Elgas EDT 101 User manual

1

Temperature transducer EDT 101

User manual

Rev. 6

December 2019

2

This document provides functional description, installation, configuration and operating

instructions for ELGAS EDT 101 temperature transducer with Modbus protocol. The

information in this document covers software revision 3.11.

Information in this document is subject to change without notice and does not represent a

commitment on the part of ELGAS, s.r.o. Improvements and/or changes in this manual or the

product may be made at any time. These changes will be made periodically to correct technical

inaccuracies or typographical errors.

3

Contents

1Introduction........................................................................................................................6

2Device overview..................................................................................................................7

2.1 Available versions................................................... Chyba! Záložka není definována.

2.2 Technical Description .................................................................................................7

2.3 Device specification....................................................................................................8

3Installation........................................................................................................................11

3.1 Mechanical Installation ............................................................................................11

3.2 Electrical installation ................................................................................................11

3.3 Cabling, grounding....................................................................................................12

3.4 Power Supply Requirements ....................................................................................13

4Modbus Communication Protocol ...................................................................................15

4.1 Modbus Protocol Overview......................................................................................15

4.1.1 Physical Communication Layer.............................................................................15

4.1.2 Transactions on Modbus networks ......................................................................15

4.2 Device Specific Features...........................................................................................16

4.2.1 Service Address.....................................................................................................16

4.2.2 Communication Buffer Length .............................................................................16

4.2.3 Response Time......................................................................................................16

4.3 Holding Registers Map..............................................................................................17

4.3.1 Holding Registers Map Overview .........................................................................17

4.3.2 Factory configuration section...............................................................................19

4.3.3 Service Configuration Section ..............................................................................20

4.3.4 User configuration section ...................................................................................20

4.3.5 Miscellaneous.......................................................................................................20

4.3.6 Measured variables ..............................................................................................20

4.3.7 Datalogger section................................................................................................22

4.3.8 Data types.............................................................................................................23

4.4 Discrete outputs map ...............................................................................................24

4.4.1 Overview of the discrete outputs map.................................................................24

4.4.2 Reset .....................................................................................................................24

4.4.3 Write EEPROM......................................................................................................24

4

4.4.4 Read EEPROM ...................................................................................................... 24

4.4.5 Stop measurement............................................................................................... 25

4.4.6 Start single measurement.................................................................................... 25

4.4.7 Start continuous measurement. .......................................................................... 25

4.4.8 Unlock user configuration section ....................................................................... 26

4.4.9 Unlock service configuration section................................................................... 26

4.4.10 Change password ............................................................................................. 26

4.5 Modbus function codes ........................................................................................... 28

4.5.1 Read multiple registers (03h)............................................................................... 28

4.5.2 Force single coil (05h) .......................................................................................... 29

4.5.3 Write multiple registers (10h).............................................................................. 30

4.5.4 Start measurement with mask (45h) ................................................................... 31

4.5.5 Synchronize datalogging (46h)............................................................................. 32

4.5.6 Erase data (47h) ................................................................................................... 33

4.5.7 Set slave address (48h) ........................................................................................ 34

4.6 Exception responses ................................................................................................ 36

5Related Publications......................................................................................................... 38

5

Abbreviations and terms

char

8-bit signed integer value

CRC

Cyclical Redundancy Check

dec

Decimal representation

EEPROM

Electrically erasable non-volatile memory

float

32-bit single precision floating point value

hex

Full scale

int

Hexadecimal representation

Modbus

16-bit signed integer value

MSB

The least significant byte

LSB

A vendor-neutral communication protocol intended for supervision and

control of automation equipment.

RS 485

The most significant byte

RTU

Standard for data transmission, where a balanced (differential)

transmission line is used in a multidrop configuration.

uchar

Remote terminal unit. One of two serial transmission modes of the Modbus

communication protocol.

uint

8-bit unsigned integer value

6

1 Introduction

Temperature transducer EDT 101 (hereinafter “transducer”) is a miniature precision device

intended for temperature measurement in applications which require a high precision and

ultra-low power consumption. The transducer has RS 485 digital interface, which makes it

ideal for use in modern digital systems.

The transducer is dedicated to connect with data loggers, gas-volume correction devices and

telemetric systems.

Regarding safety, the transducer is designed to comply with the EN 60079-11 as an intrinsically

safe device and is approved for potentially explosive atmospheres. The transducer is

manufactured and delivered in compliance with the following guidelines of the European

Parliament:

