Elster Instromet enCore FC1 User manual

Flow Computer

enCore FC1

Manual

Part 2: Operating Instructions

FC1-BA2-EN a 2013-06-26

Page 2 of 78 Operating Instructions enCore FC1

Elster GmbH

Schloßstraße 95a

D - 44357 Dortmund / Germany

Tel.: +49 - 2 31 - 93 71 10 0

Fax: +49 - 2 31 - 93 71 10 99

E-mail: Support-DO@elster.com

enCore FC1 Operating Instructions Page 3 of 78

Contents

1Introduction 6

1.1Scope of Delivery 6

1.2About these Instructions 6

1.3Explanation of Symbols 8

1.3.1Presentation of Hazard Warnings 8

1.3.2Presentation of Safety Instructions 9

1.3.3Presentation of Tips and Recommendations 9

1.4Target Group Definition 9

1.5Limitation of Liability 10

1.6Applicable Standards and Guidelines 11

2Safety 13

2.1General Safety Instructions 13

2.2Intended Use 15

2.3Unauthorized Users 16

2.4Operator Liability 16

3Design and Function 18

3.1enCore and enSuite 18

3.2FC1 Functional Description 18

3.3Device Description 20

3.4Control Panel 21

3.4.1Device Keys 22

3.4.2Touch Screen 22

3.4.3Operation and Navigation within the Display 22

3.4.4Security Switch 22

3.4.5LEDs 23

3.5Interfaces (Rear Side of Device) 25

3.6Available Process Boards 26

3.6.1ExMFE5 Process Board 26

3.6.2MFE7 Process Board 27

3.6.3MSER4 Process Board 28

3.6.4MFA8 Process Board 28

Page 4 of 78 Operating Instructions enCore FC1

4Assembly and Installation 29

4.1Line Connection 29

4.2Power Supply and Grounding 31

4.3Mounting of Process Boards 31

4.4Connection Diagrams 37

4.4.1Pt100 (EEx i) via ExMFE5 Board 37

4.4.2Pt100 (EEx d) via MFE7 Board 38

4.4.3Analog Pressure Transmitter (EEx i) via ExMFE5 Board 38

4.4.4Analog Pressure Transmitter (EEx d) via MFE7 Board 39

4.4.5Analog Pressure Transmitter (EEx i) via MFE7 Board 39

4.4.6HART Transmitter (EEx i) via ExMFE5 Board 40

4.4.7HART Transmitter (EEx d) via MFE7 Board (Internal Power Supply) 41

4.4.8HART Transmitter (EEx d) via MFE7 Board (External Power Supply) 42

4.4.9HART Transmitter (EEx i) via MFE7 Board 43

4.4.10HART Transmitter (EEx d) via MFE7 Board (redundant) 44

4.4.11HART Transmitter (EEx i) via MFE7 Board (redundant) 45

4.4.12Gas Meter (Turbine): Encoder Index, 2 LF/HF Sensors (EEx i) via

