www.eltherm.com

7

Operation Manual

Ex – Junction box Ex-it-R

BU-139

Revision 0

ATTENTION

• The following steps should only be carried out by

persons trained in handling explosive equipment.

• Strict compliance with the relevant safety regulations in

potentially explosive atmospheres is a requirement for

the safety of persons, plants and equipment.

• The persons entrusted with the planning, installation

and maintenance bear a special responsibility and must

therefore be thoroughly familiar with the applicable

regulations.

• These instructions are intended for this group of people

and contain all the important information required for

the safe handling of the ELAK-Ex-R junction boxes.

• The instructions must be kept together with the system

documentation for later use and must be kept and be

available during the entire service life of the product.

SAFETY INSTRUCTIONS

RECEIPT OF THE GOODS

On receipt of the goods, check the junction boxes and the

accessories and compare the type information with the infor-

mation on the delivery note to ensure that the correct mate-

rial has been delivered.

STORAGE

Storage should be in a dry, clean place at an ambient

temperature from 0°C to 50°C.

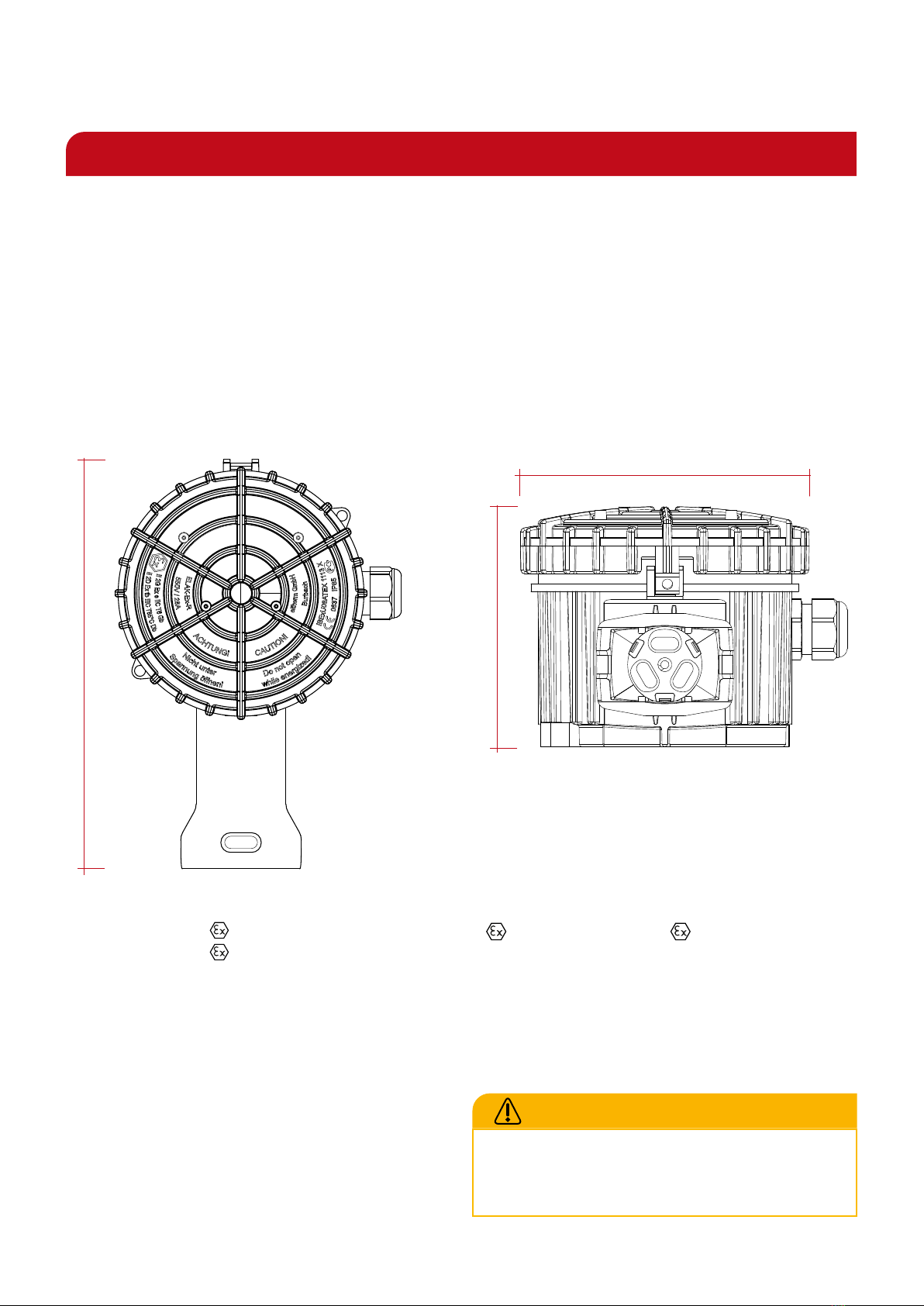

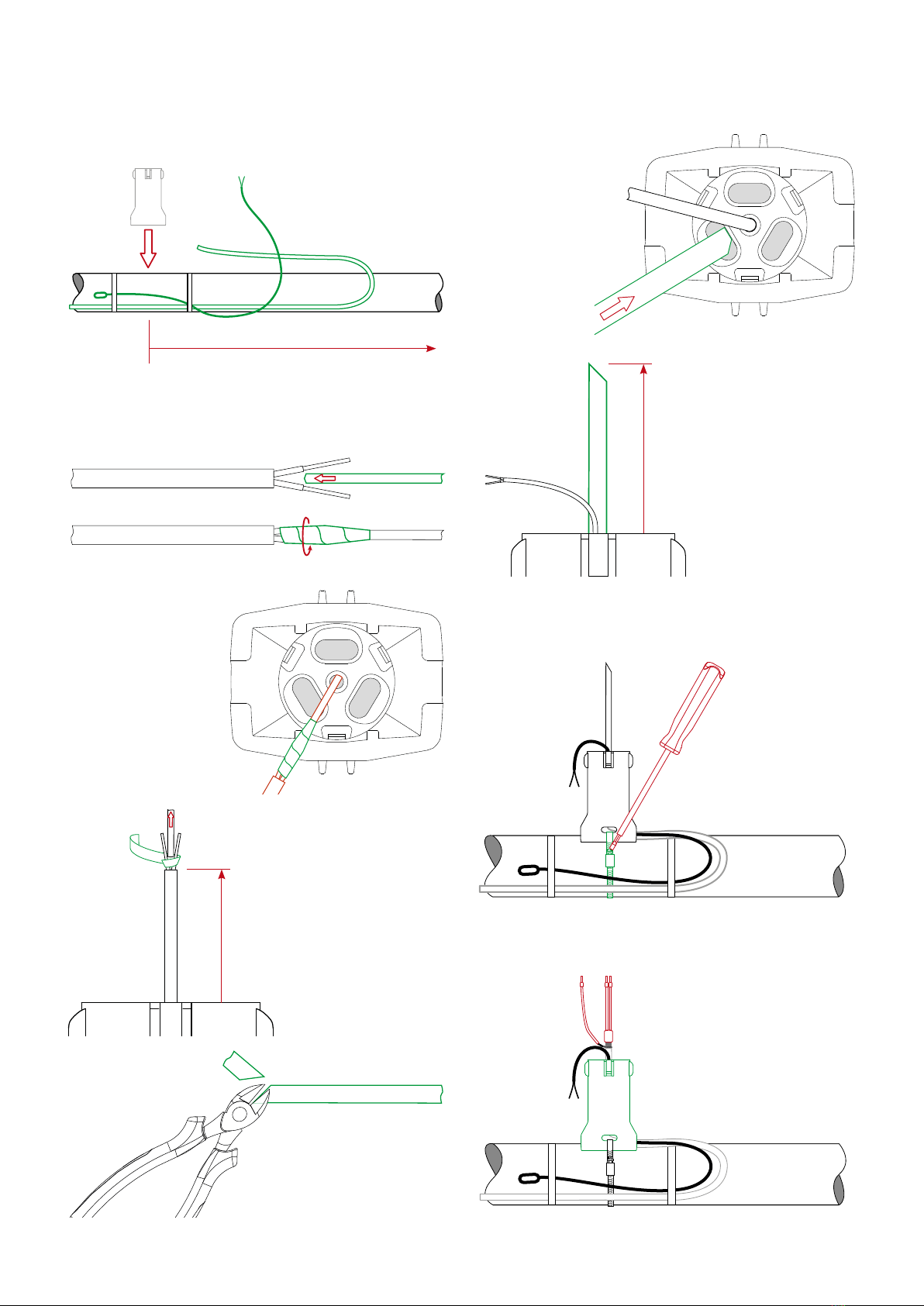

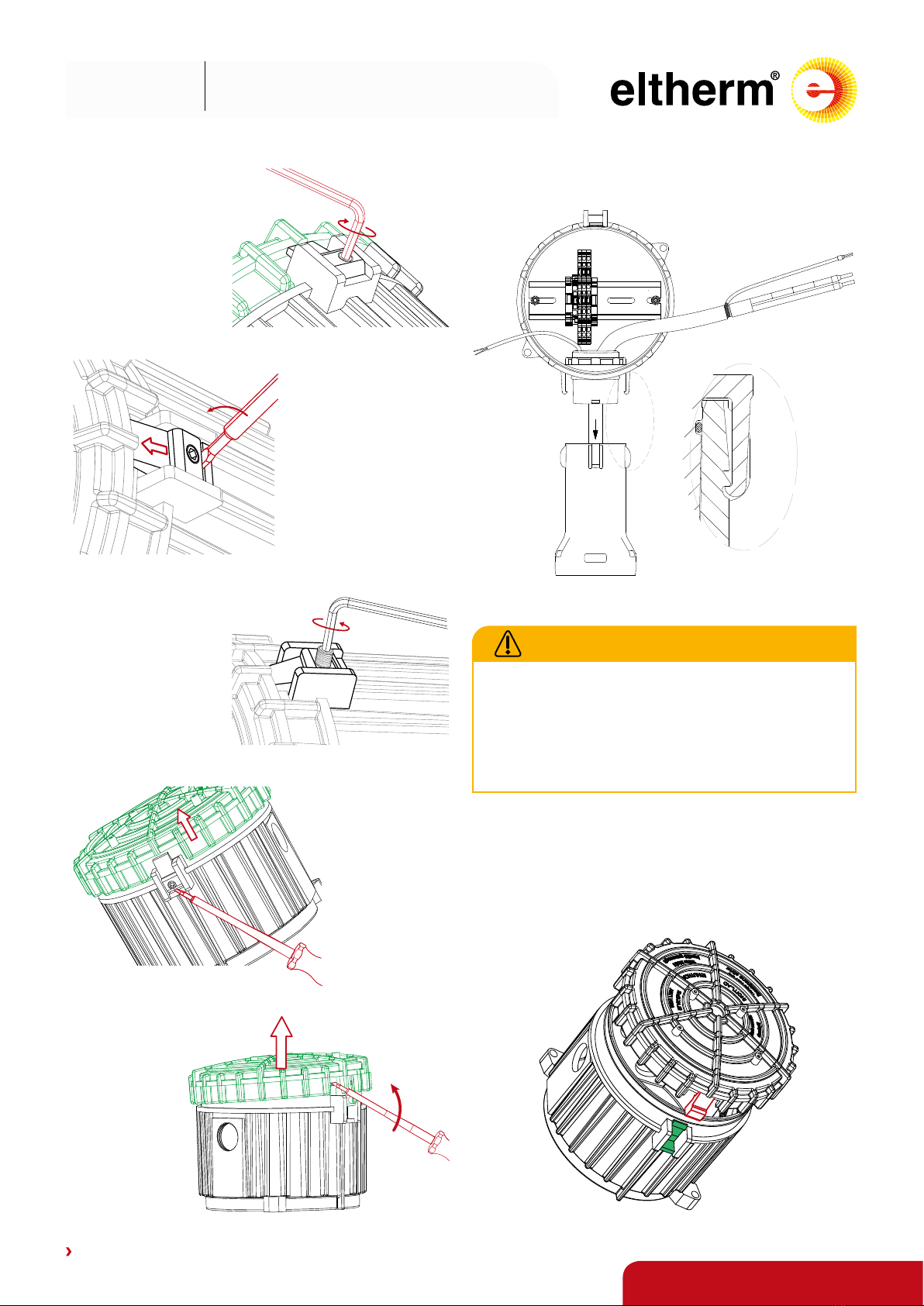

INSTALLATION

RECOMMENDED TOOLS

ASSEMBLY INSTRUCTIONS

ATTENTION

• When selecting the mounting location, take into ac-

count the degree of mechanical danger to the junction

box and the cable entries as well as the permissible am-

bient temperature.

• Ensure that the surface on which the junction box is

mounted is capable of bearing loads.

• Cables inserted into the junction box must be laid firmly

and secured against being pulled out of the cable entry

(e.g. by a cable clamp).

• Unused clamping points must be tightened.

• All cable entries, reducers and blind plugs may only be

used in conjunction with threaded connection seals, O-

rings or moulded sealing elements and must be separa-

tely tested and approved for type of protection „e“ or „t“

with EPL Gb or Db.

• Seals in the cable entries must not be exchanged or ne-

sted.

• Threaded boreholes can be reduced in size. However,

several reducers must not be reductions must not be

nested.

• Before inserting blind plugs, reducers or conduit entries

into free threaded boreholes, make sure that the threa-

ded borehole is clean and undamaged and that the re-

spective threads fit together.

