Emerald EE-HWS-A1-220 Instruction Manual

USER GUIDE &

INSTALLATION

MANUAL

All-In-One

Wi-Fi Enabled

Hot Water

Heat Pump

RESIDENTIAL

EE-HWS-A1-220 EE-HWS-A1-220E

EE-HWS-A1-270 EE-HWS-A1-270E

EE-HWS-A1-320 EE-HWS-A1-320E

COMMERCIAL

EE-HWS-A1-220-1/-2 EE-HWS-A1-220E-1/-2

EE-HWS-A1-270-1/-2 EE-HWS-A1-270E-1/-2

EE-HWS-A1-320-1/-2 EE-HWS-A1-320E-1/-2

USER GUIDE

WELCOME 4

WARRANTY 6

IMPORTANT TIPS 7

EMERALD APP 8

SMART ACTIONS AND SCHEDULING 8

WI-FI PAIRING 10 - 11

CONTROLLER INSTRUCTIONS 12 - 14

Thank you

Thank you for choosing an Emerald hot water heat pump.

Emerald designs its heat pumps to provide years of ecient

and hassle-free sustainable hot water heating.

Please take time to read this document and keep it for

future reference.

Welcome to your

Emerald heat pump

The Emerald heat pump and Emerald app oer advanced hot

water heating.

Unlike standard electric water heaters, Emerald heat pumps

leverage advanced technology to extract heat from the air,

delivering exceptional energy and cost savings. Think of it

as a reverse refrigerator, which absorbs heat from the air,

compresses it, and transfers that heat to your water.

Emerald heat pump's can save up to 80% on your hot

water costs while enjoying ecient and eco-friendly hot

water heating. Pair it with the Emerald app for even greater

energy saving and convenience.

4

5

Registering your

warranty gives

you more from

Emerald

Scan the QR code to download the Emerald app.

By connecting your heat pump to the app, your

warranty will automatically be registered.

OR

Visit emeraldenergy.com.au/registerwarranty and

follow the instructions to complete the warranty

registration.

Enjoy the benefits when you

register your warranty.

• Priority customer support.

• Tips and advice to maximise savings with your

Emerald heat pump.

• Exclusive product updates and promotions.

• Peace of mind knowing your hot water heat pump

is protected.

6

ALLOW YOUR HEAT PUMP TO

BREATH

Your heat pump needs air to work properly and

heat your hot water. If you block or restrict the

air around it, it won't work as well.

Please don't put items next to your heat pump

that can get in the way of the air it needs.

A ROUTINE CLEAN FOR YOUR

HEAT PUMP

For the best performance of your heat pump,

we suggest regular cleaning to prevent the

accumulation of dirt and leaves that could

impact its operation.

SERVICING YOUR HEAT PUMP

For best eciency, we recommend servicing

your heat pump. As with other electrical

appliances servicing can identify and resolve

issues that could aect your heating system.

Important things

to remember

There are a few key points to remember to help

keep your heat pump running smoothly.

