Elster Instromet 2000 User manual

LV6.400

FIRMWARE LV6.400

Model 2000 iss 21

202/02-09

MODEL 2000 FLOW COMPUTER

INSTRUMENT INSTRUCTION MANUAL

Model 2000 issue 21 Page No 2

In the design and construction of this equipment and instructions contained in this manual,

due consideration has been given to safety requirements in respect of statutory industrial

regulations. Users are reminded that these regulations similarly apply to installation,

operation and maintenance, safety being mainly dependent upon the skill of the operator

and strict supervisory control.

Model 2000 issue 21 Page No 3

Model 2000 issue 21 Page No 4

CONTENTS Page No.

1. INTRODUCTION...........................................................................................................................................................1

2. GENERAL DESCRIPTION............................................................................................................................................2

2.1. MODEL 2000FLOW COMPUTER FACILITIES.......................................................................................................2

2.1.1. FLOW COMPUTER TYPES............................................................................................................................2

2.1.2. FLOW COMPUTER OPERATING MODES.....................................................................................................3

2.2. FRONT PANEL CONTROLS....................................................................................................................................5

2.2.1. KEY FUNCTIONS............................................................................................................................................5

2.2.1.1. MENU SCROLL UP AND DOWN KEYS.....................................................................................................5

2.2.1.2. RETURN or ENTER KEY............................................................................................................................5

2.2.1.3. INFORMATION KEY...................................................................................................................................5

2.2.1.4. FUNCTION KEYS.......................................................................................................................................5

2.2.1.5. EXPONENT KEY.........................................................................................................................................5

2.2.1.6. NUMERIC KEYS.........................................................................................................................................5

2.2.1.7. PRINTER KEY.............................................................................................................................................5

2.2.2. INDICATOR LEDS...........................................................................................................................................6

2.2.3. FRONT PANEL PROGRAMMING PORT........................................................................................................6

2.2.4. DISPLAY..........................................................................................................................................................7

2.2.5. MAIN MENU FUNCTIONS ..............................................................................................................................8

2.2.6. MAIN MENU FUNCTION Totals......................................................................................................................9

2.2.7. MAIN MENU FUNCTION Line Conditions.....................................................................................................10

2.2.8. MAIN MENU FUNCTION Coriolis Meter .......................................................................................................10

2.2.9. MAIN MENU FUNCTION Grab Sampler.......................................................................................................11

2.2.10. MAIN MENU FUNCTION Chromatograph ....................................................................................................11

2.2.11. MAIN MENU FUNCTION Station Controller..................................................................................................11

2.2.12. MAIN MENU FUNCTION PID Controller.......................................................................................................11

2.2.13. MAIN MENU FUNCTION Gas Data ..............................................................................................................12

2.2.14. MAIN MENU FUNCTION Liquid Data ...........................................................................................................12

2.2.15. MAIN MENU FUNCTION Settings ................................................................................................................13

2.2.16. MAIN MENU FUNCTION Preset Data ..........................................................................................................13

2.2.17. MAIN MENU FUNCTION Edit .......................................................................................................................14

2.2.18. MAIN MENU FUNCTION Output set-up........................................................................................................15

2.2.19. MAIN MENU FUNCTION Alarms ..................................................................................................................16

2.2.20. MAIN MENU FUNCTION Events ..................................................................................................................16

2.2.21. MAIN MENU FUNCTION Display..................................................................................................................16

2.2.22. MAIN MENU FUNCTION System .................................................................................................................16

2.2.23. MAIN MENU FUNCTION Calibration ............................................................................................................17

2.2.24. MAIN MENU FUNCTION Board Info.............................................................................................................18

2.2.25. MAIN MENU FUNCTION Information ...........................................................................................................18

2.2.26. MAIN MENU FUNCTION General Info..........................................................................................................18

2.3. MODEL 2000 FUNCTIONS.................................................................................................................................... 19

2.3.1. PRE-SET VALUE OF TOTAL FLOWS..........................................................................................................19

2.3.2. RESET OF TOTAL FLOWS TO ZERO..........................................................................................................19

2.3.3. CLOCK...........................................................................................................................................................19

2.3.4. MAINTENANCE MODE.................................................................................................................................19

2.3.5. PROVING MODE...........................................................................................................................................19

2.3.6. HOLD TOTALS..............................................................................................................................................19

2.3.7. ACTIVE DATA SNAPSHOT REPORT...........................................................................................................19

2.3.8. CO2 EMISSION CALCULATION...................................................................................................................20

2.3.9. AGA 8 FULL CCOMPOSITION .....................................................................................................................20

2.3.10. AGA 10 VoS CALCULATION ........................................................................................................................20

2.3.11. LUBRICATION MODULE ..............................................................................................................................20

2.4. INPUT SIGNALS ....................................................................................................................................................22

2.4.1. TURBINE METER..........................................................................................................................................22

2.4.1.1. MINIMUM INPUT FREQUENCY...............................................................................................................22

2.4.1.2. TURBINE METER LINEARISATION.........................................................................................................22

2.4.1.3. BI-DIRECTION METER OPERATION ......................................................................................................22

2.4.1.4. BLADE FAILURE DETECTION.................................................................................................................23

2.4.2. ULTRASONIC GAS METER..........................................................................................................................25

2.4.2.1. UNIFORM SOFTWARE ............................................................................................................................25

2.4.2.2. METER CORRECTION FOR TEMPERATURE AND PRESSURE...........................................................25

Model 2000 issue 21 Page No 5

2.4.2.3. METER LINEARISATION..........................................................................................................................26

2.4.2.4. METER ALARMS......................................................................................................................................26

2.4.2.4.1. ACCOUNTABLE METER ALARMS................................................................................................... 26

2.4.2.4.2. NON-ACCOUNTABLE METER ALARMS..........................................................................................26

2.4.3. ORIFICE PLATE & VENTURI TUBE MEASUREMENT................................................................................ 27

2.4.3.1. DIFFERENTIAL PRESSURE MEASUREMENT....................................................................................... 28

2.4.3.1.1. DIFFERENTIAL PRESSURE UNITS................................................................................................. 28

2.4.3.1.2. HART TRANSMITTER DIFFERENTIAL PRESSURE INPUTS..........................................................28

2.4.3.1.3. ANALOGUE TRANSMITTER DIFFERENTIAL PRESSURE INPUTS...............................................28

2.4.3.2. MASS FLOW MEASURMENT LINEARISATION...................................................................................... 28

2.4.3.3. WET GAS FLOW MEASUREMENT..........................................................................................................29

2.4.3.3.1. WET GAS FLOW MEASUREMENT 1................................................................................................ 29

2.4.3.3.2. WET GAS FLOW MEASUREMENT 2................................................................................................ 29

2.4.4. CORIOLIS METER........................................................................................................................................ 29

2.4.4.1. CORIOLIS METER PULSE OUTPUT.......................................................................................................29

2.4.4.2. CORIOLIS METER SERIAL OUTPUT......................................................................................................30

2.4.4.3. CORIOLIS METER CALCULATIONS....................................................................................................... 30

