Eltek Minipack User manual

Quick Start Guide

Installation, Operation, Commissioning and Maintenance

DC Power Supply System

Integrated Applications

Mini

p

ack, PS S

y

stem

356808.103

Miscellaneous

Communication

oCAN Bus Termination (13)

oInstalling PowerSuite – PC software (13)

AC Mains

oMains Feeds versus Rectifier ID (14)

oPlug-and-Play Rectifiers versus Mains Monitoring (14)

Battery Monitoring

oBattery Symmetry – Connections (15)

oBattery Interface Card ~ Terminals & Pin-out, ( 16)

Alarms & Monitoring

oStandard Alarm Relays & Digital Inputs (17)

oAlarm Interface Card ~ Terminals & Pin-out (17)

oAlarm Interface Card, Extd. ~ Terminals & Pin-out (18)

Internal Connections

oSystem Interface Card ~ Terminals & Pin-out (19)

oLVD Latching Contactors (19)

Drawings

oBlock Diagram Minipack 48VDC, 3.2kW (21)

oBlock Diagram Minipack 48VDC, 4.8kW (22)

Introduction

oThe Smartpack based Product Range (2 )

oBrief System Description ⎯Minipack (2 )

Installation

oInstalling Smartpack and Rectifier Modules ( 3)

oInstallation and Maintenance Details

⎯Opening or Closing the Minipack Drawer Shelf (4)

⎯Mounting or Removing Minipack Blind Covers (4)

⎯Removing or Mounting Load MCBs (5)

⎯Configuring Priority and Non-Priority Load Circuits (5)

oInstallation steps; mechanical, electrical (6-7)

oLocation of Components, GA drawing; 6 and 4 rectifiers systems (8)

oConnections, Factory Settings, etc. (9)

Commissioning

oPre-start check (10 )

oCommissioning steps, Startup (10-11)

Operation

oFront keys and display (12)

oSoftware Menus (12)

Check Lists

pullout forms

oInstallation Check List

oCircuit Distribution List

oCommissioning Procedure

oMaintenance Procedure

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

2

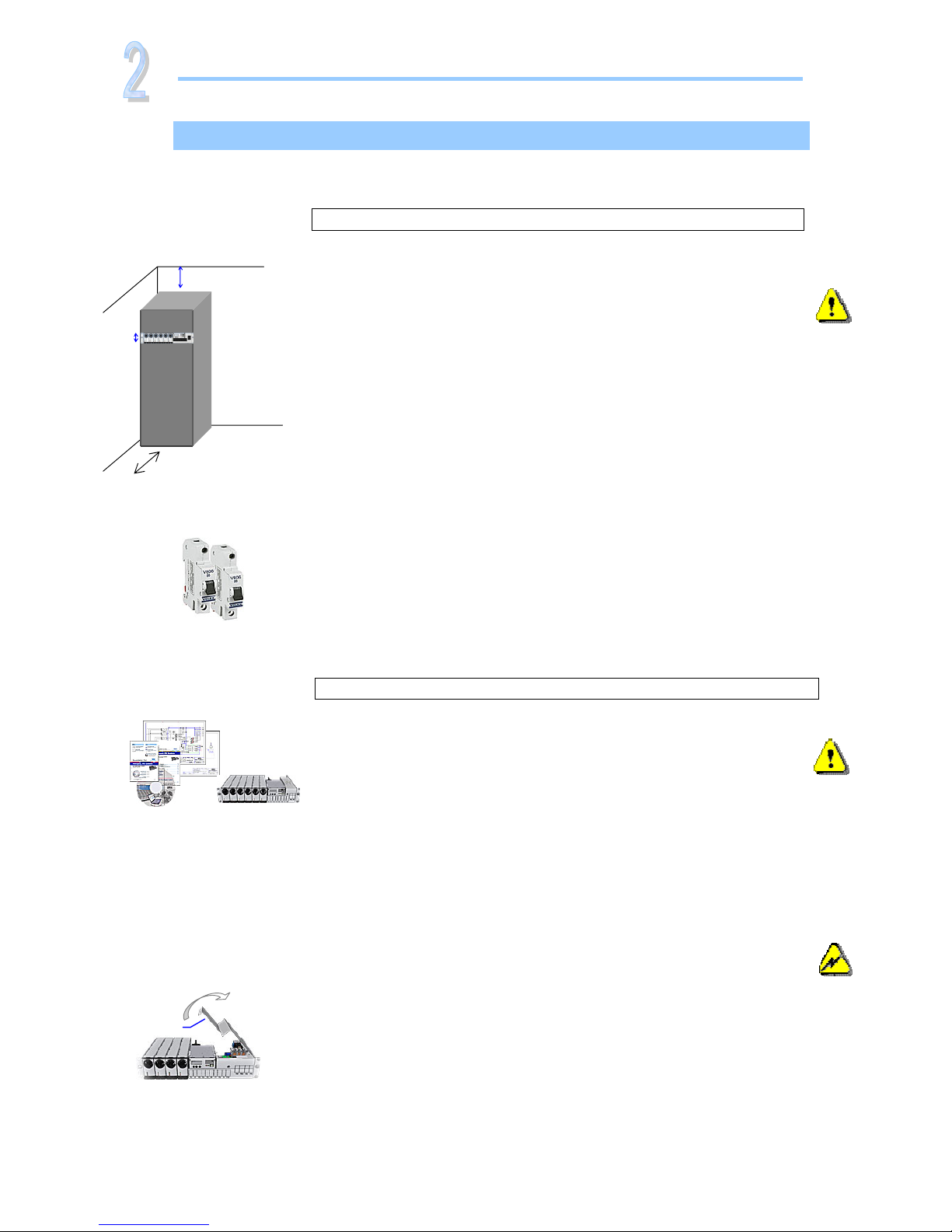

The Smartpack based Product Range

Eltek Energy's Smartpack based product range utilizes the Smartpack controller, and Flatpack2

rectifiers, Powerpack rectifiers and Minipack rectifiers as building blocks for implementing

effective DC power systems, suitable for a wide range of applications and power ratings.

Cabinetized systems are suitable for indoor or outdoor applications. In addition to the power

system and the distribution unit, the cabinet may also contain battery banks, additional

distribution and other dedicated equipment.

Integrated systems consist of the power system, which includes rectifiers and controller(s), and

the distribution unit (1U or 4U high). Integrated systems are sold primarily for mounting in

existing cabinets.

Powerpack systems are suitable for large Central Office power plants, and use three-phase

rectifier modules.

Minipack systems are suitable as small, stand-alone battery chargers and DC power supplies.

