Elgin Eagle E Series User manual

Eagle® E and F

OPERATORS MANUAL

EAGLE®SERIES E and F

OPERATORS MANUAL

Sweeper Serial Number_____________________________

Elgin Sweeper Company

Subsidiary of Federal Signal Corporation

1300 W. Bartlett Road, Elgin, IL 60120

Phone 847/741-5370

FAX 847/742-3035

P/N 0701480-D

Printed in U.S.A. Copyright 2007 Elgin Sweeper Company

Welcome to the World’s Most Popular

Four-Wheel Broom Sweeper -

The Elgin Eagle®Series E and F

i

Read this manual carefully and completely before oper-

ating the sweeper. Working with unfamiliar equipment

can lead to accidents. Understand and follow all safety

information when operating the sweeper.

Elgin employees carefully inspected the sweeper before

it left the factory. Your Elgin equipment dealer inspect-

ed the sweeper and made certain that it was in proper

working order prior to delivery.

To keep the Eagle sweeper in good working condition, it

is important to follow all maintenance and service

schedules, including

DAILY SERVICE - After every shift or 10 hours

PERIODIC SERVICE - After each period of 50, 150,

500 or 1000 hours

Refer to the maintenance schedule in the Maintenance

Section. This schedule is also displayed on the fuel

tank.

Keep this manual in the cab of the sweeper for refer-

ence. If a problem develops with the sweeper, your

Elgin Dealer has the factory-trained service personnel,

genuine Elgin parts and necessary tools and equipment

to meet your specific needs.

If you should need to contact the factory regarding

operation, maintenance or repair, please feel free to call

Elgin at 847/741-5370.

This manual will assist in the proper operation and care of the Elgin Eagle Series E and F Sweeper. It contains

specific information on features and specifications, suggested operating techniques, preventive maintenance hints

and instructions for making repairs and adjustments.

ii

LIMITED WARRANTY

ELGIN SWEEPER COMPANY warrants each new machine manufactured by it

against defects in material and workmanship provided the machine is used in a

normal and reasonable manner. This warranty is extended only to the original

user-purchaser for a period of twelve (12) months from the date of delivery to the

original user-purchaser.

ELGIN SWEEPER COMPANY will cause to be repaired or replaced, as the Company may elect, any part or parts of such

machine which the Company’s examination discloses to be defective in material or workmanship.

Repairs or replacements are to be made at the selling Elgin distributor’s location or at other locations approved by ELGIN

SWEEPER COMPANY.

The ELGIN SWEEPER COMPANY warranty shall not apply to:

1. Major components or trade accessories such as trucks, engines, tires or batteries that have a separate warranty by the origi-

nal manufacturer.

2. Normal adjustments and maintenance services.

3. Normal wear parts such as broom filters, broom wire, shoe runners and rubber deflector.

4. Failures resulting from the machine being operated in a manner or for a purpose not recommended by ELGIN SWEEPER

COMPANY.

5. Repairs, modifications or alterations which, in the Company’s sole judgment, have adversely affected the machine’s stability

or reliability.

6. Items subjected to misuse, negligence, accident or improper maintenance.

iii

The use in the product of any part other than parts approved by ELGIN SWEEPER COMPANY may invalidate this warranty.

ELGIN SWEEPER COMPANY reserves the right to determine, in its sole discretion, if the use of non-approved parts operates

to invalidate the warranty.

Nothing contained in this warrant shall make ELGIN SWEEPER COMPANY liable for loss, injury or damage of any kind to

any person or entity resulting from any defect or failure in the machine.

TO THE EXTENT LIMITED BY LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

This warranty is also in lieu of all other obligations or liabilities on the part of ELGIN SWEEPER COMPANY, including but not

limited to, liability for incidental and consequential damages on the part of the Company or the seller.

ELGIN SWEEPER COMPANY makes no representation that the machine has the capacity to perform any functions other than

as contained in the Company’s written literature, catalogs or specification accompanying delivery of the machine.

No person or affiliated company representative is authorized to give any other warranties or to assume any other liability on

behalf of ELGIN SWEEPER COMPANY in connection with the sale, servicing or repair of any machine manufactured by the

Company.

ELGIN SWEEPER COMPANY reserves the right to make design changes or improvements in its products without imposing

any obligation upon itself to change or improve previously manufactured products.