2.4.5. PRESSURE AND TEMPERATURE INPUTS................................................................................................ 32

2.4.5.1. PRESSURE UNITS...................................................................................................................................32

2.4.5.2. TEMPERATURE UNITS............................................................................................................................32

2.4.5.3. HART TRANSMITTER PRESSURE AND TEMPERATURE INPUTS......................................................32

2.4.5.4. ANALOGUE TRANSMITTER PRESSURE AND TEMPERATUREINPUTS............................................ 34

2.4.5.5. PRT TEMPERATURE INPUT ...................................................................................................................34

2.4.5.6. PRESSURE & TEMPERATURE SENSOR SCALING..............................................................................34

2.4.5.7. AVERAGE PRESSURE, TEMPERATURE & DENSITY........................................................................... 34

2.4.6. MULTIPLE TRANSMITTER INPUTS.............................................................................................................35

2.4.7. GAS DATA INPUT.........................................................................................................................................35

2.4.7.1. NORMAL OPERATION.............................................................................................................................36

2.4.7.2. ALARM OPERATION................................................................................................................................37

2.4.7.3. GAS CHROMATOGRAPH INPUT ............................................................................................................37

2.4.7.4. ANALOGUE TRANSMITTER INPUTS FOR GAS DATA..........................................................................37

2.4.7.5. HEATING VALUE UNITS.......................................................................................................................... 37

2.4.7.6. AVERAGE GAS DATA..............................................................................................................................38

2.4.8. DENSITY TRANSDUCER INPUTS...............................................................................................................38

2.4.8.1. MULTIPLE DENSITY TRANSDUCER INPUTS........................................................................................38

2.4.8.2. SOLARTRON DENSITY TRANSDUCER INPUTS ................................................................................... 39

2.4.8.3. SARASOTA DENSITY TRANSDUCER INPUTS......................................................................................41

2.4.9. RELATIVE DENSITY TRANSDUCER INPUT...............................................................................................41

2.4.10. SWITCH STATUS INPUTS ...........................................................................................................................42

2.4.11. STATION PRESSURE AND TEMPERATURE INPUTS................................................................................ 43

2.4.11.1. STATION PRESSURE UNITS.............................................................................................................. 43

2.4.11.2. STATION TEMPERATURE UNITS.......................................................................................................43

2.4.11.3. HART TRANSMITTER STATION PRESSURE AND TEMPERATURE INPUTS.................................43

2.4.11.4. ANALOGUE TRANSMITTER STATION PRESSURE AND TEMPERATURE INPUTS.......................44

2.4.11.5. STATION PRESSURE & TEMPERATURE SENSOR SCALING.........................................................44

2.4.12. SMART INDEX AND ENCODER INPUT.......................................................................................................44

2.4.13. ANALOGUE INPUT FOR GRAB SAMPLER CAN LEVEL INDICATION.......................................................44

2.5. OUTPUT SIGNALS................................................................................................................................................45

2.5.1. ANALOGUE OUTPUT SIGNALS...................................................................................................................45

2.5.2. PID CONTROL ANALOGUE OUTPUT SIGNALS......................................................................................... 45

2.5.3. SWITCHED OUTPUT SIGNALS ...................................................................................................................47

2.6. ALARMS, WARNINGSAND FAULTS....................................................................................................................47

2.6.1. ACCOUNTABLE ALARMS............................................................................................................................47

2.6.1.1. GENERAL ACCOUNTABLE ALARMS......................................................................................................47

2.6.1.2. TURBINE ACCOUNTABLE ALARMS.......................................................................................................48

2.6.1.3. ULTRASONIC ACCOUNTABLE ALARMS................................................................................................48

2.6.1.4. DIFFERENTIAL PRESSURE ACCOUNTABLE ALARMS ........................................................................48

2.6.1.5. DENSITY ACCOUNTABLE ALARMS.......................................................................................................48

2.6.1.6. STATION ACCOUNTABLE ALARMS.......................................................................................................49

2.6.1.7. SMART INDEX ACCOUNTABLE ALARMS.............................................................................................. 49

2.6.1.8. CORIOLIS METER ACCOUNTABLE ALARMS........................................................................................49

2.6.1.9. GRAB SAMPLER ACCOUNTABLE ALARMS .......................................................................................... 49

2.6.2. NON-ACCOUNTABLE ALARMS...................................................................................................................49

Model 2000 issue 21 Page No 6

2.6.2.1. GENERAL NON ACCOUNTABLE ALARMS.............................................................................................49

2.6.2.2. TURBINE NON ACCOUNTABLE ALARMS..............................................................................................50

2.6.2.3. ULTRASONIC NON ACCOUNTABLE ALARMS.......................................................................................50

2.6.2.4. DIFFERENTIAL PRESSURE NON ACCOUNTABLE ALARMS ...............................................................50

2.6.2.5. DENSITY ACCOUNTABLE ALARMS.......................................................................................................50

2.6.2.6. SMART INDEX NON ACCOUNTABLE ALARMS..................................................................................... 50

2.6.2.7. CORIOLIS METER NON ACCOUNTABLE ALARMS...............................................................................50

2.6.2.8. GRAB SAMPLER NON ACCOUNTABLE ALARMS.................................................................................50

2.6.4. FAULTS.........................................................................................................................................................51

2.6.5. WARNINGS...................................................................................................................................................51

2.6.6. HIGH AND LOW FLOW ALARMS.................................................................................................................51

2.6.7. CLEARING OF ALARMS...............................................................................................................................51

2.7. PULSED OUTPUTS FOR TOTAL FLOWS............................................................................................................52

2.8. PULSED OUTPUTSFOR CONTROL FUNCTIONS..............................................................................................54

2.8.1. FLOW DIRECTION OUTPUT........................................................................................................................54

2.8.2. FIXED OUTPUT.............................................................................................................................................54

2.8.3. DIGITAL INPUT STATUS OUTPUT.............................................................................................................. 54

2.8.4. VALVE CONTROL OUTPUT.........................................................................................................................54

2.8.5. FUNCTION OUTPUT.....................................................................................................................................54

2.8.6. GRAB SAMPLER OUTPUT SIGNALS..........................................................................................................54

2.8.6.1. GRAB SAMPLER OUTPUT OPERATION................................................................................................54

2.8.6.1.1. CONFIGURATION SETTINGS..........................................................................................................54

2.8.6.2. GRAB SAMPLER CALCULATIONS..........................................................................................................55

2.9. COMMUNICATIONS PORTS.................................................................................................................................56

2.10. INPUT 2 BOARD................................................................................................................................................57

2.11. NETWORK 2 COMMUNICATION BOARD........................................................................................................58

2.13. PRINTER FACILITY...........................................................................................................................................59

2.14. POWER SUPPLY +24V dc OPERATION..........................................................................................................59

3. INSTALLATION, INITIALISATION & CALIBRATION.................................................................................................. 60

3.1. MECHANICAL INSTALLATION..............................................................................................................................60

3.2. ELECTRICAL INSTALLATION...............................................................................................................................60

3.2.1. POWER SUPPLY..........................................................................................................................................60

