V. 07-21

www.plycem.com

V. 10-21

www.plycem.com

6INSTALLATION GUIDE FOR EUREKA CISTERN TANK

Plycem guarantees that in case it is proven that a product with its

brand is defective regarding its materials or manufacturing pro-

cess within 100 years (5 years for accessories) as of its manufac-

turing date, at the discretion of the company, x or replace the said

product. Plycem’s responsibility is exclusively limited to the cost of

the product, and it excludes the cost for installing or removing the

product or for any resulting damage.

Neither Plycem nor its distributors authorized in Central America

shall be responsible for any indirect damages or defects caused by

the incorrect installation or by the omission of any steps described

in this document. It does not cover transportation or labor costs

that may result from the incorrect application of the installation

procedures indicated. The manufacturer’s warranty only covers

manufacturing defects.

Using an Eureka Tank Product for a purpose dierent from any pur-

pose described in this document is not recommended. Any other

use will void the warranty for the Eureka Tank by Plycem -either ex-

press or implied. In no case, Plycem may be deemed responsible

for the resulting damages.

This limited standard warranty does not apply to damages result-

ing from the incorrect use of the product, the incorrect application

of the recommended materials, accidents, installation, omission of

procedures, or from inadequate maintenance.

Warranty

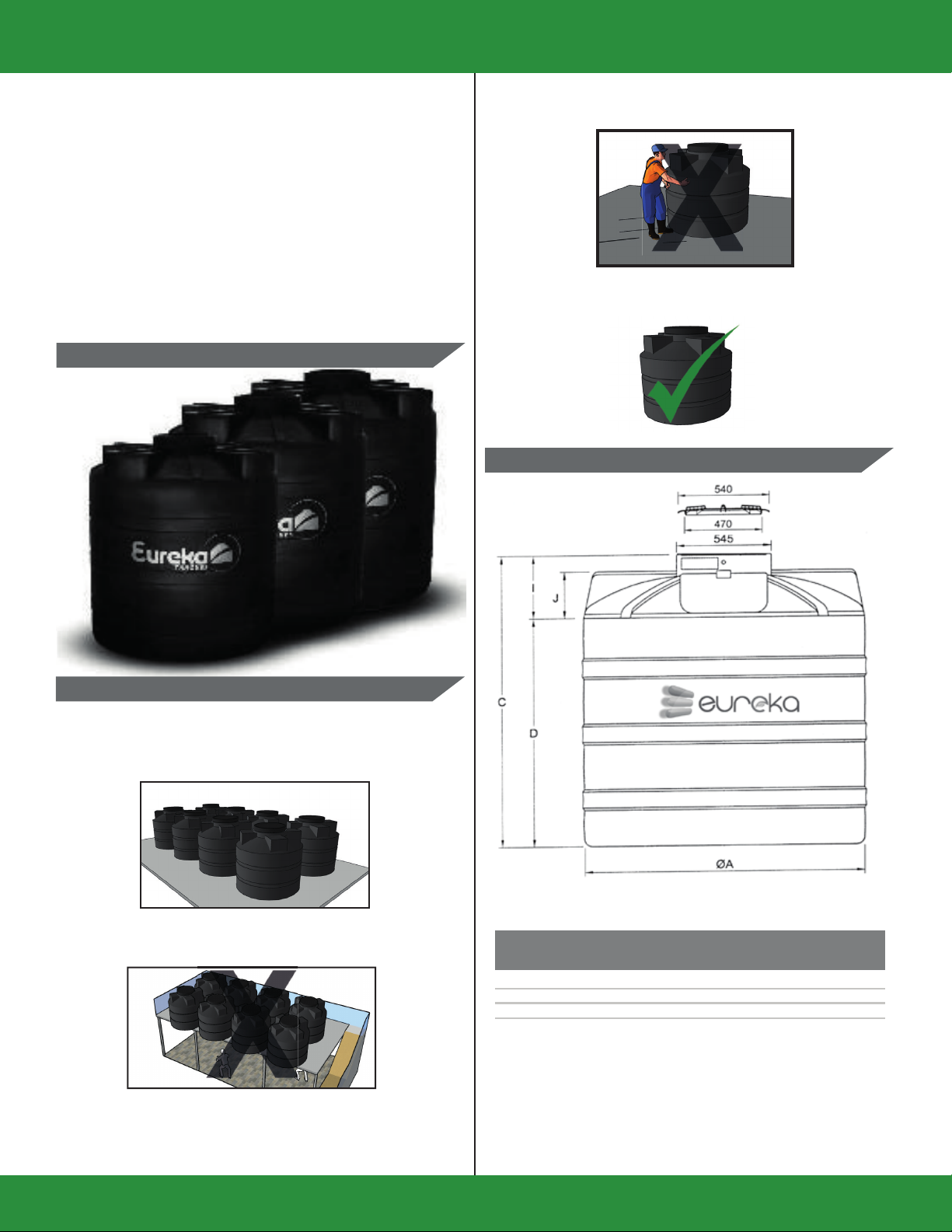

Installation precaution

General installation

1. Remove the discharge plug from

the multi-connector, remove all

contents and rinse.

