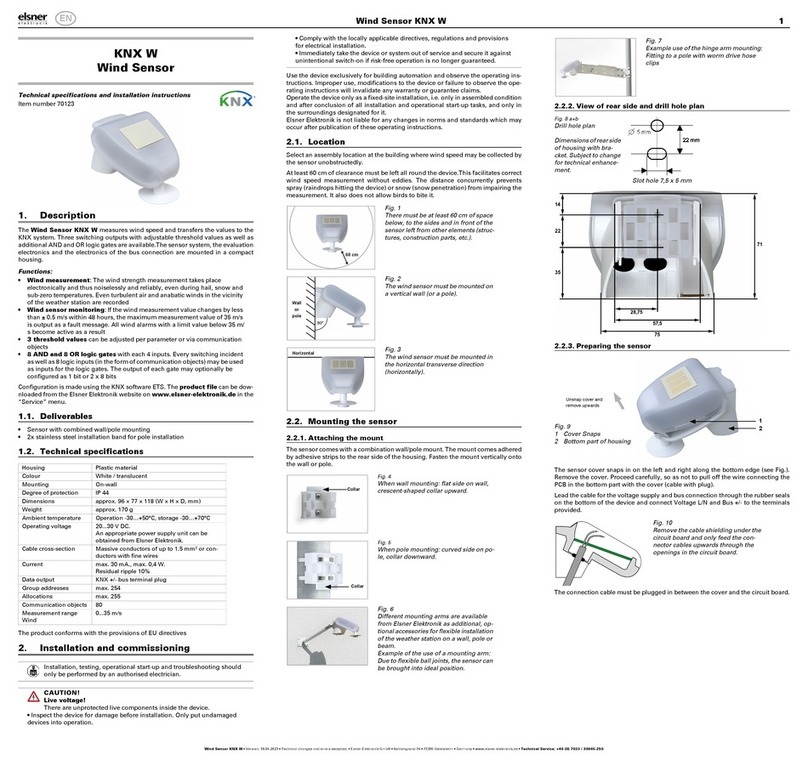

elsner elektronik Sewi AQS/TH Modbus User manual

Sewi Modbus Indoor Sensors 1

Sewi Modbus Indoor Sensors • Version: 20.09.2022 • Technical changes and errors excepted. • Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany • www.elsner-elektronik.de • Technical Service: +49 (0) 7033 / 30945-250

Sewi AQS/TH Modbus

Sewi TH Modbus

Indoor sensors

Technical specifications and installation instructions

Item numbers 30174 (Sewi AQS/TH Modbus), 30175 (Sewi TH Modbus)

1. Description

The indoor sensors Sewi AQS/TH Modbus and Sewi TH Modbus measure

the indoor temperature and humidity and also calculate the dew point temperatu-

re. The Sewi AQS/TH also records the CO2 concentration.

The devices are Modbus slaves with a RS485 interface and a RTU protocol. The

Modbus master, such as PC, SPS or MC can read the Sewi Modbus Indoor Sen-

sors measurement values with “Function 04h (Read Input Register)”.

Sewi TH Modbus Indoor Sensor Functions:

• Temperature measurements

• Humidity measurements

• Calculating the dew point temperature

Sewi AQS/TH Modbus Indoor Sensor Functions:

• Measuring the CO2 concentration in the air

• Temperature measurements

• Humidity measurements

• Calculating the dew point temperature

Tips for Dew Point Calculation:

The sensors Sewi Modbus calculate the ambient dew point temperature. This va-

lue can be used for dew point monitoring. This would require another sensor for

measuring the surface temperature of the wall or pipe. Also, the dew point needs

to be monitored (compare with temperatures) in the Modbus master.

Monitoring predetermines the possible condensate build-up on the surface, giving

a chance for timely countermeasures.

1.0.1. Deliverables

• Sensor in the housing for wall or ceiling mounting.

1.1. Specifications

The product is compliant with the provisions of the EC guidelines.

1.1.1. Measuring accuracy

After applying the operating voltage, it can take up to 15 minutes until the CO2

measured value is output correctly.

