Diagnosis Systems,

Elektor Electronics October 2002).

The circuit described here plugs

directly into this connector without

any changes necessary to the vehi-

cle.

The male J1962 connector (Figure

3) needed to plug into the vehicles

connector may be difficult to obtain

(see parts list) and you may be

tempted to improvise by connecting

to the back of the vehicle’s OBD con-

nector. If you attempt this, it should

be stressed that you should do noth-

ing to compromise the integrity of

the vehicle’s OBD network. The use

of any type of connector that could

easily short out pins (e.g., the RJ11

type phone connector) is not recom-

mended.

The circuit of the OBD/RS232

interface with the ELM323 is shown

in Figure 4. Power is derived from

the vehicle battery (nominally

14.4 V) via pin 16 of the OBD con-

nector (K1) while the vehicle earth is

at pin 5. Voltage regulator IC2 pro-

vides 5 V for the circuit and its built-

in current limit offers some protec-

tion for the circuit. Diode D7 gives

reverse polarity protection. LED D8

‘power’ indicates that the 5 V supply

is available.

TEST&MEASUREMENT

26 Elektor Electronics 11/2002

Block Diagram

2 3

XT1 XT2

0200138 - 12

5

6

Timing and

Control

Interpreter

OBD

Interface

OBDK

11

13

OBDIn

4

OBDL

12

RS232Tx

RS232Rx

LFmode

7

RSRx OBDTx

10

OBDRx

9

RSTx 8

3.58MHz

RS232

Interface

18

020138 - 2 - 13

OBD

916

Figure 2. Block diagram for the OBD-2/RS232 converter.

Figure 3. The 16-pin connector for the vehicle

diagnostic connector.

of data flowing at both the OBD and RS232

interface. The two groups of LEDs share a

common current limiting resistor because

data will only be flowing in one direction at

any one time on either of the two interfaces

(the ELM323 is not capable of true multitask-

ing). The OBD bus may also be in its initiali-

sation phase when RS232 data is sent to it so

these limiting resistors are separate for the

OBD and RS232 interface.

A crystal is fitted between pins 2 and 3 of

IC1 along with two 27 pF loading capacitors.

The capacitor values shown are typical but

these may need to be changed depending on

the crystal specification. The frequency cho-

sen is that of the NTSC standard TV colour

burst crystal and should be relatively cheap

and widely available.

Construction and test

The layout for the circuit can be seen in Fig-

ure 4. Although the PCB is single-sided it

does not need any wire links to be fitted. Con-

nector K2 is a 9-way sub-D socket (do not

make the mistake of fitting a plug).

As for the RS232 cable make sure that it is

The remaining two connections to

the vehicle (OBD Pin 7 and 15) are

the data lines described in the ISO

9141 and ISO 14230 standards. In

accordance to the standards pin 7 of

the connector is the K output while

pin 15 is the L output. We will refer

to these as the K line and L line of

the OBD system. To comply with the

specification, the ELM323 controls

these two lines using NPN transis-

tors with 510 Ωpull-up resistors.

The adapter circuit receives diag-

nostic data from the K line (pin 7 on

the OBD connector). The data is

inverted by transistor T3 before it is

read by IC1 (pin 11). This transistor

stage raises the threshold voltage to

around 4 V instead of the standard

2.5 V for a CMOS input. The effect of

this is to improve noise immunity on

the input and the stage gain speeds

up signal transition times.

For the interface to a computer

there is a very simple RS232 imple-

mentation using just RxD (Pin 2) and

TxD (Pin3) of the 9-pin sub-D con-

nector. Most RS232 interface circuits

require a voltage converter to pro-

duce a negative supply to allow the

correct signal swing for RS232 sig-

nals. This design however, stores

negative charge from the TxD line

onto capacitor C3 to ensure that data

output from the ELM323 will swing

negative when T4 switches off.

Resistor R12 limits the input current

from the computer. R13 ensures that

the RS232 input (IC1, pin 5) will be

pulled low when the connector at K2

is disconnected. Transistor T4 drives

RS232 data to the PC. The signal

voltage will swing between +5 V

(high) when T4 is conducting to

–5.1 V (low) from the negative

charge stored on C3 when T4 is off.