7

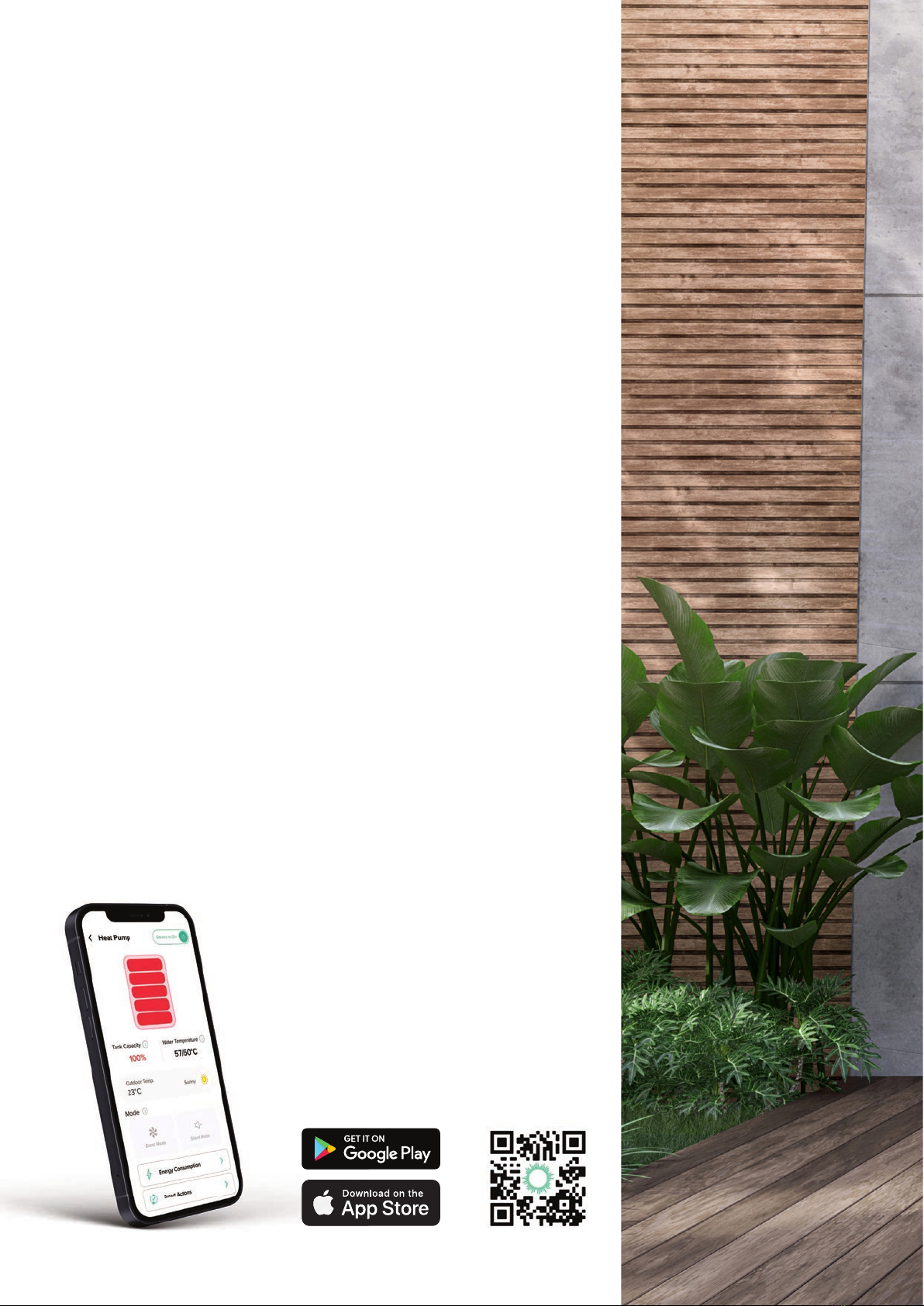

The Emerald app provides you with convenient control and monitoring

capabilities for your heat pump hot water system.

Here's what you can do with the app:

Monitor electricity consumption

View information on your heat pump hot water systems electricity usage

.

Real-time hot water temperature

Access real-time temperature data of your hot water, ensuring you always

know the current status.

Remote control anywhere, anytime

Enjoy the flexibility of remotely controlling your heat pump, allowing you

to turn it on or o from anywhere via your mobile phone.

Boost your hot water

Activate the Boost feature to speed up the heating process of your hot

water tank when you need it to be ready quickly.

Put your heat pump in Silent Mode

Opt for a quieter operation by activating Silent Mode.

Convenient control with

the Emerald app

8

Turn your heat pump

on or o anywhere,

anytime

Real-time water tank

capacity

Boost your tank to heat

your water quickly

Get valuable energy

consumption data

Real-time water tank

temperature

Quieter operation with

silent mode

Automate hot water

with Smart Actions

Smart Actions to help save

even more

What are Smart Actions?

Smart Actions is a feature designed to

automate temperature control. It allows you

to set specific rules for your heat pump,

enabling it to adjust temperature settings

based on your preferences.

How do Smart Actions work?

Smart Actions will maintain your preferred temperature

while saving you energy and money according to your

preferences.

How can you save with Smart Actions?

Eciency, Convenience and Control

Smart Actions enhance the energy eciency of your

heat pump by automating its behavior, leading to lower

energy consumption and reduced bills. These actions

simplify your routine by maintaining the hot water tem-

perature at your desired level without constant adjust-

ments, oering convenience while conserving energy.

Additionally, you enjoy personalised control, allowing

you to tailor the heat pump settings for optimal oper-

ation times and minimising energy waste, enhancing

your overall experience.

Examples of Smart Actions

• Solar Soaker

Leverage excess solar energy by setting your heat

pump to automatically turn on when your solar panels

are generating surplus power. This allows you to heat

your hot water using free solar energy.

• Set Schedules to Heat Your Water

Set your schedules so that your system will only turn

on during your o-peak electricity times - saving you

money on your electricity bills.

Set up a Smart Action in 3 easy steps:

1. In the Emerald app, click Smart Actions

2. Create and name your new Smart Action. Select a

'Trigger' that you want to activate your system e.g.

’Schedule’.

3. Set the 'Action’. This is the device you wish to be

activated by the trigger - in this case, it would be

your Heat Pump.

For step by step instructions visit:

emeraldhome.com.au/support-faq

9

Solar soaker now on.