The CO2sensor uses the last 7 minimum CO2values for automatic sensor calibrat-

ion. These 7 minimum values must be at least 18 hours apart and within the range

of 400 to 450 ppm (fresh air).

2. Installing and commissioning

Installation, testing, operational start-up and troubleshooting should

only be performed by an authorised electrician.

CAUTION!

Live voltage!

There are unprotected live components inside the device.

• Inspect the device for damage before installation. Only put undamaged

devices into operation.

• Comply with the locally applicable directives, regulations and provisions

for electrical installation.

• Immediately take the device or system out of service and secure it against

unintentional switch-on if risk-free operation is no longer guaranteed.

Use the device exclusively for building automation and observe the operating ins-

tructions. Improper use, modifications to the device or failure to observe the ope-

rating instructions will invalidate any warranty or guarantee claims.

Operate the device only as a fixed-site installation, i.e. only in assembled condition

and after conclusion of all installation and operational start-up tasks, and only in

the surroundings designated for it.

Elsner Elektronik is not liable for any changes in norms and standards which may

occur after publication of these operating instructions.

2.1. Installation location

Install and use only in dry interior rooms!

Avoid condensation.

The indoor sensor is installed on the wall or ceiling plaster.

While selecting the location, please ensure that the temperature, humidity and

CO2 measurements are minimally distorted by external influences as possible.

Possible sources of interference include:

• Direct sunlight

• Draughts from windows and doors

• Draughts from ducts coming from other rooms or the outdoors

• Warming or cooling of the building structure on which the sensor is

mounted, e.g. due to sunlight, heating or cold water pipes

• Connection lines and empty ducts which lead from warmer or colder areas

to the sensor

3. Commissioning

Never expose the device to water (e.g. rain) or dust. This can damage the electro-

nics. You must not exceed a relative humidity of 95%. Avoid condensation.

The air slots on the side must not be closed or covered.

After the operating voltage has been applied, the device will enter an initialisation

phase lasting a few seconds. During this phase no information can be received or

sent via the bus.

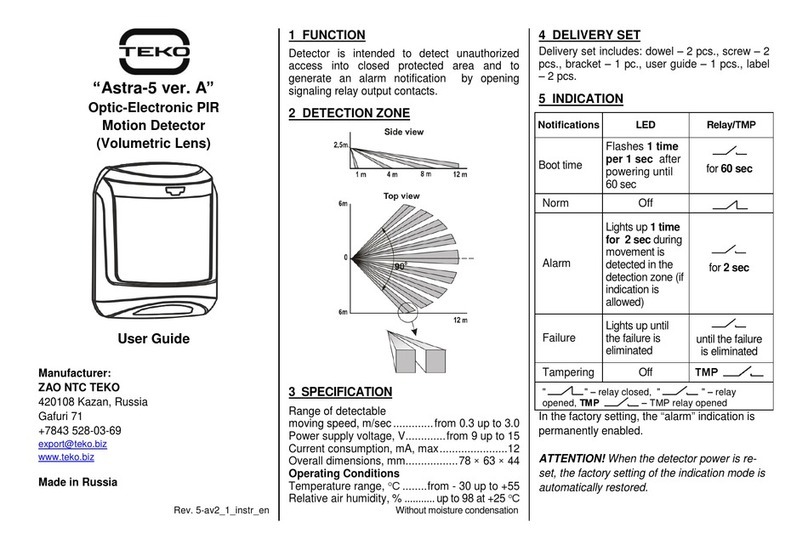

3.1. Construction of the sensor

3.1.1. Printed circuit boards/connections

ATTENTION!

Make sure the connection is correct!

• Connect the power supply to 1 and 2 only.

• Use the data connections A and B exclusively for Modbus.

ATTENTION!

CO2 sensor with sensitive membrane in Sewi AQS/TH!

When handling the device, do not damage the white membrane.

3.1.2. Housing from the outside

3.2. Assembly

ATTENTION!

Make sure the connection is correct!