3.2.2. TRANSMITTER INPUT CONNECTIONS......................................................................................................60

3.2.3. HART TRANSMITTER INPUT CONNECTIONS........................................................................................... 60

3.2.4. OUTPUT SIGNAL CONNECTIONS ..............................................................................................................60

3.3. INITIALISATION.....................................................................................................................................................60

3.3.1. INTERNAL SWITCHES.................................................................................................................................60

3.3.2. SETTING THE INTERNAL SWITCHES........................................................................................................ 60

3.3.3. OPERATION..................................................................................................................................................61

3.4. SOFTWARE INSTALLATION.................................................................................................................................61

3.5. CALIBRATION........................................................................................................................................................61

3.5.1. INPUT SIGNALS............................................................................................................................................61

3.5.1.1. DIGITAL INPUT SIGNALS........................................................................................................................61

3.5.1.2. HART INPUT SIGNALS ............................................................................................................................61

3.5.1.3. ANALOGUE INPUT SIGNALS..................................................................................................................62

3.5.2. OUTPUT SIGNALS........................................................................................................................................63

3.5.2.1. DIGITAL OUTPUT SIGNALS....................................................................................................................63

3.5.2.2. ANALOGUE OUTPUT SIGNALS..............................................................................................................63

4. MAINTENANCE...........................................................................................................................................................64

4.1. INITIAL CHECKS.................................................................................................................................................... 64

4.2. REPLACEMENT PARTS........................................................................................................................................64

4.3. INPUT BOARD LINK SETTINGS...........................................................................................................................65

4.4. INPUT 2 BOARD LINK SETTINGS........................................................................................................................65

4.5. INPUT 2 BOARD 4 WIRE PRT LINK SETTINGS...................................................................................................66

4.6. OUTPUT BOARD LINK SETTINGS.......................................................................................................................66

4.7. DISPLAY BOARD LINK SETTINGS....................................................................................................................... 67

4.8. PRT INPUT BOARD LINKSETTINGS...................................................................................................................67

4.9. COMMS BOARD LINK SETTINGS........................................................................................................................67

APPENDIX 1 Alarm Information...........................................................................................................................................68

APPENDIX 1a Alarm, Warning and Fault Codes..........................................................................................................68

APPENDIX 1b Parameter Symbols For Non-Accountable Alarms................................................................................68

APPENDIX 1c Parameter Symbols for Accountable Alarms.........................................................................................69

APPENDIX 1d Temperature Alarm...............................................................................................................................72

Model 2000 issue 21 Page No 7

APPENDIX 1e Fault Codes...........................................................................................................................................72

APPENDIX 1f Warning Codes......................................................................................................................................72

APPENDIX 2 Event Codes...................................................................................................................................................73

APPENDIX 3 Gas Chromatographs Supported................................................................................................................... 75

APPENDIX 3a Instromet Encal 2000,Daniels 2251, Daniels 2551 and ABB 8X00 Chromatographs.......................... 76

APPENDIX 3b Yamatake Model HGC303 Chromatograph.......................................................................................... 78

APPENDIX 3c Siemens Optichrome Chromatograph...................................................................................................79

APPENDIX 3d Rosemount GCX Chromatograph.........................................................................................................80

APPENDIX 3e Instromet Station Controller Type 793-7SC Chromatograph Emulation...............................................81

APPENDIX 3f Instromet Model 2000 and ENSonic Chromatograph Emulation...........................................................82

APPENDIX 3g ABB Model 3100 Chromatograph.........................................................................................................83

APPENDIX 3h Instromet ENCAL 3000 Chromatograph...............................................................................................84

APPENDIX 3i Siemens Maxum II Chromatograph.......................................................................................................86

APPENDIX 3j Daniels 2350 Chromatograph...............................................................................................................87

APPENDIX 4 External Connections..................................................................................................................................... 89

APPENDIX 5 Coriolis Communications...............................................................................................................................93

APPENDIX 6 Ultrasonic Meters...........................................................................................................................................94

APPENDIX 6a Instromet QSonic...................................................................................................................................94

APPENDIX 6b Daniels Senior Sonic.............................................................................................................................95

APPENDIX 6c FlowSIC 600..........................................................................................................................................96

APPENDIX 6d Panametrics GM 868.............................................................................................................................96

APPENDIX 6e Panametrics IGM 878............................................................................................................................97

APPENDIX 7 FIGURE LIST................................................................................................................................................. 99

Model 2000 Flow Computer Instruction Manual

1.0 INTRODUCTION

Model 2000 issue 21 Page No 1

1. INTRODUCTION

The INSTROMET Model 2000 Flow Computer is designed to calculate the total energy, volume and instantaneous flow rates

of gas and alternatively Liquids. Calculation is carried out using inputs from pulse generating turbine meters or from

ultrasonic gas meters or from differential pressure measurement across orifice plates together with temperature sensors and

transmitters for line pressure. The Model 2000 uses pre-set or active input values of relative density, gas composition data

and heating value, active values can be received directly from a gas chromatograph or can be written serially from a

supervisory system.

The flow of gas is calculated using gas compressibility (Z factor) methods selected from a list of which includes AGA 8, ISO

12213 and AGA 3 NX19 as well as fixed factors for certain applications. As an alternative the flow of gas can be calculated

using a transducer input for line density.

The flow of liquid is calculated using fixed or measured factors for density and relative density and correction based upon

measured temperature and pressure of the Liquid in accordance with API standard chapters 11.2.1M, 11.2.2M & 12.

The Model 2000 has the facility of both high and low alarms on all active input signals, the alarms can be selected to enable

a default value to be used in flow calculation for the parameter in the alarm condition. Indication is given of the time of

occurrence and clearance of the alarm state, alarm output signals are also provided.

A feature of the Model 2000 is that it can use digital communication to the differential pressure, pressure and temperature

transmitters using the HART protocol eliminating the need for calibration of the Model 2000. This feature also eliminates the

errors in flow measurement due to ambient temperature effects on the Model 2000, only the temperature coefficient of the

transmitters contribute to the error.

As an alternative the Model 2000 can be operated from transmitters that supply a 4–20mA current output and also direct

from a 100 ohm platinum resistance thermometer for temperature measurement, these types of input are measured using

analogue inputs and a high resolution A-D converter. The analogue inputs are calibrated using software.

The Model 2000 has two RS232/RS485 serial data outputs which can provide Modbus RTU or ASCII communication

protocol for operation with system devices and a serial ASCII protocol compatible with most printers.

To provide maximum security of operating data and flow measurement while maintaining flexibility with the auxiliary

functions, the Model 2000 is provided with an edit facility where selected data can be changed while security can be

preserved with critical data.

All input and output signals are tested to ensure that they are within the designed operating limits, an alarm display records

the time when alarms occur and clear. During an alarm condition the total flows can be selected to be displayed on separate

counters.

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 2

2. GENERAL DESCRIPTION

The Model 2000 Flow Computer comprises a standard size half width 19 inch rack which contains plug-in printed circuit

boards connected to a mother board.