Heat pump is running on surplus solar

power.

Your water temperature is low.

You may want to turn on boost mode.

10

11

WI-FI PAIRING

WIFI PAIRING YOUR HEAT PUMP

WIFI PAIRING STEPS

1. Download the Emerald app and log in or create a new account.

2. Tap the (+) button on the app's home screen select "Add Product."

3. Choose between Bluetooth mode (recommended) or AP mode

for device pairing.

4. Connect your mobile device to a 2.4GHz Wi-Fi network using the

correct password.

5. Ensure the Heat Pump is powered on and the controller's display

is active.

6 Follow the in-app instructions to activate Pairing Mode on the

Heat Pump based on the chosen mode.

TOP TIP: Ensure child lock is turned o by holding the power button

for 5 seconds. (1)

7. Confirm the Wi-Fi symbol is flashing on the Heat Pump's display. (2)

8. Return to the app and follow the on-screen prompts to complete

the pairing process.

9. Select the correct model number and scan the heat pump's serial

number using the app.

10. Enter the installation date.

Your Heat Pump should now be paired and available for you to

access via the Emerald app.

PAIRING TROUBLESHOOTING TIPS

If you are having trouble pairing the Heat Pump, please check the

following:

- Ensure your mobile device is connected to a 2.4GHz Wi-Fi

network.

- Ensure Wi-Fi password is correct as sometimes 2.4GHz password

can be dierent.

- If possible, move your Wi-Fi router close to your heat pump.

Alternatively, set up a Wi-Fi extender to increase signal strength.

TIP: Device will time out after 2 minutes. Even if Wi-Fi icon is still

flashing, it is recommended you follow the below steps to put device

back into pairing mode.

Press the button + or depending on pairing mode.

(1) (2)

Need assistance?

Visit online troubleshooting customer support.

emeraldenergy.com.au/contact-us

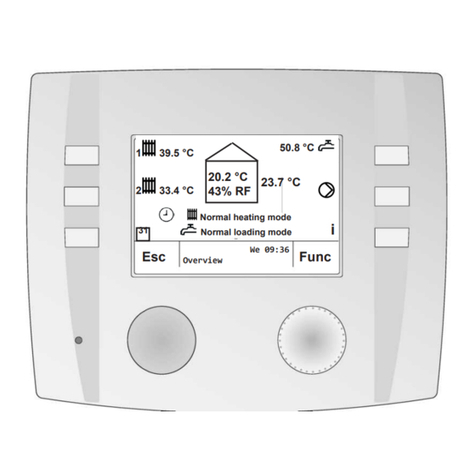

CONTROLLER INSTRUCTIONS

12

BUTTON INSTRUCTIONS

On/O

Button

• Press button for 3 seconds to unlock the controller.

• Press button for 2 seconds to turn ON/OFF system.

• Press button to return to main control panel screen from any other screen settings.

Running

Mode • When the system is turned on press button to select dierent running modes.

Up and

Dow

• Press UP or DOWN button once to set target water temperature.

• Press UP or DOWN button for 3 seconds to open the system’s running conditions.

• Under Timer or Clock setting status, press the UP or DOWN button to adjust

setting value

Clock

and

Timer

Setting

• Press button once to enter the real clock setting.

• Press button for 3 seconds to enter/exit the timer settings.

• Under timer settings, press button once to switch the timer setting value from

“hour” to “minute”.

• Under timer settings, press and hold button for 3 seconds to cancel the current

timer setting.

ICON INSTRUCTIONS

SYMBOL STATUS DESCRIPTION

Visible on screen System is in standard mode

+ Visible on screen System is in silent mode

+ + Visible on screen System is in boost mode

Visible on screen System is in defrost

Visible on screen Service required

Visible on screen Compressor is running

Visible on screen Fan motor is running

Visible on screen Electric heating element is on for heating (only for the models with element)

Flashing Electric heating element is on for sterilisation (only for the models with element)

RT Visible on screen Current water temperature in the tank

SET Visible on screen Set target water temperature in the tank

Visible on screen Display actual water temperature, set water temperature, and fault code

º

C

Visible on screen Currently showing Celsius temperature

Visible on screen Real clock time

Visible on screen Timer is on

ON Visible on screen Timer function is activated

OFF Visible on screen Timer function is deactivated

1

Visible on screen / Not visible on screen

Timing period 1 set / Timer period 1 not set

2

Visible on screen / Not visible on screen

Timing period 2 set / Timer period 2 not set

3

Visible on screen / Not visible on screen

Timing period 3 set / Timer period 3 not set

Visible on screen The controller is locked

Visible on screen / Flashing The Wi-Fi is connected / Wi-Fi is searching for connection

Visible on screen Timer setting on Monday, Tuesday, Wednesday, etc

Visible on screen Factory Mode

STAN Flashing Choosing is in standard mode

SILE Flashing Choosing is in silent mode

BOOS Flashing Choosing is in boost mode

ELE Flashing Choosing is in electric heating element mode

HP Flashing Choosing is in heat pump mode

W

POWER ON

- Sun is visible on screen.