• Connect the power supply to 1 and 2 only.

• Use the data connections A and B exclusively for Modbus.

Housing Plastic

Colour White (Cover glossy, skirting matt)

Assembly Surface, wall or ceiling installation

Protection category IP 30

Dimensions Ø approx. 105mm, height approx. 32mm

Weight Sewi AQS/TH Modbus: approx. 100g

Sewi TH Modbus: approx. 75g

Ambient temperature Operation 0 …+50°C, Storage -20 …+70°C

Ambient humidity max. 95% RH, avoid condensation

Operating voltage 24 V DC ±10%.

An appropriate power supply unit can be purchased

from Elsner Elektronik.

Cable cross-section Solid conductor up to 0.8mm2

Power max. 15mA

Interface RS485

Protocol RTU

RS485 bus load 1/8 unit load according to the RS485 standard

RS485 drive output min. 2.4V at 54 Ohm bus load

(according to the 32 standard RS485 unit loads)

Sewi TH Modbus (30175):

Temperature measure-

ment range

-40...+80°C

Humidity measurement

range

0% rH … 100% rH

Sewi AQS/TH Modbus (30174):

Temperature measure-

ment range

0°C…+50°C

Humidity measurement

range

0% rH…90% rH

CO2measurement range 100...10,000ppm

1a

A

1b

6

7

8

5

2

3

4

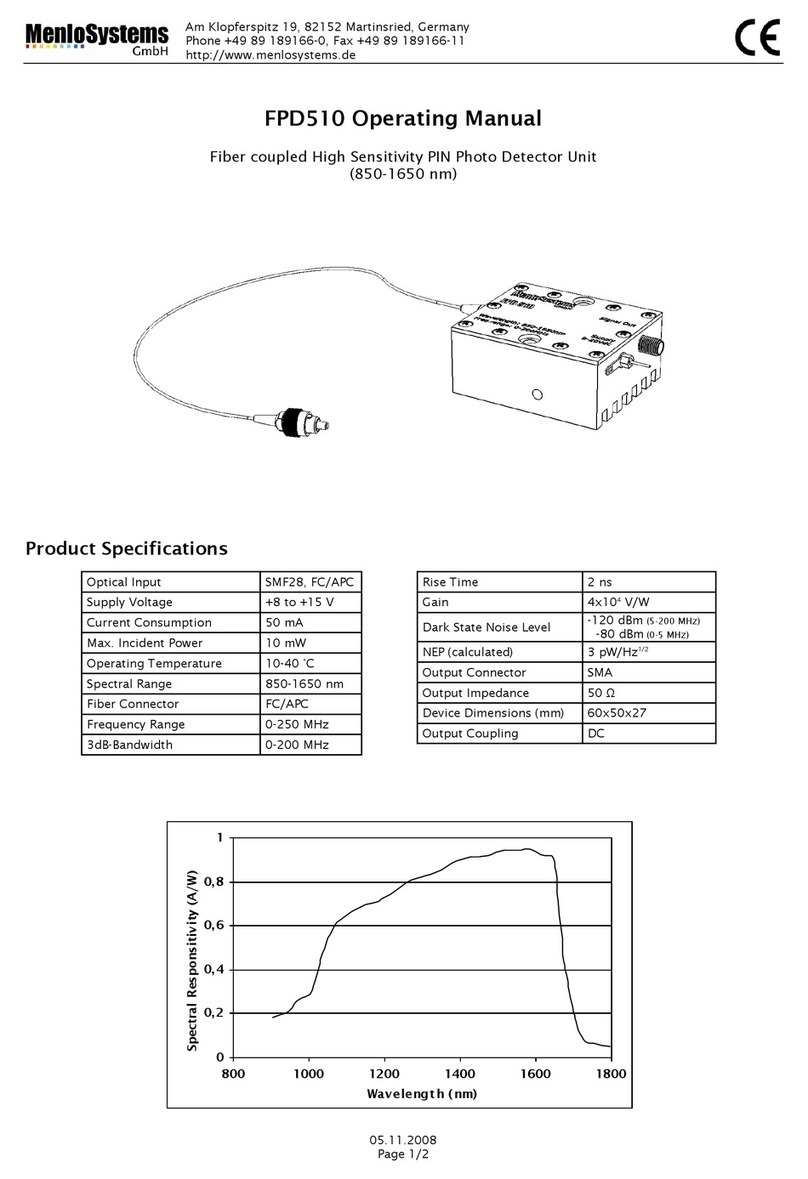

Fig. 1

1 a + b Long holes for mounting (hole distance 60mm)