ExMFE5 Board 46

4.4.13Gas Meter (Turbine): Encoder Index, 2 LF/HF Sensors (EEx i) via

MFE7 Board 46

4.4.14Gas Meter (Turbine): SMRI2 Bi-directional: 2 HF Sensors, Flow

Direction Detection (EEx i) via MFE7 Board 47

4.4.15Q.Sonic Ultrasonic Gas Meter: Serial RS485 (EEx d) via MFE7 Board 48

4.4.16FLOWSIC600 Ultrasonic Gas Meter: Serial RS485 (EEx d) via MFE7

Board 49

4.4.17Serial Interface through COM Port (CPU or MSER4 Board) 50

4.4.18Analog Output (0/4...20mA) via MFA8 Board 51

4.4.19Message Output via MFA8 Board 52

4.4.20Pulse Output via MFA8 Board 53

5Device Configuration and Commissioning 54

5.1enSuite Software 54

5.1.1System Requirements 54

5.1.2enSuite Installation 54

5.1.3Installation of the USB driver 59

5.2Device Parameterization 62

enCore FC1 Operating Instructions Page 5 of 78

5.3Commissioning the Measurement System 63

5.3.1Checking Device Settings 63

5.3.2Checking Measurement Input Values 63

5.3.3Checking Output Signals 64

5.3.4Checking Digital Communication (Modbus, etc.) 64

5.3.5Checking Measurements and Calculations 64

5.3.6Sealing (if necessary) 64

6Maintenance 65

6.1Battery Replacement 65

6.2Cleaning 68

6.3Customer Service 69

6.4Replacement Parts and Accessories 69

6.5Warranty Conditions 70

7Decommissioning / Disposal 71

7.1Storage 71

7.2Disposal 72

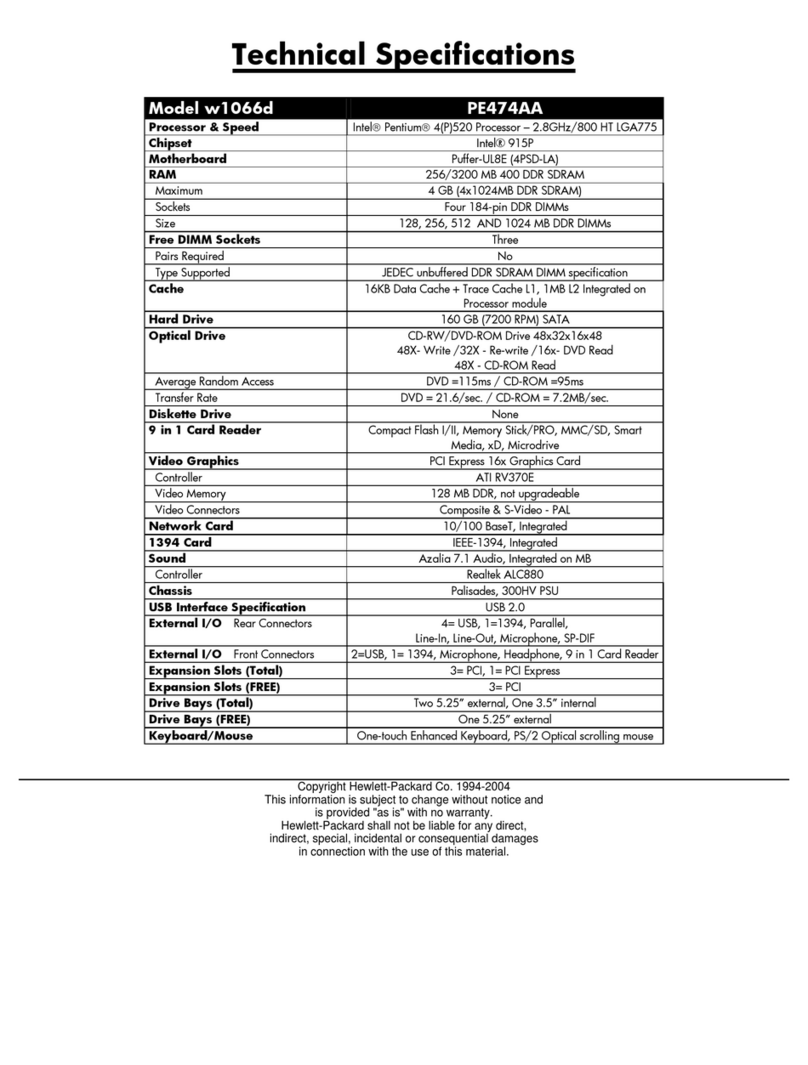

8Technical Data 73

8.1General 73

8.2Inputs 74

8.3Outputs 75

8.4Interfaces for Digital Communication 75

9Index 76

10Appendix 78

1 Introduction

Page 6 of 78 Operating Instructions enCore FC1

1 Introduction

1.1 Scope of Delivery

The enCore FC1's scope of delivery includes:

enCore FC1 electronic flow computer

Confirmation of conformity or factory test protocol

Dispatch list / delivery note

FC1 manual - Part 1 (Brief instruction) and Part 2 (Operating

instructions)

enSuite installation CD

USB cable (A/B type)

Accessories (plugs incl. housing)

1.2 About these Instructions

The documentation on hand is Part 2 (Operating instructions) of the overall

documentation, and describes the assembly, installation, commissioning and

maintenance of the enCore FC1 flow computer (called FC1 below).