2014/34/EU relating to equipment and protective systems intended for use in potentially

explosive atmospheres

2014/30/EU relating to electromagnetic compatibility

Basic features

Ranges -25 .. +70°C or -40 .. +70°C

RS 485 digital interface, Modbus communication protocol

Ultra-low power consumption: 3 μA standby, 1 mA active, supply voltage from 2.8V

High accuracy: 0.2°C

Small size, rugged housing

Certified as explosion-proof with type of protection II1G Ex ia IIC T4 Ga

7

2 Device overview

2.1 Technical Description

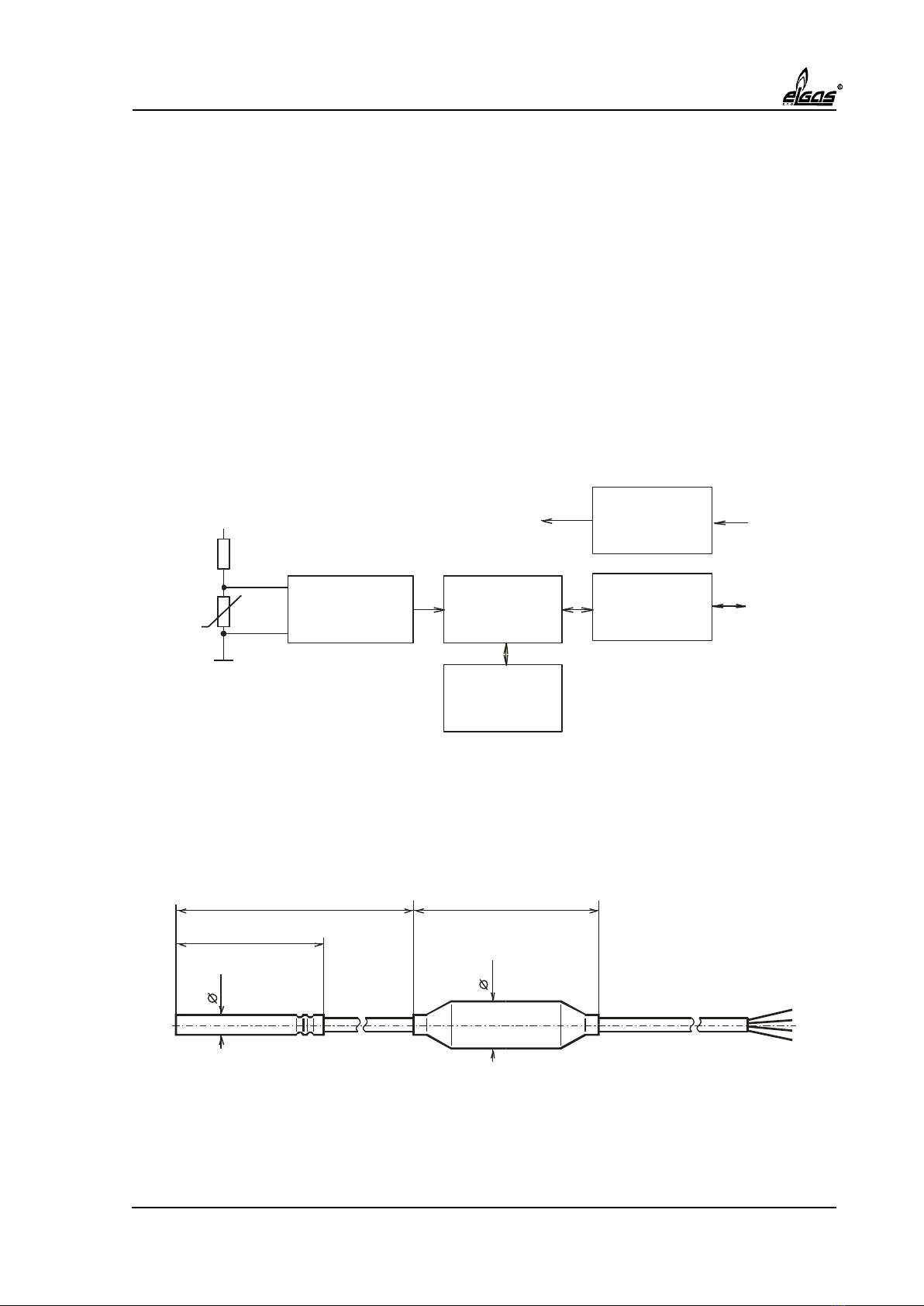

Chyba! Nenalezen zdroj odkazů. shows functional diagram of the transducer. Temperature is

measured by platinum resistive sensor. The signal from the sensor is converted by a high-

resolution analog-to-digital converter into digital form and processed by the microcontroller.

Microcontroller digitally compensates the non-linearity of the sensor using calibration data.

The calibration data is stored in non-volatile EEPROM memory during transducer

manufacturing.

Temperature readout as well as all control functions are accessible via RS 485 interface. The

transducer is capable to measure the temperature on request or continuously in preset time

intervals and store values in its internal memory for later retrieval.

