Instruction Manual

D101351X012

646 Transducer

January 2015

2

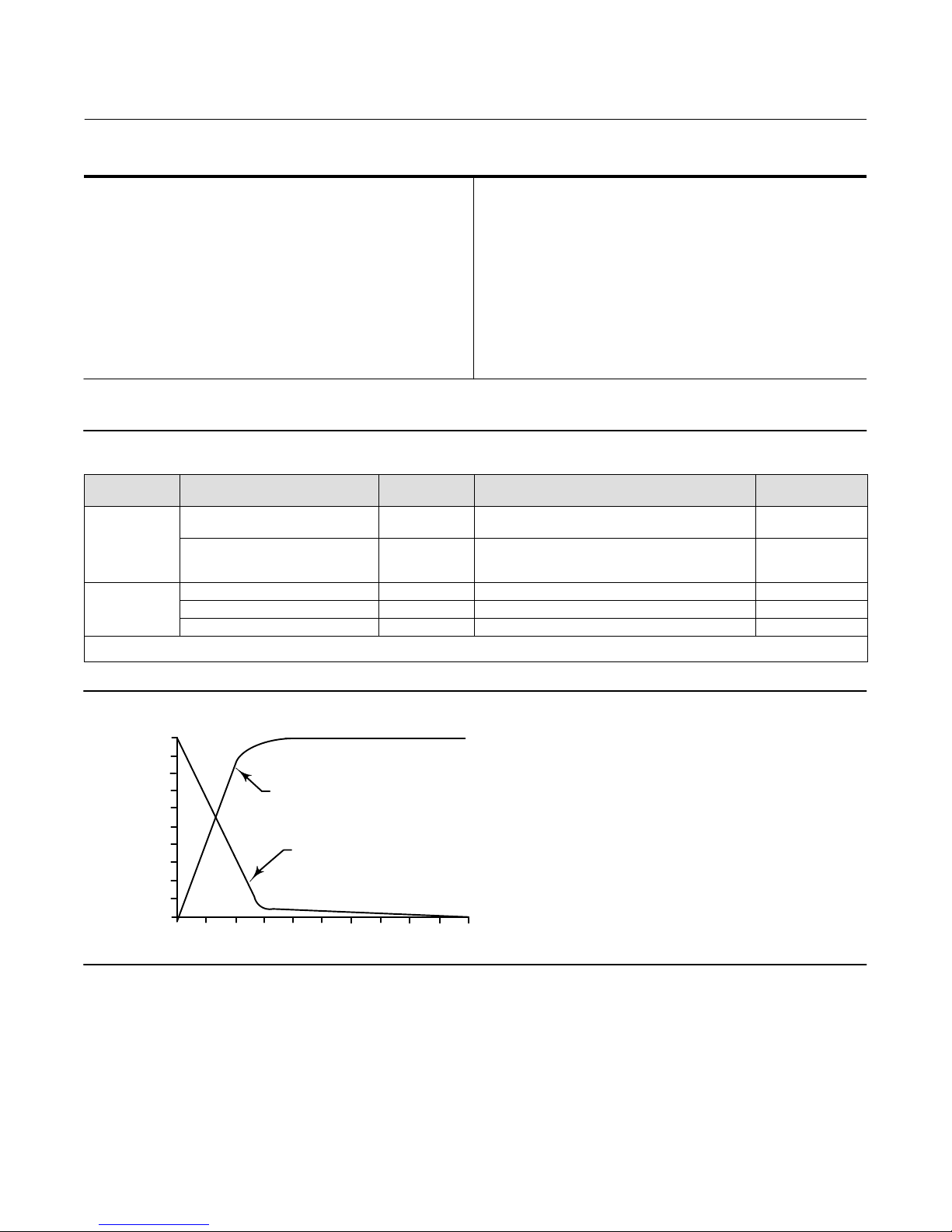

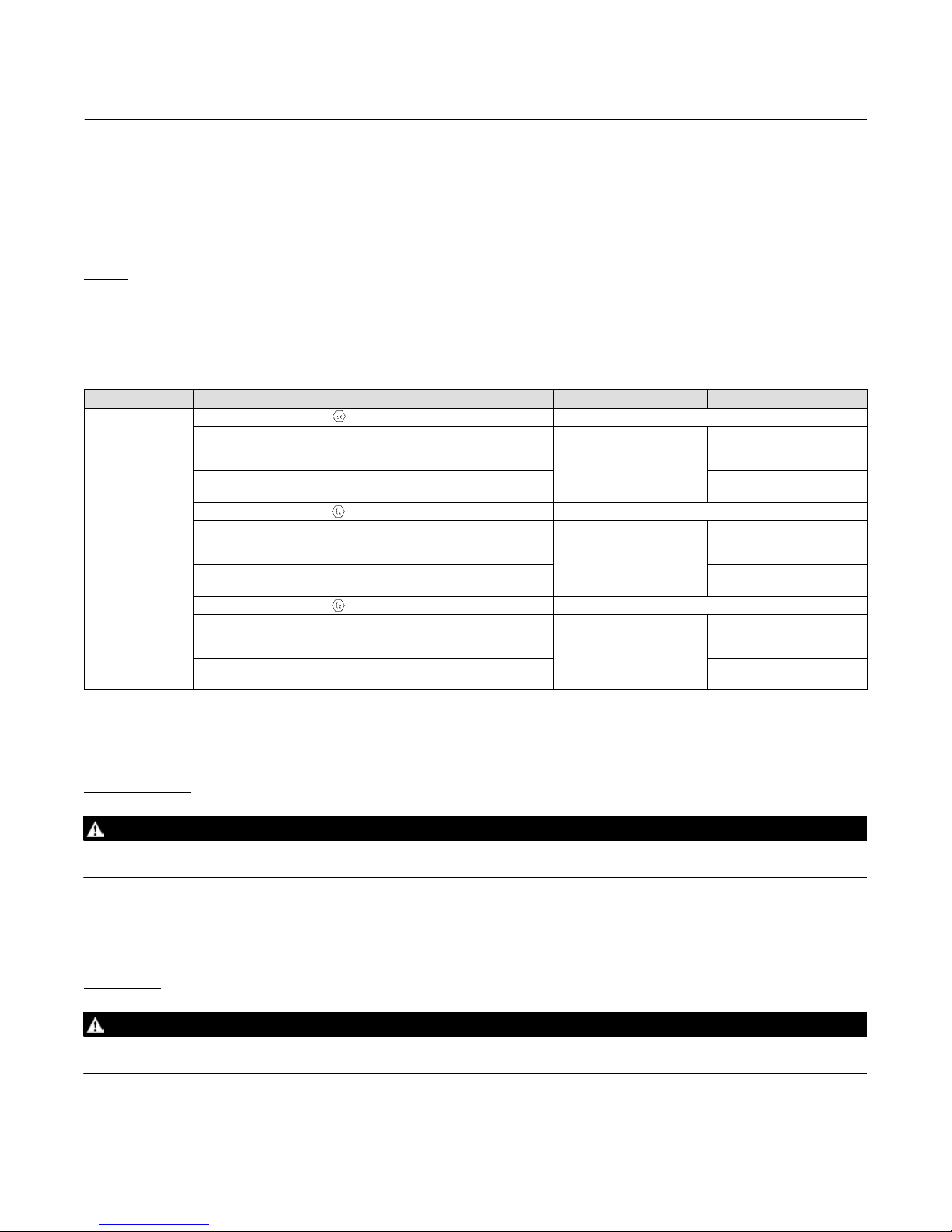

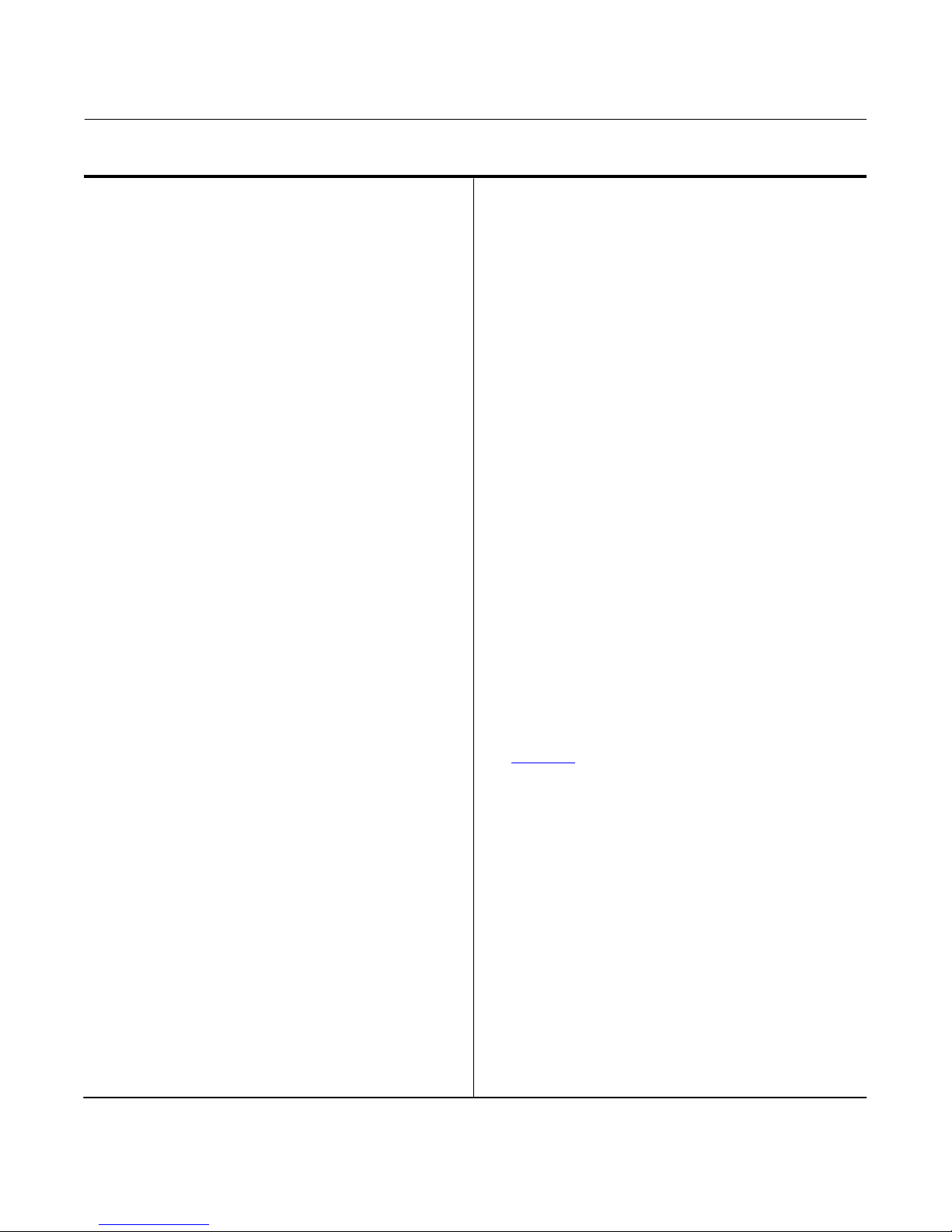

Table 1. Specifications

Input Signal

4-20 mA DC, constant current with 30 VDC maximum

compliance voltage

Equivalent Circuit

The 646 equivalent circuit is a series circuit consisting

of a constant voltage drop (battery) of approximately

2.1 VDC and a total resistance of 143 ohms. Input is

shunted by three 6.8 V zener diodes (see figure 6).

Output Signal

0.2 to 1.0 bar (3 to 15 psig) direct acting only

Supply Pressure(1)

Recommended: 1.4 bar (20 psig)

Minimum: 1.4 bar (20 psig)

Maximum: 3.4 bar (50 psig)

Average Steady‐State Air Consumption(2)(3)

0.08 m3/hr (3 scfh) at 1.4 bar (20 psi) supply pressure

Maximum Output Air Capacity(2)

8.0 m3/hr (300 scfh) at 1.4 bar (20 psig) supply

pressure

Performance(4)