A hard copy of this portion of the documentation is included in the delivery

scope of the FC1.

These instructions make it possible to work with the FC1 in a safe and

efficient manner.

Compliance with all the safety and handling instructions specified in these

operating instructions is a prerequisite to working with the FC1 in a safe

manner and using it properly, and for obtaining accurate measurement and

calculation results.

In addition, compliance is also necessary with the guidelines, standards,

local accident prevention regulations and general safety regulations that

apply for the FC1's area of application.

Introduction 1

enCore FC1 Operating Instructions Page 7 of 78

The entire FC1 documentation consists of three parts:

Part 1 Brief instruction

Part 1 of the documentation briefly describes the legally relevant

properties of the FC1 flow computer. Apart from topics such as General

device information and Technical data, Display and Operation, Basic

functionalities and Description of compulsory AFBs (Application

Function Blocks), there is an Appendix including approval certificates

and other legally relevant documents (if applicable). A hard copy of this

portion of the documentation is included in the scope of delivery.

Part 2 Operating instructions

Part 2 is the document on hand. A hard copy of this portion of the

documentation is included in the scope of delivery.

Part 3 Configuration of the Device Software

Description of the Basic System including SFBs

(System Function Blocks, basic functionalities)

Descriptions of available AFBs (Application

Function Blocks)

Part 3 is a composition of several documents and is delivered in

electronic form only.

This part of the manual is intended for all specialized readers who are

interested in AFB functionality details. In particular, these

documentations explain how to configure the device parameterization

according to requirements. The information provided is completed by

the parameter descriptions included in the enSuite online help (enSuite

= PC software supporting enCore devices).

These instructions are a component of the product and must be kept in the

immediate vicinity of the FC1, so installation, operational, maintenance and

cleaning personnel may access them at any time.

The graphical illustrations in these instructions serve to depict the facts that

are being explained, and are therefore not necessarily true to scale and may

differ from the actual design of the FC1.

1 Introduction

Page 8 of 78 Operating Instructions enCore FC1

The data and material properties that are presented below are

guidelines. They must be reviewed for each individual case and

corrected if necessary.

1.3 Explanation of Symbols

1.3.1 Presentation of Hazard Warnings

Hazard warnings indicate hazardous situations that may result in material

damage and bodily harm up to death if disregarded.

Hazardous warnings are presented as described below:

DANGER WORD!

Type of danger

Consequences in case of non-compliance

- Avoiding danger

The danger word signals the hazard level:

DANGER!

…indicates an immediately hazardous situation that leads to death or

severe injury.

WARNING!

…indicates a possibly hazardous situation that may lead to death or

severe injury.

CAUTION!

…indicates a possibly hazardous situation that may lead to slight or

minor injuries.

ATTENTION!

…indicates a possibly hazardous situation that may lead to material

damage.

Introduction 1

enCore FC1 Operating Instructions Page 9 of 78

1.3.2 Presentation of Safety Instructions

Safety instructions include notes and information that can lead to FC1

functions not working correctly or not working at all if disregarded.

Safety instructions are presented as described below:

Safety instruction text

1.3.3 Presentation of Tips and Recommendations

Tips include notes and information that make it easier for the user to operate

the FC1.

Tips are presented as described below:

Tip text

1.4 Target Group Definition

The present documentation is directed to qualified electricians in the fields of

switch cabinet construction and maintenance, as well as qualified personnel

with specialized knowledge in device assembly, installation and

commissioning.

The qualifications for different areas of activity are listed below:

Trained individual

was instructed by the plant operator in an informational session on the

tasks assigned to him or her, and on possible hazards in case of

improper behavior.