Analog-to-Digital

Converter

Voltage

Regulator

Microcontroller Driver / Receiver

RS485

EEPROM

Memory

Regulated

Power Supply

RS485

Bus

Power

Supply

Uref

Rn

Pt 1000

Uref

Rn

Pt 1000

Figure 1. Functional diagram of the transducer

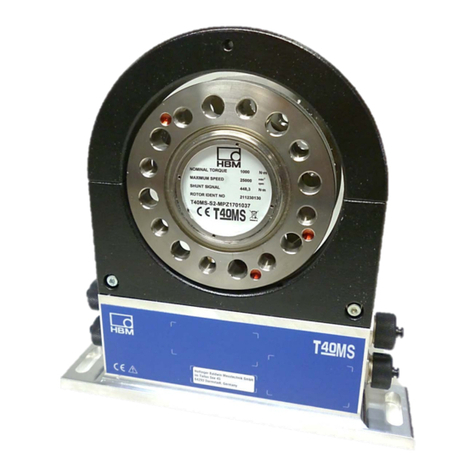

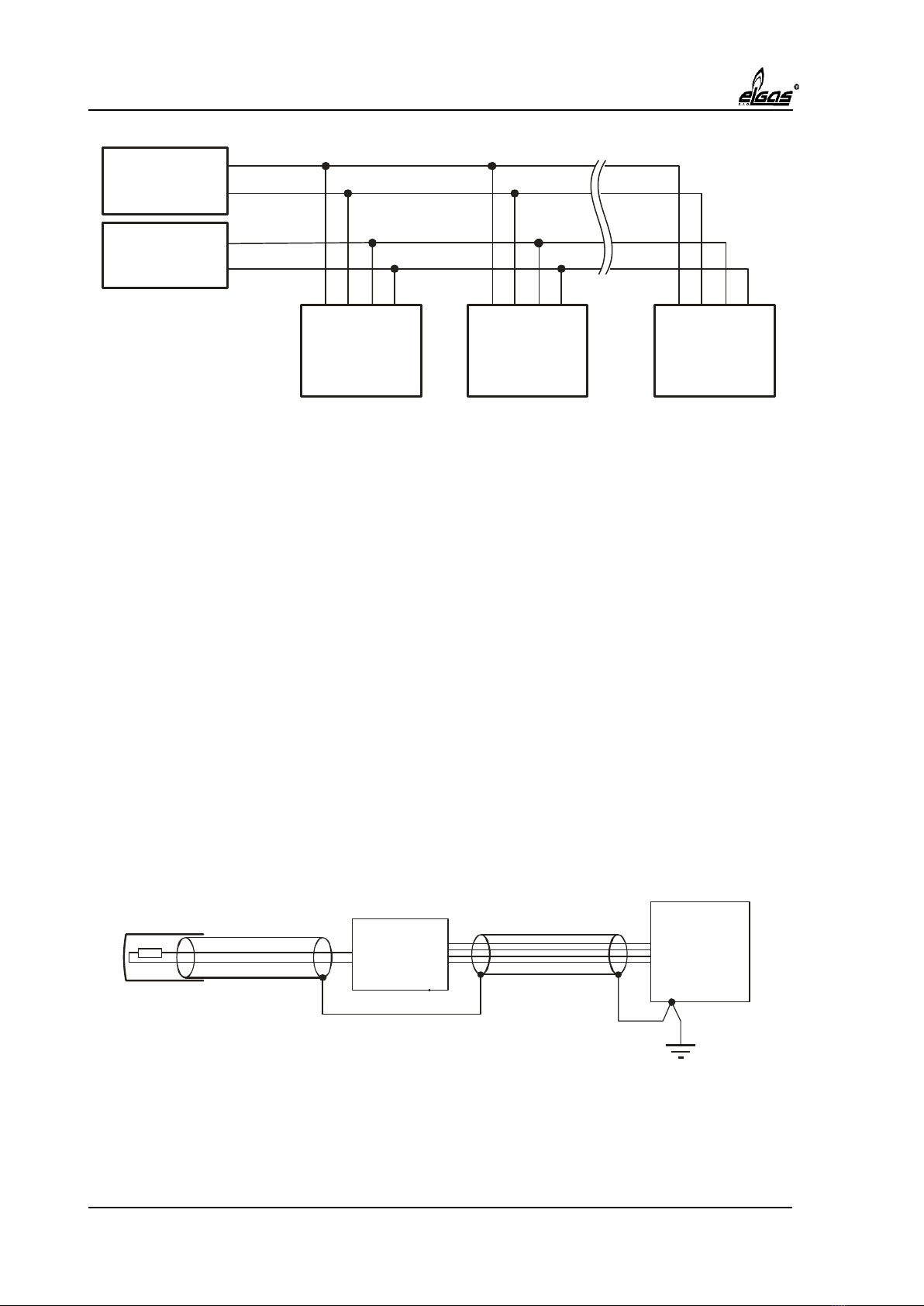

Physically, the transducer consists of the temperature sensor mounted in stainless-steel stem

50 mm long and the cable. A cylindrical plastic case with electronics is integrated into the

cable.

200 64

17

5.7

50

Figure 2. Dimensional drawing of the transducer.

8

2.2 Device specification

Measurement ranges

Standard range: -25°C to +70°C

Extended range: -40°C to +70°C

Temperature sensor

Platinum resistive element Pt 1000 mounted in ANSI 316L stainless-steel stem, stem diameter:

5.7 mm, stem length: 50 mm standard

Measured media

Liquids and gases, chemically compatible with stainless-steel ANSI 316L

Accuracy

0.2°C within the full measurement range

Includes non-linearity, repeatability and long-term stability.

Electrical connection

Integral shielded cable 4 x 0.25 mm2length 2.6 m with external diameter between 5 to 7 mm.