Brief System Description ⎯Minipack

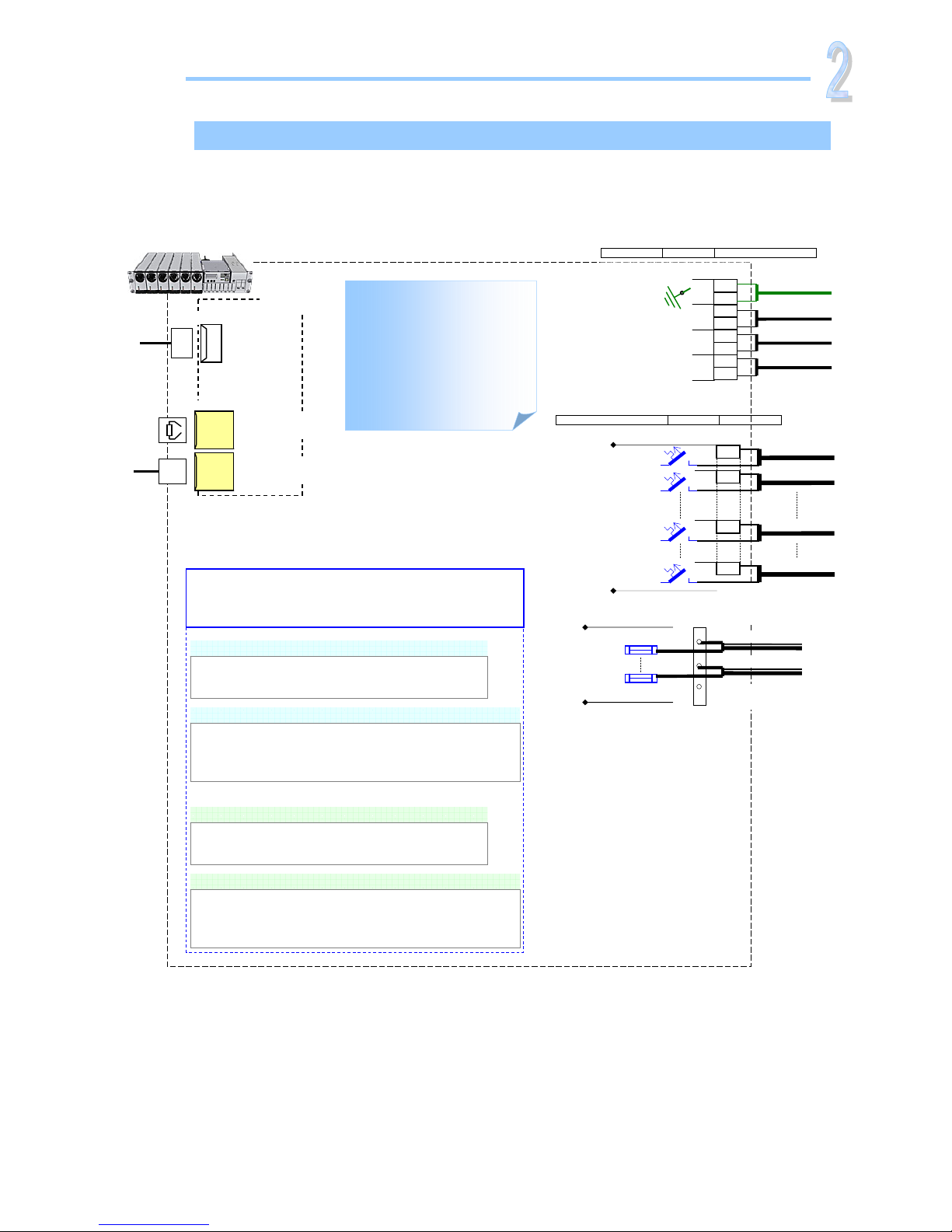

The Minipack PS system is a compact and cost-effective DC power supply system, specifically

developed for the telecom industry.

Example of a typical Minipack PS system for DC power supply of telecom equipment. The

system is supplied from an external AC mains supply, and is delivered in one power shelf for

integration in existing cabinets (integrated). An external battery bank is to be connected.

Introduction

Flatpack

2

System, Integrated

4U and 1U Distributions

Flatpack

2

System, Cabinetized

Indoor and Outdoor Cabinets

Powerpack System Minipack System, Integrated

Minipack

Batte

r

y st

r

ing #1

Symmetry

Alarm &

Temp. Senso

r

LVLD

LVBD

Fuse Alarm

AC Fuses,

external

(230V)

Telecom

equipment

AC Supply

(Single- or

three-

p

hase

)

Batte

r

y

Fuses

Load Fuses

& MCBs

Smartpack

(Ctrl. Unit)