Despite the simplicity of this RS232

interface it works very well.

Pin 4 of IC1 is tied high to force

the microcontroller to send a line

feed (LF) character after each car-

riage return (CR) character.

The four LEDs connected to pins

7, 8, 9 and 10 give a visual indication

TEST&MEASUREMENT

2711/2002 Elektor Electronics

+5V

X1

3.579545MHz

C1

27p

C2

27p

K2

DB9

1

2

3

4

5

6

7

8

9

D4 D5D3 D2

R8

330Ω

R9

330Ω

C6

100n

C4

100n

C5

100n

C3

100n

R10

10k

R12

47k

R2

2k2

R4

2k2

R6

10k

R1

510Ω

R3

510Ω

R5

10k

R7

4k7

R11

4k7

R13

100k

T3

BC557B

T4

BC557B

T1

BC547B

T2

D6

1N4148

D1

1N4148

RS232Rx

RS232Tx

ELM323

LFmode

OBDIn

OBDRx

OBDTx

IC1 RSRx

RSTx

OBDL

OBDK

XT2XT1

11

14

10

12

13

23

1

5

4

6

7

8

9

78L05

IC2

D8

R14

680Ω

POWER

+5VD7

1N4001

K1

10

1112

1314

1516

12

34

56

78

9

2x

020138 - 11

OBD

(ISO)

RS232

5V

– 5V1

– 0V5

– 9V3

– 8V9

Figure 4. The OBD-2 to RS232 adapter circuit diagram.

a standard extension cable with the pins

wired 1:1; not a null modem cable where the

wires are connected quite differently.

Refer to the parts list for suppliers of the

special components used in this design.

(ELM323 and OBD plug). Hopefully a UK sup-

plier emerges following publication of this

article.

Once everything has been soldered in

place check closely that all the components

are correctly fitted and that there are no sol-

der bridges on the track side. Now the circuit

is complete you are probably anxious

to try it out, but resist the temptation

to plug it into the vehicle connector

without first making some prelimi-

nary tests. Power up the circuit on

the bench using either a 12 V mains

supply or a 9 V battery together with

a computer with a serial interface.

Connect the power supply positive

to pin 16 (+ 12 V) and the negative

to pin 5 (ground). If everything is in

order the green LED will come on to

indicate that the circuit has power),

The red LEDs will then briefly light.

The 5 V supply can now be checked.

When everything is in order the

next step is to connect the vehicle

adapter to the serial port of a PC. It

is now possible to check voltages

around the circuit and compare them

with the typical values given on the

circuit diagram. The +5 V and –0.5 V

shown on pins 6 and 5 of IC1 should

be fairly close to these values but the

voltage on pin 3 of connector K3 is

derived from the PC and depends

largely on the type of interface chip

used in the external computer. It can

be anything from about - 3 V to

- 12 V. The voltage on capacitor C3 is

dependent on the level of this volt-

age and should be about one diode

drop (0.4 to 0.6 V) higher than the

voltage measured at the TxD pin. In

the circuit diagram TxD is assumed

as –9.3 V which then gives -8.9 V

after the voltage drop across D6.

Should you find that the voltage

levels are substantially lower than

the values shown on the diagram

then it is important to find the prob-

lem before we can proceed any fur-

ther. A short circuit on the RS232

interface will usually not result in

damage to the PC because the sig-

nals are current-limited.

For a functional test of the serial

interface we obviously need some

software to run on the PC to send

and receive serial data. The win-

dows program accompanying this

project (to be described in a follow-

up article) would be a suitable tool

for this job but if you are anxious to

TEST&MEASUREMENT

28 Elektor Electronics 11/2002

(C) ELEKTOR

020138-1

C1

C2

C3

C4

C5

C6

D1

D2 D3 D4 D5

D6

D7

D8

H1 H2

H3H4

IC1

IC2

K1 K2

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

T1 T2

T3

T4

X1

020138-1

(C) ELEKTOR

020138-1

Figure 5. The PCB layout (board available ready-made).