Reference Accuracy: ±0.5% of full scale output span;

includes combined effects of hysteresis, linearity, and

deadband

Independent Linearity: ±0.5% of full scale output span

Hysteresis: 0.4% of full scale output span

Frequency Response: Gain is attenuated 3 dB at 10 Hz

with transducer output signal piped to a typical

instrument input

Temperature Effect: ±4% of full scale output span per

55_C (100_F) change

Supply Pressure Effect: 0.2% of full scale output span

per psi supply pressure change

Vibration Effect: Less than 1% of full scale output span

when tested to SAMA PMC 31.1, Condition 3

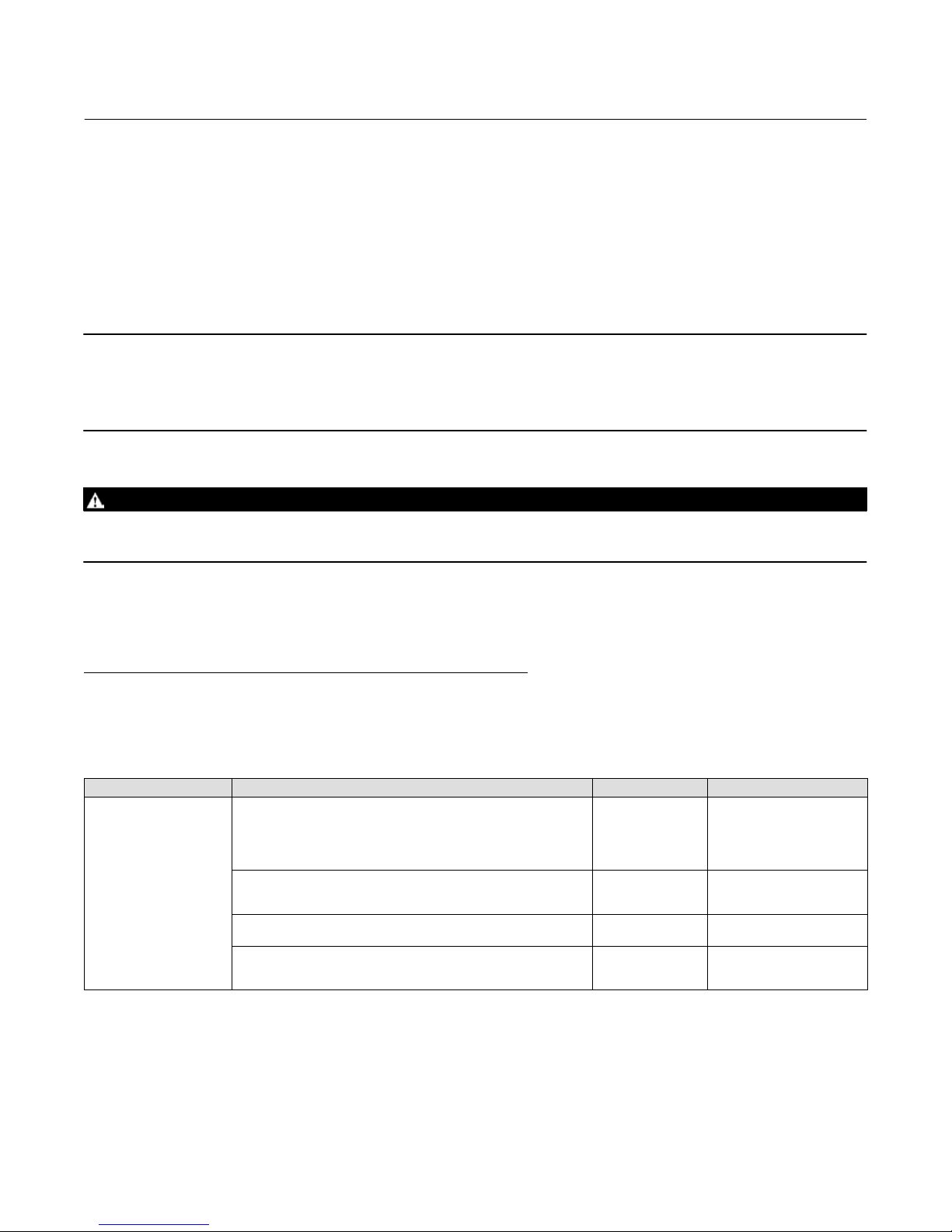

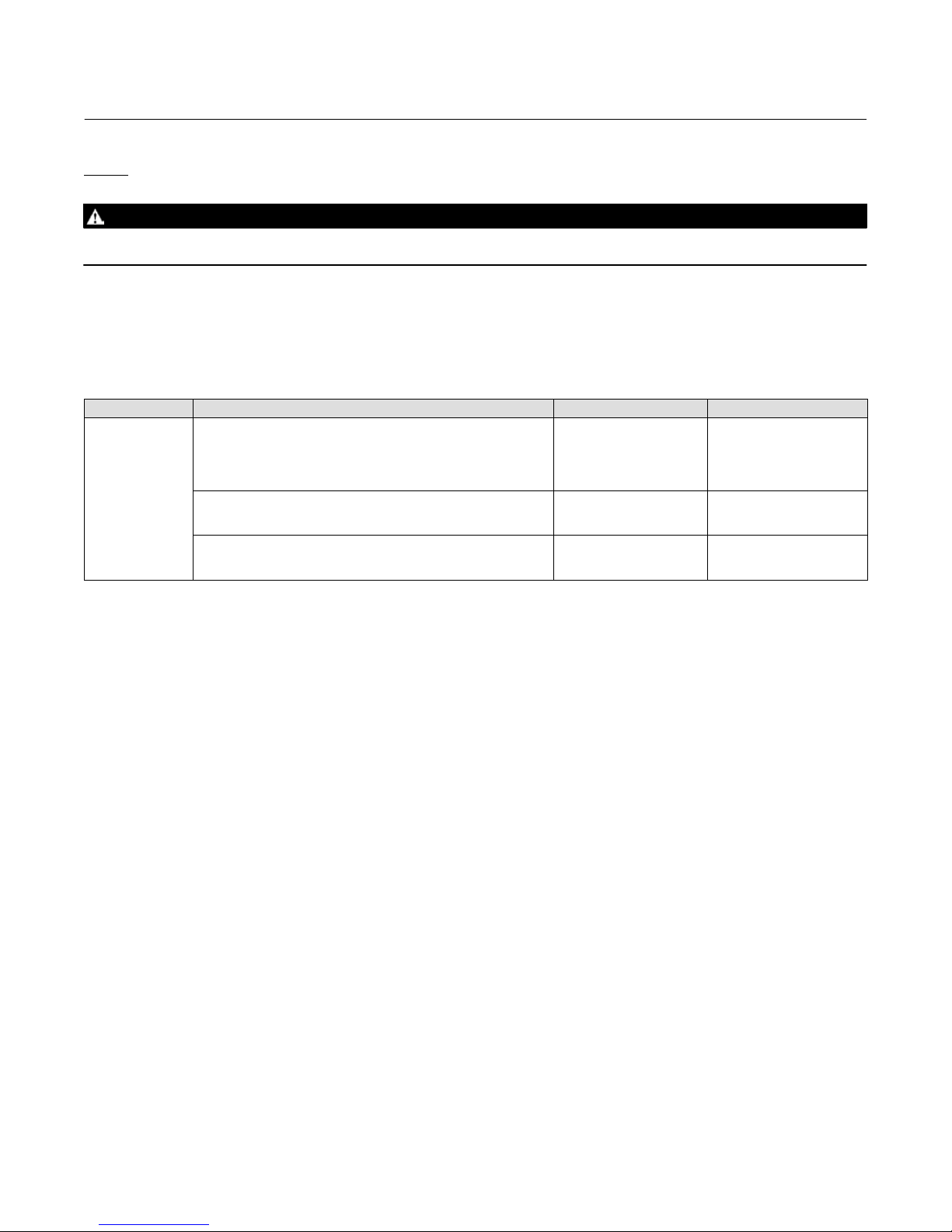

Electromagnetic Compatibility

Meets EN 61326‐1 (First Edition)

Immunity—Industrial locations per Table 2 of

the EN 61326‐1 standard. Performance is

shown in table 2 below.

Emissions—Class A

ISM equipment rating: Group 1, Class A

Operating Ambient Temperature Limits(1)

-40 to 71_C (-40 to +160_F)

Electrical Classification

CSA—Intrinsically Safe, Explosion proof, Type n,

Dust‐Ignition proof, DIV 2

FM—Intrinsically Safe, Explosion proof, Type n,

Non‐incendive, Dust‐Ignition proof

ATEX—Intrinsically Safe, Flameproof, Type n

IECEx—Intrinsically Safe, Flameproof, Type n

Refer to Hazardous Area Classifications and Special

Instructions for the “Safe Use” and Installation in

Hazardous Locations starting on page 5 for

additional information.