Specialist

has the ability, because of his or her technical training, knowledge and

experience, as well as his or her knowledge of the relevant regulations,

to carry out the work to the FC1 assigned to him or her, and to

recognize and avoid possible hazards on his or her own.

1 Introduction

Page 10 of 78 Operating Instructions enCore FC1

Gas specialist

has the ability, because of his or her technical training, knowledge and

experience, as well as his or her knowledge of the relevant standards

and regulations, to carry out work to gas systems, and to recognize

possible hazards on his or her own. A gas specialist receives training for

the specific location in which he or she works, and is acquainted with

the relevant standards and regulations.

Metrology expert

has the ability and is authorized, because of his or her technical training,

knowledge and experience, to carry out fiscally protected work to gas

systems within the scope of legal metrology. A metrology expert is

trained to work with fiscally protected devices and systems, and is

acquainted with the relevant standards and regulations that apply in

specific countries.

Qualified electrician

has the ability, because of his or her technical training, knowledge and

experience, as well as his or her knowledge of the relevant standards

and regulations, to carry out work to electrical systems, and to recognize

and avoid possible hazards on his or her own. A qualified electrician

receives training for the specific location in which he/she works, and is

acquainted with the relevant standards and regulations.

1.5 Limitation of Liability

All specifications and instructions in these operating instructions were

compiled under consideration of applicable standards and regulations, the

current state of the art and the knowledge and experience we gained over

the years.

The manufacturer assumes no liability for loss due to:

Non-compliance with these operating instructions

Use of the device not in accordance with its intended use

Use of the device by non-instructed personnel

Unauthorized device modifications

Introduction 1

enCore FC1 Operating Instructions Page 11 of 78

Technical changes

Use of non-authorized replacement parts

The actual scope of delivery may differ from the explanations and

descriptions included here in case of special device designs, the use of

additional ordering options or because of the latest technical changes.

The obligations arranged in the delivery contract apply, as do the General

Terms and Conditions, manufacturer delivery conditions and current legal

regulations that apply at the time the contract was concluded.

Read through these operating instructions carefully before

beginning any work to and with the FC1, especially before

commissioning the device!

The manufacturer assumes no liability for loss and malfunctions that

result from non-compliance with these instructions.

We reserve the right to make technical changes within the scope of

improving performance characteristics and continuous development of the

device.

1.6 Applicable Standards and Guidelines

The construction, production and operation of the FC1 are based on the

following standards and guidelines:

EN 12405-1

(Gas meters - Conversion devices - Part 1: Volume conversion)

EN 61000-6-2

(Electromagnetic compatibility - Immunity for industrial environments)

EN 61000-6-3

(Electromagnetic compatibility - Emission standard for residential,

commercial and light-industrial environments)

EN 60079-0

(Explosive atmospheres - Equipment - General requirements)

1 Introduction

Page 12 of 78 Operating Instructions enCore FC1

EN 60079-11

(Explosive atmospheres - Equipment protection by intrinsic safety "i")

EN 60079-17

(Explosive atmospheres - Electrical installations inspection and

maintenance)

EN 60079-25

(Explosive atmospheres - Intrinsically safe systems)

ISO 12213

Parts 1-3 (Natural gas – Calculation of compression factor)

ISO 6976

(Natural gas – Calculation of calorific values, density, relative density,

and Wobbe index from composition)

Safety 2

enCore FC1 Operating Instructions Page 13 of 78

2 Safety

2.1 General Safety Instructions

WARNING

Risk of explosion

A risk of explosion exists if the FC1 is improperly installed

and connected!

The FC1 must be installed outside of ex-zones 0, 1 and 2.

The FC1 can be equipped with hardware modules that are

approved as associated electrical apparatus of category ib

with intrinsically safe electrical circuits according to

EN 60079-11 (i.e. input boards with the designation ExMFE5).

The FC1 is therefore suitable for being connected to

transmitters, pulse and signal generators that are located in

hazardous areas (e.g. zone 1). A mixed connection of

intrinsically safe and non-intrinsically safe circuits to these

hardware modules is not permitted.

