ELSTO PT2-010 Series User manual

Power, Control &

Green Solutions

elsto.eu

T+31(0)88 7865200

Einfo@elsto.eu

English

Porter Series Controllers

PT2-05 / PT2-010 / PT2-010XX/XXX

Instruction Manual

ELSTO Drives & Controls Voorhout • Rotterdam • Weert • Hoogerheide • België T+31(0)88 7865200 E[email protected] Welsto.eu

ELSA010000-004 DRAFT 1

2

Section Page

1. Models ....................................................... 3

2. Do's and Don’ts ......................................... 3

3. Wiring ......................................................... 3

4. Power Connections .................................... 4

5. Throttle wiring ............................................. 4

Section Page

6. Battery and Motor Current ........................ 5

7. Mounting .................................................. 5

8. Dismantling ............................................... 6

9. Service ..................................................... 6

10. Specifications ........................................... 7

Index

ELSTO Drives & Controls Voorhout • Rotterdam • Weert • Hoogerheide • België T+31(0)88 7865200 E[email protected] Welsto.eu

ELSA010000-004 DRAFT 1

3

1. Models

The Porter is a simple, single direction controller designed for electric bicycles, golf caddies, small material handling machines, electric

wheelbarrows and other similar applications.

It has extremely simple wiring and operates over a wide battery voltage range (12v to 48v) so it is a very versatile controller. It also

accepts either a Hall effect throttle or a resistive potentiometer.

2. Do’s and Don’ts

Do not

• Do not allow the pot wires to short to ground or B+. This could

damage the controller.

• Do not allow water to enter the controller or contact the board.

• Do not turn acceleration or deceleration adjustments fully

clockwise (fast), we suggest no further than 9 o'clock (diagram

shows them central at 6 o'clock).

Do

• Do read the instructions thoroughly before installing the

controller.

• Do fit motor suppression components [see our website for

details].

• Do twist the motor wires together if possible.

• Do use proper 6.3mm push-on connectors. Elsto can supply a

suitable lead set.

• Do be aware that motor current is (sometimes much) greater

than battery current.

3. Wiring

Just seven connections are needed and are shown in the diagram below.

Motor + (internally connected to Battery +)

Motor -

Battery +

Battery -

3 wires for speed pot and ignition.

Porter 5-10-10XXX V2.4 07/19 Page 3 www.4qd.co.uk

3. Wiring

Just seven connections are needed and are shown in the diagram below.

Motor + (internally connected to Battery +)

Motor -

Battery +

Battery -

3 wires for speed pot and ignition.

Figure 1: Porter Wiring

ELSTO Drives & Controls Voorhout • Rotterdam • Weert • Hoogerheide • België T+31(0)88 7865200 E[email protected] Welsto.eu

ELSA010000-004 DRAFT 1

4

4. Power Connections

2.5mm² cable is adequate for most applications of the Porter 5, but 4mm2 or 6mm2 may be preferred, especially for the motor and for

the Porter 10.

Caution Take care when connecting the battery and motor wiring - connecting a battery wire to a motor terminal can destroy the

controller.

Motor Wiring

If the motor rotates in the wrong direction, exchange M+ and M- wires.

We recommend keeping the motor wires close together, and if possible twisting them together. If one is not already fitted, we also

recommend fitting a 10nF 100V disc ceramic motor suppression capacitor across the brushes of the motor.

Battery Wiring

Keep the battery wiring as short as possible. The Porter is protected against reversed battery (60v max) but will not work with the

battery reversed. Again, keep the motor wires close together and twisted together if possible.

Battery Circuit Breaker or Fuse

A circuit breaker or fuse is advised in the battery connections, to act as an emergency disconnect in the event of a fault in wiring or any

other component. In some applications such a circuit breaker is a legal requirement. A sensible rating for this breaker is the same as the

motor's continuous current. Otherwise a 30 amp breaker should be adequate for most uses with the Porter 5 or 60 amp with the Porter

10.

5. Throttle Wiring

Connections

Pin FunctionA 1k5 resistor to pin B

B 0v (internally connected to battery –ve via reverse polarity protection MOSFET)

C Speed voltage from pot (1-4V)

D 5V. This can feed up to 10mA at a battery voltage of 24V or lower.

E 1k5 resistor to pin D

10k Pot

Connects to pins A, C and E.

The ignition switch may be separate or a switched pot can be used.