2.

3. Do a nal cleaning of the inside

walls and bottom with a clean, dry

rag or mop.

4.

5. Install the discharge plug on the

manifold and open the valve that

supplies water to your home.

6.

7. Turn on the water supply to your

Cistern, wait for it to ll and it is

ready to use.

5

6

7

8

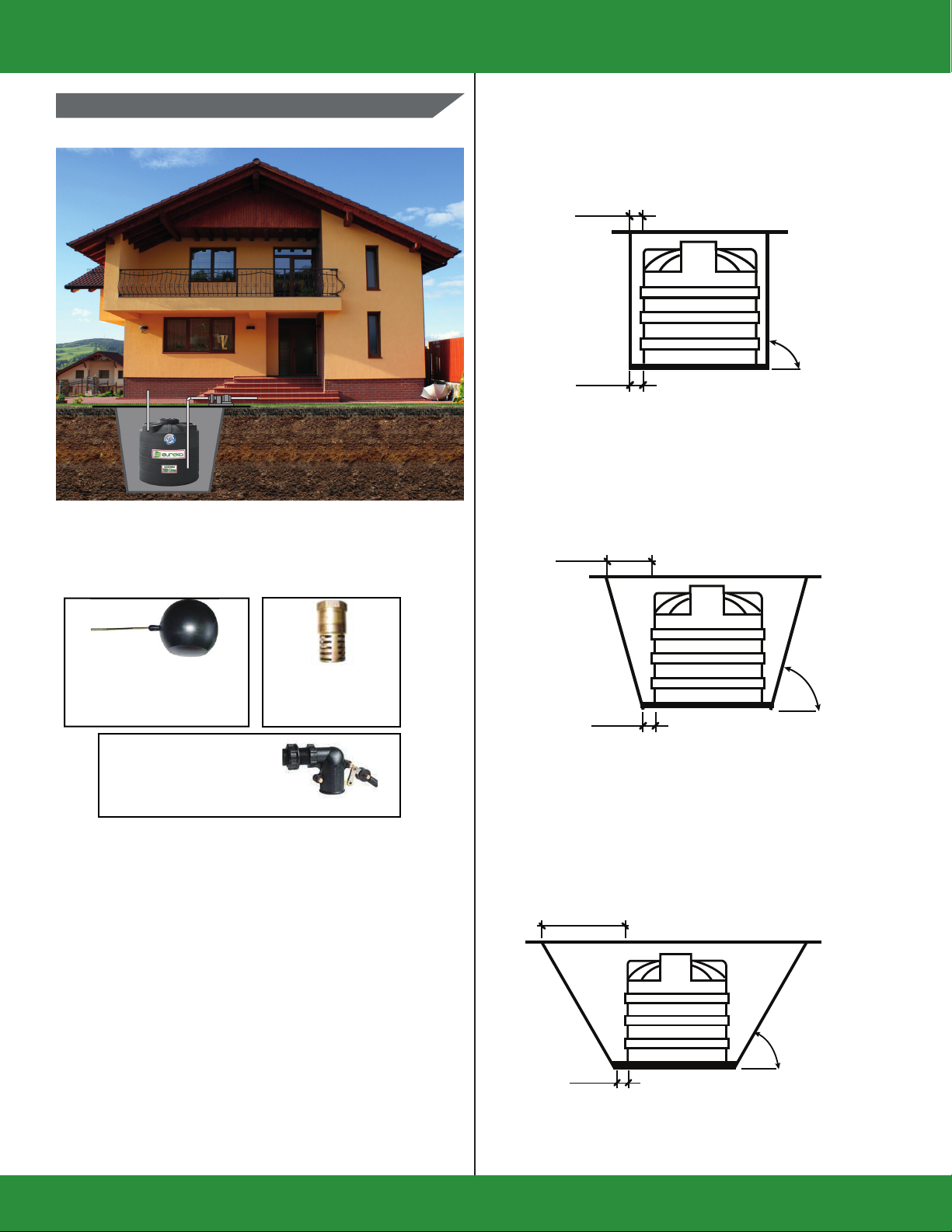

• Cisterns should be washed before installation.