The Model 2000 front panel contains a liquid crystal display, keyboard, display buttons and indicator LED's. The liquid crystal

display (LCD) is a graphic dot matrix type which is used to display all of the data entered and flow information. Thekeyboard

is used to select the data to be entered into the Model 2000 memory and select all of the displayed information.

Input and output signals are connected to the Model 2000 by 9 pin D type connectors and plug in terminal blocks located at

the rear or the unit. The Model 2000 is operated from a 24Vdc. supply.

The front and rear panel arrangement are shown in figures 1and 2.

2.1. MODEL 2000 FLOW COMPUTER FACILITIES

2.1.1. FLOW COMPUTER TYPES

The Model 2000 Flow Computer can be configured into the following basic types of measurement device.

a) Turbine Gas 1 Stream, 2 Stream or 3 Stream. t1, t2, t3

Gas flow computer 1, 2 or 3 measurement streams using Turbine or pulse type meters as the primary

flow measurement device and Pressure, Temperature andCompressibility for flow correction.

b) Ultrasonic Gas 1 Stream. u1

Gas flow computer 1 measurement stream using an Instromet Ultrasonic meter as the primary flow

measurement device (Uniform communication to meter) and Pressure, Temperature and

Compressibility for flow correction.

Gas flow computer 1 measurement stream using an FlowSIC 600 ultrasonic meter, Panametrics

GM868 or Daniel Senior Sonic ultrasonic meter as the primary flow measurement device (Modbus

RTU communication to meter) and Pressure, Temperature and Compressibility for flow correction.

c) Ultrasonic Gas 2 Streams or 3 Streams. u2, u3

Gas flow computer 2 or 3 measurement streams using Instromet Ultrasonic meters as the primary

flow measurement devices (Modbus RTU multidrop communication to meter) and Pressure,

Temperature and Compressibility for flow correction.

Gas flow computer 2 or 3 measurement streams using an FlowSIC 600 ultrasonic meter,

Panametrics GM868 or Daniel Senior Sonic ultrasonic meter as the primary flow measurement

devices (Modbus RTU multidrop communication to meter) and Pressure, Temperature and

Compressibility for flow correction.

d) Orifice Gas 1 Stream or 2 Stream. o1

Gas flow computer 1 or 2 measurement streams using Orifice plate measurement as the primary flow

measurement device and Pressure, Temperature and Compressibility for flow correction.

e) Turbine DensityGas 1 Stream. td1

Gas flow computer 1 measurement stream using Turbine or pulse type meter as the primary flow

measurement device and Density measurement for flow correction.

f) Ultrasonic Density Gas 1 Stream. ud1

Gas flow computer 1 measurement stream using an Instromet Ultrasonic meter as the primary flow

measurement device and Density measurement for flow correction.

g) Orifice Density Gas 1 Stream. od1

Gas flow computer 1 measurement stream using Orifice plate measurement as the primary flow

measurement device and Density measurement for flow correction.

h) Turbine Liquid 1 Stream, 2 Stream or 3 Stream. lt1, lt2, lt3

Liquid flow computer 1, 2 or 3 measurement streams using Turbine or pulse type meters as the

primary flow measurement device andTemperature for flow correction.

i) Turbine Liquid Density 1 Stream. ltd1

Liquid flow computer 1 measurement stream using Turbine or pulse type meters as the primary flow

measurement device and Line Density for flow correction.

j) Ultrasonic Liquid 1 Stream. lu1

Liquid flow computer 1 measurement stream using an Instromet Ultrasonic meter as the primary flow

measurement device and Temperature for flow correction.

k) Venturi 1 Stream or 2 Stream. vt1, vt2

Steam flow computer 1 or 2 measurement streams using Venturi measurement as the primary flow

measurement device and Pressure, Temperature and Compressibility for flow correction. This flow

computer is for STEAM measurement only.

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 3

l) Station Controller. stn

Device to calculate Station Flow values from up to 5 individual flow computers and to distribute gas

data information to those flow computers.

m) Wet Gas Venturi 1 Stream WGV1

Steam flow computer 1 measurement stream using Venturi measurement as the primary flow

measurement device and Pressure, Temperature and Compressibility for flow correction. This flow

computer is for Wet Gas measurement only.

n) Wet Gas Venturi type 2 flow line Stream WGV21

Flow line Steam flow computer measurement stream using Venturi measurement as the primary flow

measurement device Mass flow transmitter incorporating measurements for Differential Pressure,

Pressure, Temperature and Compressibility for flow correction. This flow computer is for Wet Gas

measurement only.

o) Liquid Coriolis Meter 1 Stream or 2 Stream. lc1, lc2

Liquid flow computer 1 or 2 measurement streams using Micro Motion type Coriolis Meter

measurement as the primary flow measurement device and Density measurement device. Optional

Pressure and Temperature measurement for flow correction.

The basic type selected must be configured into the M2000 using the set-up software, this will then determine the circuit

boards required and inputs and outputs to be configured.

The Model 2000 will calculate the volume of gas or liquids using pre-set or active gas data and active input signals for

pressure and temperature and either inputs from pulse generating turbine meters, a high frequency pulse input used for flow

calculation and a low (or reference) frequency input from the index or from an Instromet type Ultrasonic gas meter or from

the differential pressure measurement across an orifice plate. The function and correction of all types of available input is

described in section 2.3 of this manual.

The flows calculated are displayed on the LCD display as a 12 digit number (8 digits- decimal- 4 digits) with the scaling

factor, units and symbol.

e.g. +Vn1 = 12345678.1234 X 100 m3

The scaling factor (symbol twf) is entered via the keyboard. The Model 2000 can be selected to total the flow on a separate

counter when an alarm condition occurs.