Other pot values between 5k and 25k can be used, but be aware you

may need to use resistors [either the internal ones or external] to get

an input voltage between 1V & 4V to avoid dead areas at the top and

bottom of the pot travel. The ideal value of the resistors is 1/3 of the

pot value.

Magura Throttle

The Magura throttle, as supplied by Elsto is 5k. Be aware that the

wires on the Magura are slightly oversize for the IDC connector, we

recommend using a short length of 7 x 0.2mm cable as an adaptor to

prevent the pins of the connector shorting out.

Hall Effect Throttle

Connects to pins B, C and D. Pin D has 5v present to feed the pot

top. It should be the type than gives 1v at zero speed and 4v at full

speed. Some throttles are reversed and will not be suitable. Max Hall

current 10mA, for use on 12v and 24v only as standard [Hall throttles

can be used above 24v if a suitable resistor is added in series with

pin D]. There are many makes of Hall effect throttle and wiring colours

are not standardised.

Porter 5-10-10XXX V2.4 07/19 Page 4 www.4qd.co.uk

4. Power Connections

2.5mm² cable is adequate for most applications of the Porter 5, but 4mm2or 6mm2

may be preferred, especially for the motor and for the Porter 10.

Caution Take care when connecting the battery and motor wiring - connecting a

battery wire to a motor terminal can destroy the controller.

Motor Wiring

If the motor rotates in the wrong direction, exchange M+ and M- wires.

We recommend keeping the motor wires close together, and if possible twisting

them together. If one is not already fitted, we also recommend fitting a 10nF 100V

disc ceramic motor suppression capacitor across the brushes of the motor.

Battery Wiring

Keep the battery wiring as short as possible. The Porter is protected against

reversed battery (60v max) but will not work with the battery reversed. Again, keep

the motor wires close together and twisted together if possible.

Battery Circuit Breaker or Fuse

A circuit breaker or fuse is advised in the battery connections, to act as an

emergency disconnect in the event of a fault in wiring or any other component. In

some applications such a circuit breaker is a legal requirement.

A sensible rating for this breaker is the same as the motor's continuous current.

Otherwise a 30 amp breaker should be adequate for most uses with the Porter 5 or

60 amp with the Porter 10.

5. Throttle Wiring

Connections

Pin Function

A 1k5 resistor to pin B

B 0v (internally connected to battery –ve via reverse polarity protection

MOSFET)

C Speed voltage from pot (1-4V)

D 5V. This can feed up to 10mA at a battery voltage of 24V or lower.

E 1k5 resistor to pin D

10k Pot

Connects to pins A, C and E.

The ignition switch may be

separate or a switched pot can

be used.

Other pot values between 5k

and 25k can be used, but be

aware you may need to use

resistors [either the internal

Porter 5-10-10XXX V2.4 07/19 Page 5 www.4qd.co.uk

ones or external] to get an input voltage between 1V & 4V to avoid dead areas at

the top and bottom of the pot travel. The ideal value of the resistors is 1/3 of the pot

value.

Magura Throttle

The Magura throttle, as supplied by

4QD is 5k. Be aware that the wires

on the Magura are slightly oversize

for the IDC connector, we

recommend using a short length of

7 x 0.2mm cable as an adaptor to

prevent the pins of the connector

shorting out.

Hall Effect Throttle

Connects to pins B, C and D. Pin D has

5v present to feed the pot top.

It should be the type than gives 1v at

zero speed and 4v at full speed. Some

throttles are reversed and will not be

suitable. Max Hall current 10mA, for

use on 12v and 24v only as standard

[Hall throttles can be used above 24v if

a suitable resistor is added in series with

pin D]. There are many makes of Hall

effect throttle and wiring colours are not standardised.

Ignition Switch

An ignition switch should be connected in the pot or throttle circuit to switch off the

controller when not in use. Without this switch the controller is still powered up and

drains about 17mA from the battery.

When ignition is switched off, the controller will ramp the motor down to zero speed

(at whatever deceleration rate you have set) and then switch itself off.

Voltage Input

The Porter may be fed from a voltage

source between 1V and 4V. This can

be PWM supplied from a

microcontroller or even 4QD's own

DMR-203 radio control interface. The

controller will react to the DC average

value of the applied waveform. A 10K

resistor is required to activate the

internal ignition, connected as shown.

More details of how to control the Porter from a microcontroller are in the

knowledgebase on our website.