STANDBY

- Screen is on but sun is not visible

POWER OFF

- Screen is blank.

CONTROLLER INSTRUCTIONS

OPERATION INSTRUCTIONS

CONTROLLER LOCK AND UNLOCK

• In the locked state, press the button for 5 seconds, control

panel will beep once, then the control panel is unlocked.

• The control panel locks automatically when no operation has

been detected for 60 second.

WATER TANK TEMPERATURE SETTING

Press the or button on the control panel to adjust target water

temperature of the heat pump.

SELECT RUNNING MODE

Standard Mode:

• Under this mode, the + STAN icon lights up (STAN will flash).

• The setting range is optional with 15ºC – 60ºC (Commercial-1:

63ºC, Commercial-2: 70ºC) for target water temperature.

• Heat pump will cycle (Turn OFF/ON) based on the set target

temperature.

Silent Mode:

• Press the button to switch to Silent mode. Under this mode,

the + icons light up (SILE will flash). The setting range is

optional with 15ºC - 60ºC for target water temperature.

• Heat pump will run with a lower noise signature.

• This is a one-shot function and will return to standard mode after

one cycle or 24 hours.

Boost Mode (non-element):

• Press the button to select Boost mode. Under this mode,

the + icons light up (BOOS will flash).

• The setting range is optional with 15ºC - 65ºC (Commercial-1:

65ºC, Commercial-2: 70ºC) for target water temperature.

• In Boost mode, the heat pump will run with a larger heating

capacity.

• If the target water temperature ≤60ºC, Boost mode will work

by increasing the inverter strength to heat the tank faster.

• This is a one-shot function and will return to standard mode after

one cycle or 24 hours.

Boost Mode (element):

• Press the button to select Boost mode. Under this mode,

the + + icons light up (BOOS will flash).

• The setting range is optional with 15ºC - 70ºC (Commercial-1:

70ºC, Commercial-2: 70ºC) for target water temperature.

• In Boost mode, the heat pump will run with a larger heating

capacity.

• If the target water temperature ≤60ºC, both the heat pump and

electric heating element work simultaneously during the entire

heating cycle to heat the tank faster.

• This is a one-shot function and will return to standard mode after

one cyc.le or 24 hour.

Maintenance Mode (element system only):

• If the heat pump fails, the electric heating element heats the

water up to the target water temperature.

• Control panel will beep intermittently and have an icon on the

control panel screen.

REAL TIME CLOCK SETTING

1. On the control panel, press the button once to enter the real-

time clock setting.

2. On initial set-up, date will need to be set on real time clock e.g.

“YYYY”, “MM”, “DD”.

3. Press the button once, and the “hour” will flash. To set the

hour of the real-time clock, press the or buttons.

4. After setting the hour, press the button again, the “minute” will

flash. To set the minute of the real-time clock, press the or

buttons.

5. Press the button again to confirm the current clock setting

and return to the main control panel screen.

TIMER SETTING

1. Press the button for 3 seconds to begin setting your timer.

You can set 3 dierent ON/OFF time periods.

2. Press the or buttons to interact with the control panel timer

settings.

3. The “1” symbol and “hour” of the timer will be visible. Press the

or buttons, to set the “hour” in which you want the system

to turn ON.

4. Press the button again, the “minute” of the timer will be visible.

Press the or buttons to set the minutes of the system “1” timer.

5. Press the button again to enter the OFF setting of system “1”

timer, this is the time the system will turn OFF.

6. Press the button to complete the System “1” timer. The heat

pump can have two more system timers (2 and 3). Press the

button to exit the timer settings and return to the main control

panel screen.

7. If the ON and OFF times are set at the same value for system “2”

and “3” timers, system “1” timer will override system “2” and “3”

timers.

8. After setting all three system timers in the timer settings, press the

button to confirm the current set value and return to the main

control panel screen.

9. The system does not need to have all three timers active.

10. The main control panel screen will show a number (1,2,3) next to

your real-time clock, indicating which timer is currently active and

what operation status it is currently in (ON/OFF)

11. To deactivate a system timer, access the system timer settings.

Press the button to navigate through each system timer (1,2,3).

Press the button for 3 seconds to deactivate the system timer

currently shown on the control panel. The control panel will return

to the main interface once completed.

WEEKLY TIMER

1. Press the button once shortly, the systems real-time clock will

be flashing. Press the button for 3 seconds to enter weekly

timer.