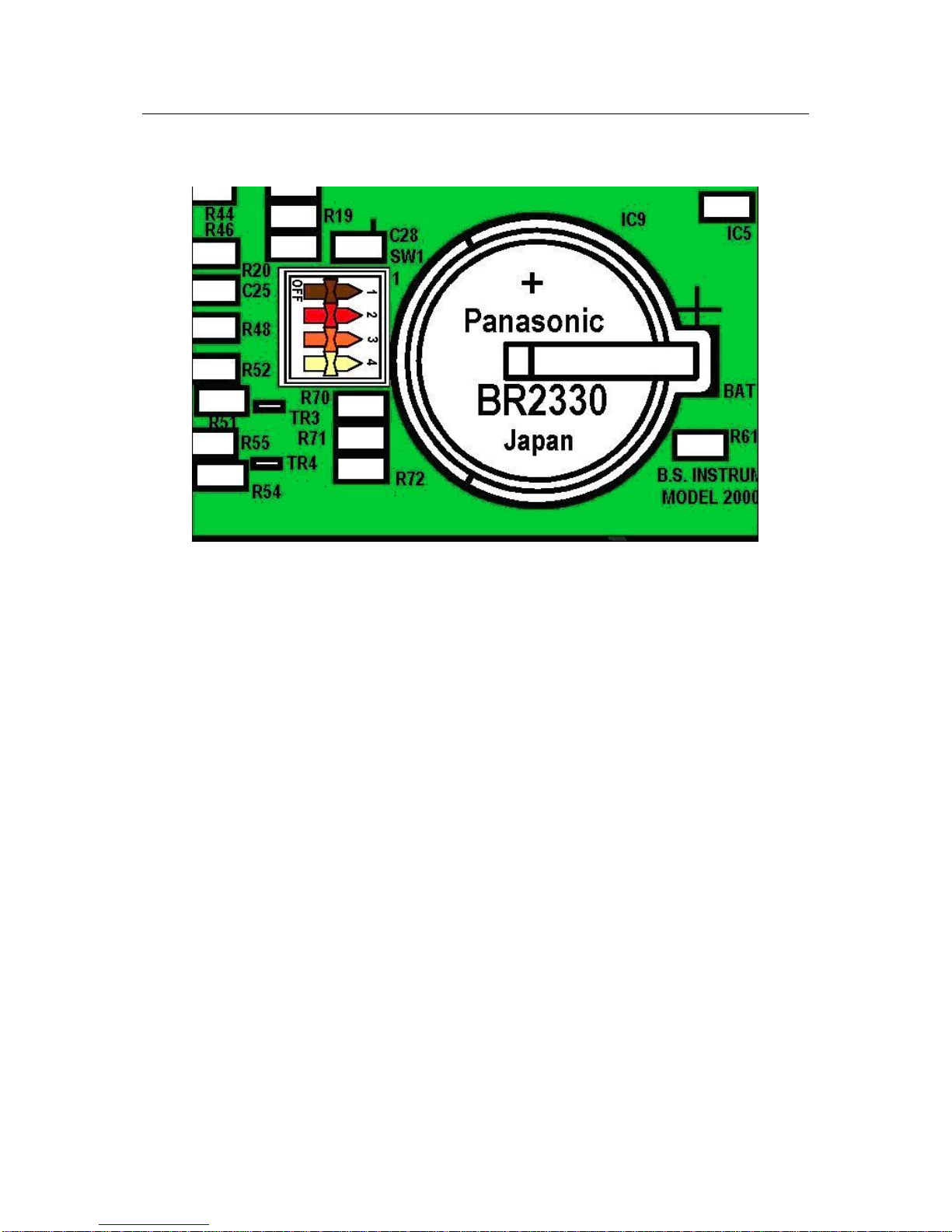

2.1.2. FLOW COMPUTER OPERATING MODES

The security, set-up and operational modes of the Model 2000 is initiated by the setting of mode switches located under an

access hole on the side of the Model 2000 the access hole is normally covered by a plastic cover and can also be sealed

using a self adhesive security label (See figure 16 for details) .

The designationand function of the mode switches is as follows:-

Normal RUN mode:-

Switch No. ON OFF

1 Security 1 Off Security 1 On

2 Security 2 Off Security 2 On

3 Run Mode

4 Backup Battery On Backup Battery Off

Programming Boot mode:-

Switch No. ON OFF

1 Security 1 Off Security 1 On

2 Irda Infra Red or Front Panel USB

Connector Rear Connector Skt 1

3 Boot Mode

4 Backup Battery On Backup Battery Off

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 4

View of Microprocessor Board Showing Mode Switches and Backup Battery

To place the Model 2000 in fully secure mode (i.e. no data can be altered either via communication or via the EDIT mode )

Mode switches 1 and 2 must be in the OFF position.

To place the Model 2000 in partial secure mode (i.e. selected data can be altered either via communication or via the EDIT

mode ) one of the security Mode switches must be OFF the other must be ON.

To place the Model 2000 in fully open mode (i.e. all data can be altered either via communication or via the EDIT mode )

Mode switches 1 and 2 must be in the ON position.

Mode switch 3 should only be set to the Boot (OFF) position if a new operating programme is going to be downloaded into

the machine. In all other modes of operation mode switch 3 must be placed in the run (ON) position.

Mode switch 4 enables the battery backup (ON/OFF) function for shipping, long term storage and transportation this should

be set to the OFF position, and should only be set to the ON position immediately prior to operation of the Model 2000.

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 5

2.2. FRONT PANEL CONTROLS

All of the controls necessary to operate the Model 2000 are located on the front panel and provide the following functions:-

2.2.1. KEY FUNCTIONS

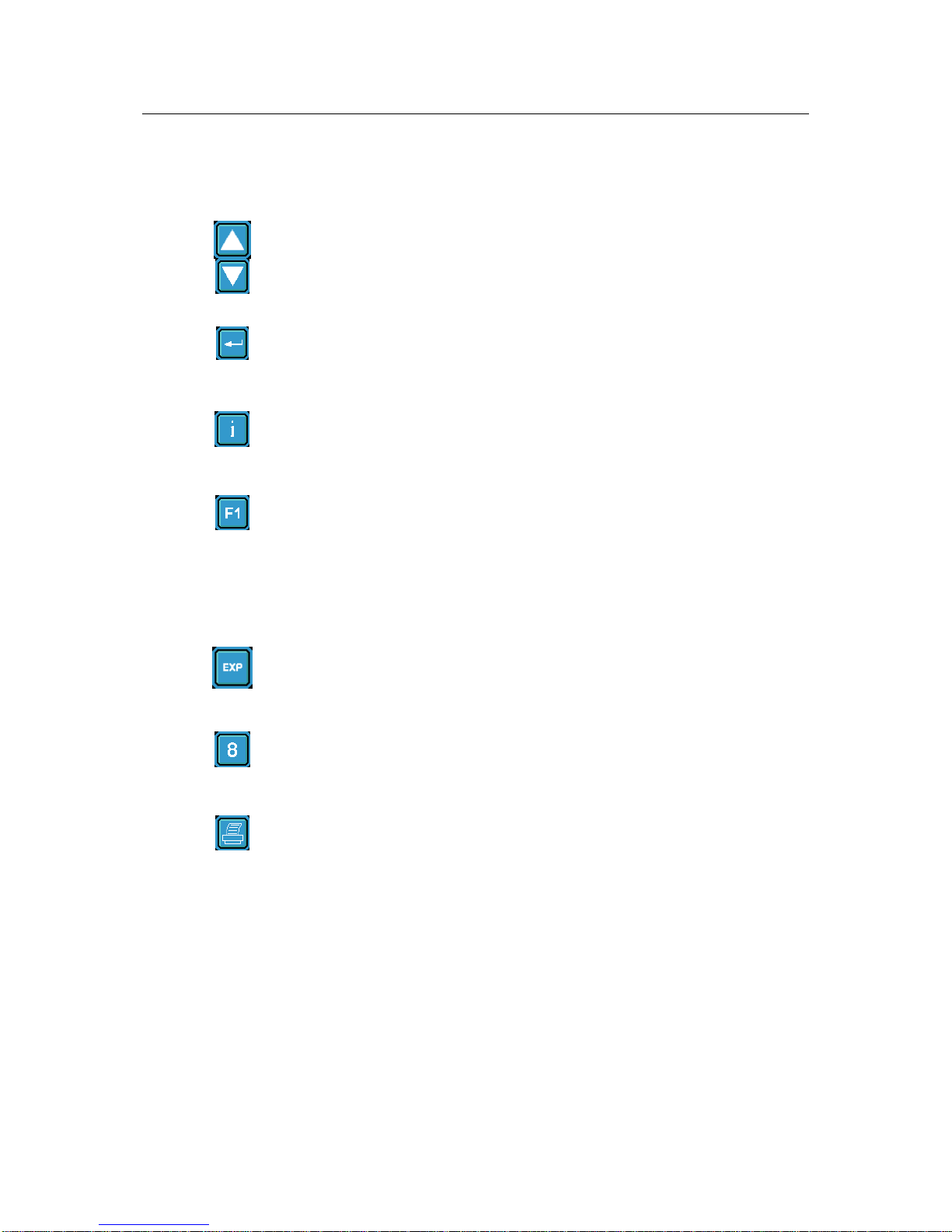

2.2.1.1. MENU SCROLL UPAND DOWN KEYS

SCROLL UP KEY Use to move the menu item highlight bar up to the required line of

data that is going to be selected.