COMPONENTS LIST

Resistors:

R1,R3 = 510Ω

R2,R4 = 2kΩ2

R5,R6,R10 = 10kΩ

R7,R11 = 4kΩ7

R8,R9 = 330Ω

R12 = 47kΩ

R13 = 100kΩ

R14 = 680Ω

Capacitors:

C1,C2 = 27pF

C3-C6 = 100nF

Semiconductors:

D1,D6 = 1N4148

D2-D5 = LED, red

D8 = LED, green

D7 = 1N4001

T1,T2 = BC547B

T3,T4 = BC557B

IC1 = ELM323 *

IC2 = 78L05

Miscellaneous:

K1 = 16-way boxheader

K2 = 9-way sub-D socket (female), angled

pins, PCB mounting

X1 = 3.579545MHz quartz crystal (NTSC),

32pF parallel resonance

16-way OBD-2 plug *

PCB, order code 020138-1 (see Readers

Services page)

*Suggested source for ELM323 and OBD

plug kit:

Küster Datensysteme (KDS)

Geibelstrasse 14

D-30173 Hannover

Germany

Tel. (+49) 511 886059

Fax (+49) 511 8093329

E-Mail: OBD-Service@KDS-Online.com

*OBD connector parts also available from

www.scantool.net

www.autoxray.com

should be able to unravel all of your vehicles

secrets. We have gathered together some

information to help you in this quest and all

of this is available to download from the Elek-

tor Electronics website under the following

headings:

–Communication between the PC and the

ELM323.

–AT commands.

–OBD bus initialisation.

–OBD commands.

–Diagnostic test modes.

–Read out and evaluation of fail codes.

–Clearing fail codes.

–ELM232 fail codes.

This detailed information should be of inter-

est not only to anyone building this project

but also to those of you thinking of develop-

ing an application based around the OBD sys-

tem. In a forthcoming article we concentrate

on the software for this project and include

tips and code examples along with the other

programs already mentioned above.

(020138-2)

Note:

Much of the material in this article is taken from a

data sheet from Elm Electronics, Canada. The

original can be downloaded from:

www.elmelectronics.com/dsheets.html

test the interface then a terminal

emulator program such as HyperTer-

minal will do. With any luck it should

already be loaded on your Windows

system, usually in ‘Program Files’

under ‘Accessories’. If not then the

program can be downloaded free of

charge from: www.hilgraeve.com

HyperTerminal should be initialised

with the following communication

parameters: Data rate 9600 Baud, 8

Data bits, no Parity bit, 1 Stop bit

and no handshake (no hardware

handshake and no XOn/Xoff hand-

shake). This is abbreviated to:

9600,8N1.

Assuming that the interface is

correctly connected you should see

the four red LEDs light up and the

following message will appear on

the screen:

ELM323 v1.0

>

This gives the version number of the

microcontroller software and also

indicates that the IC is working cor-

rectly, and that the communication

baud rate and receive path (the Rx

input to the PC) is in order. The ‘>’

character is a prompt issued by the

ELM323 indicating that it is ready to

accept data from the RS232 port.

Messages from the PC can be

intended for the internal use by the

ELM323 or for the vehicles diagnostic

system. The ELM323 handles all the

communication and determines the

message destination by analysing

its character strings. Commands for

the ELM323 are always prefixed

with ‘AT’ commands just like the

command set for Hayes compatible

modems, while instructions for the

OBD are ASCII coded hexadecimal

numbers (0 to 9 and A to F). As a

test, enter the command ATE1 (turn

echo on) followed by the enter key, if

there is no ‘OK’ response check the

earth connection (Pin 5) and check

the settings in the terminal emulator

program to ensure that ‘No hand-

shake’ is selected.

now for the car clinic

It is undoubtedly easier to communi-

cate with the OBD system by using

the Windows based program that

we referred to earlier. This program

will be featured in the next article on

this project. If you can’t wait, then

the terminal emulator can meet out

needs again; armed with a copy of

the OBD-2 interface documentation

and the ELM323 command set you

TEST&MEASUREMENT

2911/2002 Elektor Electronics

Figure 6.The fully populated PCB. The red LEDs indicate transmitting and receiving data through the ports.