• After connection, all openings must be closed tightly

(cover, threaded boreholes, cable entries). Use suitable

open-end, ring or socket spanners to tighten the cable

entries. The torques (see before) must be observed.

• ATTENTION: Excessive tightening may impair the IP pro-

tection class!

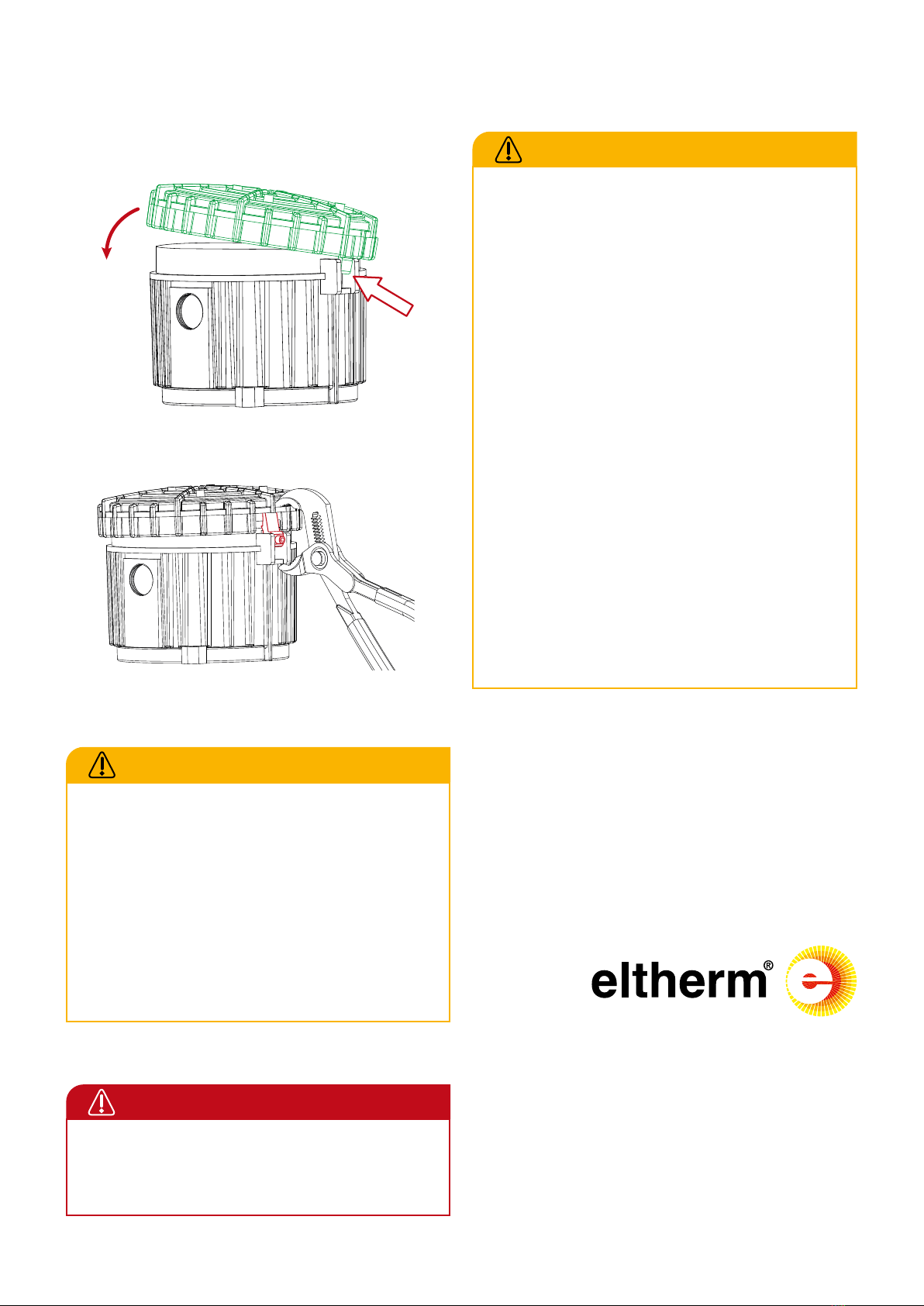

• The lid of the junction box is designed to mount a iden-

tification plate provided by the customer. Use screws Ø

2.2 x 6 mm for fastening.

REQUIRED WRENCH SIZES

Size

Clamping

range

Wrench

size

Torques

Thread Screw

[mm] [mm] [Nm]

M20 5,5 - 13 24 3,75 3,5 - 2,5

M25 8 - 17 29 5 5 - 3