ELGIN SWEEPER COMPANY, Elgin, Illinois, U.S.A.

iv

Safety Information

General ................................................................. S-1

Eagle Safety Labels ........................................... S-10

Description

Elgin Eagle Sweeper ........................................... D-1

History of Sweeping/Principles of Operation

Why Sweep? .................................................. D-2

History of Sweeping...................................... D-2

Mechanical/Broom Sweepers........................ D-3

Eagle .............................................................. D-3

Water Spray................................................... D-4

Brooms........................................................... D-5

Conveyor ........................................................ D-5

Hopper ........................................................... D-7

Air Bag Suspension....................................... D-7

Controls ......................................................... D-8

General Data ....................................................... D-9

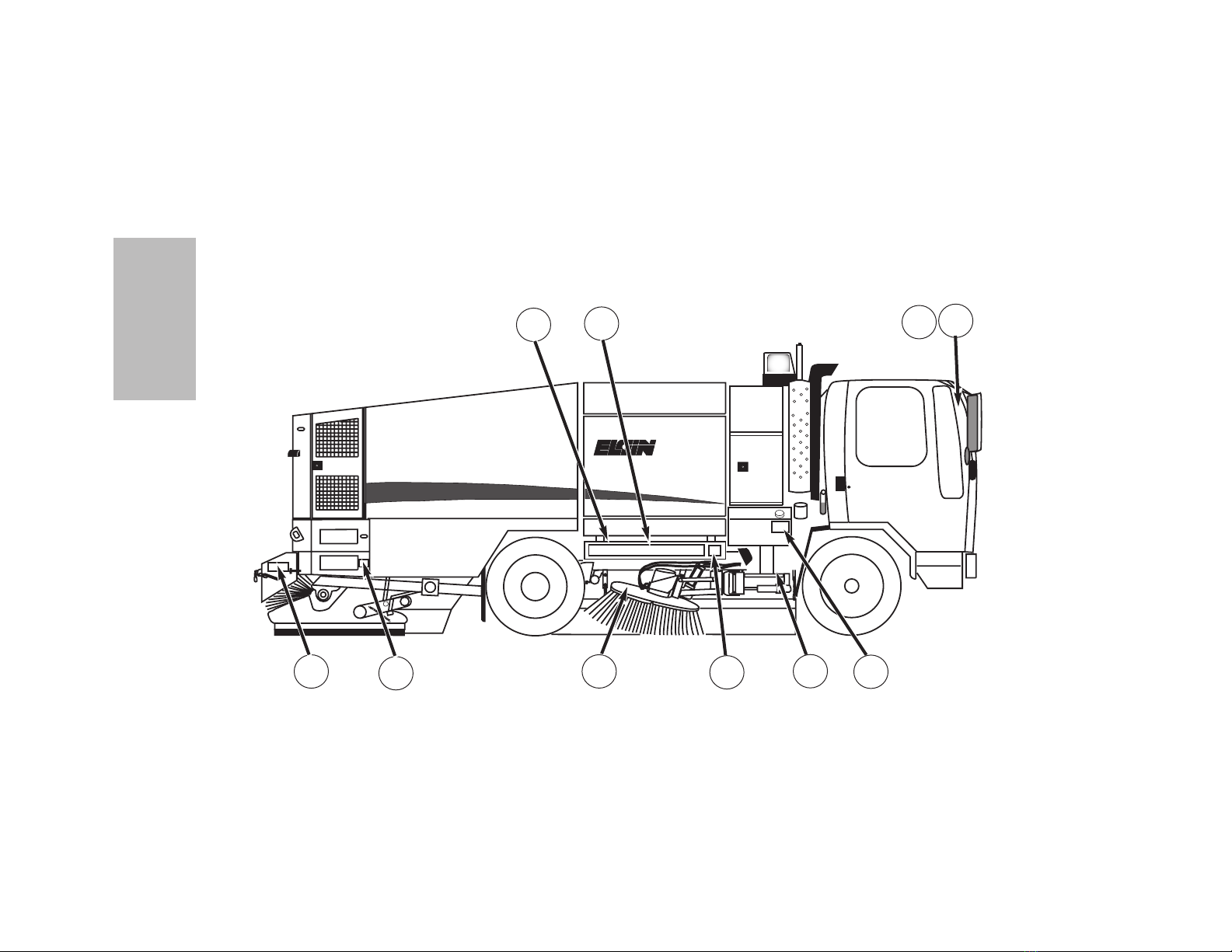

Eagle Side View ................................................. D-11

Eagle SE Rear View .......................................... D-12

Operation

Instruments and Controls................................... O-1

Operating Checklist ............................................ O-6

Starting the Unit................................................. O-8

Cold Weather Starting .........................................O-9

Transport............................................................ O-10

Sweeping ............................................................ O-11

Sweeping Patterns............................................. O-14

Reversing the Conveyor .................................... O-17

Dumping the Hopper......................................... O-18

Stopping the Sweeper ....................................... O-20

At End of Shift....................................................O-20

Maintenance

Scheduled Maintenance.......................................M-1

Daily Service Checklist ................................ M-1

Periodic Service Checklist.............................M-2

After 50 Hours ....................................... M-2

After 150 Hours ..................................... M-2

Addl. After 150 Hours for Series F ....... M-3

After 500 Hours ..................................... M-3

After 1000 Hours ................................... M-4

v

Table of Contents

Addl. After 1000 Hours for Series F ..... M-4

Maintenance Drawings........................................M-5

Daily Washdown ................................................. M-7

Service Procedures

Towing ...............................................................SP-1

Auxiliary Engine.................................................SP-4

Air Pre-Cleaner ........................................... SP-4

Air Cleaner .................................................. SP-5

Inspecting the Filter..............................SP-6

Cleaning the Outer Element.................SP-7

Auxiliary Engine Fluids ............................. SP-7

Fuel System................................................. SP-7

Draining the Fuel Water Separator........... SP-9

Changing Fuel Filter .................................. SP-9

Bleeding the Fuel System......................... SP-10

Hydraulic System ............................................ SP-11

Spray Water System........................................ SP-12

