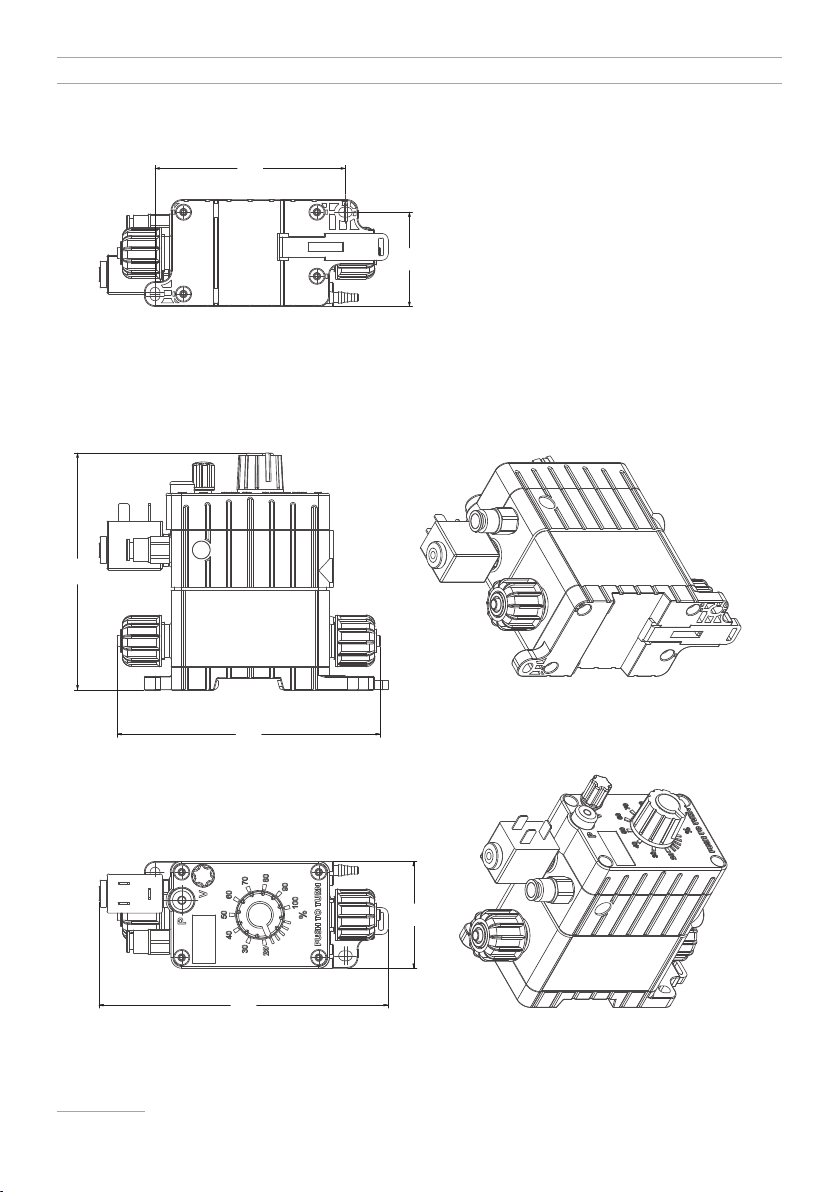

7

Basic operations

PRIMING

To prime the pump without touching chemicals please perform these operations:

- connect all hoses into proper places (delivery hose, suction hose, outgassing hose).

- open outgassing valve and turn on the pump.

- set pump’s single injection at 100%;

- press the priming button until the pump head is filled up.

Connect the pump to the compressed air hose. Let compressed air enter into the pump.

All air inside the pump head will exit through the outgassing outlet. When product will leak from it, close immediately the

outgassing valve. If dosing product is particularly dense, to facilitate the priming, insert on vent pipe a syringe of 20 cc and

suck inside.

DOSING

Pump’s technical features are printed on a label located on pump’s box: model, supply voltage, working counterpressure (Kpa/

bar) and pump capacity (l/h).All these dosing information are calculated by dosing water at 20 °C temperature, at the maximum

counterpressure reported on the label, using the injection valve and the % knob set to maximum. Dosing accuracy is ± 2% l/h

at constant maximum counterpressure and 1 cps flow (max viscosity: 60 cps).

Caution: injection capacity is a constant value but a variation in counterpressure or product’s viscosity may cause

some changes. For further details see “Delivery curves” paragraph.

HOW DOES IT WORK?

“RACV”pneumatic dosing pump works only with compressed air without lubrificant and/or condensed water.Air supply pressure

range must be at 6bar (87PSI) (±10%).

At the max injection/min value, 120 injection/min, the pump has a 0.5 seconds working cycle: 0.25 seconds active (compressed

air is in the pump) and 0.25 passive (compressed air is not in the pump).

Solenoid valve and PLC for compressed air control must be regulated on this values.

SOLENOID VALVE

The solenoid valve should be driven by a PLC or any other equipment that can operate it with a direct voltage supplied in pulses,

frequency must be 2 Hertz with a 50% duty cycle.

Connect the solenoid valve using the standard connector. Attention: solenoid valves can have several power supplies, power

supply is specified on the solenoid valve label.