Other lengths of cable on request. Cable shielding is not connected to the stainless-steel stem.

Power supply

The transducer requires external DC power supply. Transducer terminal voltage must be

between 2.8 to 5.0 V

Power consumption

Standby: 3 μA typical / 10 μA maximum

Measurement and communication: 0.8 mA typical / 4 mA maximum

Power consumption is not dependent on the supply voltage. Power consumption during the

communication depends on the bus impedance.

Start-up time

The transducer is ready to operate 20 ms after power supply is applied.

Communication interface

RS 485, 2-wire, half-duplex, minimum bus impedance 1.5 kΩ. Unterminated bus is

recommended for low-power consumption. Maximum wiring length is 100 m.

Communication protocol

9

Modbus RTU, speed 38400 bit/s, 1 start bit, 8 data bits, no parity, 1 stop bit. Standard functions

supported: Read holding registers (code 03h), Force single coil (code 05h) and Write holding

registers (code 10h). Non-standard functions with codes 45h, 46h, 47h, 48h are implemented.

Datalogging

The transducer is able to measure temprature automatically in regular intervals and store the

measured values in the memory to be retrieved from later on.

Measurement period: adjustable 125 ms to 512 s

Data memory capacity: 80 values

Time base accuracy: 100 ppm

Electric insulation

Resistance between the stem/cable shielding and signal or power supply wires is greater than

10 MΩ at 500 V AC.

Physical specifications

Dimensions: see chapter 2.1

Weight: 100 –150 g (depending on mechanical version)

Environmental specifications

Operating temperature: -40°C to +70°C as sandard

Storage temperature: -40°C to +85°C

Humidity: 0% to 95% relative, without condensation

Protection: IP 65

Vibrations: 10 g sinus 10-2000Hz, ČSN EN 60068-2-6 [3]

Electromagnetic compatibility

Complies with immunity requirements for industrial environments EN 61000-6-2 [2]

Explosion-proof design

10

Equipment with the “i” protection type (intrinsically safe equipment) in compliance with

EN 60079-0 [4] and EN 60079-11 [5]. The certificate registered under No. FTZÚ 18 ATEX 0142X

at the Physical-Technical Testing Institute Ostrava-Radvanice, notified body No. 1026.

Environment classification: Zone 1, 2 according to the EN 60079-14 [6]

Protection class: II1G Ex ia IIC T4 Ga

Safety descriptions:

Ui= 9.9 V

Ci = 2.65 μF

Li= 0 μH

Pi= 1.10 W for Ta<70°C

11

3 Installation

3.1 Mechanical Installation

Temperature transducer is intended for mounting into a thermowell on piping. Operating

position of the transducer is arbitrary. The depth of the thermowell must be 50 mm minimum.

The transducer stem must be inserted to the very bottom of the thermowell and secured by

the fastening nut against pulling-out. It is recommended to fill the space around the stem

inside the thermowell with silicone oil.

3.2 Electrical installation

Wires in the cable or the connector pins carry the following signals:

Signal

Description

color

GND

negative power rail (ground)

green

PWR

positive power rail

brown

DATA-

RS 485 inverted data signal

yellow

DATA+

RS 485 non-inverted signal

white

To operate the transducer, apply DC voltage 2.8 to 5.0 V across PWR and GND terminals and

connect the DATA+, DATA- signals with the corresponding terminals on the host RS 485 port.

The transducer does not provide electrical insulation between the RS 485 bus and the

transducer power supply.

