BA-en-3021-1912_R23ATR 3

List of Contents

1 Overview and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

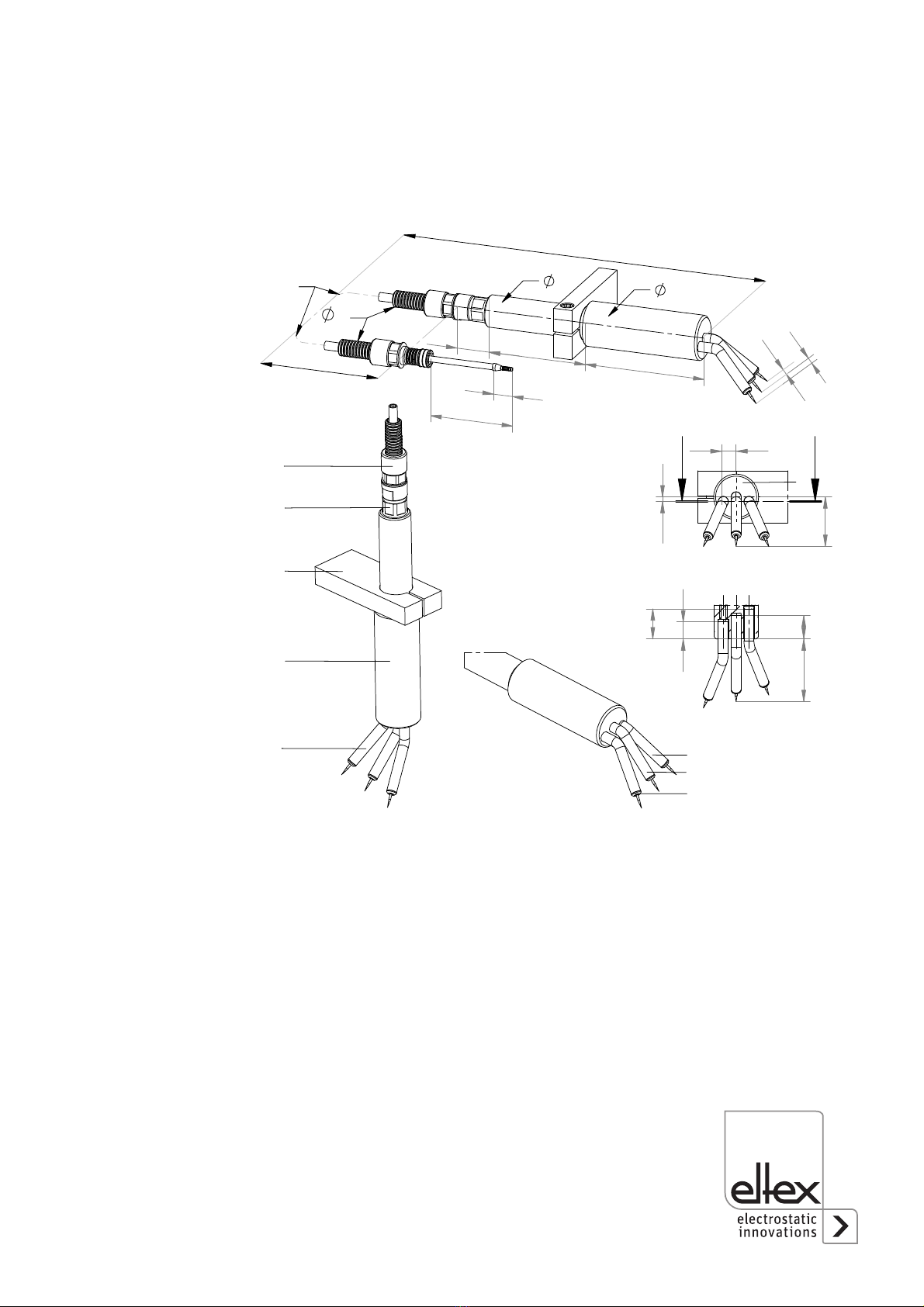

1.1 Overview point charging bar R23ATR/L. . . . . . . . . . . . . . . . . . . . . . 5

1.2 Overview point charging bar R23ATR/R . . . . . . . . . . . . . . . . . . . . . 6

1.3 Overview point charging bar R23ATR11 . . . . . . . . . . . . . . . . . . . . . 7

1.4 Design options of the point charging bar . . . . . . . . . . . . . . . . . . . . . 8

1.4.1 Design options of the point charging bar R23ATR . . . . . . . . . . . . . . 8

1.4.2 Design options of the point charging bar R23ATR11 . . . . . . . . . . . . 9

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Identification of risks and hazards . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Work and operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Contact protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Inspection of the protective resistors contact protection. . . . . . . . . 13

2.6 Technical advance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Installation and assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Installation of the point charging bar . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Distance of the emission tips from the material web . . . . . . . . . . . 15

3.3 High voltage cable of the charging bar . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 Version with fixed cable connection . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.2 Version with detachable cable connection . . . . . . . . . . . . . . . . . . . 16

3.4 Connecting the high voltage cable of the charging bar to the

high voltage generator KNH34 / KNH64, KNH35 / KNH65 . . . . . . 17

3.5 Connecting the high voltage cable of the charging bar to the

high voltage generator POWER CHARGER PCSC . . . . . . . . . . . . 18

3.6 Disconnecting the high voltage cable . . . . . . . . . . . . . . . . . . . . . . 19

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Setting the operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9 Spare parts and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27