SUMMARY

GENERAL SAFETY GUIDELINES......................................................... 4

1. DESCRIPTION............................................................................... 5

1.1 PRIUS Series............................................................................ 5

1.3 Features .................................................................................. 8

1.3.1 PLUNGER............................................................................. 9

2. INSTALLATION.............................................................................. 12

2.1 Installation warning................................................................. 12

2.2 Commissioning steps.............................................................. 13

2.2.1 Pump location...................................................................... 13

2.2.2 Oil filling .............................................................................. 13

2.2.3 Piping connection................................................................. 14

2.2.4 Pump head .......................................................................... 14

2.2.5 Foot filter ............................................................................. 14

2.2.6 Installation drawings............................................................ 15

3. ELECTRICAL WIRING .................................................................... 16

3.1 Preliminary checks................................................................... 16

3.2 Connection diagrams............................................................... 16

4. START UP18

4.1 Start up................................................................................... 18

5. PRIMING 19

5.1 How to prime the pump .......................................................... 19

6. MAINTENANCE............................................................................ 20

6.1 Maintenance schedule............................................................. 20

6.2 Maintenance inspection .......................................................... 20

6.3 Shutdown ............................................................................... 21

7. TROUBLESHOOTING ..................................................................... 22

7.1 Repair service.......................................................................... 22

8. COMPATIBILITY TABLE ................................................................. 23

8.1 Chemical compatibility table.................................................... 23

8.2 Materials................................................................................. 23

Figures

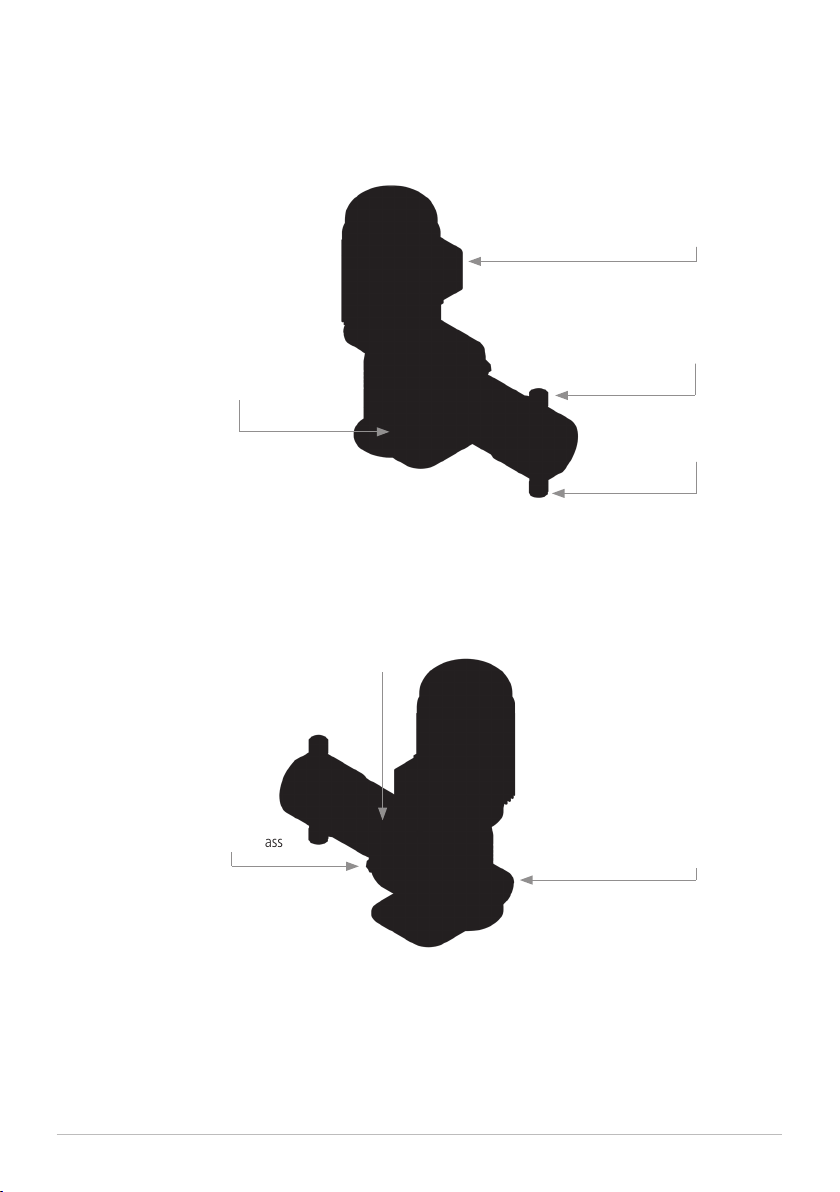

Fig. 1. PRIUS P pump ............................................................... 7