ELSTO Drives & Controls Voorhout • Rotterdam • Weert • Hoogerheide • België T+31(0)88 7865200 E[email protected] Welsto.eu

ELSA010000-004 DRAFT 1

5

Ignition Switch

An ignition switch should be connected in the pot or throttle circuit to switch off the controller when not in use. Without this switch the

controller is still powered up and drains about 17mA from the battery.

When ignition is switched off, the controller will ramp the motor down to zero speed (at whatever deceleration rate you have set) and

then switch itself off.

Voltage Input

The Porter may be fed from a voltage source between 1V and 4V. This can be PWM

supplied from a microcontroller or even Elsto's own DMR-203 radio control interface.

The controller will react to the DC average value of the applied waveform. A 10K

resistor is required to activate the internal ignition, connected as shown.

More details of how to control the Porter

from a microcontroller are in the

knowledgebase on our website.

Adjustments

There are two adjustments as shown on page 3. These control the rates at which the motor accelerates and decelerates. Optimum

setting depends on your machine but do not choose too fast a rate or you may get jerky and unsafe performance.

Pot Fault Protection

The Porter incorporates protection such that it will not fail to full speed if the pot goes faulty or a wire brakes. However if the pot zero

wire breaks, then the controller will ramp down very slowly to zero speed and, as it does this, the speed pot will have little effect. If this

happens, use the ignition switch to ramp down at whatever rate you have the deceleration ramp set to.

6. Battery and Motor Current

Be aware that, except at full speed, the battery current will be less than the motor current, and the motor voltage less than the battery

voltage.

The motor current times the motor volts is the same as battery current times the battery volts.

At full speed, motor current should not exceed 100 amps, and that not for long, or the reverse battery MOSFET will be destroyed,

damaging the circuit board. The instantaneous motor current limit is much higher than this on the Porter 10.

Porter 5-10-10XXX V2.4 07/19 Page 5 www.4qd.co.uk

ones or external] to get an input voltage between 1V & 4V to avoid dead areas at

the top and bottom of the pot travel. The ideal value of the resistors is 1/3 of the pot

value.

Magura Throttle

The Magura throttle, as supplied by

4QD is 5k. Be aware that the wires

on the Magura are slightly oversize

for the IDC connector, we

recommend using a short length of

7 x 0.2mm cable as an adaptor to

prevent the pins of the connector

shorting out.

Hall Effect Throttle

Connects to pins B, C and D. Pin D has

5v present to feed the pot top.

It should be the type than gives 1v at

zero speed and 4v at full speed. Some

throttles are reversed and will not be

suitable. Max Hall current 10mA, for

use on 12v and 24v only as standard

[Hall throttles can be used above 24v if

a suitable resistor is added in series with

pin D]. There are many makes of Hall

effect throttle and wiring colours are not standardised.

Ignition Switch

An ignition switch should be connected in the pot or throttle circuit to switch off the

controller when not in use. Without this switch the controller is still powered up and

drains about 17mA from the battery.

When ignition is switched off, the controller will ramp the motor down to zero speed

(at whatever deceleration rate you have set) and then switch itself off.

Voltage Input

The Porter may be fed from a voltage

source between 1V and 4V. This can

be PWM supplied from a

microcontroller or even 4QD's own

DMR-203 radio control interface. The

controller will react to the DC average

value of the applied waveform. A 10K

resistor is required to activate the

internal ignition, connected as shown.

More details of how to control the Porter from a microcontroller are in the

knowledgebase on our website.

7. Mounting

Porter 5-10-10XXX V2.4 07/19 Page 6 www.4qd.co.uk

Adjustments

There are two adjustments as shown on page 3. These control the rates at which

the motor accelerates and decelerates. Optimum setting depends on your machine

but do not choose too fast a rate or you may get jerky and unsafe performance.

Pot Fault Protection

The Porter incorporates protection such that it will not fail to full speed if the pot

goes faulty or a wire brakes. However if the pot zero wire breaks, then the

controller will ramp down very slowly to zero speed and, as it does this, the speed

pot will have little effect. If this happens, use the ignition switch to ramp down at

whatever rate you have the deceleration ramp set to.

6. Battery and Motor Current

Be aware that, except at full speed, the battery current will be less than the motor

current, and the motor voltage less than the battery voltage.

The motor current times the motor volts is the same as battery current times the

battery volts.

At full speed, motor current should not exceed 100 amps, and that not for long, or

the reverse battery MOSFET will be destroyed, damaging the circuit board. The

instantaneous motor current limit is much higher than this on the Porter 10.