2 LEDs: Green Power/Operating voltage.

Red Error/Sensor error or incorrect data.

yellow Com/Bus communication.

3 DIP switch for slave address (see detailed view)

4 interface parameter DIP switch (see detailed view)

5 Sensors for temperature, humidity

6 plug for connection, suitable for a solid conductor up to 0.8mm²

1: 24 V DC (+), 2: GND (-).

Data A: Modbus D0, Data B: Modbus D1.

The reference potential for data lines is GND (-) of the power supply.

7CO

2 sensor (only for the Sewi AQS/TH Modbus)

8 Cable bushing

A Mark for aligning the cover

Fig. 2

A Recess to open the housing.

When closing the housing, the recess aligns to

the marking on the skirting

A

Fig. 3

Open the housing. To do this, carefully lift the

cover from the skirting. Start at the recess (Fig.

2: A).

Fig. 4

Lead the power cable through the cable bus-

hing in the skirting.

Fig. 5

Screw the skirting to the wall or the ceiling.

Hole distance 60mm.

60mm

Fig. 6

Connect the power supply

1 (+)/2 (GND, -) and data lines

A (Modbus D0) / B (Modbus D1)

to their designated terminals.

The reference potential for data lines is GND (-)

of the power supply.

Fig. 7

Close the housing by positioning the cover and

snapping it into place. Position the recess in the

cover over the marking on the skirting (Fig. 1+2:

A).

EN

Sewi Modbus Indoor Sensors 2

Sewi Modbus Indoor Sensors • Version: 20.09.2022 • Technical changes and errors excepted. • Elsner Elektronik GmbH • Sohlengrund 16 • 75395 Ostelsheim • Germany • www.elsner-elektronik.de • Technical Service: +49 (0) 7033 / 30945-250

3.3. Bus communication

3.3.1. Bus load

The RS485 transceiver used has a 1/8 standard RS485 bus load (1/8 unit load) and

can achieve at least 2.4V at 54 Ohm. It is operated in the location of a bus with 32

users with standard bus load. If users with less than the standard bus load are con-

nected to an RS485 bus, then the bus can be operated with more users. For instan-

ce, if users with a 1/8 bus load are connected, then up to 32×8 = 256 users can be

connected to the bus.