Only intrinsically safe protection class [EEx ib] II C

temperature and pressure transmitters must be connected to

the respective ExMFE5 connection terminals.

Only pulse transmitters of protection class [EEx ib] II C must

be connected to the respective ExMFE5 connection terminals.

All signals from the potentially explosive area (zone 0, zone 1,

zone 2) that are connected to hardware modules other than

ExMFE5 must be blocked off by means of appropriate ex-

isolators.

The regulations in the relevant standards, especially

EN 60079-0, EN 60079-11, EN 60079-17 and EN 60079-25,

must be obeyed unconditionally.

2 Safety

Page 14 of 78 Operating Instructions enCore FC1

The following safety and warning instructions must be observed

unconditionally:

Any individual appointed to perform work to or with the FC1

must read and understand these operating instructions before

beginning work. This also applies if the individual concerned

has already worked with such a device or a similar one, or was

instructed by the manufacturer.

In order to avoid risks and to ensure that the FC1 performs in

an optimal manner, no changes or modifications that were not

expressly authorized by the manufacturer may be performed to

the device.

The FC1 must not be exposed to temperatures below -25°C or

above +60°C during storage.

A temperature that is between -10°C and +55°C must be

ensured while the FC1 is being operated.

The FC1 is supplied with power by means of 24V DC, and this

power supply must be protected externally using a 1A time-

delay fuse.

The grounding is connected to PE of the power supply socket

for equipotential bonding.

The range limits stated in the certificates of conformity for the

boards to be connected (e.g. EC type examination certificate

ATEX) must be observed.

If the device is used within the scope of legal metrology, the

range limits that are stated in the respective approval

certificate (e.g. EC type examination certificate MID) must be

observed.

Section 3.6: Available Process Boards contains a description of

process boards.

Safety 2

enCore FC1 Operating Instructions Page 15 of 78

2.2 Intended Use

The FC1 is designed and constructed solely for its intended use as

described here.

The FC1 is a process computer that handles the information of external

measurement devices and signal transmitters being connected to the FC1

device.

The FC1 is primarily used for gas measurement. In this case, the main task

of the device is to convert the gas volume measured at operating conditions

to base conditions (volume conversion). Additionally, the related thermal

energy and mass can be calculated. The measured and/or calculated data

can be logged and monitored.

The FC1 device may also carry out other functions and calculations (e.g. a

mass or volume conversion for liquids). Please refer to Part 3 of the FC1

Manual for a description of available functions (AFBs).

In addition, the FC1 can be used to measure, record and monitor other

process signals.

Compliance with all the specifications in these operating instructions also

falls under the device's intended use.

Any use of the FC1 that goes beyond or deviates from its intended use is

considered a misuse of the device, and may lead to hazardous situations.

Claims of any kind due to loss resulting from non-intended use of the device

are excluded.

2 Safety

Page 16 of 78 Operating Instructions enCore FC1

2.3 Unauthorized Users

Individuals whose ability to react is impaired, e.g. because of drugs, alcohol

or medication as well as physical or health restrictions are not permitted to

operate, assemble or configure the device.

2.4 Operator Liability

The FC1 is used in industrial applications. The FC1 operator is therefore

subject to legal obligations of occupational health and safety.

In addition to the safety instructions in these operating instructions, current

regulations of safety, accident prevention and environmental protection must

be observed for the FC1 area of application.

The following items especially apply:

The operator must ensure compliance with the current regulations of

safety, accident prevention and environmental protection that apply for

the overall system in which the FC1 is integrated.

The operator must keep himself/herself informed of the applicable

occupational health and safety regulations, and determine, over the

course of a risk assessment, the additional risks that arise from the

specific working conditions when the FC1 is being used. The operator

must include these items in the form of operating instructions for the

FC1.

The operator must review, over the entire operational life of the FC1,

whether the operating instructions prepared by him or her correspond to

the current status of the bodies of regulations, and revise the

instructions if necessary.