SCROLL DOWN KEY Use to move the menu item highlight bar down to the required line of

data that is going to be selected.

2.2.1.2. RETURN or ENTER KEY

RETURN or ENTER The enter key allows the value of data to be entered or highlighted

item to be selected. It is generally used when an item of data is tobe

edited, selectedor confirmed.

2.2.1.3. INFORMATION KEY

INFORMATION KEY The information key can be used to provide additional screen helpor

information . Whenever the is shown in the display of the Model

2000 this key can be pressed and the additional information will be

shown as a helpor information box.

2.2.1.4. FUNCTION KEYS

FUNCTION KEYS The keys shown with the symbols [F1] , [F2] , [F3] & [F4] are the

function keys, these keys will have different operating functions

depending upon the particular page that is currently in use. The

particular function for each individual key is shown directly above

each key as a highlighted bar on the Model 2000 display. Note that

not function keys will operate on all pages, if a function key has no

function then there will be no function indicated above it.

2.2.1.5. EXPONENT KEY

EXPONENT The exponent key (future use) can be used to exponent type

numbers where allowable.

This key currently has no function.

2.2.1.6. NUMERIC KEYS

NUMERIC KEYS The keys shown with the symbols [1], [2], [3], [4], [5], [6], [7], [8], [9],

[0], [.] & [-] can used when entering or editing numeric values into

the memory of the model 2000.

2.2.1.7. PRINTER KEY

PRINTER The printer key is a shortcut key to the printer function menu, this

key will only function if a printer has been set up in the Model 2000

and is functioning correctly. The symbol ¬will appear on the

bottom left hand corner of the display if there are printer reports

available to be printed.

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 6

2.2.2. INDICATOR LEDS

There are five indicator LED's on the Front panel of the Model 2000, from top to bottom these are as shown:-

Power ON GREEN

Accountable Alarm RED

Non-accountable Alarm RED

Fault RED

Low or High Flow Limit YELLOW

2.2.3. FRONT PANEL PROGRAMMING PORT

There are two types of Model 2000 Front Panel programming ports both have exactly the same function they differ in the

method of connection from a PC to the Model 2000.

On earlier models of the Model 2000 in the bottom left hand corner as shown in Figure 1 is a small opaque red window, this

is the Infra red programming port. It is designed such that a PC equipped with a Remote Infra red device connected

externally to one of its communication ports can send and receive data to the Model 2000 through this port, without any

physical contact.

On later models of the Model 2000 in the bottom left hand corner as shown in Figure 25 is a small USB A type connector,

this is the Front panel programming port. It is designed such that a PC equipped withUSB ports can be connected directly to

this connector using a USB A to A cable supplied with the Model 2000. Specific drivers which enable this function to work

correctly are supplied on the install disc of the Model 2000 together with installation instructions for the various PC windows

platforms.

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 7

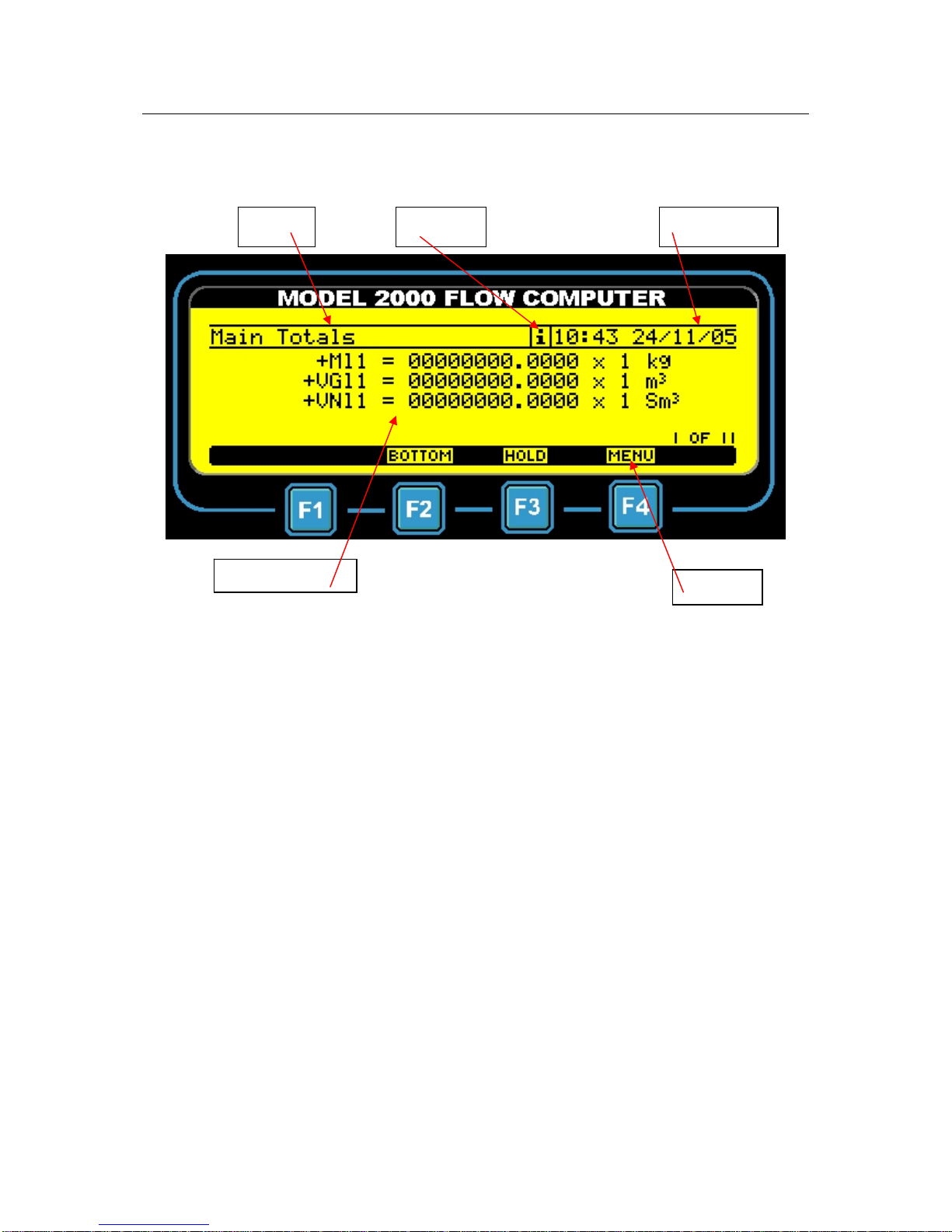

2.2.4. DISPLAY

The Display of the Model 2000 is divided into a number of sections as can be seen as follows:-

Typical Display Page

The top of the Display page shows the page title, the information symbol (if information is available on this page) and the

current Model 2000 time and date.