PowerSuite

A

pplication

USB cable

DC

distribution DC Supply

48V

*

CAN Bus

Minipack rectifiers

A

larm Outputs NC-C-NO

Digital Inputs Remote

Monitorin

g

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

3

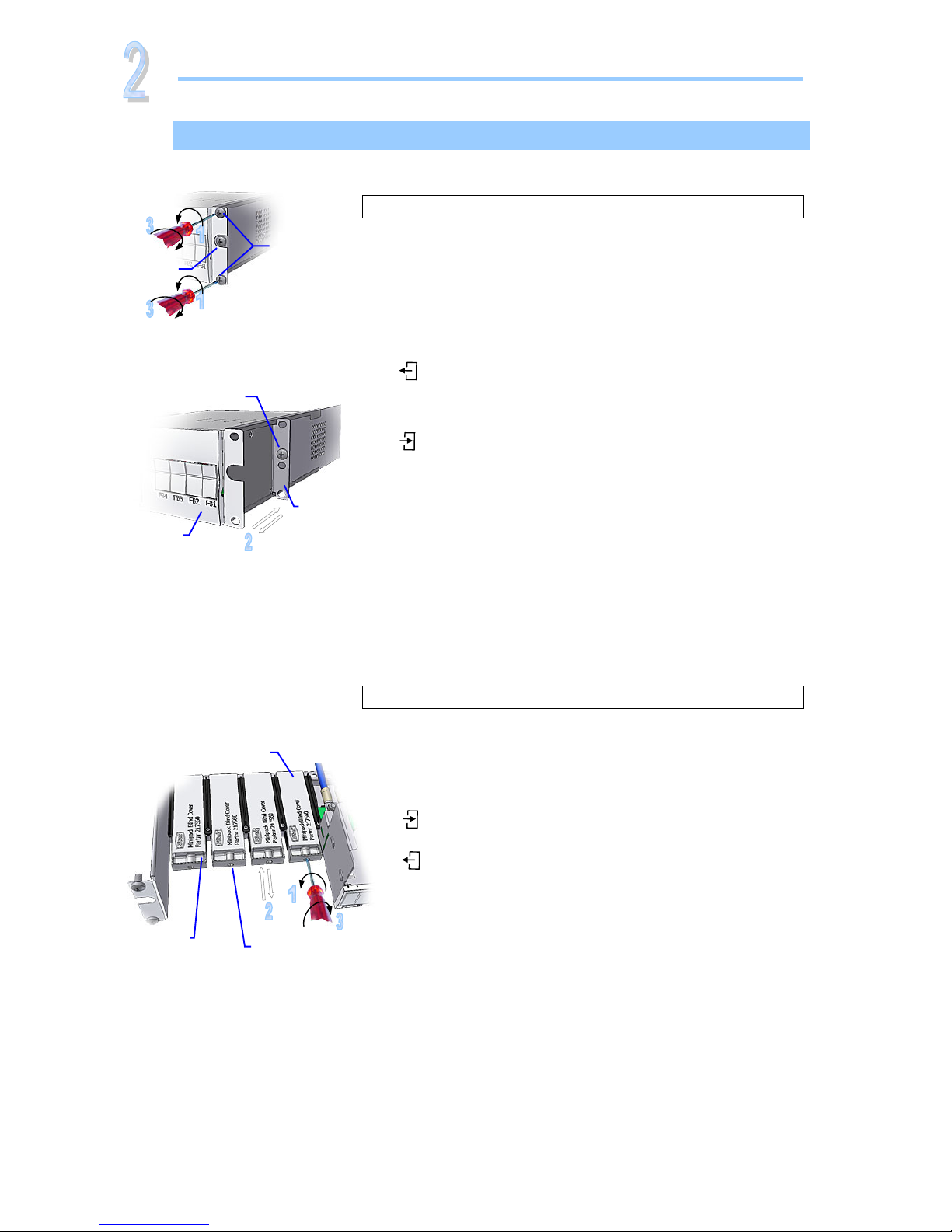

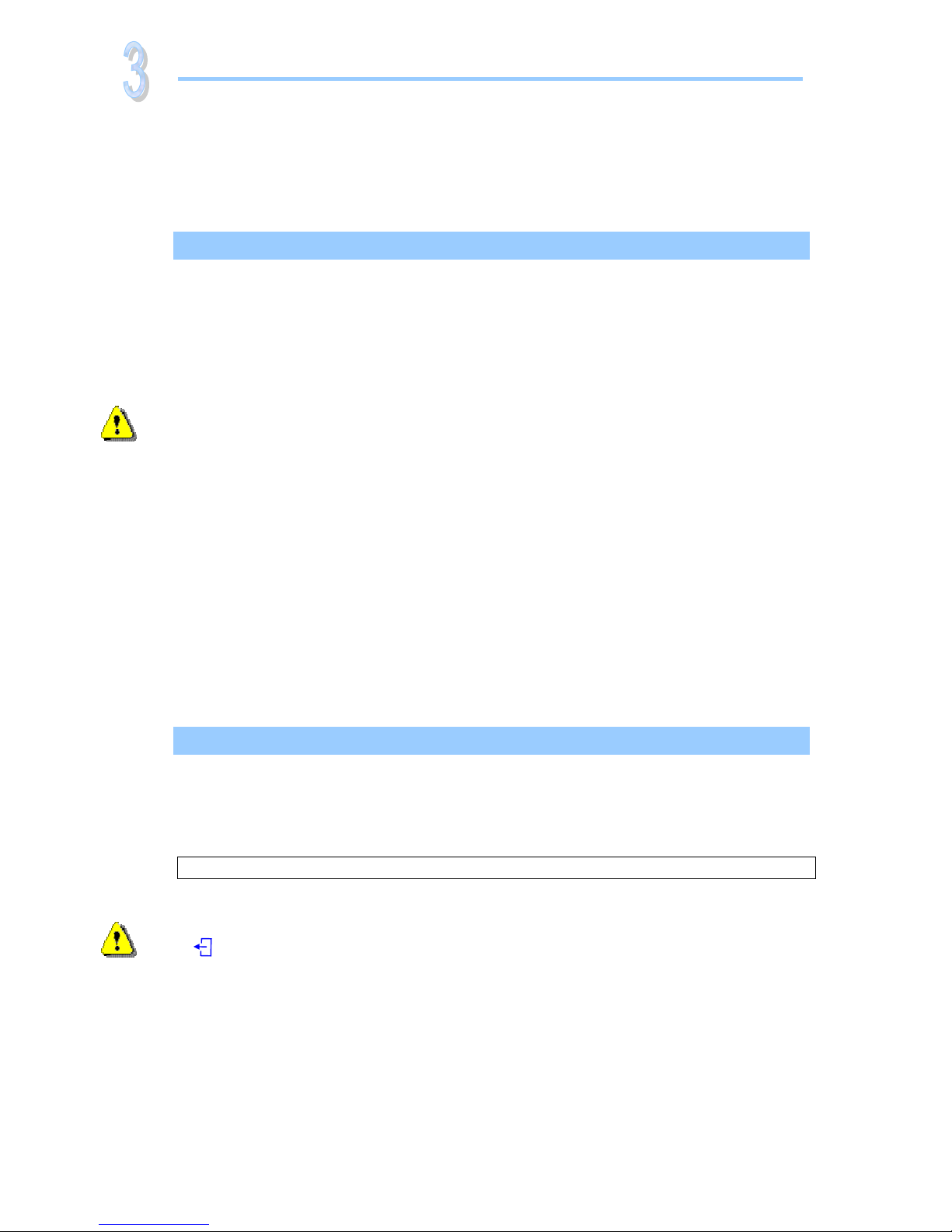

Installing Smartpack and Rectifier Modules

Smartpack

controller

Handle in locked position

Hole to release the

handle’s spring

mechanism

Handle in

unlocked

p

osition

Mounting or Removing Smartpack Controller

Mounting the Smartpack controller

1. Open the handles by

inserting a screwdriver into the holes to release the spring

mechanism

2. Insert the module fully into the power shelf, after plugging the

cables to the rear panel

3. Lock the handles by

pushing the handles up into their housings (locked position), so

that the module is securely locked

Removing the Smartpack controller

1. Open the handles by

inserting a screwdriver into the holes to release the spring

mechanism

2. Remove the module by

using both handles to pull the module loose gently; support from

underneath; unplug the cables connected to the rear panel

Minipack

rectifier

Locking Screw

Mounting

Rail

Front Handle

Device

hazard

CAUTION: Do not hand-carry the controller by its handles. Cables and circuit

boards are plugged to the controller’s rear panel. Open the handles before

inserting the controller into the power shelf.

Device

hazard

CAUTION: The modules may be warm. Remove the locking screw before

inserting them into the power shelf (hot-pluggable).

Do not relocate already hot-plugged rectifiers to other positions in the power

shelf. New rectifiers must be hot-plugged in the power shelf, one at time,

starting from the left with position 1, 3, 5 and 2, 4, 6.

Mounting or Removing Minipack Rectifier Modules

1. Unlock the module by

using a screwdriver to loosen the locking screw

2. Insert or remove the module by

sliding it on its mounting rail fully into the power shelf, so that

the module makes proper contact (hot-pluggable)

or

using the front handle to pull the module loose; support from

underneath before the unit is completely free

3. Lock the module by

screwing home the locking screw (locked direction). Then, the

module will be securely locked in the shelf, or ready for transport

4. Mount blind covers in

unused module locations

Electric

shock

Controller & Modules

Installation

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

4

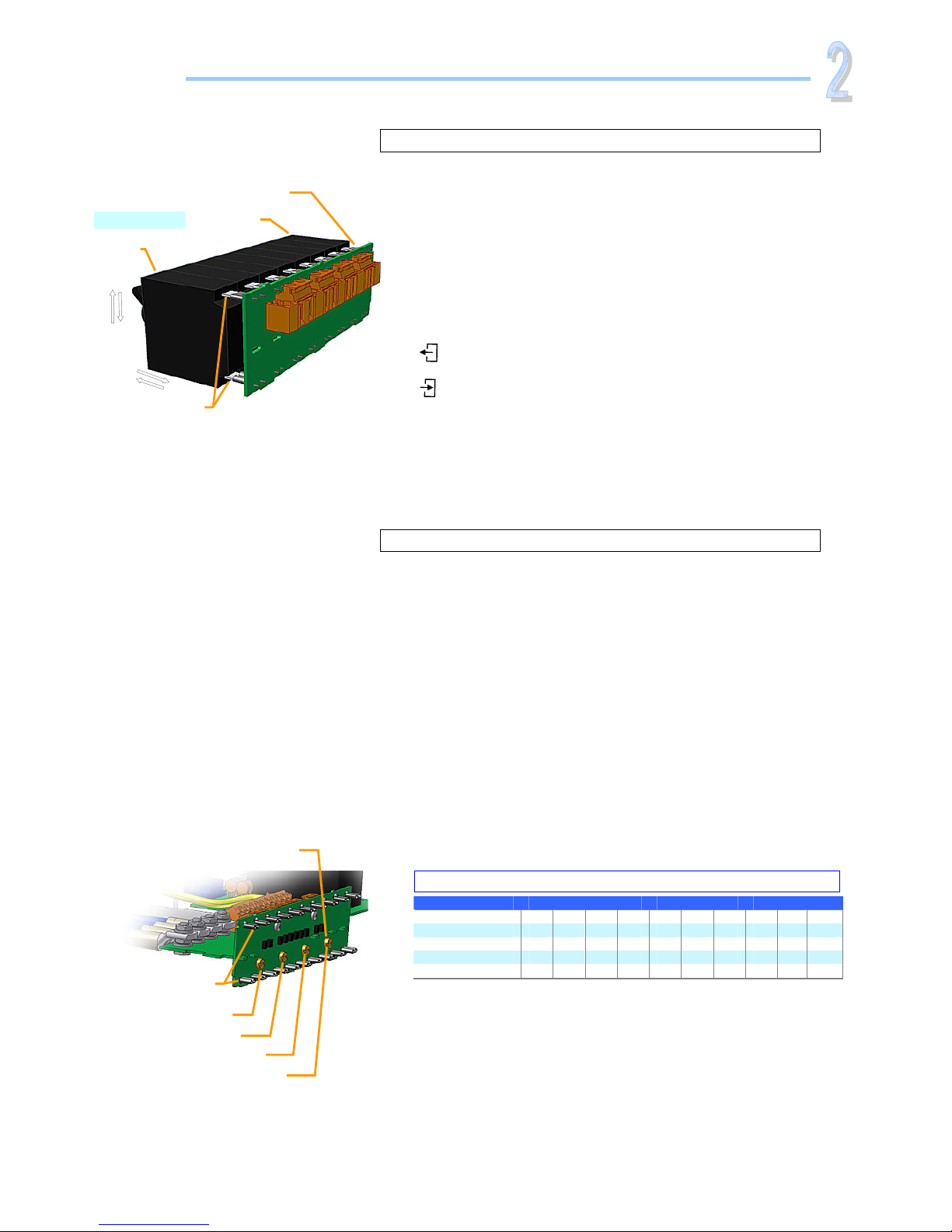

Installation and Maintenance Details

Installation

Details

Mounting or Removing Minipack Blind Covers

1. Unlock the blind cover by

using a screwdriver to loosen the locking screw

2. Insert or remove the blind cover by

sliding it on its mounting rail fully into the power shelf

or

sliding it out, by inserting your fingers in the cover’s front

handle and pulling it loose

3. Lock the blind cover by

screwing home the locking screw (locked direction).