Sweeping Patterns........................................... SP-14

Side Broom Adjustment .............................SP-14

Side-to-Side Angle............................... SP-14

Front-to-Back Angle ........................... SP-15

Down Pressure.................................... SP-16

Main Broom Adjustment ...........................SP-17

Dirt Shoe Adjustment...................................... SP-17

Dirt Deflector ................................................... SP-18

Conveyor........................................................... SP-19

Daily Washdown .............................................. SP-21

Winter Storage................................................. SP-24

Spring Start-up................................................ SP-27

Troubleshooting

Glossary

vi

RECOGNIZE SAFETY

INFORMATION

This is the safety-alert symbol. When

you see this symbol on your machine or in

this manual, be alert to the potential for

personal injury.

Follow recommended precautions and safe

operating practices.

UNDERSTAND SIGNAL WORDS

A signal word – DANGER, WARNING, or

CAUTION – is used with the safety-alert

symbol. DANGER identifies the most seri-

ous hazards.

This symbol and these signal words appear

on the machine and in the operator’s manu-

al. Read and understand the following defin-

itions of the signal words before operating

or working on the machine.

DANGER DANGER is used to

indicate the presence of a hazard which will

cause severe personal injury, death, if the

warning is ignored.

WARNING WARNING is used to

indicate the presence of a hazard which can

cause severe personal injury or death, if the

warning is ignored.

CAUTION CAUTION is used to

indicate the presence of a hazard which will

or can cause minor personal injury, if the

warning is ignored.

An additional signal word – NOTICE – is

used to alert the reader to information that

does not deal with personal safety.

SAFETY

S-1

SAFETY INFORMATION

NOTICE NOTICE is used to notify people

of installation, operation, or maintenance

information which is important but not haz-

ard-related.

CALIFORNIA PROPOSITION 65

WARNING

Please note this warning and remember:

• Always start and operate the engine in a

well-ventilated area;

• If in an enclosed area, vent the exhaust to

the outside;

• Do not modify or tamper with the exhaust

system.

FOLLOW SAFETY

INSTRUCTIONS

Carefully read all safety mes-

sages in this manual and on

your machine safety signs.

Keep safety signs in good

condition. Replace missing or

damaged safety signs. Be

sure new equipment compo-

nents and repair parts

include the current safety

signs.

Replacement safety signs are available from

your Elgin Sweeper dealer.

Learn how to operate the machine and how

to use controls properly. Do not let anyone

operate the machine without instruction.

Keep your machine in proper working condi-

tion. Unauthorized modifications to the

machine may impair function and/or safety

and affect machine life.

SAFETY

S-2

CALIFORNIA

PROPOSITION 65 WARNING

Diesel engine exhaust and some of its constituents

are known to the State of California to cause

cancer, birth defects and other reproductive harm.

If you do not understand any part of this

manual and need assistance, contact your

Elgin Sweeper dealer.

WEAR APPROPRIATE

CLOTHING

Wear close fitting clothing and safety equip-

ment appropriate to the job. Exercise cau-

tion with anything that could be caught in

the machinery, such as jewelry and long

hair.