The centre section is the main display area this generally shows the selected data that is appropriate for this page, together

with the page number and total number of pages that applies to the current section.

The bottom line of the display is shown in reverse format and gives the current function of the four function keys F1, F2, F3

and F4.

Page Title Information Time and Date

Main Display Area Function

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 8

2.2.5. MAIN MENU FUNCTIONS

The main operating Menu of the Model 2000 can be accessed in a number of ways depending upon the current operational

state of the Model 2000 and the current display page. These methods are either to select Menu using the function keys, or to

select Main Menu from the current menu list or if the unit has just been switched on and is displaying the start up page, the

Main menu will be on the display.

The items available in the Main menu item list are as follows:-

Totals

Line Conditions

∗Coriolis Meter

∗Grab Sampler

∗Chromatograph

∗Station Controller

∗PID Controller

∗Liquid Data

∗Gas Data

Settings

Preset Data

Edit

∗Output set-up

Alarms

Events

Display

System

Calibration

Board Info

∗Information

General Info

Items marked ∗will only be shown in the Main Menu if they are selected to operate.

Depending upon the type of machine set-up or connected to, when some of the above items are selected the user will be

prompted with a sub-menu to select from the following:-

Station

General

Chromatograph

Stream 1

Stream 2

Stream 3

This menu would be limited to Station, General, Chromatograph, Stream 1 and 2 if the unit was only a two stream device,

and to General, Chromatograph and Stream 1 if the unit was a single stream device.

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 9

2.2.6. MAIN MENU FUNCTION Totals

This menu item is a read only display and when selected will show all the pages of flow totals availablein this machine these

will include:-

For Turbine Machines

+Vbu Uncorrected Volume from Meter “Un-haltable” i.e. always counts

+Vb Uncorrected Volume from Meter

+Vbc Uncorrected Volume corrected for meter non-linearity

+Vbcu Uncorrected Volume corrected for meter non-linearity “Un-haltable” i.e. always counts

+Vb Uncorrected Volume from Monitor

+Vn Corrected Volume

+Vnu Corrected Volume from Meter “Un-haltable” i.e. always counts

+M Mass

+Mu Mass “Un-haltable” i.e. always counts

+E Energy

+Eu Energy “Un-haltable” i.e. always counts

For Ultrasonic Machines

+Vbu Uncorrected Volume from Meter “Un-haltable” i.e. always counts

+Vb Uncorrected Volume from Meter

+Vbcu Uncorrected Volume corrected for meter non-linearity “Un-haltable” i.e. always counts

+Vb Uncorrected Volume from Monitor

+Vn Corrected Volume

+Vnu Corrected Volume from Meter “Un-haltable” i.e. always counts

+Vdry Corrected Volume of dry gas

+Vdryu Corrected Volume of dry gas “Un-haltable” i.e. always counts

+M Mass

+Mu Mass “Un-haltable” i.e. always counts

+E Energy

+Eu Energy “Un-haltable” i.e. always counts

For Wet Gas Venturimachines

+Mguc Mass gas from Venturi no correction for wetgas

+Mgc Mass gas from Venturi corrected for wet gas

+Mlc Mass liquid corrected

+Ngl Line Volume of gas

+Ngb Base Volume of gas

+Nll Line Volume of Liquid

+Nlb Line Volume of Liquid

+Mw Mass of Water

+Mc Mass of Condensate

All the above Venturi Totals are also available in un-haltable versions

For Wet Gas Venturi type 2 machines

+Mguc Mass gas from Venturi no correction for wetgas

+MgS Mass saturated gas from Venturi corrected for wet gas

+MgD Mass dry gas from Venturi corrected for wet gas

+ML Mass liquid corrected

+MTP Mass two phase product including Water

+MC Mass condensate liquid corrected

+MW Mass Water liquid corrected

+MM Mass Methanol liquid corrected

+Mhc Mass Hydro Carbon corrected

+VnG Standard Volume of gas

+VnC Standard Volume of condensate

+VnW Standard Volume of Water

+E Energy

All the above Venturi Totals are also available in un-haltable versions

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 10

For Coriolis meter machines

+Ml Mass of Liquid in kg primary flow source.

+Mls Mass of Liquid in kg secondary flow source.

+VGl Volumeof Liquid at Line conditions in m3

+VNl Volume of Liquid at base conditions in m3

+Mw Mass of Water in kg.

+VGw Volume of Water at Line conditions in m3

+VNw Volume of Water at base conditions in m3

+Mc Mass of Condensate in kg.

+VGc Volume of Condensate at Line conditions in m3

+VNc Volume of Condensate at base conditions in m3

All the above Coriolis Totals are also available in un-haltable versions

Primary and secondary source from the Coriolis meter can be either serial data via Modbus communication or pulse

accumulation via pulse input.

For All machine types if enabled

+CO2 Mass of CO2

Which are then sub-divided into groups as follows:-

•Main Totals

•Alarm Totals

•Main Totals when HOLD function last operated

•Alarm Totals when HOLD function last operated

•Current 15 min, Hour, Day and Month non-accumulated Totals

•Previous 15 min, Hour, Day and Month non-accumulated Totals

•Last Day non-accumulated Totals

•Previous Hour, Day and Month accumulated Totals

•Previous Hour, Day and Month accumulated Alarm Totals

•Current Hour, Day and Month non-accumulated Alarm Totals

•Previous Hour, Day and Month non-accumulated Alarm Totals

•Last Day and non-accumulated Alarm Totals

The items will be divided into pages with a maximum of four items per page, each item will be displayed with the

corresponding symbols, scaling factors and units.

2.2.7. MAIN MENU FUNCTION Line Conditions

This menu item is a read only display and when selected will show all the pages of line conditions available in this machine

these will include:-

General sub-menu items, i.e. items that relate to the machine and not specifically to streams.

Digital Input Status The Status inputs appear as Digital i/p X.Y on the M2000 display

Where

Xis the input number 1, 2 or 3

Y is the USER Board Slot number 1, 2, 3, 4 or 5.

Stream Nsub-menu items, i.e. items that relateto the streams

Flow Rates

Peak Flow rates and Time and Date of occurrence

Line Pressure and Temperature and status

Line and Base Compressibility

Line Density

Correction Factors

Meter Information

Station sub-menu items, i.e. items that relate to station functions only in a Multistream machine.

Station Flow rates

The items will be divided into pages with a maximum of four items per page, each item will be displayed with the

corresponding symbols, scaling factors and units.