When selecting personnel to operate the device, make sure you

comply with the specific regulations of the overall technical plant

that concern age and occupation.

Safety 2

enCore FC1 Operating Instructions Page 17 of 78

The operator must definitively regulate and establish the responsibilities

for FC1 assembly, connection, commissioning, operation and

maintenance.

The operator must ensure that all employees who work with the FC1

have read and understood these operating instructions. In addition, the

operator must train these personnel at regular intervals and inform them

of the risks involved with the device.

The operator of the overall system in which the FC1 is integrated must

provide personnel with the required protective equipment.

In addition, the operator is responsible for ensuring the FC1 is always in

technically perfect condition. The following items therefore apply:

The operator must ensure that the installation and maintenance work

described in these operating instructions are performed properly.

The operator must have all safety installations checked regularly to

ensure they function correctly and are complete.

3 Design and Function

Page 18 of 78 Operating Instructions enCore FC1

3 Design and Function

3.1 enCore and enSuite

enCore is the name of an Elster product platform for sophisticated

measuring instruments. All enCore devices are based on the same hardware

components and software concepts.

enSuite is the name of the PC software that supports enCore devices along

with a number of other Elster devices. The enSuite software provides tools

for configuration, parameterization, diagnosis, software download and other

services.

The enCore FC1 device is a process computer based on the enCore

platform.

3.2 FC1 Flow Computer: Functional Description

The FC1 is a process computer that is primarily used as flow computer for

natural gas, i.e. for measuring and calculating the gas flow (flow conversion).

Please refer to Part 3 of the FC1 manual for information about further fields

of application.

If the FC1 is used for flow conversion, various measuring instruments have

to be connected to the device (gas meters, pressure transmitters,

temperature transmitters and optional gas quality measurement devices).

The FC1 has different interface options available for each of these

measuring instrument types:

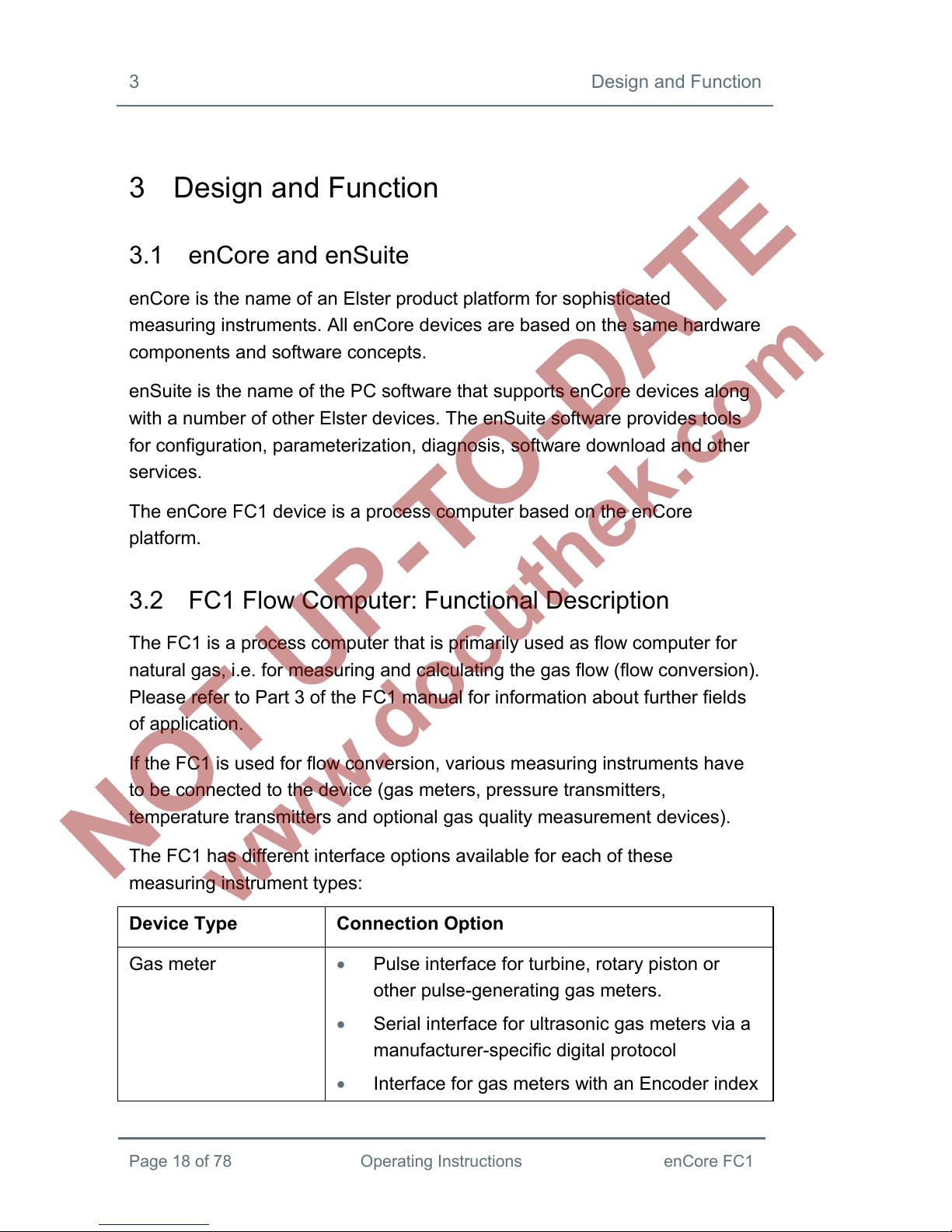

Device Type Connection Option

Gas meter Pulse interface for turbine, rotary piston or

other pulse-generating gas meters.

Serial interface for ultrasonic gas meters via a

manufacturer-specific digital protocol

Interface for gas meters with an Encoder index

Design and Function 3

enCore FC1 Operating Instructions Page 19 of 78

Pressure transmitter 4…20 mA analog input

HART protocol interface

Temperature

transmitter

Resistance input for Pt100 with 4-wire

technology

HART protocol interface

Gas quality

measurement devices

Serial interface

TCP/IP interface

Table 1

Number of streams and their flow directions

The number of streams and their flow directions is variable since device

hardware and software can be extended. This number depends upon the

number of board slots available, individual hardware settings and the

software configuration.