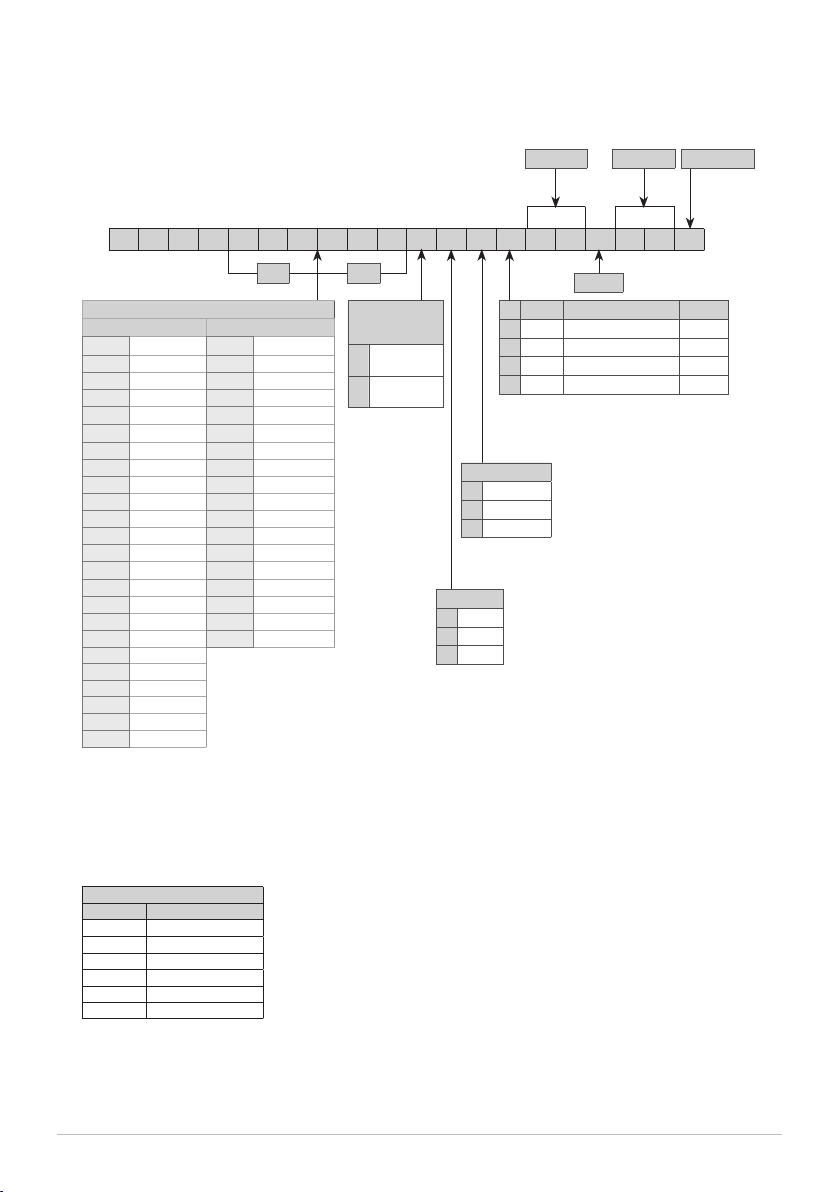

Fig. 2. Installation drawings ..................................................... 15

Tables

Tab. 1. Capacity............................................................................ 8

Tab. 2. PRIUS P - PP pump head.................................................... 10

Tab. 3. PRIUS P - SS pump head .................................................... 11

Tab. 4. Acceptable oil for lubricating.............................................. 13

Tab. 5. Guide to troubleshooting. .................................................. 22

Tab. 6. Chemical compatibility table............................................... 23