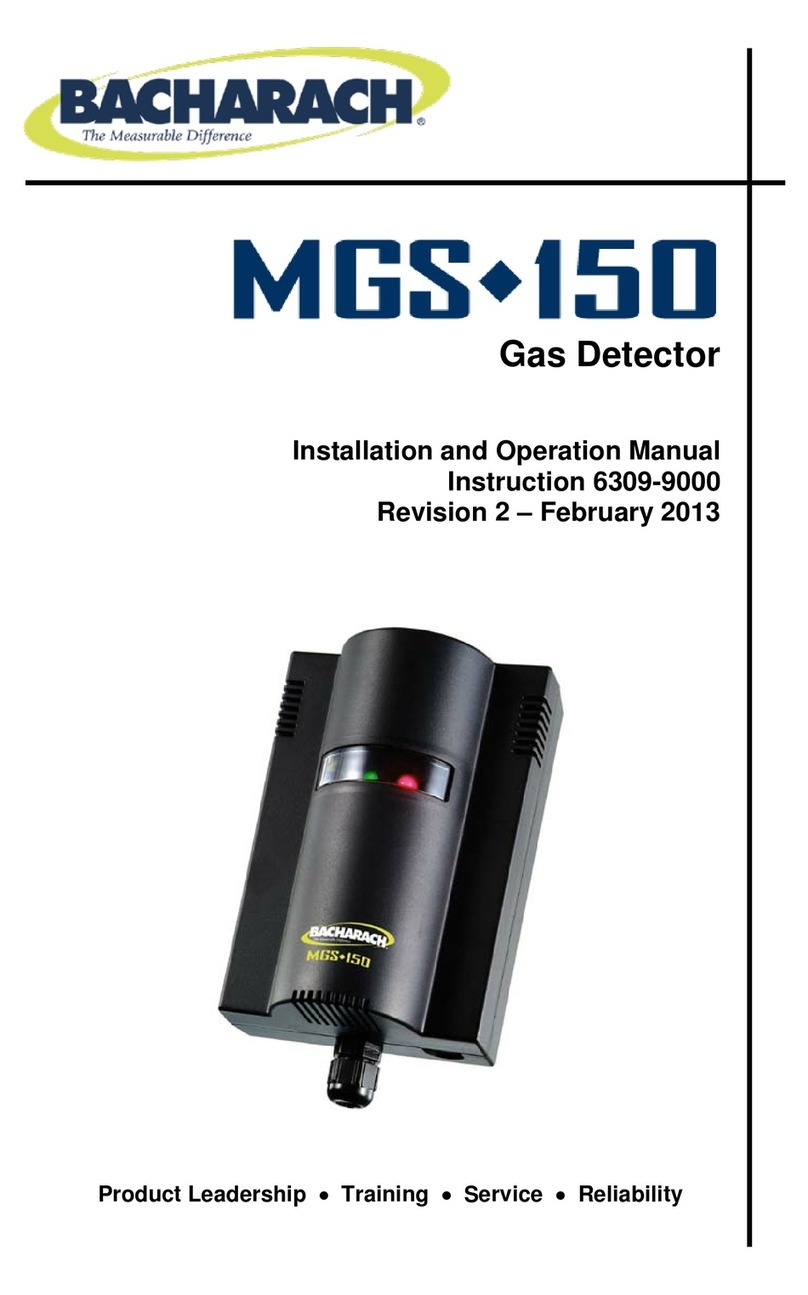

3.3.2. Setting the bus communication

If all DIP switches are in the OFF position (factory setting), the following parame-

ters are set:

Address: 1

Baud rate: 19,200

Parity: Even

Timing: Off

Setting the slave address:

The slave address is set in the 8-bit DIP switch “address”. Address 1 is selected, if

all switches are at OFF. Address 0 is reserved for broadcast information. Addresses

larger than 247 are invalid.

The address has binary coding. So, for example, switches 1, 2, 3, 4 and 6 need to

be set to ON for address 47.

Interface parameters:

The interface parameters are set in the second 8-bit DIP switch. If the first 4 swit-

ches are set to OFF, the binary rate setting is 19,200 baud. If one of these switches

is set to ON, it has the corresponding baud rate.

Parity: If both switches are “ODD” and “NONE” on “OFF”, the parity is EVEN. Only

“ODD” or “NONE” can switch the corresponding parity check.

“EE MB” switch: without function

“TERM” switch: Bus termination 124 Ohms

4. Maintenance

The air slots on the side must not get dirty or covered. As a rule, it is sufficient to

wipe the device with a soft, dry cloth twice a year.

5. Transfer protocol

5.1. Sewi TH Modbus (30175):

5.1.1. Function 04H Read Input Register TH-AP Modbus

Before the first measurement and in case of a faulty sensor, all registers are at

“-32768”.

5.1.2. Query string from the master

Example query string for reading all data for slave address 1:

01H, 04H, 00H, 00H, 00H, 03H, B0H, 0BH

5.1.3. Output string for the master

Before the first measurement and in case of a faulty sensor, all registers are at

“-32768”.

5.2. Sewi AQS/TH Modbus

5.2.1. Function 04H Read Input Register TH-AP Modbus

Before the first measurement and in case of a faulty sensor, all registers are at “-

32768”.