Then, the blind cover will be securely locked in the shelf,

or ready for transport

Minipac

k

blind cove

r

Locking screw

to secure the blind cover

Front handle

Fastening screw

for the shel

f

frame

Fastening screws

for the drawer

Minipack Sliding Drawer Shelf

in Operation Position

Opening or Closing the Minipack Drawer Shelf

To access the Minipack distribution area, you have to open the

sliding drawer shelf. Do following to open or close the drawer:

1. Unlock the drawer shelf by

using a screwdriver to loosen the upper and lower locking

screws. Do not loose the screw in the middle!

2. Open or close the drawer shelf by

holding the drawer from the side plates and sliding it

outwards.

The drawer shelf is the in the Maintenance Position.

or

sliding it on its mounting rail fully into the shelf

3. Lock the drawer shelf by

screwing home the upper and lower locking screws.

The drawer is then securely locked in the shelf, in its

Operation Position

Shelf

Frame

Fastening screw

for the shelf frame

Minipack Sliding Drawer Shelf

in Maintenance Position

F1, F2…Plastic

Cove

r

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

5

Details

Installation

Configuring Priority and Non-Priority Load Circuits

CAUTION: Power must be OFF during configuration! Only one

screw may be removed.

1. Remove the F1, F2… plastic cover by

unscrewing the cover’s frontal screw,

then inserting a small screwdriver into the cover’s gap and

carefully press down and out to release the locking tabs.

2. Switch OFF and unplug the actual MCBs by

switching the MCB handle to “0” (upwards),

then using your fingers to pull out the MCB

3. Remove the actual Priority Load Screw by

using a screwdriver to unscrew the Priority Load Screw

(refer to table below).

Keep the removed screw in the clip, on the cover’s inside

Plugs for MCB1

Priority Load Screws

(accessible with unplugged MCBs)

F3-F10 Screw (Y6)

F5-F10 Screw (Y7)

F7-F10 Screw (Y24)

F9-F10 Screw (Y25)

Screw Removed F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

None P P

P

P

P

P

P

P

P

P

Y25 NP NP NP NP NP

NP

NP

NP P P

Y24 NP NP NP NP NP

NP

P P

P P

Y7 NP NP NP NP P P

P P

P P

Y6 NP NP P P

P P

P P

P P

WARNING: Only one screw can be removed at a time.

P=Priority Load Circuits NP =Non Priority Load Circuits

Configuration of Priority & Non Priority Load Circuits

Plug for MCB1

MCB1

MCB8

Minipack front

0

1

MCB8

(Upper and

lower plugs)

Removing or Mounting Load MCBs

CAUTION: Power must be OFF during this operation!

1. Remove the F1, F2… plastic cover by

unscrewing the cover’s frontal screw,

then inserting a small screwdriver into the cover’s gap and

carefully press down and out to release the locking tabs.

2. Switch OFF the MCB by

switching the MCB handle to “0” position (upwards)

3. Remove or insert the MCB by

using your fingers to pull out and unplug the MCB

or

pressing the MCB into the upper and lower plugs

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

6

Installation Steps

Check off in the Installation Check List, that you find in the pullou

t

section of this folder. Also, refer to the system’s specific drawings.

Installation

For external AC fuses and AC input cable ratings, refer to your site’s AC

supply specification. In general, a site with better AC supply quality

(stable nominal voltage) may use smaller breakers.

Mechanical Installation

Power is OFF!

Carry out the following:

4 Remove packaging and check equipment

oCheck you have received all the parts and correct documentation

oInspect the equipment for physical damage (report any damages)

oLeave rectifier modules in their packaging or in the selves, if

factory installed. To be installed under commissioning

5 Remove the cabinet’s top cover and dummy front panel

oConnection terminals are accesses by opening the drawer shelf

oBattery shelves (if any) are placed behind the lower panels

6 Position and fasten the subassembly

oMinipack is fastened in existing 19” or in ETSI cabinets, using

brackets

7 Mount the external batteries on the shelves

oStart (if applicable) placing the batteries on the lower shelf first,

and continue upwards

oDo not terminate the battery cables yet!

8 Open the Minipack drawer shelf and lift the plastic cover

oUnlock the upper and lower screws and slide the drawer shelf

open; read the Installation & Maintenance Details chapter

oLift the Melenex plastic cover to access the connection terminals

Electric

shock

Device

hazard

Minipack PSS, Doc. Chart, Spec.

Drawings, CD-ROM

Minipack drawer shelf slid out in

the maintenance position

Plastic Cove

r

Preparing the Installation Site

Begin preparing the following:

1 Organize the installation site

oA 2U high spare location in existing 19”, 250 mm cabinet

oMin. Clearances: 60 cm in front

oExplosive atmospheres are to be avoided. Ensure suitable

ventilation

2 Prepare the installation tools

oUse insulated tools suitable for telecom installations

3 Prepare AC Supply: AC input cable(s) and fuses

oCorrect type AC supply is available

oExternal AC fuses have correct rating

oAC input cable(s) are sized correctly

EMC

regard

600 mm

2U

200 mm

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

7

Installation

Electrical Installation

Power is OFF!

Carry out the following: (Refer to the system’s specific drawings)

CAUTION: The cable lengths must be long enough (service loop) to allow

opening the Minipack drawer shelf.

9 Make the system completely voltage free

oSwitch OFF or remove all load fuses (MCB1, MCBx), battery

fuses (Fb1, Fbx) and the AC supply fuses, in external fuse

boards

10 AC Connections

oCheck AC configuration: the external AC supply consists of 3

single phase mains feed and earth (PE)

oConnect the AC Earth wires (PE) to the terminals X5:1-2 (PE)

oConnect the AC input cables to the terminals X5:3-4, 5-6, 7-8.

Cable and terminal block labeling are to correspond

11 DC Connections ⎯Load Circuits

oDC Earth (TE); check that the common DC Output Rail is

connected to “Telecom Earth” (TE) at only one place (at the

cabinet , cable X7A, or at a central distribution point)

oFor each DC load, connect one of the cables to the common DC

output terminal, and the other to terminal X6B:F1, F2, etc.

12 DC Connections ⎯Alarm & Signal Circuits

oRefer to your system’s connection drawings and configuration, or

to the “Miscellaneous, Alarms & Monitoring” section, terminal

blocks X1, X2A and or X2B.

oTerminate Alarm Circuit cables to the relay output terminals

oTerminate Signal Circuit cables to the digital input/output

terminals

13 DC Connections ⎯Battery Cables

Careful! Use correct polarity.

For 48V systems using the battery symmetry mid-point

measurement, refer to the figure in this page.

For other measurement methods, refer to the Battery Symmetry

Connections chapters in this guide’s Miscellaneous section.