• The tank should always be cleaned every six months. Check

the lter and connections and make necessary adjustments

and repairs.

• The Cistern should always be covered.

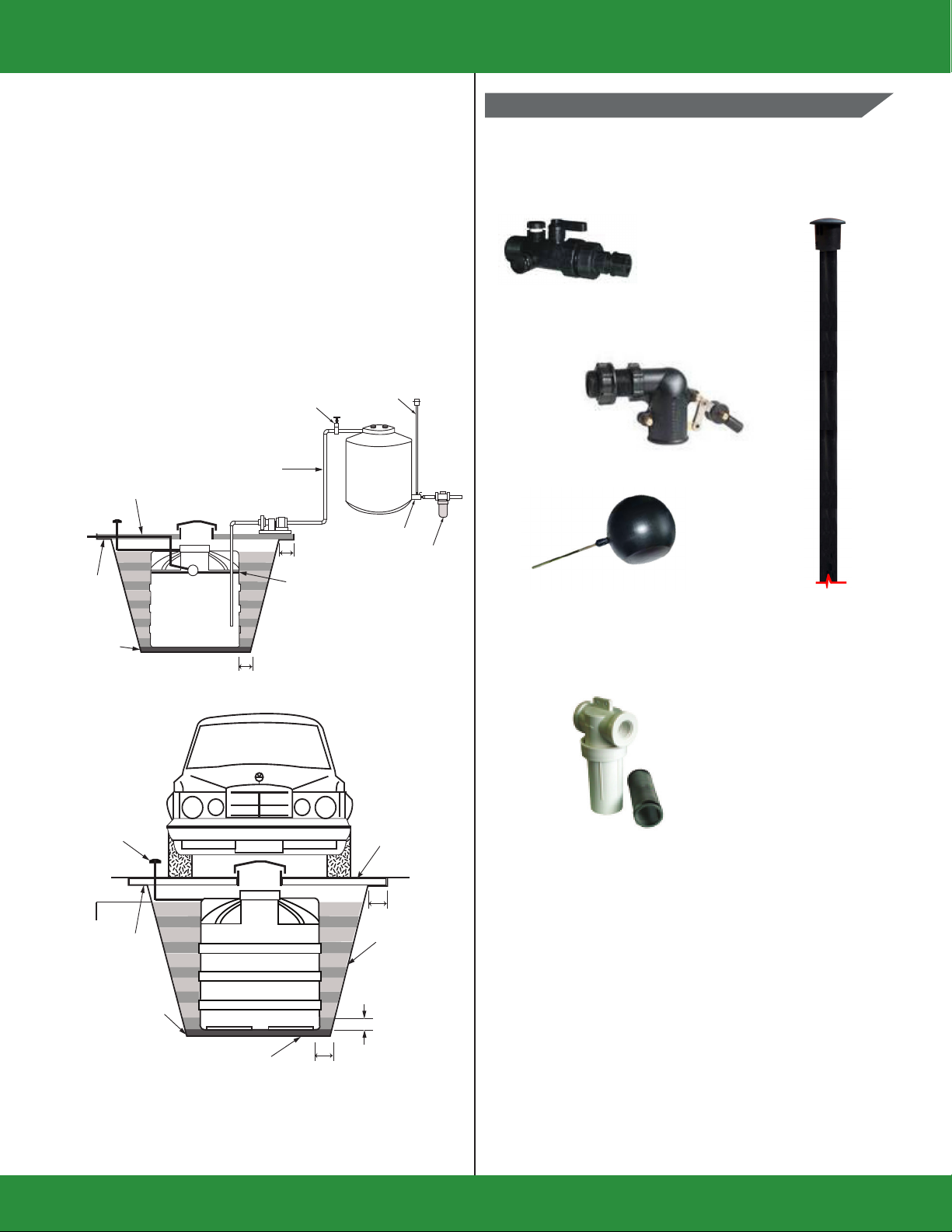

• When using a pumping system, the inlet pipe should be

anchored to cushion any movement on the Cistern connector.

• The system should be installed in an easily accessible location

to allow for inspection and to facilitate proper maintenance.

• When storing the Cistern before installation, be sure to keep it

in an upright position on a smooth, level surface.

• The temperature of the liquid to be stored must not exceed 60°

Celsius.

• For the installation of additional accessories to the Cistern, it is

important to consult your authorized supplier beforehand.