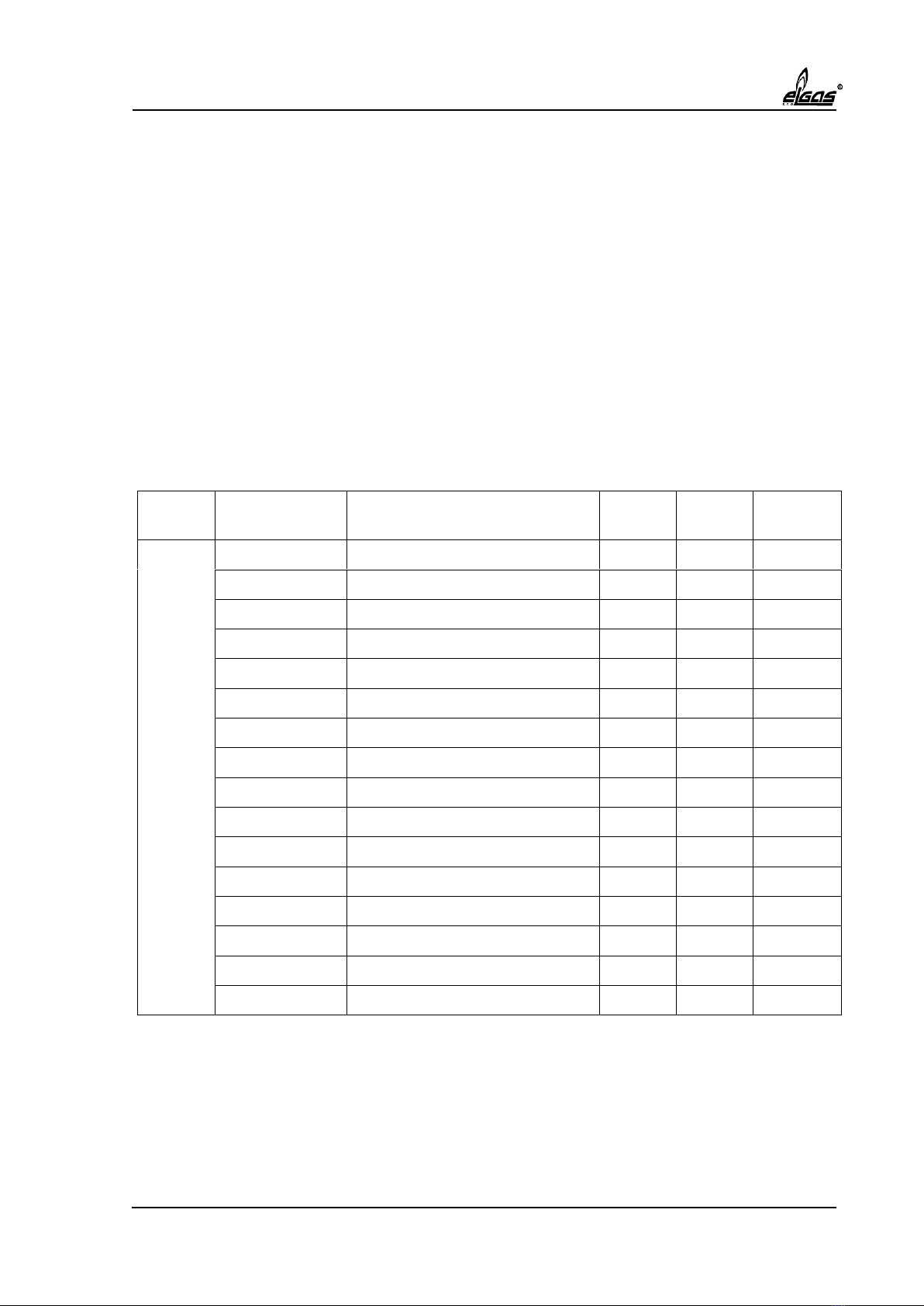

Fig. 3 shows connection of the transducers into the data network. In the RS 485 network, up

to 32 units can be connected at the same time while every unit must have a unique slave

address set.

12

RS 485

Host DATA+

DATA-

Power

Suppl +

-

Transducer Transducer Transducer

DATA+

DATA+

DATA+

DATA-

DATA-

DATA-

PWR

PWR

PWR

GND

GND

GND

....

Fig.3 Transducers connection into data network.

To achieve low power consumption, the transducer uses a special RS 485 driver with limited

slew rate. It is recommended to leave the RS 485 bus unterminated to maintain power

consumption as low as possible. The bus impedance must not be lower than 1.5 kΩ. The length

of the bus should not exceed 100 m. Otherwise, a signal distortion due to reflections can occur

and communication reliability can be deteriorated.

Any standard RS 485 driver / receiver can be used in the host, however for the low power

applications with unterminated bus it is recommended to use a driver with a reduced slew-

rate and a receiver with a high input impedance. Suitable types are MAX 3471 form Maxim

Integrated Products or ADM 483E from Analog Devices.