For each battery shelf:

CAUTION: Mount cable lugs upside down on the (+) battery cables

a Mount 3 intercell links to connect in series 4 battery blocks

b-c Connect battery cables to fuses (Fb1, Fb2, etc.) and

Common Battery (X7A) and to the battery shelf’s outer

terminals; black (+); blue (-)

d-e Connect battery symmetry cables, if applicable, to the input

terminals, and to the center terminal of the battery string

(+) and to the -48V outer terminal. Deviation from factory

settings requires Symmetry reconfiguration via PowerSuite

f-g Connect the temperature sensor cable, if applicable, to the

D-Sub plug or input terminal, and fix the temperature

sensor (at the end of the cable) to a suitable place in the

middle of the installed battery bank

Electric

shock

Minipack drawer shelf slid out in

the maintenance position

Service Loop

Cable lengths

enabling to open

the drawer shel

f

Device

hazard

—

(-48V) Oute

r

Terminal

+

0V Oute

r

Terminal

Link 2 (X7A)

(DC Earth) Common

Battery X7A

EG

Batter

y

Fuse, Fbx

Intercell Links

Batter

y

Cable

Symmetry 1

2-1

Chassis

Card Art.200576

+

-

15 pins D-Sub

(male)

Tem

p

. senso

r

Temp. Sensor cable 1

Block1

- ++-+-+-

Block4Block3

Cable lugs mounted

upside down

Common Battery

Cables (+)

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

8

Location of Components, GA drawing

Refer to the specific drawings included with your Minipack PS system, for

information regarding the exact location of components in your system.

Installation

NOTE: For information about connecting

Battery Symmetry, Temperature Sensor,

Alarm and Monitoring circuits, refer to

section “Miscellaneous”, and read the

Battery Monitoring, Alarms & Monitoring

chapters.

CAN1

CAN bus communication with rectifiers (to Smartpack rear)

CON5A, For internal connections

(to Smartpack rear)

Common Battery (+)

X7A, Battery connections

DC Earth

X7A, Exchange Ground (EG) or system

ground. Link connected to chassis

Fb1, Fb2

Battery connections (−)

AC Mains

AC Mains & Earth (PE) Terminals

Plastic Protective Cover fo

r

AC Terminals

Forward sliding

drawer shelf

Top view

Mini

p

ack Rectifie

r

Location of

Smart

p

ack controlle

r

Common DC Output (+)

Load terminal block

DC Output (

−

)

Load terminal block

Cable Fastening Plate

X5:

p

in 1

X6B:

p

in 1

LVLD latching contactor (optional)

LVBD latching contacto

r

Minipack, 6 Rectifiers

(48V, 4800W)

Front view

Battery Fuses

Load MCBs

Smartpack controlle

r

Mini

p

ack rectifiers

CAN1

CAN bus communication with rectifiers

(to Smartpack rear)

CON5A, For internal connections

(to Smartpack rear)

Common Battery (+)

X7A, Battery connections

DC Earth

X7A, Exchange Ground (EG) or

system ground.

Link connected to chassis

Fb1, Fb2, Fb3, Fb4

Battery connections (−)

AC Mains

AC Mains & Earth (PE) Terminals

Plastic Protective Cover fo

r

AC Terminals

Forward sliding

drawer shelf

Top view

Mini

p

ack Rectifie

r

Location of

Smart

p

ack controlle

r

Common DC Output (+)

Load terminal block

DC Output (−)

Load terminal block

Cable Fastening Plate

X5:

p

in 1

X6B:

p

in 1

LVLD latching contactor (optional)

Fb1

LVBD latching contacto

r

Minipack, 4 Rectifiers

(48V, 3200W)

Front view

Battery Fuses

Load MCBs

Smartpack controlle

r

Mini

p

ack rectifiers

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

9

Connections, Factory Settings, etc

Refer to your system’s specific drawings for the exact connection points.

Installation

Minipack

PS System, Integrated

The figure shows the posi-

tion of the relay contacts

when the PS system is in

alarm mode of operation;

the relay coils are then

de-energized (fail-safe

mode). The relay outputs

are preprogrammed from

factory (Factory Settings).

CAN

Com

Cable

CAN bus

End-of-Line

Plug (120Ω)

(Rear)

Smartpack

(Front)

USB

Com

Cable USB 2.0

Type B serial port

CAN1 port

RJ45, 8 pins

CAN1 port

RJ45, 8 pins

(For CAN bus

termination, see section

“Miscellaneous”)

FUNCTION SIGNAL TERM. POINT

X

5

AC Mains Inputs

6

5

4

3

2

1

7

8

PE

PE

N3

L3

N2

L2

N1

L1 2.

5

mm

2

, max.

wire section

M4 terminals

Mains Feed 1

Mains Feed 2

Mains Feed 3

A

C Earth (PE)

FUNCTION SIGNAL PIN-OUT

Load Fuses

MCB1

MCB2

X6A

2

1

10

8

+

+

+

+

6 mm

2

, max. wire section

Load Circuit 1

X

6B

Load Circuit 2

MCB8 Load Circuit 8

MCB10 Load Circuit 10

(Minipack systems with 6 rectifiers

have 8 DC load outputs available.

Systems with 4 rectifiers have 10

DC load outputs)

Common

Battery “Rail”

Battery

Fuses

Fb1

Fbx

Battery Cables, string 1

Battery Cables, string x

M6 screws, cable lugs

max. 15 mm width

X

7A

Interface Cards Connections

Refer to the connections for the actual terminal circuit boards

installed in your system

Battery Connections (X4)

Terminal Circuit Board, Art. 200576

Battery Symmetry 1-4 and Temp. Sense 1

(See page 16 for pin-out information)

Battery Connections, Extended (

X

3)

Terminal Circuit Board, Art. 200576

Batt. Symmetry 5-8, Temp. Sense 2, Batt. Current and Batt. Fuse Fail

(Not applicable for Smartpack RS232 D-Sub option, on rear panel)

(See page 16 for pin-out information)

Alarm Outputs & Digital Inputs (

X

1)

Terminal Circuit Board, Art. 218470

Digital Input 1-2 and Relay Output 1-2

(See page 17 for pin-out information)

Alarm Outputs & Digital Inputs Extended (

X

2A &

X

2B)

Terminal Circuit Board, Art. 218473

Digital Input 3-6 and Relay Output 3-6

(Not applicable for Smartpack Ethernet option)

(See page 18 for pin-out information)

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

10

The Minipack PSS startup consists of following stages:

I. Perform a pre-start check before the PS system is switched ON

II. Switch ON the system with disconnected load; adjust output voltage

III. Adjust the nominal output voltage with connected batteries and load

Pre-Start Check

Power is OFF!

Check off in the Commissioning Procedure, that you find in the pullout section of this folder.

If you have just finished the system installation successfully and filled in the Installation

Check List, jump over the Pre-Start Check and continue with stage II.

Before you switch ON the Minipack PS system, verify the following:

1. System installation is completed

oEnsure a correctly performed system installation, with correct polarity on all

connections (Installation Check List filled in)

oAll cabling is securely terminated and supported

oAll components, terminal blocks, MCBs/ fuses, etc. are clearly labeled

2. Battery and load fuses are disconnected

oVerify that all battery and load MCBs/ fuses are switched OFF

3. AC input cable(s) and AC Earth wire (PE) are terminated

oMake sure that the AC input cable(s) are correctly connected to the AC terminals

oVerify that the AC input cable(s) and external AC fuses are sized and rated as specified

oCheck that AC Earth (PE) is terminated, and electrically connected to chassis

4. Site specific parameters and settings are known

oRead the site specific drawings and documentation

5. AC supply and all MCBs, fuses are switched OFF

oMake sure that all external AC fuses and internal MCBs/ fuses are switched OFF

Commissioning Steps, Startup

Check off in the Commissioning Procedure, that you find in the pullout section of this folder.

After the ”Pre-start Check” is performed, you can begin with stage II. During the stage, you

will switch ON the Minipack PSS — while the batteries and load are disconnected ⎯then

measure the output voltage, and adjust it if required. Carry out the following:

Startup and No-Load Adjustments

Power is ON!