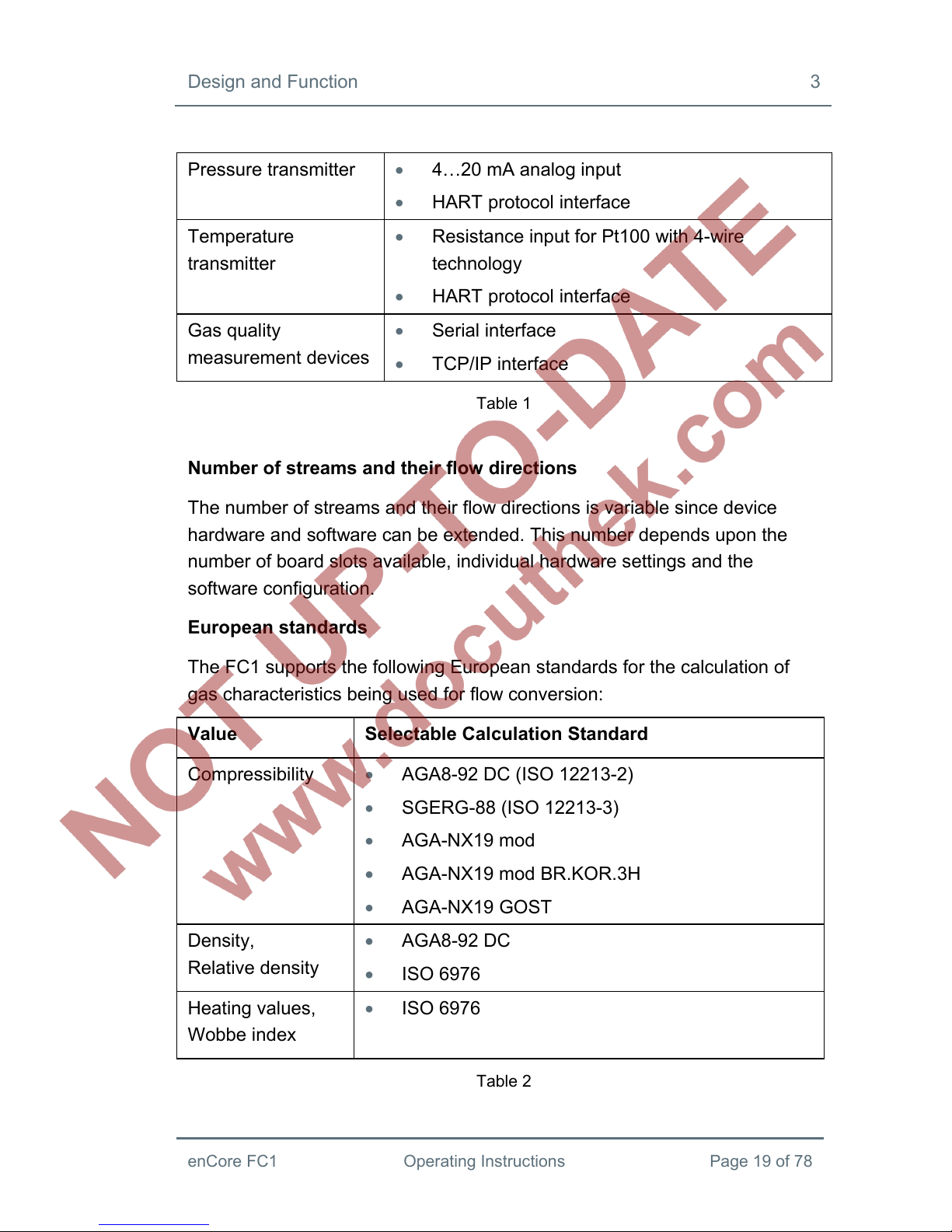

European standards

The FC1 supports the following European standards for the calculation of

gas characteristics being used for flow conversion:

Value Selectable Calculation Standard

Compressibility AGA8-92 DC (ISO 12213-2)

SGERG-88 (ISO 12213-3)

AGA-NX19 mod

AGA-NX19 mod BR.KOR.3H

AGA-NX19 GOST

Density,

Relative density

AGA8-92 DC

ISO 6976

Heating values,

Wobbe index

ISO 6976

Table 2

3 Design and Function

Page 20 of 78 Operating Instructions enCore FC1

Dependent on the field of application, other European or International

standards are supported as well.

3.3 Device Description

The FC1 is housed in a 19“ casing with a mounting width of 1/3 (max. 4

process boards) or a mounting width of 1/2 (max. 7 process boards). The

touch screen as well as 2 function keys and 5 navigation keys for operation

are located on the front of the device. In addition, the USB port, security

switch and two status LEDs are located on the front of the device.

At the rear side of the device, the CPU board provides a TCP/IP interface

and two RS232 / RS422 / RS485 serial interfaces. These interfaces are

provided in order to connect gas quality measurement devices or other

devices that have a protocol interface.

Various other I/O boards can be mounted from the rear side of the device.

The maximum number of boards depends upon the housing design. A

maximum of four process boards can be installed in a device with a

mounting width of 1/3, while a maximum of seven can be installed in a

device with a mounting width of 1/2.

The configuration of the I/O board mounting is variable. In principle, any I/O

board can be inserted into any slot. Dependent on the board type, there may

be individual restrictions (please refer to section 3.6, process board

descriptions).

The following board types are currently available:

ExMFE5 Ex input board

MFE7 input board

MFA8 output board

MSER4 serial process board

Section 3.6 contains a description of process boards.

Other manuals for enCore FC1

1

Table of contents

Other Elster Instromet Desktop manuals