Operating equipment safely requires the full

attention of the operator. Do not wear radio

or music headphones while operating the

machine. Use caution while using a cellular

telephone while operating the equipment.

HANDLE FUEL SAFELY —

AVOID FIRES

Handle fuel with care. It

is highly flammable. Do

not refuel the machine

while smoking or when

near open flame or

sparks.

Always stop the engine

before refueling the

machine. Fill the fuel tank outside.

Prevent fires by keeping the machine clean of

trash, grease, and debris. Always clean up

spilled fuel.

SAFETY

S-3

DRIVING THE SWEEPER

Operate the sweeper only when all guards

are fitted and in their correct position.

Before moving the machine, check the

immediate vicinity of the machine for

bystanders. Use the horn as a warning

immediately before moving the machine.

AVOID CONTACT WITH

MOVING PARTS

Everyone must be clear of the

sweeper before the engine is

started and before the brooms

are started.

Many moving parts, such as the

side brooms, cannot be complete-

ly shielded, due to their function.

Stay clear of these moving ele-

ments during operation.

Keep hands, feet, and clothing away from

power driven parts.

AVOID OVERLOADS

Observe the maximum per-

missible axle loads and total

weights.

PARK SWEEPER SAFELY

Set the parking brake, turn off the engine

and remove the keys.