1. Disconnect all rectifier modules, without removing them (keep original location)

oVerify that all Minipack rectifier modules are disconnected (unplugged) but NOT

physically removed from the power shelf.

Also, read about the correct rectifier position, page 14, and how to mount them, on

page 3.

2. Switch ON the system

oSwitch ON the AC input supply (external AC fuses) to the Minipack system

3. Measure and verify that the AC input voltage is correct

oMeasure the AC terminals’ input voltage at the system’s AC Mains terminals

oVerify that the AC voltage is within range

Commissioning

Device

hazard

Device

hazard

I

II

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

11

4. Mount all Minipack rectifier modules in the power shelves (keep original location)

oPlug all rectifiers firmly inwards ⎯one module at a time, allowing a 2s delay ⎯to plug

them in the same self location. Secure them with the locking screws. Refer to page 3.

oMount Minipack blind covers over unused positions

5. Ensure that the Smartpack and all rectifier modules are working: LEDs are ON

oVerify correct operation, by monitoring the modules’ LED lamps and display:

No alarm are present on rectifiers. The Smartpack displays fuse alarms

6. Connect the a PC to the PS system (to facilitate operation)

oPlug a standard USB A-B cable between the PC and the Smartpack controller

oStart PowerSuite on the PC by selecting: Start > All Programs > Eltek > PowerSuite

Refer to chapter “Installing PowerSuite ⎯PC Application”, page 13, if required

oOn the toolbar, click the “Connect” button to establish connection

7. Measure and adjust DC output voltage

oRead the DC output voltage on the controller’s display

oWith a multi-meter, measure the DC output voltage at the most accessible point, e.g.

between the common DC rail and the lower connection of one of the priority load MCBs

oIf required, adjust the voltage using the controller’s front keys or via PowerSuite

8. Verify the alarm relays are working correctly (alarm relay test)

oRun the alarm relay test using the controller’s front keys (refer to page 12) or via

PowerSuite (select the menu Go > Output Test)

9. Make sure the System Setup is in accordance with configuration

oVerify system settings using the controller’s front keys or via PowerSuite

oUse the opportunity to enter site related information, number of used AC phases,

type of batteries, etc.

Load Adjustments

Power is ON!

Now, you can begin with stage III, where you will adjust again the output voltage to the

battery voltage, and connect the batteries and the load. Carry out the following:

10. Adjust DC output voltage to measured battery voltage

oMeasure the battery voltage is within range (check connections have correct polarity)

oAdjust DC output voltage — using the controller’s front keys (refer to page 12) or via

PowerSuite— to equal the measured battery voltage.

(Important adjustment to avoid arcing when connecting the batteries)

11. Unplug all rectifiers but one, and connect the battery fuses /MCBs

(CAUTION: Have only one rectifier connected, when switching ON the battery fuses.

Thus, avoiding damaging all rectifiers, due to possible incorrect polarity connections, etc.)

oDisconnect all rectifiers but one, by unlocking the locking screw and pulling them

partially out. Do NOT physically remove them from the power shelf

oSwitch ON all battery fuses or MCBs

12. Adjust DC output voltage again to equal the nominal battery voltage

oAdjust DC output voltage — using the controller’s front keys or via PowerSuite — to

equal the nominal battery voltage (or the nominal load voltage, when not using batteries)

13. Plug in again all rectifiers, and verify the rectifiers’ current sharing

oConnect all rectifiers again by pushing them firmly inwards ⎯Repeat step 4, in stage II

oWait for about 2 min., and check — using the PowerSuite application —that each of the

rectifiers delivers the same output current. A deviation of 1A is acceptable.

14. Connect the load breakers and verify that no alarms are displayed

oSwitch ON all load MCBs/ fuses

oVerify correct operation: rectifiers and controller display no alarms

Commissioning

Device

hazard

Device

hazard

III

Quick Start Guide Minipack PS System

356808.103, v1-2006-12

12

Front Keys and display, menus, etc.

Operation

Minipack Rectifier Module — front panel

Power LED is OFF (mains unavailable), Flashing

(controller accessing information) or ON (powered).

Warning LED is ON (derating or similar minor

warning), Flashing (over-voltage mode) or OFF (OK)

Alarm LED is ON (shutdown or similar major alarm)

or OFF (OK, no alarm)

Smartpack Control Unit — front keys, display, etc

Display: is in Status Mode (displays the system’s

status) or in Menu Mode (displays the menu structure).

Operation: Press on the

key to change from

Status Mode to Menu Mode. Press the

or

keys to scroll up or down and navigate to find menu

options (function or parameter). Press then the

key to select the function.

Menus: When you “enter” Menu Mode (Level 1),you

access the User Options. You may also scroll down to

password protected Service Options. Default password

<0003> should be changed.

Powe

r

LED Lamp (green)

Warning

LED Lamp (yellow)

Alarm

LED Lamp (red)

Graphical

Display

16 char. x 2 lines

LCD display

”Up” arrow key

”Down” arrow key

”Enter” key

USB

0ype B port

Smartpack control uni

t

Minipac

k

rectifie

r

Powe

r

LED Lamp (green)

Warning

LED Lamp (yellow)

A

larm

LED Lamp (red)

Software Menus ~ Smartpack controller

User menu <UserOption>

AlarmResetÆ

NomVolt

BoostVolt

LoBattMaj

VoltageInfo LoBattMin

HiBattMaj

HiBattMin

LVBD

LVLD 1.1

DisplayMessagesÆMessage ↓↑

SoftwareInfoÆ

SerialNumberÆ

NoOfRects. nn

RectCurrent

Rectifier Info RectSerialNumber

Rect.PrimaryVolt

Rectifier Status

Rectifier Temp

Rect. OutputVolt

Rectifier SW Ver

NoOfPhases nn

Mains Info Mains Status

Mains Voltage

Temp Level InfoÆLevel ↓↑

NoOfString Nn

BattStringCurr ↓↑

Battery Info BattStringTemp ↓↑

BattBlockVolt ↓↑

Level 2 Level 3

…

Firmware 402073.003 1v00

Service menu <ServiceOption>

NomVolt ↓↑

BoostVolt ↓↑

LoBattMa

j

↓↑

V

oltAd

j

ustment LoBattMin ↓↑

HiBattMa

j

↓↑

HiBattMin ↓↑

LVBD ↓↑

LVLD 1.1 ↓↑

V

oltCalibration ÆVoltCal ↓↑

Chan

g

ePassword ÆPassword ↓↑

SetManBoostTime Æ↓

↑

Start

/

Sto

p

Boost Æ

A

uto Boost Conf. ÆEnable/Disable ↓↑ & Th

r

eshold

Nxt Test DateTime Date ↓↑ Time

End Volt ↓↑

Batt Test Setu

p

MaxTestDu

r

↓↑

Test Int ↓↑

Guard Time ↓↑

Start

/

Sto

p

Test Æ

NoOfRects.

;

nn ÆReset

Char

g

e Curr Lim. ÆEnable/Disable ↓↑ & Max

Batter

y

Setu

p

NumOfSt

r

in

g

↓↑

CellCa

p

Ah nn ↓↑

Out

p

ut Control ÆVolta

g

eCtrl / Tem

p

Com

p

↓

Chan

g

e Date/Time ÆDate ↓↑ Time ↓↑

Alarm Out

p

ut 1 ↑

Rela

y

Test Alarm Out

p

ut 2 ↑

Batt Contacto

r

↑

Load Contacto

r

↑

Alarm Out

p

ut nn ↑

BattLifeTime Rst Æ

Level 2 Level 3

…

Firmware 402073.003 1v00

PULLOUT

Check Lists Pullout

Pull out the pages with the gray outer band,

and use them as check lists

Eltek Energy AS

Tel. +47 32 20 32 00

Internet: www.eltekenergy.com E-Mail: [email protected]

Form 174-gb-v1-C01_356808-103_qstart-inst-comm-oper_minipack-pss.doc_mfm_2006-12-29

INSTALLATION CHECK LIST

System Data

Minipack PS System

Minipack Power Supply System, type: Article No.:

Site, name:

Serial No.: Software, version No.: Rectifiers, type & number of:

AC Input Voltage, measured: Battery Type: Battery Capacity: Installation carried out by, name:

Site Preparations

CARRY OUT FOLLOWING

:

OK

1. Organize the installation site

oPrepare a 2U high spare location in existing 19”, 250 mm cabinet; Check min. clearance: front access, 60 cm

oEnsure the installation site is suitably ventilated and in a non-explosive atmosphere.