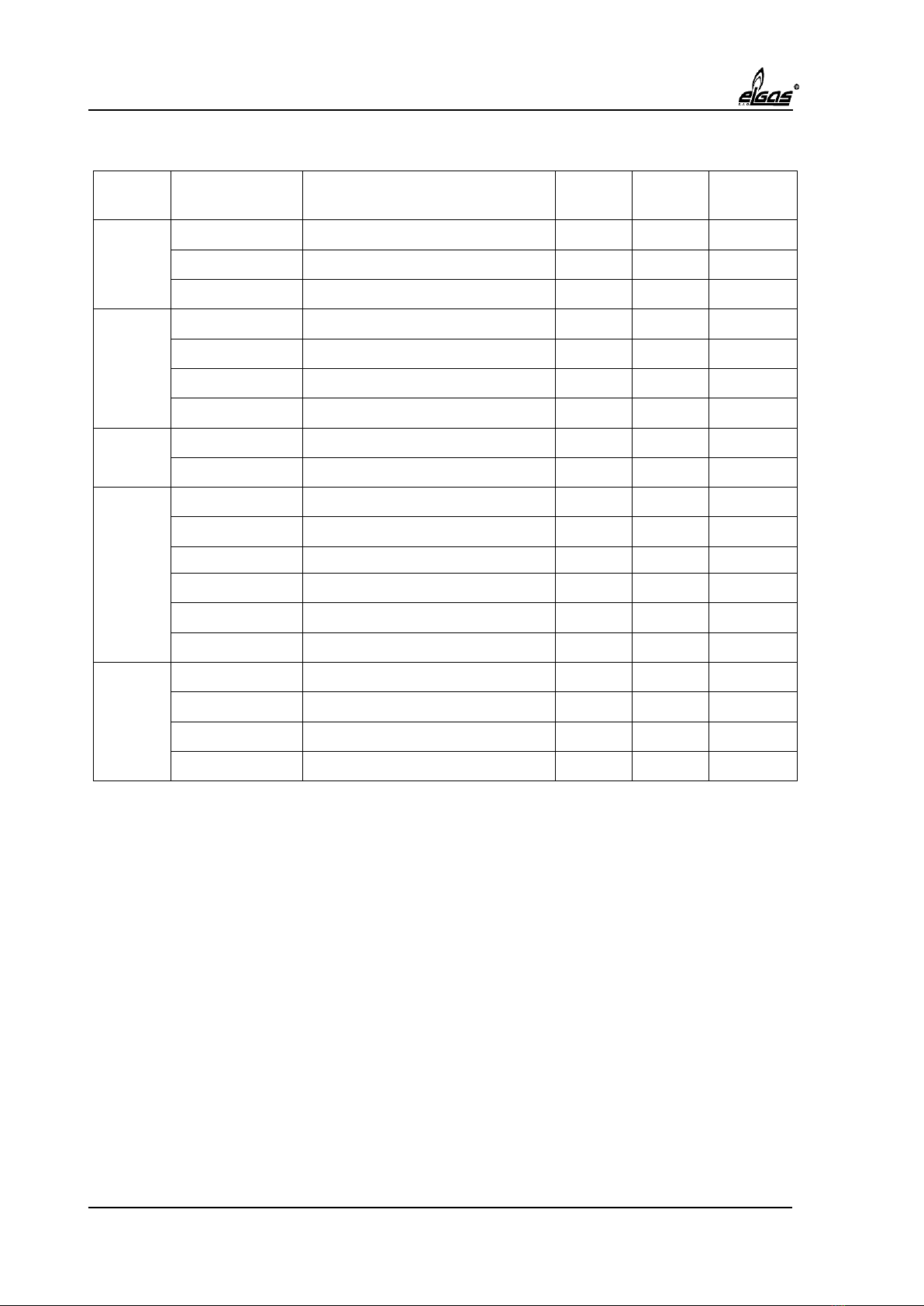

3.3 Cabling, grounding

The transducer is interconnected with the host using a shielded 4-wire. The cable should not

be laid along power cables, lightning conductors and long metal objects, it should not pass

through areas with strong electro-magnetic disturbances or discharges.

The cable shielding on the side of the host should be connected with ground and with the host

enclosure, if this is metallic. The cable shielding is not connected to the transducer stainless-

steel stem.

Host

Transducer

Fig. 4. Transducer grounding

13

3.4 Power Supply Requirements

The transducer is optimized for very low-power applications. It operates from unregulated

single supply voltage in range 2.8 V to 5.0 V. The supply current is independent from the supply

voltage.

The transducer uses an advanced algorithm to maintain the power consumption at a minimum

level. Only the modules of the transducer which are necessary for the requested function are

powered on. Due to the power consumption management, the supply current varies

significantly depending on the function being performed. Figure 5 shows an example of the

supply current profile. The first part shows a supply current waveform, when a simple query

is received, processed and responded back on the RS 485 bus by the transducer. The second

part shows a supply current waveform during measurement.

Mesurement

Standby

Transmitting response

Receiving query

Standby

Fig. 5 Supply current profile example.

14

The following table summarizes transducer’s typical average supply current for various

measurement periods. The values include power consumption during the measurement and

during necessary communication with the host to initiate the measurement and read

measured values.

Measurement period [s]

Average supply current [µA]

Continuous measurement

800

1

100

10

10

30

6

Standby

3

15

4 Modbus Communication Protocol

The following text describes implementation of the Modbus communication protocol in the

transducer. In order to assure a complete understanding of the operation of the device, the

user should familiarize himself with the Modbus protocol in detail in the reference

literature [1].

Numeric values are given in decimal representation by default. If hexadecimal representation

is used, suffix “h” or “hex” is added.

4.1 Modbus Protocol Overview

The transducer is a Modbus compatible measurement device. The transducer supports 8-bit

Remote Terminal Unit (RTU) data transmission mode with a subset of the standard commands

used by the most Modbus compatible host controllers and a few proprietary commands.

4.1.1 Physical Communication Layer

Communication is carried over the RS 485 bus at baud rate 38400 bit/s. The transmitted

characters have 1 start bit, 8 data bits and no parity, 1 stop bit. These parameters are not

configurable.

4.1.2 Transactions on Modbus networks

The Modbus protocol uses a master/slave technique to control bus access. There can be one

master and up to 247 slave devices. Only the master can initiate a transaction. Transactions

are either a query/response or broadcast/no response. During the query/response transaction

master sends a query to the single slave which process it and responds. During the

broadcast/no response transaction the query is processed by all slave devices but none of

them responds.

Queries, responses and broadcasts are transmitted as frames with a fixed structure. In RTU

mode, frames start with a silent interval of at least 3.5 character times. The first field then

transmitted is the address field followed by a function field, a data field, and CRC field.

Following the last transmitted character, a silent interval of at least 3.5 character times marks

the end of the frame. A new frame can begin after this interval.