7. Mounting

The flat aluminium plate should be bolted onto the metalwork of the machine to act

as an additional heatsink, as shown above.

Mounting holes are 43.2mm apart and are 4.2mm diameter for M4 screws. The

current the Porter gives reduces as the MOSFET (heatsink) temperature increases,

so a large, thick heatsink, with good air-flow, will increase the length of time high

current can be used. Heatsink compound (thermal paste) should be used between

the Porter's own heatsink and your additional one to increase heat flow between

them, especially at high currents.

The flat aluminium plate should be bolted onto the metalwork of the machine to act as an additional heatsink, as shown above.

Mounting holes are 43.2mm apart and are 4.2mm diameter for M4 screws. The current the Porter gives reduces as the MOSFET

(heatsink) temperature increases, so a large, thick heatsink, with good air-flow, will increase the length of time high current can be used.

Heatsink compound (thermal paste) should be used between the Porter's own heatsink and your additional one to increase heat flow

between them, especially at high currents.

ELSTO Drives & Controls Voorhout • Rotterdam • Weert • Hoogerheide • België T+31(0)88 7865200 E[email protected] Welsto.eu

ELSA010000-004 DRAFT 1

6

The length of time for which maximum current can be drawn is limited by the speed with which heat can be removed from the integral

heatsink to the extra heatsink. As a rule-of-thumb, the heatsink should not be allowed to get too hot to touch.

Water Resistance

The box is not sealed, so some thought must be given to mounting it if water is likely to get at it. The box is best mounted horizontally

but guard against water falling on the connectors or running down leads and thus into the connectors.

8. Dismantling

Remove the two cover fixing screws (shown on page 3). Pull the cover away from the heatsink. The cover can now be slid off the 5 way

connector.

Re-assembly is the reverse of this. Make sure the cover is correctly aligned with its plastic base and push firmly together at the heatsink

end - the board is a close fit into the cover.

If you ever need to remove the heatsink from the PCB please be sure to note carefully the arrangement of the black and white insulating

washers. After reassembly make sure there is no connection between the heatsink and the centre pins of all the MOSFETs.

9. Service

In the event of any problem please contact us before returning a suspect controller.

Please include a completed returns form with the returned controller [see website].

Details of service charges are on the website.

Warranty

All our controllers have a warranty against defective manufacturing for 12 months from the date of shipment. The warranty doesn’t

cover damage caused by incorrect installation.

ELSTO Drives & Controls Voorhout • Rotterdam • Weert • Hoogerheide • België T+31(0)88 7865200 E[email protected] Welsto.eu

ELSA010000-004 DRAFT 1

7

10. Specifications

Model Porter 5 Porter 10

Nominal voltage range V 12 – 48

Minimum / maximum voltage V 10 – 55

Motor current A [max] 95 190

Motor current A [1 minute] 75 120

Motor current A [continuous] 50 [depends on

mounting / cooling]

100 [depends on

mounting / cooling]

Regen braking Y

Dimensions [mm] 136 x 62 x 35

Weight [g] 140

Power connections 6.3mm push-on blades

Input 5k to 25k pot, 0 – 4V, Hall effect 6mA max @48V

Reverse polarity protection Y

Overvoltage protection Y [68V]

Under voltage protection Y [8V]

Pot fault protection Y [>50k]

Current limit – drive Y

Ramping Acceleration and deceleration adjustable between

0.1S and 5S

Power down state (motor) Diode

Ignition, Electronic pot

Heatsink Basic integral

Switching frequency 20 kHz

Quadrants 2

Branches elsto.eu

ELSTO Drives

Loosterweg 7

2215 TL Voorhout - NL

T+31(0)88 7865200

• Engineering and production of bespoke

transmission systems.

ELSTO Controls

Carolus Clusiuslaan 1

2215 RV Voorhout - NL

T+31(0)88 7865800

• Engineering and production of

control solutions and control boxes.

• Sales of frequency inverters, servo drives

and integral control systems.

STOLK Services

Voltweg 20

4631 SR Hoogerheide - NL

T+31(0)88 7865400

• Maintenance Repair Overhaul.

• Preventive and corrective maintenance of

transmissions on industrial plants.

• Overhaul of generator sets.

• Specialist in ATEX maintenance.

• Regional Sales of electro mechanical

transmissions and inverters.

ELSTO Services

Copernicusstraat 9 C

6003 DE Weert - NL

T+31(0)88 7865460

• Regional Sales of electro mechanical

transmissions and inverters.