5.2.2. Query string from the master

Example query string for reading all data for slave address 1:

01h, 04h, 00h, 00h, 00h, 05h, 30h, 09h

5.2.3. Output string for the master

Before the first measurement and in case of a faulty sensor, all registers are at “-

32768”.

6. Disposal

After use, the device must be disposed of in accordance with the legal regulations.

Do not dispose of it with the household waste!

Register Parameter Data Type Data Value Range

0 Temperature Signed 16Bit -400 to +1,250 -40 to +125°C

1 Relative humidity Signed 16Bit 0 to 1,000 0 to 100%

2 Dew point temperature Signed 16Bit -400 to +1,250 -40 to +125°C

Byte

no.

Variable Explanation

0 Slave address xx

1 Command 04H Read Input Registers

2 Start Address High Byte xx Register start address

3 Start Address Low Byte xx

4 Word Count High Byte xx Number of registers to read

5 Word Count Low Byte xx

6 CRC Low Byte xx

7 CRC High Byte xx

Byte

no.

Register

address

Variable Explanation

0 Slave address xx

1 Command 04H Read Input Register

2 Number of bytes xx Master requirement * 2

3 0 Temperature High Byte xx with prefix, value/10 =

Temperature xx.x°C

4 Temperature Low Byte xx

Fig. 8:

Detailed view of the DIP switches

5 1 Relative Humidity High

Byte

xx Value/10 = relative humidity

xx.x%

6 Relative Humidity Low

Byte

xx

7 2 Dew point Temperature

High Byte

xx with prefix, value/10 =

Dew point Temperature

xx.x°C

8 Dew point Temperature

Low Byte

xx

9 CRC Low Byte xx

10 CRC High Byte xx

Register Parameter Data Type Data Value Range

0 Temperature Signed 16Bit -400 to +1,250 -40 to +125°C

1 Relative humidity Signed 16Bit 0 to 1,000 0 to 100%

2 Dew point temperature Signed 16Bit -400 to +1,250 -40 to +125°C

3CO

2Signed 16Bit 100 to +10,000 100 to +10,000

4 CO2 module

Autocalibration Mode

1 = on; 0 = off

16 Bit 0 to 1

Byte

no.

Variable Explanation

0 Slave address xx

1 Command 04H Read Input Registers

2 Start Address High Byte xx Register start address

3 Start Address Low Byte xx

4 Word Count High Byte xx Number of registers to read

5 Word Count Low Byte xx

6 CRC Low Byte xx

7 CRC High Byte xx

Byte

no.

Register

address

Variable Explanation

0 Slave address xx

1 Command 04H Read Input Register

2 Number of bytes xx Master requirement * 2

3 0 Temperature High Byte xx Value/10 = with prefix,

Temperature xx.x°C

4 Temperature Low Byte xx

5 1 Relative Humidity High

Byte

xx Value/10 = relative humidity

xx.x%

6 Relative Humidity Low

Byte

xx

7 2 Dew point Temperature

High Byte

xx Value/10 = with prefix,

Dew point Temperature

xx.x°C

8 Dew point Temperature

Low Byte

xx

93 CO

2High Byte xx Value = CO2in xxx ppm

10 CO2Low Byte xx

11 4 Autocalibration Mode

High Byte

0 1 = on; 0 = off

12 Autocalibration Mode

Low Byte

xx

13 CRC Low Byte xx

14 CRC High Byte xx

Byte

no.

Register

address

Variable Explanation

This manual suits for next models

3

Other elsner elektronik Security Sensor manuals

Popular Security Sensor manuals by other brands

KRATOS SAFETY

KRATOS SAFETY FA 10 201 00 manual

Carrier

Carrier Graviner Mk7 INSPECTION & CLEANING INSTRUCTIONS

STEINEL

STEINEL IS 180-2 installation instructions

Honeywell

Honeywell C7076F Product handbook

Leeo

Leeo Smart Alert quick start guide

Honeywell

Honeywell Fire Sentry FS7-2173-2RP Installation guide and operating manual