SAFETY

S-4

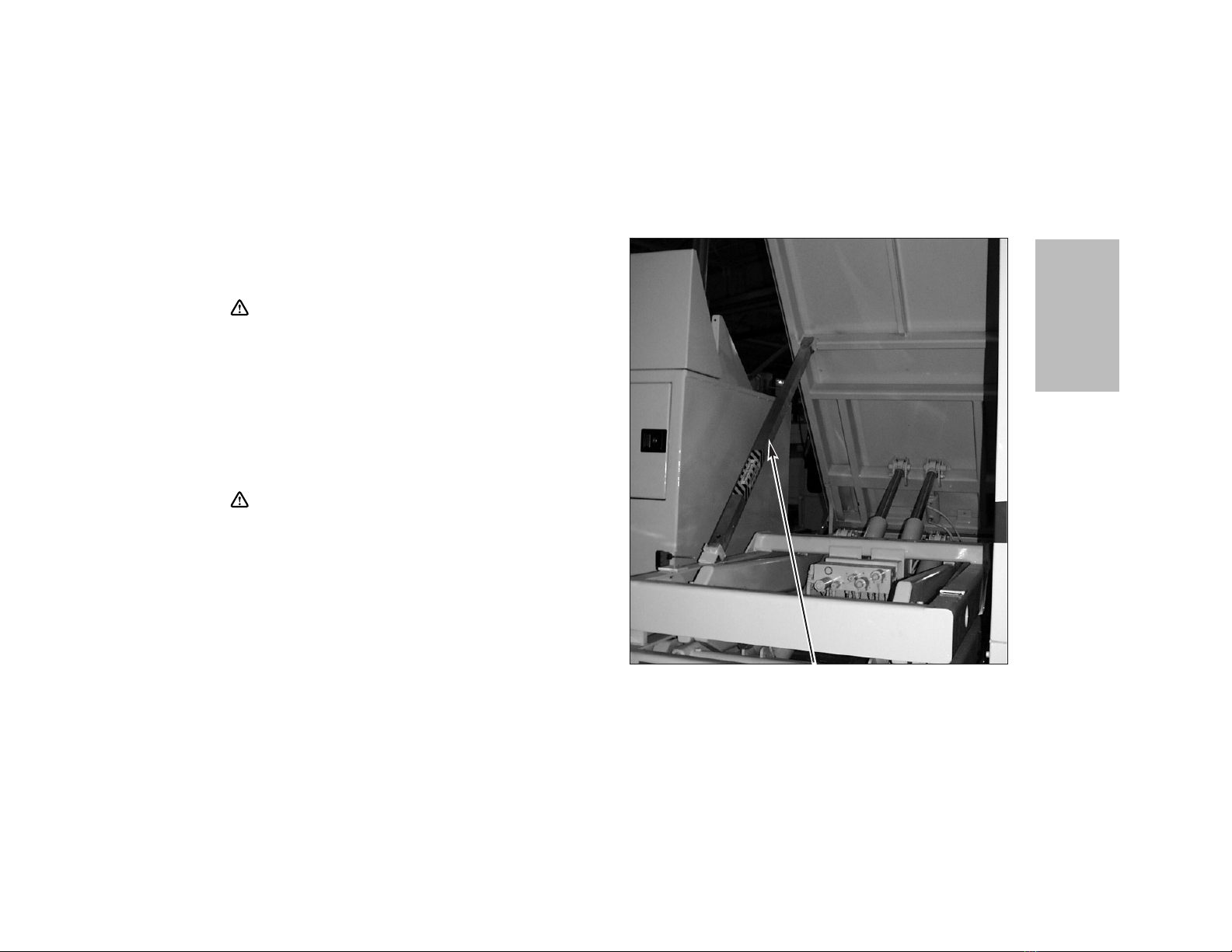

HOPPER SAFETY SUPPORTS

(Serial number F-1000 and above)

WARNING

To prevent damage or injury, check for

obstructions above and in front of the

machine, before raising or tilting the hopper.

When the EAGLE Series-F hopper is fully

raised, its highest point is over 21 feet above

the ground. Overhead wires, cables or tree

branches can be easily snapped by the hopper

and hardly felt by the operator.

WARNING

DO NOT work under or around a raised hop-

per without adequate safety bracing to sup-

port the hopper in the event of a hydraulic

failure. The best method for safe access to the

machine behind the hopper is with the hopper

tilted outward in the dump position with the

hopper tilt support bar in place.