2. The weekly timer settings can be changed by pressing the or

button.

3. Weekly timer will turn your system on once per week on the

allocated day that has been set on the control panel.

4. To deactivate the weekly timer, press the button once, the

systems real-time clock will be flashing. Press the button for

3 seconds to cancel the weekly timer and return to the main

control panel screen.

13

CONTROLLER INSTRUCTIONS

OPERATION INSTRUCTIONS

MEMORY FUNCTION AND OTHER FUNCTIONS

1. The Control panel has a power-down memory function.

2. The control panel backlight will be on for 60 seconds before

turning o if there is not further input.

3. In boost mode, only the current mode, water tank temperature,

and time are displayed.

MANUAL STERILISATION

ONLY AVAILABLE FOR THE MODELS WITH ELECTRIC HEATING

ELEMENT

1. Press and hold the + + for 5 seconds to enter the

manual disinfection state.

2. The symbol lights up, indicating that it has entered the

disinfection state, start the electric heating to heat the water to

65°C and maintain the water temperature between 63°C - 65°C.

After 30 minutes later, it will automatically exit the disinfection

state, and the symbol will go out.

3. Only available for the models with electric heating element.

FORCED DEFROSTING

1. In the power-on state, press the + buttons for 5 seconds

to enter the forced defrosting the icon lights up during forced

defrosting.

2. When shutdown or forced defrosting reaches the set time or

temperature, the system automatically exits forced defrosting and

enters normal heating water status. The icon goes out during

forced defrosting.

ELECTRIC HEATING ELEMENT CONTROL

ONLY FOR EE-HWS-A1-220E(-1/2) & EE-HWS-A1-270E(-1/2)

1. When defrosting, electric heating element is forced to be turned

on if heating is required; The electric heating element is not

allowed to be turned on within 60 seconds after the machine is

powered on or after the electric heating element is turned o.

2. When the ambient temperature is ≤ -7°C, the heat pump will be

not allowed to turned on, and the electric heating element is

automatically activated to produce hot water. When the ambient

temperature ≥ 5°C The electric heating is stopped.

3. When high pressure protection or exhaust high temperature

protection occurs, the compressor will be locked o, and the

electric heating element is automatically activated to produce hot

water.

4. When exhaust temperature sensor failure, coil temperature

sensor failure, gas return temperature sensor failure, the electric

heating element will be automatically activated on above

conditions, which is not restricted by the ambient temperature

requirement.

LEGIONELLA CONTROL

For legionella control our systems heat at least 45% of the water tank

to 60ºC daily. This sterilisation process will occur daily regardless of

any manual setting changes made to the controller.

14

INSTALLATION

GUIDE

SAFETY PRECAUTIONS 16

GENERAL INFORMATION

Measurements 17

Components 18

INSTALLATION 19 - 20

PLUMBING CONNECTIONS 21 - 23

ELECTRICAL CONNECTIONS 24 - 25

CONTROLLER INSTRUCTIONS 26 - 27

COMMISSIONING THE SYSTEM 28

OPERATION AND MAINTENANCE 29

FAQs 30

SPECIFICATIONS 31

IMPORTANT NOTICE

Please read this manual carefully before you

attempt to install this product. Failure to do so

may result in the product not working according

to its design.

INSTALLATION & OPERATION

• This heat pump uses R290 (propane) refrigerant, classified as a

flammable gas in accordance with AS 1677.

To service components that use this refrigerant, such as the

compressor, it is essential to engage a refrigeration mechanic

with the appropriate Australian refrigerant handling license.

• Do not puncture or subject the heat pump to flames.

• Keep in mind that the refrigerant may not have a detectable odor.

• When storing the heat pump, be sure to adhere to AS/NZS 5601

compliance requirements.

• Both national and state regulations govern the storage, transpor-

tation, and handling of hazardous materials, including flammable

gases. The maximum quantity and arrangement of equipment

allowed for transportation or storage will be determined by

heat pump regulations.

WARNING

• If you suspect a refrigerant leak, switch o the unit at the mains

and contact the service agent. Additionally, avoid smoking or

using electrical equipment to prevent injury from refrigerant leaks.

• To minimise the risk of fire, avoid storing chemicals or flammable

materials near the heat pump, and never use flammable sprays

like hairspray or paint in its vicinity, as a refrigerant leak combined

with an external ignition source could lead to fire.

• Avoid storing or transporting this heat pump in areas with

potential ignition sources, such as open flames.

• End of life recycling: The refrigerant must not enter the

atmosphere. Only have the refrigerant removed by qualified

professional.

If the hot water system has not been used for two weeks or longer,

there's a chance that a dangerous amount of highly flammable

hydrogen gas may have built up inside the water heater.