MICROCONTROLLER

30 Elektor Electronics 11/2002

In the Windows Device Manager, you will see

all currently connected USB devices listed

under ‘USB Controller’. Figure 1 shows the

entries for a USB device using the Cypress IC

with no EEPROM and a USB data spy for Bin-

Ter m.

Writing your own complete driver ‘from

the ground up’ is almost impossible for nor-

mal mortals. Fortunately, Cypress provides

the EZUSB driver not only as an installable

version, but also in the form of source

code.

A device driver is divided into two parts,

consisting of an INF file containing setup

information and a SYS file, which is the actual

device driver. The INF file can be edited using

a simple text editor. A C++ compiler is

necessary for generating the SYS file.

If you do not already know how to pro-

gram in C, that’s not such a big hurdle. You

will need Microsoft Visual Studio 6 with the

DDK (Driver Development Kit) addition for

Windows 2000, and naturally you will also

need the device driver source code from

Cypress.

Be sure to install Visual Studio and related

packages without modifying the installation

paths. For the device driver, you will need the

EZ-USB Development Kit, which you have

USB Driver

Programming (2)

writing your own device driver

By M. Müller and C. Ehmer

In the previous issue of Elektor Electronics, we described how device drivers

are used. Now it’s time to modify a Cypress device driver. You only need a

couple of programs for this, even if you have never worked with Microsoft

Visual Studios. All of the

necessary steps are

described in minute detail.

Figure 1. The Windows Device Manager list with a user-generated driver.

Required items

System requirements:

Windows 2000 or Windows XP

Internet access

Programs and tools:

MmVisual BinTerm, version 2.2.2421 or later

Borland Delphi 6 or Microsoft Visual Basic

Cypress Semiconductor EZ-USB Development Kit

Microsoft Visual C++ 6

Microsoft DDK2000 Driver Development Kit for Windows 2000

Hardware

A working Cypress AN2131SC IC (with EEPROM) connected to the USB, or a BinTerm

adapter connected to the USB. The latter circuit will be described in a coming issue of

Elektor Electronics. A BinTerm adapter connected to the USB is highly suitable for

experimental projects, since it avoids the need to store program code in EEPROM. All

programs are transferred to the device by BinTerm at runtime.

MICROCONTROLLER

3111/2002 Elektor Electronics

with your own driver. The items to be modi-

fied are shown in bold in Listing 1.

Before starting to edit the INF file, save it

with a new name, and then enter the new

name in the [xxx.Files.Inf] section. Next,

change the company name (‘Cypress’) to your

own name. The descriptors that Windows

displays in the Device Manager window are

entered in the [Strings] section. The device

driver that you produce should also have a

new SYS file. Give the existing SYS file a new

name, such as ‘MYSYS.SYS’, and correspon-

dingly change all ‘EZUSB’ identifiers to

‘MYSYS’. Ensure that the file name of the

device driver does not contain any non-stan-

dard characters or spaces — in other words,

use only letters and numerals, with at most

eight characters!

The most important items are the VID and

PID numbers. They may lie in the range of 1

to 65534, and they are given in hexadecimal

form. A VID number can be rented (for a fee)

from the USB Organisation (www.usb.org) by

anyone who wants to do so. If the VID is regi-

stered, the product is allowed to carry a USB

symbol and the number is guaranteed to be

unique. However, the fee is not exactly cheap.

The solution proposed here is to use freely

already installed and used in Part 1

of this series.

Setup information

Windows always needs an INF file

for installing a device driver. Such a

file contains the data specifying

what should be installed, where it

should be installed and how it

should be installed. This file should

be modified to meet your particular

needs, since you don’t want the

Cypress device driver to conflict

R2

4k7

R3 8

VCC

VCC

GND

1

2

3

7

E0

E1

E2

WC

020109 - 12

4

5

6

SDA

SCL

SDA

SCL

35

36

4k7

IC3a

24C64

IC1c

AN2131SC

EEPROM connection

Figure 2. Circuit diagram of the EEPROM extension.