SAFETY

S-5

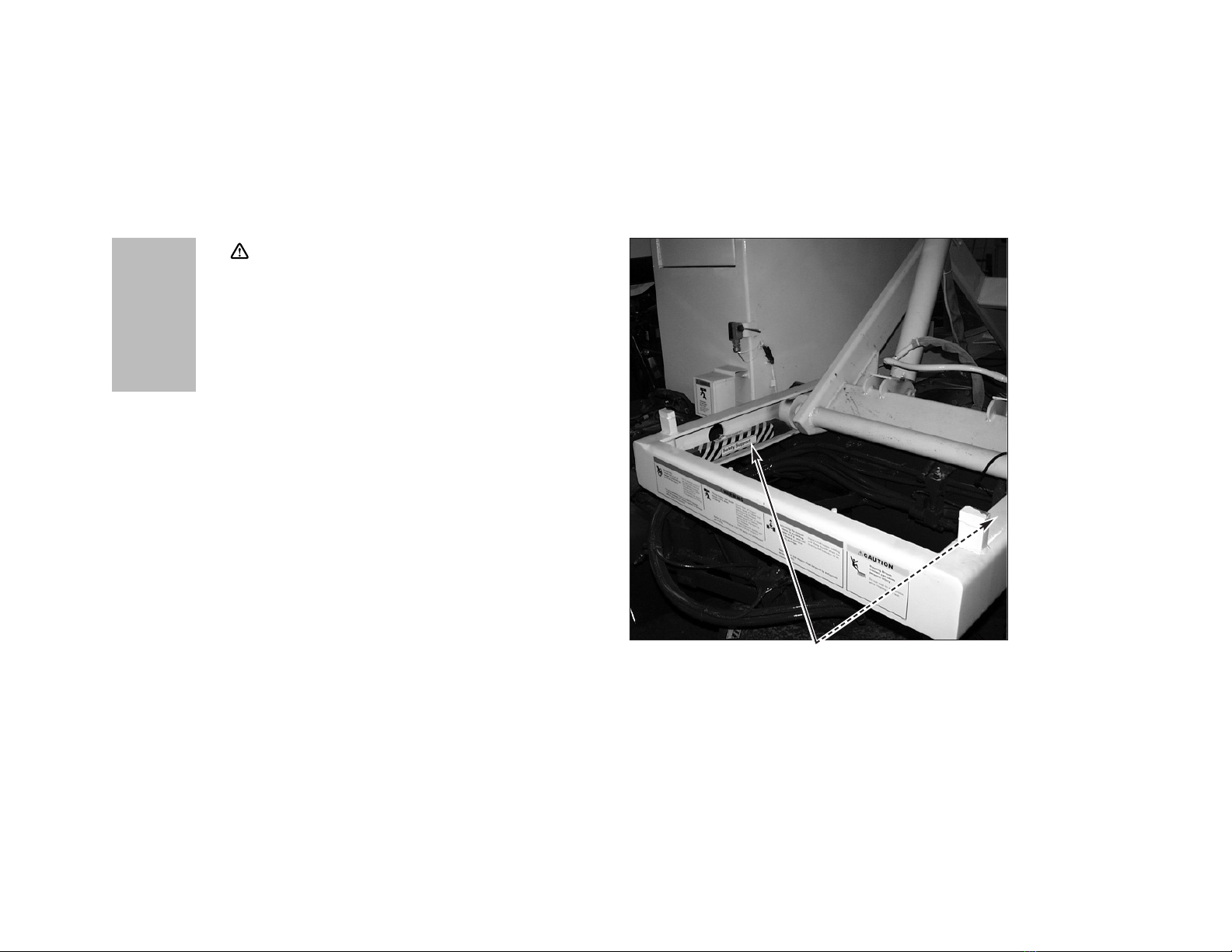

HOPPER TILT SUPPORT BAR

(IN PLACE)

WARNING

DO NOT work under a raised hopper without

adequate safety bracing to support the hopper

in the event of a hydraulic failure. If access to

the machine under the hopper is required, be

certain the raised hopper safety bar is in

place.

SAFETY

S-6

RAISED HOPPER SAFETY BAR

(IN PLACE)

AVOID ELECTRICAL

POWER LINES

Do not raise the hopper while under

power lines.

Do not raise the hopper while under trees,

bridges, etc.

Lower the hopper to transport position

before moving the machine.

AVOID MACHINE INSTABILITY

Parking brake must be set before raising

the hopper.

Raise the hopper only when the sweeper is

parked on firm, level surfaces.

Lower the hopper to transport position

before moving the machine.

PRACTICE SAFE

MAINTENANCE

Keep the area clean and dry. Remove any

build-up of grease, oil or debris.

Never lubricate or service the machine

while it is moving. Keep all parts in good

condition and properly installed. Fix dam-

age immediately. Replace worn or broken

parts.

PREVENT BATTERY

EXPLOSIONS

Battery gas can explode. Keep

sparks and flames away from

batteries. Use a flashlight to

check battery electrolyte

level.

Never check battery charge by

SAFETY

S-7

placing a metal object across the posts. Use

a voltmeter or hydrometer.

Always remove the grounded (–) battery

cable first and replace it last.

Do not charge a frozen battery; it may

explode. Warm the battery to 60° F (16 °C).

AVOID OVERLOADING

ELECTRICAL SYSTEM

Before modifying, adding, removing,

etc. any electrical/electronic compo-

nent(s), verify that the circuitry and

components do not overload the elec-

trical system.

Contact your Elgin Sweeper dealer, if

you have any questions or need assistance.

AVOID HIGH PRESSURE

FLUIDS

Escaping fluid under pres-

sure can penetrate the skin,

causing serious injury. Avoid

the hazard by relieving pres-

sure before disconnecting

hydraulic or other high pres-

sure lines. Tighten all con-

nections before applying pressure. Search for

leaks with a piece of cardboard. Protect hands

and body from high pressure fluids. If accident

occurs, seek immediate medical attention.

Keep hands and body away from pinholes and

nozzles which eject fluids under high pressure.

SAFETY

S-8

USE PROPER TOOLS

Use tools appropri-

ate to the work.

Makeshift tools and

procedures can cre-

ate safety hazards.

Use power tools only

to loosen threaded parts and fasteners.

For loosening and tightening hardware, use

the correct size tools. DO NOT use U.S.

measurement tools on metric fasteners, or

vice versa. Avoid bodily injury caused by

slipping wrenches.

Use only service parts meeting Elgin

Sweeper specifications.

OBSERVE ENVIRONMENTAL

PROTECTION REGULATIONS

Be mindful of the

environment and

ecology.

Before draining any

fluids, find out the

correct way to dis-

pose of them.

Observe the relevant environmental protec-

tion regulations when disposing of oil, fuel,

coolant, brake fluid, filters, and batteries.

SAFETY

S-9

Eagle

SAFETY

S-10

EAGLE SAFETY LABELS - PART ONE OF THREE

12

3

4

5F-1 37

F-2 6

(Start F-1000)

This manual suits for next models

1

Table of contents

Popular Floor Machine manuals by other brands

Advance acoustic

Advance acoustic SW8000 Instructions for use

IPC

IPC LION 1460 manual

JohnsonDiversey

JohnsonDiversey TASKI ergodisc 165 Instructions for use

MasterCraft

MasterCraft MTHC16EHR-WET Operation & maintenance manual

Hofmann

Hofmann MTS 300 operating instructions

Superabrasive

Superabrasive LAVINA ELITE Series user manual