To safely disperse this gas, follow these steps:

1. Turn on a hot water tap and let it run for several minutes until you

no longer hear the discharge of gas. You can use a sink, basin, or

bath outlet for this purpose, but avoid using a dishwasher, clothes

washer, or any other appliance.

2. While performing this procedure, make sure there is no smoking,

open flames, or electrical appliances in the vicinity.

3. If hydrogen gas is released through the tap, it may produce an

unusual sound similar to air escaping.

Taking these precautions will help ensure the safe dissipation of any

accumulated hydrogen gas in the water heater.

SAFETY PRECAUTIONS

INSTALLATION & OPERATION

• Ensure the installation adheres to the AS/NZS 5149 Standards.

• Read these instructions thoroughly before attempting to install or

operate this system.

• This heat pump must be installed, commissioned, and serviced by

an authorised person in accordance with local regulations.

• Only an electrician should handle tasks involving access covers

or water heating components, as they involve exposing 240V

wiring.

• In case of damage to the system's power supply, it must be

replaced by an authorised person. Avoid touching the power

connections or plugs with wet hands.

• Be cautious not to touch the pipework, as it may be hot.

• Do not place any objects on or against this heat pump.

• Keep chemicals or flammable materials away from this heat pump.

• Do not operate the heat pump with collectors or covers removed.

• Do not activate the heat pump unless the cylinder is filled with

water.

• Ensure the household electrics have a reliable earth connection.

• This heat pump must be safeguarded with a residual current

device of the appropriate rating.

• Do not tamper with any permanent labels or warning plates

attached to the external cover of this heat pump.

• Always engage a trained personnel if you need to relocate this

heat pump after professional installation.

• Maintenance and repair work should only be carried out by

trained and qualified personnel.

• The electrical connection to this product should use a 20A RCD/

MCB or RCBO with a test button function.

• Ensure that children never use this heat pump.

16

GENERAL INFORMATION

MEASUREMENTS

Model (Residential) EE-HWS-A1-220E EE-HWS-A1-220 EE-HWS-A1-270E EE-HWS-A1-270 EE-HWS-A1-320E EE-HWS-A1-320

Model (Commercial)

EE-HWS-A1-220E-1(-2)

EE-HWS-A1-220-1

EE-HWS-A1-270E-1(-2)

EE-HWS-A1-270-1 EE-HWS-A1-320E-1 EE-HWS-A1-320-1

Water Tank Volume 220L 270L 320L

Optional Running Modes Standard / Silent /

Booster / E-Heater

Standard / Silent /

Booster

Standard / Silent /

Booster / E-Heater

Standard / Silent /

Booster

Standard / Silent /

Booster / E-Heater

Standard / Silent /

Booster

Unpacked Dimension 600*600*1598mm 600*600*1598mm 600*600*1826mm 600*600*1826mm 600*600*2050mm 600*600*2050mm

Packed Dimension 670*670*1730mm 670*670*1730mm 670*670*1956mm 670*670*1956mm 670*670*2170mm 670*670*2170mm

Net Weight 118kg 118kg 136kg 136kg 146kg 146kg

Gross Weight 126kg 126kg 145kg 145kg 154Kg 154kg

17

EE-HWS-A1-220E(-1/-2)

(The electric heating element is not included in EE-HWS-A1-220)

Power cable hole Display

Thermal sensor

Electric heating element

Magnesium anode

Condensate drainage hole

TPR safety valve

Hot water outlet

Cold water inlet

102 836 151

1598

EE-HWS-A1-270E(-1/-2)

(The electric heating element is not included in EE-HWS-A1-270)

Power cable hole

Thermal sensor

Electric heating element

Magnesium anode

Condensate drainage port

TPR safety valve

Hot water outlet

Cold water inlet

151

1826

1064

102

Display

Display

Power cable hole

Electric heating element

Thermal sensor

Magnesium anode

TPR safety valve

Hot water outlet

Cold water inlet

Condensate drainage hole

2054

1292

102 151

EE-HWS-A1-320E(-1)

(The electric heating element is not included in EE-HWS-A1-320)