• Cistern tanks are not re resistant. Do not store them near a

ame or heat exceeding 80° Celsius.

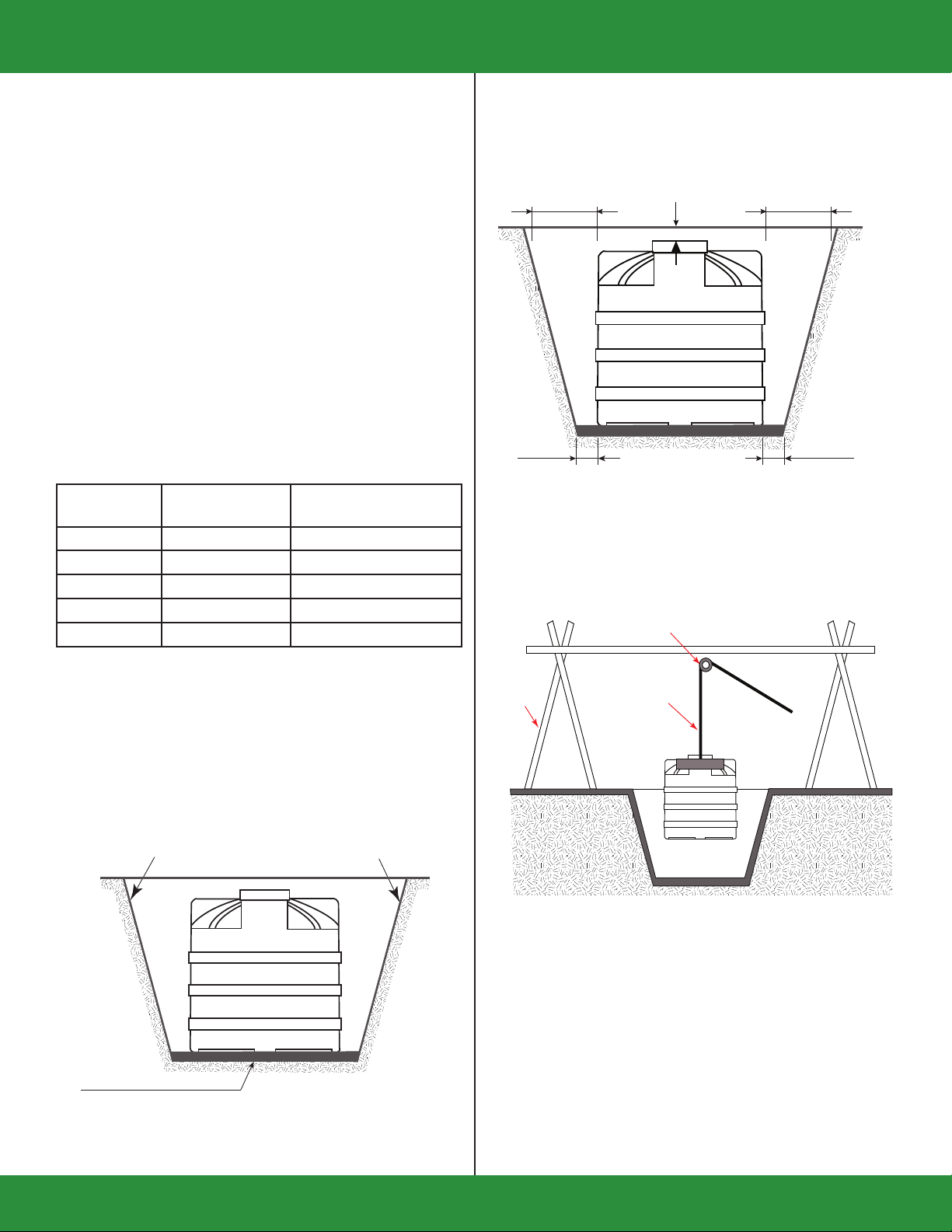

• Make sure the level of the support surface of the tank.

• Make sure that the support surface is larger than the bottom

of the tank.

• Do not place the tank on irregular ground.

• Do not place the tank on separate parts or beams.

• Do not place the tank on irregular surfaces, vegetation, roots

or elements that may damage the bottom of the tank.

1. Shut o the water supply to the

Cistern.

2. Empty your cistern until there

is about 5 cm of water at the

bottom.

3. Shut o the water supply to your

house by closing the valve.

4. Wash the inside walls and the

bottom of your Cistern with

a plastic bristle brush and

disinfectant liquid soap.

1

2

3

4

Maintenance

5.

6.

7.

8.