Table 1

[Version]

provider=%Cypress%

[Manufacturer]

%Cypress%=Cypress

[Cypress]

%USB\VID_0547&PID_2131.DeviceDesc%=EZUSB.Dev, USB\VID_0547&PID_2131

[DestinationDirs]

EZUSB.Files.Ext = 10,System32\Drivers

EZUSB.Files.Inf = 10,INF

[EZUSB.Dev]

CopyFiles=EZUSB.Files.Ext, EZUSB.Files.Inf

AddReg=EZUSB.AddReg

[EZUSB.Dev.NT]

CopyFiles=EZUSB.Files.Ext, EZUSB.Files.Inf

AddReg=EZUSB.AddReg

[EZUSB.Dev.NT.Services]

Addservice = EZUSB, 0x00000002, EZUSB.AddService

[EZUSB.AddService]

DisplayName = %EZUSB.SvcDesc%

ServiceBinary = %10%\System32\Drivers\ezusb.sys

[EZUSB.AddReg]

HKR,,NTMPDriver,,ezusb.sys

[EZUSB.Files.Ext]

ezusb.sys

[EZUSB.Files.Inf]

ezusbw2k.Inf

[Strings]

Cypress=”Cypress Semiconductor”

USB\VID_0547&PID_2131.DeviceDesc=”Cypress EZ-USB (2131Q/2131S/2135S) - EEPROM missing”

selected VID and PID numbers. This means

that conflicts can arise with devices from

other manufacturers. We suggest changing

the VID number to ‘8B16’ and the PID number

to ‘A001’.

The VID (vendor ID), PID (product ID) and

DID (device ID) form a set of three 16-bit data

words that the Cypress IC reports to the ope-

rating system. The VID and PID numbers are

used to search for, install and load

the device driver.

In order to be able to use your

VID and PID with the Cypress IC,

you will need an EEPROM. Figure 2

shows how an 8-KB EEPROM can be

added to the circuit used in Part 1 of

this article series. Program the follo-

wing sequence of numbers into the

EEPROM, starting at address 0:

B0h start byte

copy IDs

16h, 8Bh VID = 8B16h

01h, A0h PID = A001h

01h, 00h DID = 0001h

The next time the USB device is

plugged in, the Cypress IC will

report this new identifier to the ope-

rating system, allowing Windows to

install a suitable driver.

Using C++ to modify the

SYS device driver

Start Visual C++ Studio, select

‘Open Working Area’ from the ‘File’

menu and open the file named

MICROCONTROLLER

32 Elektor Electronics 11/2002

Figure 3. Testing the device driver in BinTerm.

Table 2

NTSTATUS DriverEntry( IN PDRIVER_OBJECT DriverObject, IN PUNICODE_STRING RegistryPath)

{ NTSTATUS ntStatus = STATUS_SUCCESS;

PDEVICE_OBJECT deviceObject = NULL;

: :

DriverObject->MajorFunction[IRP_MJ_DEVICE_CONTROL] = Ezusb_ProcessIOCTL;

: :

DriverObject->DriverExtension->AddDevice = Ezusb_PnPAddDevice;

: :

}

Table 3

NTSTATUS Ezusb_CreateDeviceObject(IN PDRIVER_OBJECT DriverObject,

IN PDEVICE_OBJECT *DeviceObject, LONG Instance)

{ NTSTATUS ntStatus;

WCHAR deviceLinkBuffer[] = L”\\DosDevices\\Ezusb-0”;

UNICODE_STRING deviceLinkUnicodeString;

WCHAR deviceNameBuffer[] = L”\\Device\\Ezusb-0”;

::

deviceLinkBuffer[18] = (USHORT) (‘0’ + Instance);

deviceNameBuffer[14] = (USHORT) (‘0’ + Instance);

Table 4

NTSTATUS Ezusb_ProcessIOCTL(IN PDEVICE_OBJECT fdo, IN PIRP Irp)