GENERAL INFORMATION

18

COMPONENTS

No. DESCRIPTION QTY REMARK

1 Feet 4 PP

2 Bottom tray 1 Galvanised plate

3 Position block 4 PP

4 Outer casing 1 Galvanised plate

5 Hand grip 2 ABS

6 Electric heater cover 1 Galvanised plate

7 Decorative rubber ring 4 ABS

8 Enamel tank 1

9 Microchannel heat exchanger 1 Aluminium alloy

10 Electric heater 1

11 Microchannel outlet 1 TP2M

12 Microchannel inlet 1 TP2M

13 Bottom bracket 1 Galvanised plate

14 Curve adapter 1 PVC

15 Condensate drainage port 1 PVC

16 Condensate tray 1 ABS

17 Self tapping screw 8

18 Top lid 1 Galvanised plate

19 Power cable screw 1 PP

20 Controller cover 1 PVC

21 Controller 1

22 Electric box cover 1 Galvanised plate

23 Terminal block 1

24 Main board 1

25 Relay 1

26 Electric box 1 Galvanised plate

27 Electric box bracket 1 Galvanised plate

28 Evaporator bracket 2 Galvanised plate

29 Top unit tray 1 Galvanised plate

30 Evaporator 1

31 Fan motor bracket 1 Galvanised plate

32 Fan motor 1

33 Fan blade 1 ASG20

34 Fan box 1

35 Fan box cover 1

36 EEV 1

37 Transition pipe 1 TP2M

38 Compressor 1

39 4 way valve 1

*The electric heating element is not included in EE-HWS-A1-220(-1) & EE-HWS-A1-270(-1)

INSTALLATION

19

All Emerald Energy heat pumps must be installed by a licensed

plumber in compliance with the guidelines specified in AS/NZS

3500.2, which pertains to the "National Plumbing and Drainage Code

for Hot Water Supply Systems - Acceptable Solutions."

CHOOSE A SUITABLE LOCATION

• Ideally, the Heat Pump should be installed outdoors. However,

for indoor installations, please ensure that the chosen location

complies with the requirements outlined in AS/NZS 5149.

• Make sure there is ample space for installation and maintenance,

with a recommended minimum vertical distance of 300mm.

• The product must be installed in a dry environment free from

humidity.

• Ensure that the supporting surface is level (with a horizontal angle

not exceeding 2°) and capable of bearing the weight of the heat

pump when filled with water. Refer to the technical data for the

heat pump's weight.

• Choose a suitable outdoor location for the exhaust air vent, and

be sure to insulate the exhaust air ducting to prevent condensa-

tion when the system is in operation.

• Ensure there is easy access to the system for maintenance pur-

poses.

• Always provide extra space for pipe connections and power

cables.

• Avoid installing the product on a surface with loose coverings,

as it may produce excess noise during operation.

• Avoid installing the product in areas with toxic gases or mineral

oils, as these locations are not suitable.

• When installing near a coastline within 500 meters, be mindful

that extra maintenance may be necessary. Insucient shelter

from coastal conditions can shorten the system's lifespan and

potentially void the warranty.

If you install the product in an environment prone to frost,

take all necessary precautions to ensure proper insulation

of all pipework.

TRANSPORTING THE HEAT PUMP

• To ensure the warranty remains valid, it's crucial to store and

transport Emerald heat pumps in an almost upright position with

a tilt angle of no more than 30°. Storing or transporting the unit

horizontally will void the warranty.

• Always transport the system while it's inside it's packaging.

• The packaged system weighs 138KG for models EE-HWS-A1-220

and EE-HWS-A1-220E, and 156KG for models EE-HWS-A1-270 and

EE-HWS-A1-270E. For safe handling and to prevent damage, it's

necessary to have two people carry the system at all times.

• Please be aware that the external casing of the unit is prone to

denting and damage. When moving the unit, exercise care and

caution, as any marks caused by improper handling are not

considered defects and are not covered under the warranty.

MINIMUM INDOOR INSTALLATION

REQUIREMENTS

• The indoor area for heat pump installation should exceed the

following sises:

For a 220L unit, the area should be at least 67m².

For a 270L unit, the area should be at least 47m².

For a 320L unit, the area should be at least 29m²

• If the heat pump must be installed in a smaller indoor space but is

connected to an adjacent room, there must be a fixed open door

connecting the rooms. A fixed open door cannot be closed under

any circumstances.

• Place heat pumps a safe distance away from potential ignition

sources or corrosive environments to prevent the risk of fire or

damage.

• Consider the serviceability of the heat pump during installation,

ensuring there is enough space for maintenance and repair tasks.

• Follow all relevant electrical and safety standards during.

• Regularly perform maintenance and inspections on both the heat

pump and the ventilation system to ensure safe and ecient

operation.

Always remember installers must diligently adhere to all Australian

standards. Our guidelines should be viewed as supplementary

information and do not override established standards.

Pallet for

transportation

only

Do not tilt

beyond 30º

INSTALLATION

20

INSTALLATION OF THE HEAT PUMP

1. BASE

• The unit must be installed on a concrete plinth or a stable structure

capable of supporting weights exceeding 400kg. It's crucial that

the supporting structure remains stable over time and does not

shift, especially due to factors like water drainage. You'll need

a concrete base that's at least 50mm thick or a well-seasoned

hardwood slat with a minimum thickness of 25mm. If you're using

concrete base pavers, make sure they have a minimum dimension

of 600mm x 600mm.