2. Prepare the installation tools

oCheck that insulated tools suitable for telecom installations are used

3. Prepare AC Supply: AC input cable(s) and fuses

oCheck the AC supply is the correct type, and that the external AC fuses and AC input cable(s) are suitably rated

Mechanical Installation

Power is OFF!

CARRY OUT FOLLOWING

:

OK

4. Remove packaging and check equipment

oCheck you have received all the parts and correct documentation.

oInspect the equipment for physical damage (report any damages)

oLeave rectifier modules in their packaging or in the selves, if factory installed. (commissioning task)

5. Remove the cabinet’s top cover and dummy front panels

oCheck that cable entry from the top is possible

oConnection terminals are accesses by opening the drawer shelf

6. Position and fasten the subassembly

oSubassemblies in existing 19” or in ETSI cabinets, using brackets.

7. Mount the external batteries on the shelves

oStart (if applicable) on the lower shelf first, and continue upwards

oDo not terminate the battery cables yet!

8. Open the Minipack drawer shelf and lift the plastic cover

oUnlock the upper and lower screws and slide the drawer shelf open, then lift the Melenex plastic cover

Electrical Installation

Power is OFF!

CARRY OUT FOLLOWING

:

OK

9. Make the system completely voltage free

oSwitch OFF or remove all load fuses (MCB1, MCBx), battery fuses (Fb1, Fbx) and external AC supply fuses

10. AC Connections

oCheck AC configuration: Make available 3 single phase mains feed and earth (PE)

oConnect the AC Earth wire (PE) to the terminals AC Earth (PE)

oConnect the AC input cable(s) to the terminals. Cable and terminal block labeling are to correspond

11. DC Connections ⎯Load Circuits

oTerminate DC Earth (TE):

Common DC Output Rail is connected to TE at only one place

oFor each DC load, connect one of the cables to the common DC output terminal; the other to the fuse terminal

12. DC Connections ⎯Alarm & Signal Circuits

oRefer to your system’s connection drawings and configuration, or to the Quick Start Guide

oTerminate Alarm Circuit cables to the relay output terminals

oTerminate Signal Circuit cables to the digital input/output terminals

13. DC Connections ⎯Battery Cables Careful! Use correct polarity.

For each battery shelf,

oMount 3 intercell links to connect in series 4 battery blocks

oConnect battery cables to fuses and Common Battery, and to the shelf’s outer terminals; black (+); blue (-)

oConnect battery symmetry cables, if applicable, to the input terminals

oConnect the temperature sensor cable, if applicable, to the D-Sub plug or input terminal, and fix the sensor (at the

end of the cable) to a suitable place in the middle of the installed battery bank

Approval

Responsible of installation, sign.: Date: Approved by customer, sign.:

EMC

regard

Electric

shock

Device

hazard

Electric

shock

CIRCUIT DISTRIBUTION LIST

System Data

Minipack PSS, type: Article No.:

Site, name:

CIRC

.

NO

.

FUSE

-

TYPE

MCB

LVLD

CONTROLLED

DESCRIPTION

FUSE

AMPERE

CABLE

mm

2

Fb1

Fb2

Fb3

Fb4

F1

F2

F3

F4

F5

F6

F7

F8

F9

F10

LOAD BATT.

Eltek Energy AS

Tel. +47 32 20 32 00

Internet: www.eltekenergy.com E-Mail: [email protected]

Form 175-gb-v1-C01_356808-103_qstart-inst-comm-oper_minipack-pss.doc_mfm_2006-12-29

Eltek Energy AS

Tel. +47 32 20 32 00

Internet: www.eltekenergy.com E-Mail: [email protected]

COMMISSIONING PROCEDURE

System Data

Minipack PS System

Supplier’s Order No.: Minipack Power Supply System, type: Article No.:

Site, name:

Serial No.: Software, version No.: Rectifiers, type & number of:

AC Input Voltage, measured: Battery Type: Battery Capacity: Commissioning carried out by, name:

Pre-Start Check

Power is OFF!

CHECK FOLLOWING

:

OK

1.

Minipack system installation is completed;

The Minipack Installation Check List is filled in.

All cabling is securely terminated with correct polarity

2. All battery and load MCBs/ fuses are disconnected

3. AC input cable(s) and AC earth wire (PE) are terminated

4. Site specific parameters and settings are known

5. AC supply and all MCBs/ fuses are switched OFF

Start-up, No-Load & Load Adjustments

Power is ON!

CARRY OUT FOLLOWING

:

OK

1. Disconnect all rectifier modules, without removing them (keep original location)

2. Switch ON the system (external AC fuses ON)

3. AC input voltage is correct;

Measure and verify

4. Insert all Minipack rectifiers in their original locations in the power shelves

5. The Smartpack and all rectifier modules are working, LEDs are ON;

Verify

6. Connect a PC to the PS system

Install the PowerSuite software, if required

7. DC output voltage;

Measure and adjust

8. Alarm relay test;

Verify all alarm relays are working correctly

9. System Setup is in accordance with configuration

Enter site spec. info in PowerSuite

10. Adjust DC output voltage to equal measured battery voltage

Check correct polarity!

11. Unplug all rectifiers but one, and connect all battery fuses/ MCBs

12. Adjust DC output voltage to equal nominal battery or load voltage

13. Plug in again all rectifiers, and verify the rectifiers’ current sharing

14. Connect all load MCBs/ fuses, and verify no alarms are displayed

Approval

Responsible of commissioning, sign.: Date: Approved by customer, sign.:

Device

hazard

I

II

Device

hazard

III

Device

hazard

Form 176-gb-v1-C01_356808-103_qstart-inst-comm-oper_minipack-pss.doc_mfm_2006-12-29

PULLOUT

Eltek Energy AS

Tel. +47 32 20 32 00

Internet: www.eltekenergy.com E-Mail: [email protected]

WARNING: Maintenance work on live equipment is only to be performed by authorized and

qualified persons using insulated tools. Hazardous voltages inside may cause terminal injury.

Electric

shock

MAINTENANCE PROCEDURE

System Data

Minipack PS System

Minipack Power Supply System, type: Article No.:

Site, name:

Serial No.: Software, version No.: Rectifiers, type & number of:

AC Input Voltage, measured: Battery Type: Battery Capacity: Maintenance carried out by, name:

System Inspection

Power is ON!

CARRY OUT FOLLOWING

:

OK

1. Site specific parameters and settings are known.

User manuals and site specific connection & arrangement drawings are available.

2. The battery bank has been fully charged in advance.

At least for 12 hours since start-up or mains failure. Enables correct measurements & calibration

3. The equipment is free from damage, dust or dirt; verify.

Carefully vacuum clean or remove any accumulation of dust, corrosion or dirt.

4. All cabling and copper bars are securely terminated and supported.

Correct any loose connections, excessive cable temperature, defective insulation, etc.

5. The Smartpack & all rectifier modules are ON, no alarm present; verify.

Otherwise, correct and put the PS system in normal mode of operation.

6. All rectifier’s functionality & Smartpack’s keys and display work OK; verify

Correct possible abnormalities before continuing.

7. Connect the PS system to a PC (install the PowerSuite application if required)

The PowerSuite program in the PC enables system configuration from the PC.

8. Rectifiers’ load current sharing; verify.

Use the PowerSuite PC application to check all rectifiers output the same amount of current (±1A)

9. Display the stored log of Alarm Messages.

Using the keypad on the Smartpack controller or from the PC.