The entire message frame must be transmitted as a continuous stream. If a silent interval of

more than 1.5 character times occurs before completion of the frame, the receiving device

ignores the incomplete message and assumes that the next byte will be the address field of a

new message.

Frame format

Start

3.5 char

times

Address

field

1 char

Function

field

1 char

Data

field

n chars

CRC

field

2 chars

End

3.5 char

times

16

Address field

In a query frame, the address field contains a slave address. In a response frame, the address

field contains the address of the responding slave device.

Valid slave addresses are in the range of 1 –247 decimal. Address 0 is reserved for broadcast

messages. Any query message with a slave address of 0 is a broadcast message which all slave

devices process but they do not generate any response.

Function field

In a query frame or a broadcast frame, the function field contains a function code, which

indicates the command to be performed. In a response frame, the function field contains a

copy of the function code received in the query. If the most significant bit in the function field

is set, an error occurred during the query processing. In this case the data field contains an

exception code that explains the particular error.

Data field

The data field contains information that is specific to each individual function.

CRC field

The CRC field contains a 16 bit CRC error check value that is used to verify the integrity of the

message frame.

4.2 Device Specific Features

4.2.1 Service Address

Due to the small dimensions of the transducer, no DIP switches or similar components can be

used for slave address setting. Instead, the slave address is software configurable. In some

cases, however, the slave address can be unknown. Thus, a service address 248 (dec) has been

assigned which the transducer always responds.

Any query frame with a slave address of 248 (dec) the transducer processes and generates a

response. The response is returned with the actual slave address in the address field instead

of the service address 248 (dec). When using the service address, only one transducer may be

connected on the bus with the only exception of the query with the “48h” function code as

described hereinafter in chapter Chyba! Nenalezen zdroj odkazů..

4.2.2 Communication Buffer Length

The transducer implements communication buffer 64 bytes long. If the length of the query

frame exceeds capacity of the buffer, the frame is flushed and no response is generated. If the

master requires such amount of data to be sent which exceeds the capacity of the buffer, the

response is truncated to the total frame length of 64 bytes.

4.2.3 Response Time

The transducer responds 4 to 20 ms after the last character of the query has been received.

The exact time of the response depends on the query length, response length and on the

function processed.

17

4.3 Holding Registers Map

The transducer’s memory is mapped into Modbus holding registers address space

(4xxxx reference). This address space can be read by the Read multiple registers (03h)

command and written by the Write multiple registers (10h) command. The commands are

described in chapter Chyba! Nenalezen zdroj odkazů.. All registers are 16-bit long.

Register numbers shown in the text are in the 4xxxx format which follows the Modicon

protocol specification for data item addressing. The actual register address sent in the Modbus

message frame is the register number shown in the text minus 40001. In other words, the

leading "4" is omitted, and the remaining 4-digit number is decremented by 1.

4.3.1 Holding Registers Map Overview

An overview of all holding registers of the transducer is shown in the table. Description of the

individual registers is in the following paragraphs.

Section

name

Register

number

Register name

Data

type

Access

control

Stored in

EEPROM

Factory configuration

40001

Hardware revision number

uint

FP

N

40002

Software revision number

uint

read only

N

40003 –40004

Serial number

ulong

FP

Y

40005

Sensor type

uint

FP

Y

40006

not used

FP

Y

40007

Units

uint

FP

Y

40008 –40009

Operation range lower limit

float

FP

Y

40010 –40011

Operation range upper limit

float

FP

Y

40012 –40013

Measurement range lower limit

float

FP

Y

40014 –40015

Measurement range upper limit

float

FP

Y

40016

not used

FP

Y

40017

Primary channel offset+gain

uint

FP

Y

40018

Auxiliary channel offset+gain

uint

FP

Y

40019 –40052

Calibration coefficients

float[17]

FP

Y

40053

Coefficient format

uint

FP

Y

40054

not used

FP

Y

18

Holding register map overview - 2nd part

Section

name

Register

number

Register name

Data

type

Access

control

Stored in

EEPROM

Service

config.

40055 –40056

Offset trim

float

SP

Y

40057 –40058

Span trim

float

SP

Y

40059 –40061

not used

SP

Y

User

config.

40062

Modbus slave address

uchar

UP

Y

40063

Group assignment register

uchar

UP

Y

40064

Default operation mode

uchar

UP

Y

40065 –40066

for internal use, do not change

UP

Y

Misc.

40067 –40068

Password

ulong

N

N

40069 –40071

not used

N

N

Measured

variables

40072 –40073

Primary chan. direct readout

float

N

N

40074 –40075

Auxiliary chan. direct readout

float

N

N

40076 –40081

not used

N

N

40082

Temperature

uint

N

N

40083

Status register

uint

N

N

40084

not used

N

N

Datalogger

section

40085

Delay

uint

N

N

40086

Period

uint

N

N

40087

Number of samples

uint

N

N

40088 –40167

Data memory

uint[80]

N

N

Memory locations marked in column “Stored in EEPROM” as “Y” can be stored into the

transducer’s non-volatile EEPROM memory using Write EEPROM function (see paragraph

4.4.3). The stored configuration is recalled after power-up or using Read EEPROM function

(see paragraph Chyba! Nenalezen zdroj odkazů.).