2.2.8. MAIN MENU FUNCTION Coriolis Meter

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 11

This menu item is a read only display and when selected will show the status of any serially connected Liquid Coriolis Meter

and Meter data, this page will only be shown if a Coriolis M2000 type has been selected using the M2000 windows software.

The data items available are as follows:-

Current read Status Reading Data or Waiting

Last read Status OK or Comms Problem

CM Status Meter Status Information

CM Mass Meter Mass flow rate in kg/hr

CM Density Meter Density in kg/m3

CM Volume Meter Volume flow rate in m3/day

CM temperature Meter Temperature

CM pressure Meter Pressure

CM Mass and Volume Totals

The items will be divided into pages with a maximum of four items per page.

2.2.9. MAIN MENU FUNCTION Grab Sampler

This menu item is a read only display and when selected will show a sub menu as below:-

Sampler 1

Sampler 2

Sampler 1 shows the status and operational state of Liquid Grab Sampler 1 and Sampler 2 shows the same information for

Liquid Grab Sampler 2. The data items available are as follows:-

Sampler current and remaining Volume in cc

Sampler Volume in m3

Required, current and remaining Sampler pulses to fill the can

Sampler Rate in cc/m3

Can fill level in %

Grab Sampler Status

The items will be divided into pages with a maximum of four items per page.

2.2.10. MAIN MENU FUNCTION Chromatograph

This menu item is a read only display and when selected will show the status of any connected Gas Chromatograph, this

page will only be available if a gas chromatograph has been set up using the M2000 windows software. The data items

available are as follows:-

Current read Status Reading Data or Waiting

Last read Status OK or Comms Problem

Chr Stream Number

Chr Analysis N/A, Analysis or Calibrate

Chr State N/A, Idle, Analysis or Calibrate

Chr Status 1 16 bits of Status

Chr Status 2 16 bits of Status

The items will be divided into pages with a maximum of four items per page. See page 75 for details of Gas Chromatographs

that are supported and the Modbus Communication addresses that are read by the Model 2000. The above is a typical

example so notall theabove data items may be available for alltypes of Gas Chromatograph.

2.2.11. MAIN MENU FUNCTION Station Controller

This menu item is a read only display and when selected will show all the pages of data relating to the set up of the Station

Controller. This will include:-

Number of Connected units and their communication ids.

Current operating Status of Read and Writes to those units.

2.2.12. MAIN MENU FUNCTION PID Controller

This menu item is a read only display and when selected will show all the pages of available information that relate to the

Proportional, Integral and Derivative control outputs in this machine.

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 12

2.2.13. MAIN MENU FUNCTION Gas Data

This menu item is a read only display and when selected will show a sub menu as below:-

Preset

Received

Used

Hourly Average

Daily Average

The menu item Preset contains all gas data max, min, hi, lo and keypad entry values.

The menu item Received contains all gas data values that have been received either from a connected gas

chromatograph or from a supervisory system or as analogue inputs, together with the status of that

number for example N/A which means not available, a value has not been received.

The menu item Used contains the gas data values that are being used in the Model 2000 and the origin of

the number i.e.Keypad, OK or LGV.

The menu items Hourly and Daily averages display the current average values for all the gas components.

The Hourly average is calculated over the last complete hour and the daily average is calculated over

the last complete day from contract hour to contract hour. The Hourly and Daily Averages can be

selected to be calculated from either received Chromatograph values, received Serial (Modbus)

values or received analogue values.

All of the items of Gas data in this machine will be divided into pages with a maximum of four items per page, each item will

be displayed withthe correspondingsymbols, scaling factors and units.

2.2.14. MAIN MENU FUNCTION Liquid Data

This menu item is a read only display and when selected will show a sub menu as below:-

Preset

Received

Used

Hourly Average

Daily Average

The menu item Preset contains Specific Gravity (relative density) Liquid data, max, min, hi, lo and keypad

entry values together with theunits of temperature measurement for liquid correction.

The menu item Received contains Specific Gravity (relative density) Liquid data values that have been

received either from a connected chromatograph or from a supervisory system or as analogue inputs,

together with the status of that number for example N/A which means not available, a value has not

been received.

The menu item Used contains the Specific Gravity (relative density) Liquid data values that are being used in

the Model 2000 and the origin of the number i.e. Keypad, OK or LGV.

The menu items Hourly and Daily averages display the current average values for Specific Gravity (relative

density). The Hourly average is calculated over the last complete hour and the daily average is

calculated over the last complete day from contract hour to contract hour. The Hourly and Daily

Averages can be selected to be calculated from either received Chromatograph values, received

Serial (Modbus) values or received analogue values.

Model 2000 Flow Computer Instruction Manual

2.0 GENERAL DESCRIPTION

Model 2000 issue 21 Page No 13

2.2.15. MAIN MENU FUNCTION Settings

This menu item is a read only display and when selected will show all the pages of Setting Information available in this

machine these will include:-

General sub-menu items that relate to the machine.

Serial Number up to 8 digits

Contract Hour 0 = Midnight

Energy Units MJ, Kwh, kcal, therms or BTU

Maintenance Mode On or Off

Chromatograph sub-menu items that relate to the gas chromatograph.

Chromatograph type Selected from a list

Communication ID Modbus id

Read Time How often data is read

Chromat status Ignore GC alarms

C6+ code % of higher components

Stream N sub-menu items that relate tothe streams

CompressibilityEquation in use

Combustion / Base Temperatures

Meter Correction Equations in use

Orifice Equations and calculation methods in use

Energy calculation using Superior or Inferior Heating Values

Total or Flow rate suspension under Low Flow conditions

Total or Flow rate suspension under Alarm conditions

Alarm Counter functions

Gas data alarm use Last Good Value or Keypad

Gas Chromatograph stream number

Station sub-menu items that relate to station functions. Only in a Multistream machine.

Sum Stream into Station Totalsor Flow rates

The items will be divided into pages with a maximum of four items per page, each item will be displayed with the

corresponding symbols, scaling factors and units.

2.2.16. MAIN MENU FUNCTION Preset Data

This menu item is a read only display and when selected will show all the pages of Pre-set Data available in this machine

these will include:-

Alarm Levels (not gas data)

All Constants

Base Conditions

Number of Pressure Sensors and On/Off for each

Pressure Sensor selection

Pressure sensor deviation and keypad values

Pressure Units and Gauge or Absolute

Number of TemperatureSensors and On/Off for each

Temperature Sensor selection

Temperature sensor deviationand keypad values

The items will be divided into pages with a maximum of four items per page, each item will be displayed with the

corresponding symbols, scaling factors and units. Any item that has no value or has not been set will be shown as --------

Table of contents

Other Elster Instromet Desktop manuals

Popular Desktop manuals by other brands

Dell

Dell Precision 7960 Service manual

Compaq

Compaq dc5850 - Microtower PC Technical reference guide

Dell

Dell Inspiron 24-5490 Setup and specifications

Lenovo

Lenovo ThinkCentre 0401 Hardware Maintenance Manual

Lenovo

Lenovo ThinsStation P320 Hardware Maintenance Manual

IBM

IBM NetVista A20 Guide de l'utilisateur