System Adjustment

CARRY OUT FOLLOWING

:

OK

1. DC Output Voltage Calibration; ensure correct display readings.

If measured DC output voltage at the load terminals deviates more than ±1% from the display reading, calibrate the

output voltage from the Smartpack’s keypad or the PC.

2. Load & Battery Current Calibration; verify correct display readings.

Measure with a clip-on ammeter the battery current & every load circuit current. Calculate the total load & battery

current. If the calculated total values deviate more than ±1% from the display readings, calibrate the current from the

PC (calibration value>50% of system’s max. capacity)

3. DC Output Voltage Adjustment; measure and adjust.

Measure and, if required, adjust the output voltage to the nominal voltage recommended by the battery manufacturer.

(Voltage measurements to be done at the DC rail, with little load current)

4. Alarm Relay Test; verify all alarm relays are working correctly.

From the Smartpack’s keypad or PC use the Relay Test function; verify activation of external equipment

5. Battery bank control; measure and verify battery specifications.

Follow the recommendations of the actual battery manufacturer.

Approval

Responsible of maintenance control, sign.: Date: Approved by customer, sign.:

Form 177-gb-v1-C01_356808-103_qstart-inst-comm-oper_minipack-pss.doc_mfm_2006-12-29

PULLOUT

Check Lists Pullout

Pull out the pages with the gray outer band,

and use them as check lists

Table of contents

Other Eltek Power Supply manuals

Popular Power Supply manuals by other brands

Dynatronix

Dynatronix Diamond 36kW Series operating manual

Pulsar

Pulsar PSBOC1552455 manual

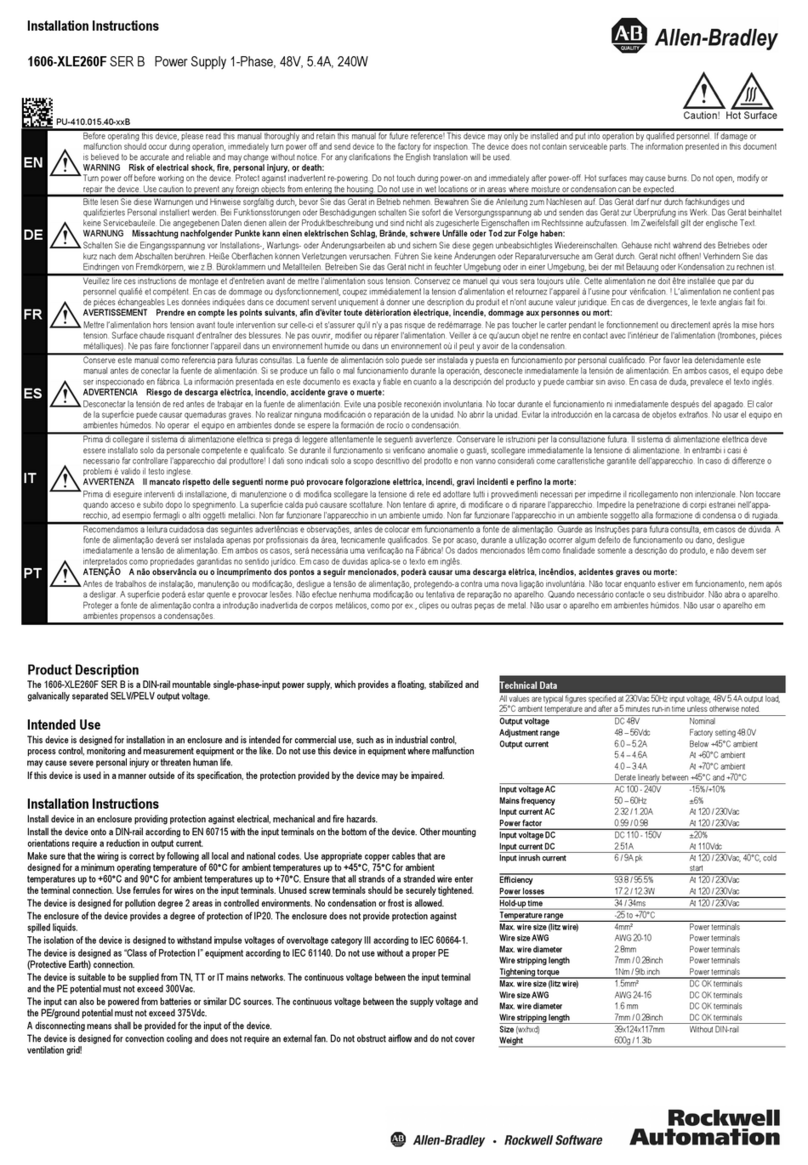

Rockwell Automation

Rockwell Automation Allen-Bradley 1606-XLE260F installation instructions

Antec

Antec HCG-520M user manual

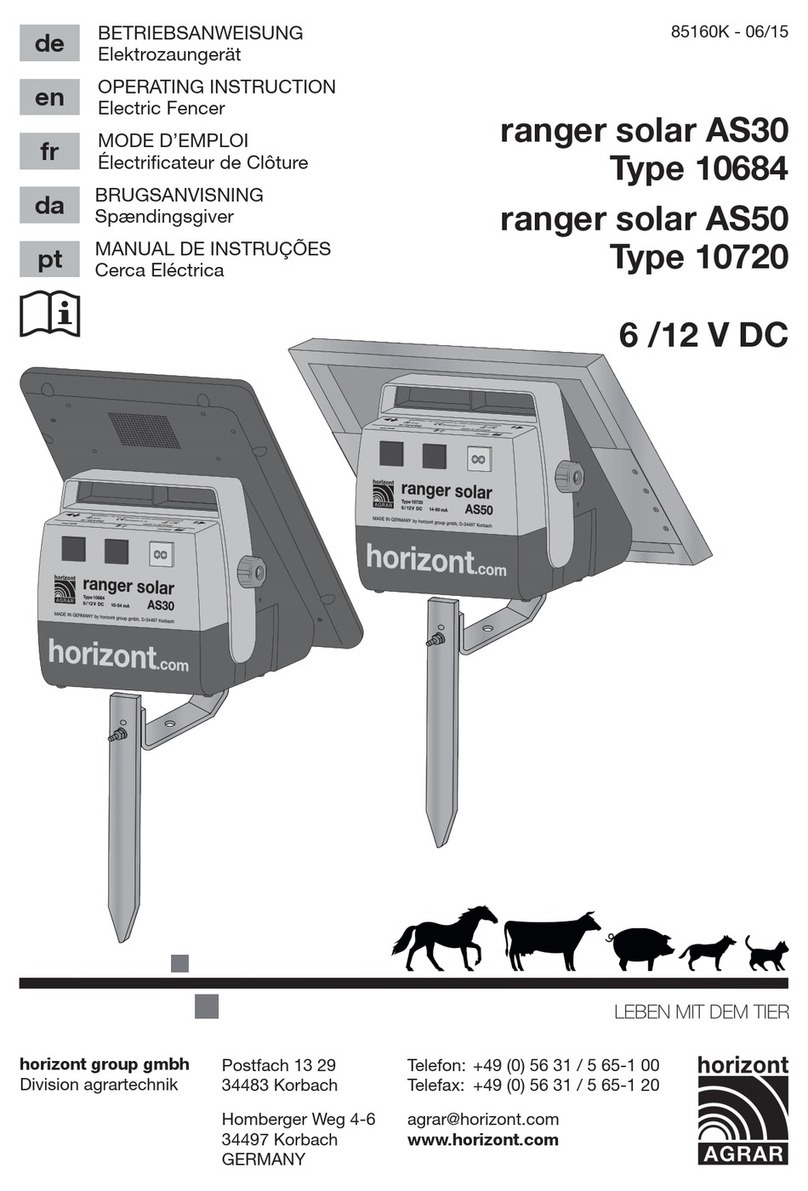

Horizont Agrar

Horizont Agrar ranger solar AS30 Operating instruction

KEPCO

KEPCO 1KW-EL quick start guide