{ : :

switch (ioControlCode)

{

case IOCTL_Ezusb_VENDOR_REQUEST: // = $00222014

length = Ezusb_VendorRequest (fdo, (PVENDOR_REQUEST_IN) ioBuffer);

if (length)

{ Irp->IoStatus.Information = length;

Irp->IoStatus.Status = STATUS_SUCCESS;

} else

{ Irp->IoStatus.Status = STATUS_SUCCESS;

}

break;

Table of contents

Popular Computer Hardware manuals by other brands

Rockwell Automation

Rockwell Automation 1760-DU Series installation instructions

Cisco

Cisco Prisma II Installation and operation guide

Aaeon

Aaeon SBC-556/L manual

Bitspower

Bitspower Summit M Pro instruction manual

ST

ST UM2168 user manual

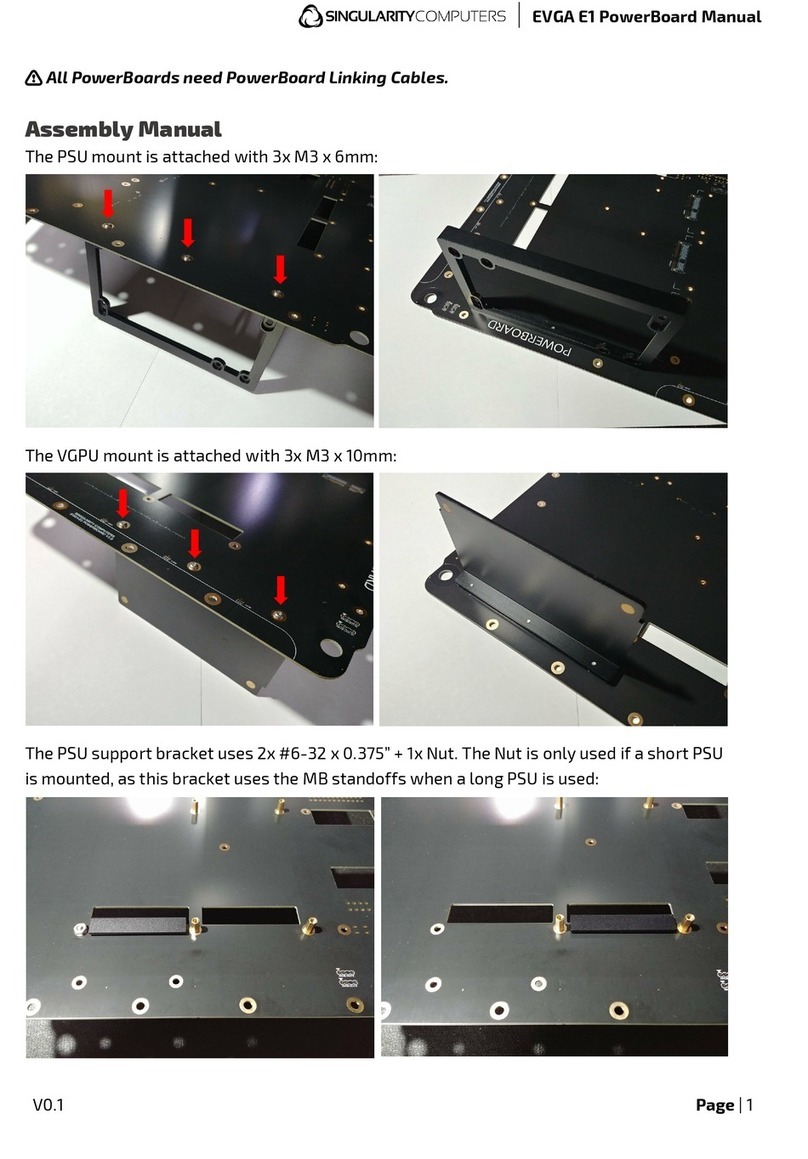

SINGULARITY COMPUTERS

SINGULARITY COMPUTERS PowerBoard EVGA E1 Assembly manual