• Repair, Overhaul and maintenance of all

makes and types of transmission

components.

• Maintenance Repair Overhaul.

• Winding an balancing of electric motors.

• Sales in België and Luxemburg of

electro mechanical transmissions

(motors, reductors, linear drives and

components) and inverters.

• Engineering and production of bespoke

transmission systems.

ELSTO Belgium

(formerly BOEKHOLT)

T+32(0)3 355 1010

ELSTO Drives & Lifting

Strickledeweg 96

3044EL Rotterdam - NL

T+31(0)88 7865600

• Regional Sales of electro mechanical

transmissions and inverters.

• Specialist in couplings and

open drives

• Sale of lifting aids, lifts and

hydraulic auxiliary systems

• Sales, installation and maintenance of

disabled lifts

ELSTO Drives

Loosterweg 9

2215 TL Voorhout - NL

T+31(0)88 7865200

• Sales of electro mechanical transmissions

(motors, reductors, linear drives and

components) and inverters.

This manual suits for next models

4

Table of contents

Popular Controllers manuals by other brands

SOMFY

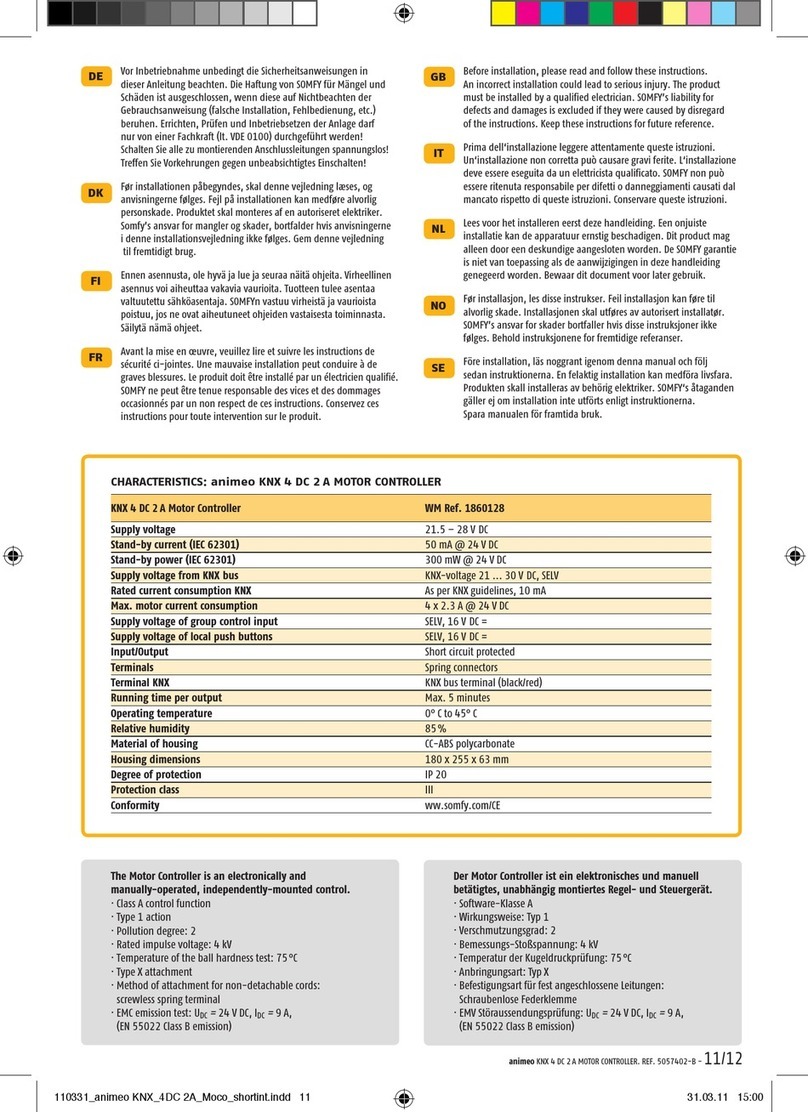

SOMFY animeo KNX 4 DC 2 A installation guide

Nitrous Express

Nitrous Express MAXIMIZER-II Installation and user manual

Smartgen

Smartgen HAT600R Series user manual

Bosch

Bosch PVA-4CR12 Operation manual

Hall Research Technologies

Hall Research Technologies CNT-IP-264 user manual

Pilz

Pilz PNOZmulti Classic PNOZ ms3p TTL operating manual