Memory locations marked in column “Access control” as “N” can be read and written with no

restrictions. Memory locations marked as “FP” (Factory password), “SP” (Service password)

and “UP" (User password) can be read without restriction, but can be written only when the

particular section is unlocked using a password. The unlocking procedure is described in

paragraphs Chyba! Nenalezen zdroj odkazů. and Chyba! Nenalezen zdroj odkazů..

19

4.3.2 Factory configuration section

This section contains a basic information about the transducer and calibration data. The

parameters are entered during manufacturing and calibration procedures and cannot be

changed by the user.

Hardware revision number identifies a version of the transducer’s hardware.

Software revision number identifies a version of the transducer’s software. MSB indicates a

main revision number, LSB sub-revision number.

Serial number identifies each transducer individually.

Sensor type. Information about the type of the sensor. Code 10h is used for the temperature

sensor.

Units. Information about physical units used for Measurement and Operation range limits

representation. Code 20h is used for °C.

Measurement range lower and upper limit provide the range of input temperature in which

the transducer is calibrated and in which measures with the specified accuracy.

Operation range lower and upper limit provide the range of input temperature which is

correctly handled by the analog-to-digital converter and numerical calculation. If the

temperature value is outside the measurement range but inside the operation range, the

measurements are still performed but the accuracy is undefined.

Standard values of the limits of the measurement and operation range are shown in the

following table:

Transducer range

(information on label)

Measurement range [°C]

Operation range [°C]

Lower limit

Upper limit

Lower limit

Upper limit

-25°C to +70°C

-25

70

-50

100

-40°C to +70°C

-40

70

-50

100

Primary channel offset and gain provide an offset and gain of the analog-to-digital converter

when primary channel (temperature) is measured. The offset is stored in the MSB of the

register, the gain in the LSB.

Auxiliary channel offset and gain provide an offset and gain of the analog-to-digital converter

when auxiliary channel is measured. The offset is stored in the MSB of the register, the gain in

the LSB.

Calibration coefficients are used to calculate actual temperature using values obtained from

the analog-to-digital converter for the primary and auxiliary channel.

Coefficient format specifies a layout of the coefficients and algorithm for calculation.

20

4.3.3 Service Configuration Section

Parameters in the Service configuration section allows to adjust the offset and span of the

transducer. The default parameters are entered during calibration procedure and can be

changed only by an authorized person using Service password.

Offset trim is an additive constant which defines the shift of the transducer characteristics

relative to the factory calibration data. When the transducer is factory calibrated, the Offset

trim is set to 0.0000. During the field calibration the value can be changed to compensate for

possible characteristics deviation.

Span trim is a multiplicative constant which defines the change of the slope of the transducer

characteristics relative to the factory calibration data. When the transducer is factory

calibrated, the Span trim is set to 1.0000. During the field calibration the value can be changed

to compensate for possible characteristics deviation.

4.3.4 User configuration section

User configuration section contains parameters used for Modbus network setup. The section is

protected by the User password to prevent accidental change of settings.

Modbus slave address contains address to which the transducer responds. When entering a

new address, this is valid immediately after writing to this register.

Group assignment register defines group(s) the transducer belongs to. Transducers belonging

to the same group can be forced to start measurement simultaneously by a single Start

measurement with mask command transmitted as broadcast as described in paragraph 4.5.4.

Default operation mode specifies whether the transducer after power-up or reset starts the

continuous temperature measurement or not. When changing this register, Write EEPROM

command must be issued to store the change in the EEPROM memory.

Code

Default operation mode

00h

standby

01h

continuous measurement

4.3.5 Miscellaneous

This section contains registers used for password manipulation. The password protects write

access to the configuration sections.

Password. After writing correct value to the password registers, desired section can be

unlocked for writing by Unlock section function (see paragraphs Chyba! Nenalezen zdroj

odkazů. a Chyba! Nenalezen zdroj odkazů. ).

4.3.6 Measured variables

In this section, measured and calculated variables are stored. All variables are updated at the

end of each single temperature measurement.

Table of contents

Popular Transducer manuals by other brands

Balluff

Balluff Micropulse BTL5-A series user guide

Mianyang Weibo Electronic

Mianyang Weibo Electronic WBV411S07 user manual

TWK Elektronik

TWK Elektronik PMU-04 user manual

OHIO SEMITRONICS

OHIO SEMITRONICS DCT Series operating instructions

GHM

GHM GRMU 2000 MP operating manual

S+S Regeltechnik

S+S Regeltechnik HYGRASGARD AFF-20 operating instructions

Balluff

Balluff BTL7-A5 Series Condensed guide

Emerson

Emerson Fisher 646 instruction manual

Matelec

Matelec FPC-12571 quick start guide

S+S Regeltechnik

S+S Regeltechnik PHOTASGARD FSHKM Operating Instructions, Mounting & Installation

Thyracont

Thyracont VSH87PN operating instructions

turck

turck IM12-TI02-2TCURTDR-2I Series quick start guide