Housing

CSA—Type 3 Encl.

FM—NEMA 3, IP54

ATEX—IP64

IECEx—IP54

Mount instrument with vent on side or bottom if

weatherproofing is a concern.

Other Classifications/Certifications

INMETRO— National Institute of Metrology, Quality

and Technology (Brazil)

KGS— Korea Gas Safety Corporation (South Korea)

Contact your Emerson Process Management sales

office for classification/certification specific

information

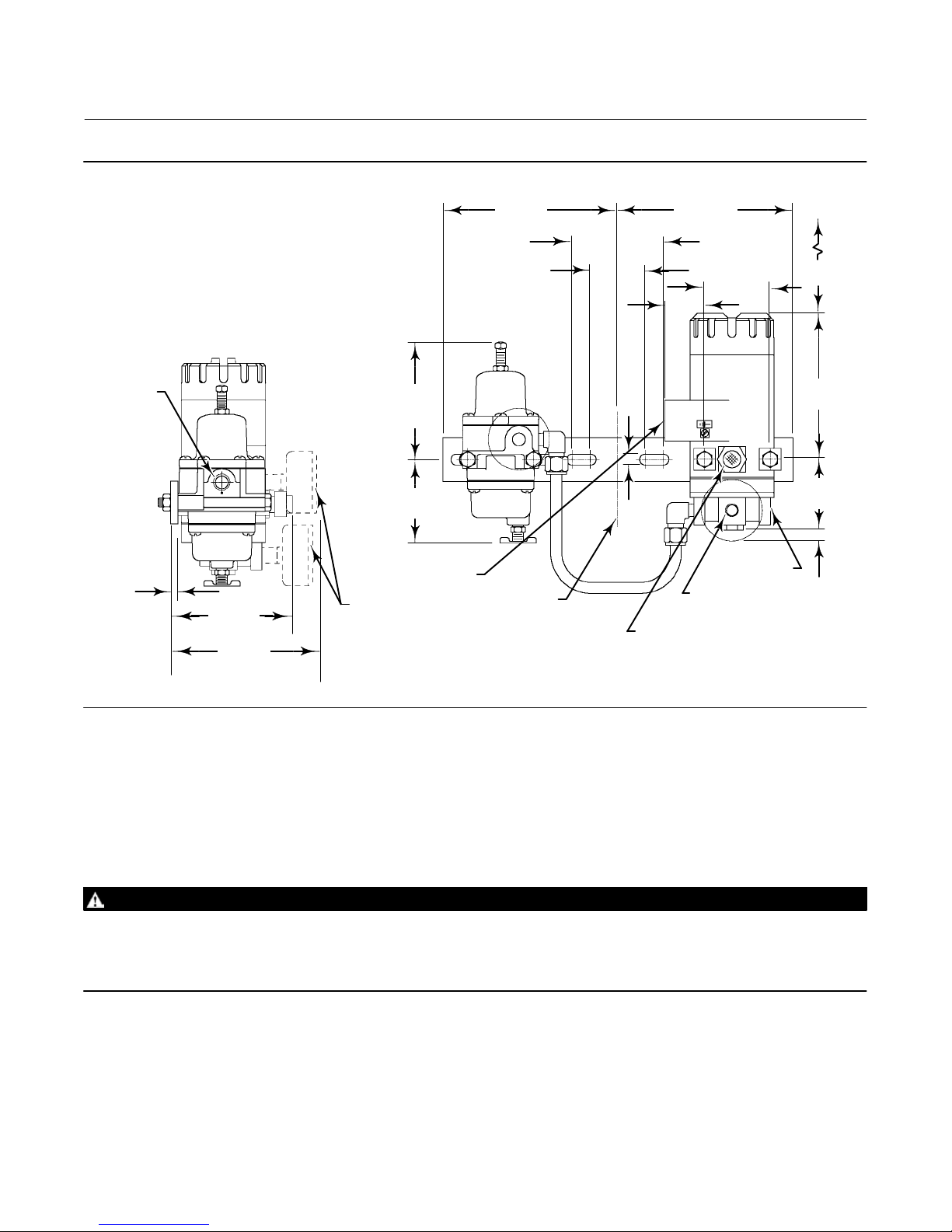

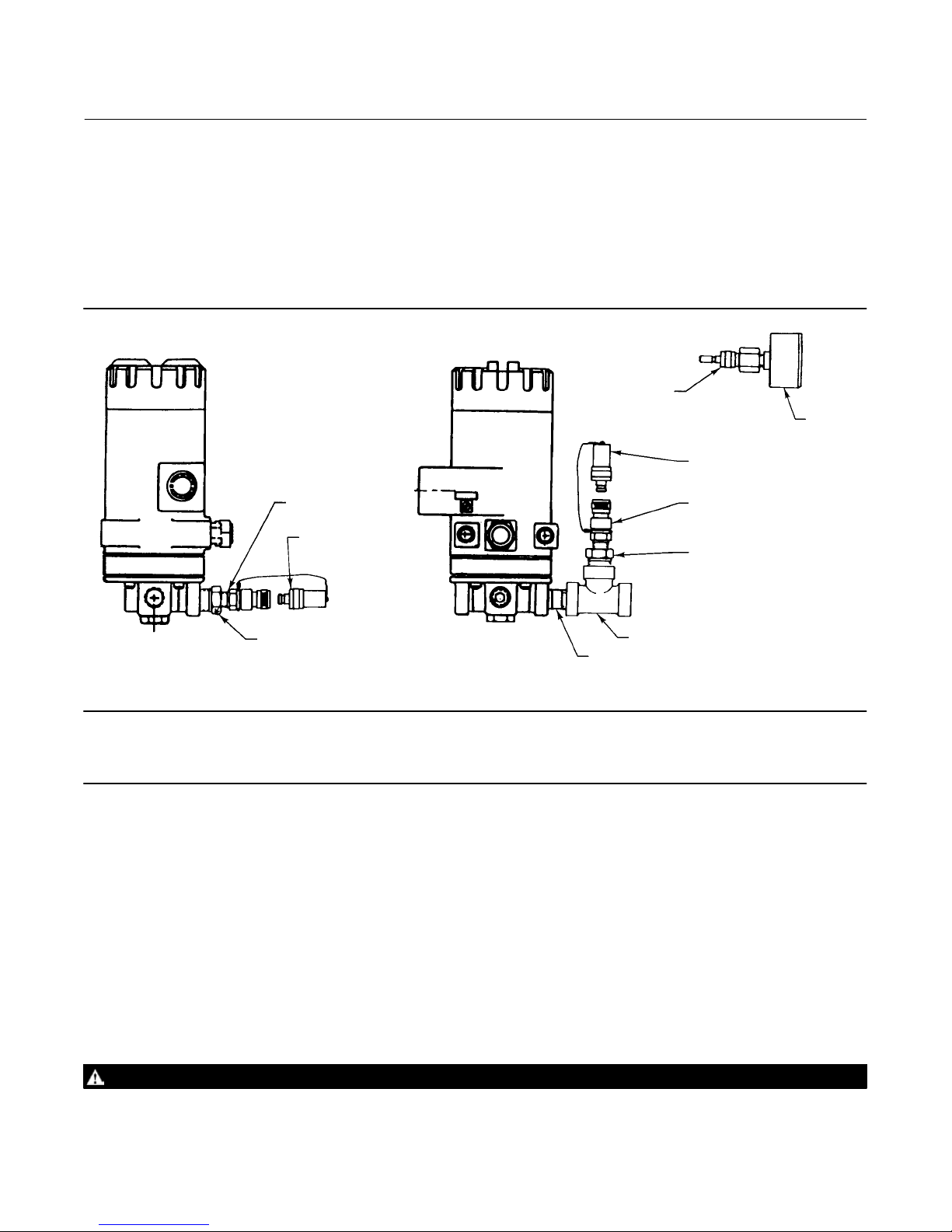

Connections

Supply and Output Pressure: 1/4 NPT internal

connection

Vent: 1/4 NPT internal

Electrical: 1/2‐14 NPT conduit connection

Wire Size: 18 to 22 AWG

Adjustments

Zero and Span: Trim potentiometers (20 turn) for

zero and span adjustments are located under the

housing cap (see figure 7)

-continued-