2

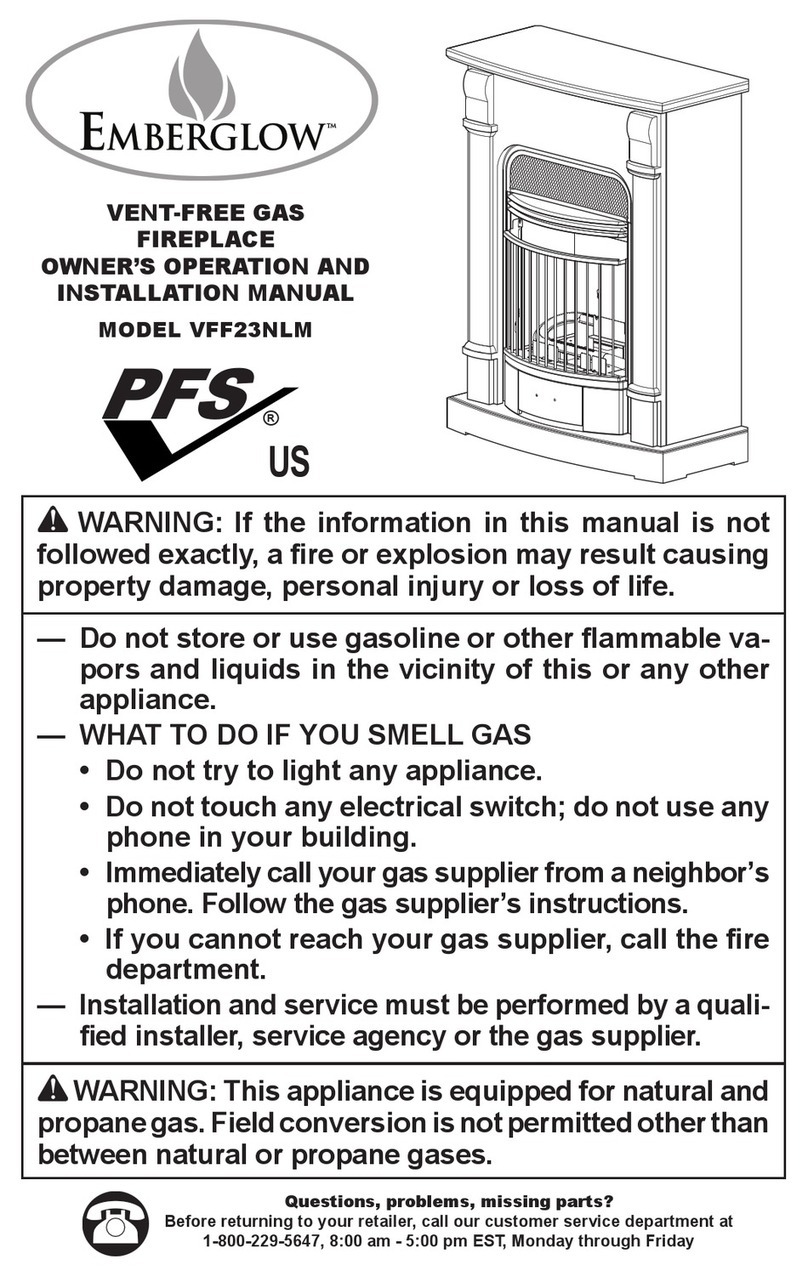

WARNING: Improper installation,

alteration, service, or maintenance can cause

injuryorpropertydamage. Refer to this manual for

correct installation and operational proced-

ures. For assistance or additional information

consult a qualified installer, service agency,

or the gas supplier.

WARNING:

only in a solid-fuel burning masonry or UL127

factory-built fireplace, constructed of noncom-

bustible material, and connected to a working

flue. (See page 5 for minimum flue opening.)

WARNING: This is a gas-fired appliance. It uses

from the room in which it is installed.

combustion and ventilat-

must be provided. Refer to the National

Z233.1/NFPA 54,Air for Com-

bustion and Ventilation .

WARNING: This product contains chemi-

the State of California to cause

cancer or birth defects, or other reproductive

WARNING: Keep flue open when operating

IMPORTANT: Read this owner’s manual carefully

andcompletely before trying to assemble, op-

erate, or service this log set. Improper use of

this log set can cause serious injury or death

from burns, fire, explosion, electrical shock,

and carbon monoxide poisoning.

DANGER: Carbon monoxide poisoning may

lead to death!

Carbon Monoxide Poisoning:Early signs of carbon

Natural and Propane/LP Gas: Natural and propane/LP

gases are odorless. An odormaking agent is added to the

gas. The odor helps you detect a gas leak. However,

the odor added to the gas can fade. Gas may be present

even though no odor exists.

Make certain you read and understand all warnings.

Keep this manual for reference. It is your guide to safe

and proper operation of this log set.

WARNING: Any change to this log set or its con-

trols can be dangerous.

1. This appliance, as supplied, is only for use with the

type of gas indicated on the rating plate. This appliance

is convertible for use with propane/LP.

Safety ............................................................... 2-3

Product Identification ........................................... 3

Local Codes .........................................................4

Unpacking ............................................................4

Product Features ................................................. 4

Operation

................... ...........

.. .............................

Inspecting Burners ............................................

Cleaning and Maintenance ................................12

Service Hints .....................................................

Technical Service ...............................................

Troubleshooting ...........................................12-13

Replacement Parts ......................................14-15

Warranty ............................................ Back Cover

SAFETY

adjustment,

This appliance is for installation

air (oxygen)

Provisions for adequate

ion air

Fuel Gas Codes, ANSI

cals known to

harm.

unit.

monoxide poisoning resemble the flu, with headaches,

dizziness, or nausea. If you have these signs, the log

set may not be working properly. Get fresh air at once!

Have log set serviced. Some people are more affected

by carbon monoxide than others. These include pregnant

women, people with heart or lung disease or anemia,

those under the influence of alcohol, and those at high

altitudes.

2. What to do if you smell gas:

Shut off gas supply.

• Do not try to light any appliance.

Do not touch any electrical switch; do not use any

neighbor’s

phone. Follow the gas supplier’s instructions.

3. Never install the log set:

• In a recreational vehicle

• Wherecurtains, furniture, clothing, or other flammable

objects are less than 42" from the front, top, or sides

o f the log se t

• In high traffic area

(see Conversion

Instruction, P.7 )

Installation

•

• Immediately call your gas supplier from a

•

phone in your building.

• In windy or drafty areas

4- 9

................ ................ .......

........................................... 10

11

12

12

• If you cannot reach your gas supplier, call the fire

department.