• Make sure all four feet of the unit are supported by the base you're

using to avoid any potential warranty issues.

• Ensure proper drainage is in place to handle any potential

overflow.

• During installation, it's essential to position the unit completely

vertically and level to facilitate proper condensate drainage.

If the system is installed with a tilt exceeding 3° it could void the

warranty.

• If there's a risk of property damage due to water leakage, you must

install a safety tray, also known as an overflow tray.

2. AIR FLOW

• Do not install the unit in areas where there is a risk of falling

debris, such as leaves, as this could block air vents or cause

damage to the unit.

• Avoid placing the system in locations with multiple walls or

structures.

• When installing the unit under fixtures or home eaves, follow

these clearance requirements:

- Maintain a minimum clearance of 300mm above the unit.

- Provide a 600mm clearance to the right side of the system

(when facing it).

- Allow for a 150mm clearance to the left side of the system

(when facing it).

- Position the unit at least 150mm away from your home's wall to

ensure full access for servicing and to prevent cold air circulation.

• Install the unit to ensure that the control interface is easily

accessible for users. There should be clear access to the

electrical panel located at the back of the system. Improper

installation could result in voiding the warranty or require

additional charges to rectify the system's compliance.

WARNING

• A minimum of 20m3 of unobstructed space surrounding the unit.

• For indoor installations the ensure that the location complies with

the requirements of AS/NZS 5149.

• The electrical access point and display panel should always be

accessible.

VENTILATION GUIDELINES:

These guidelines pertain to the proper operation of the heat pump

and are not related to the storage of flammable refrigerants. It's

important to ensure that the location complies with AS/NZS 5149

requirements.

Ideally, the heat pump should be installed outdoors. However, for

indoor installations, it's crucial to be aware of potential issues and

take preventive measures.

One significant concern with indoor installations is the risk of air

recirculation. In confined spaces, the air temperature can gradually

decrease, leading to a decrease in the heat pump's eciency and,

in some cases, even failure.

To prevent this, make sure the ambient air temperature doesn't drop

below 5°C. Continuously monitor the air temperature within the space

to ensure adequate ventilation throughout the heat pump's lifetime.

To maintain a stable air temperature, consider the following

recommendations:

• For indoor installations, choose spaces with an air volume greater

than 53m³.

• If the area is smaller than 53m³, ensure cross ventilation. Cross

ventilation can be achieved either naturally or mechanically.

• Natural ventilation occurs when there are appropriately sized

openings on opposite ends of the enclosure, facilitating cross

airflow.

• When using mechanical ventilation through a supply or extract fan,

ensure a minimum air volume of 1000 m³/h (278 L/s).

• In mechanically ventilated areas, establish a make-up air pathway.

This can take the form of grilles, undercut doors, open doors, open

windows, etc.

• To achieve eective cross ventilation, position the make-up air

pathway on the opposite side of the enclosure from the fan.

fan exhaust

300mm

600mm

150mm

PLUMBING CONNECTIONS

21

PLUMBING CONNECTIONS

COLD WATER SUPPLY OUTLET

• The cold water supply connection uses a G 3/4″ female thread.

• To connect the cold water supply, use a G 3/4″ socket.

• The cold water supply outlet can also serve as a drainage point for

emptying the system.

HOT WATER CONNECTION

• The hot water supply connection also uses a G 3/4″ female thread.

• Connect the hot water supply using a G 3/4″ socket.

• To ensure thermal eciency, insulate all hot water lines and

connections with a minimum 13mm closed-cell insulation.

• All hot water supply components must be made of copper.

CONDENSATE DRAIN

• When heat is extracted from the atmosphere through evaporator

coils, it generates condensation in the form of water. In places with

higher humidity, this condensation occurs at a faster rate.

• To collect the water by-product, a condensate tray is placed at the

base of the heat pump. Any surplus water from this tray is chan-

neled through the condensate drain.

• The system comes with a pre-installed condensate drain connection

elbow. It is essential to route the condensate into the nearest storm

water drain using a drainage pipe. Failing to do so could lead to

issues like termite attraction and the growth of algae and moss.

• Ensure that the condensate line is free of kinks, and since the water

relies on gravity for flow, it should only run downward to facilitate

unobstructed water flow.

PRESSURE & TEMPERATURE RELIEF TPR VALVE

• The system comes with a TPR (Temperature and Pressure Relief)

valve that matches the water heater tank's pressure rating. If the

TPR valve is missing, please get in touch with your supplier.

The valve is rated with a capacity of 850kPa, 10kW, and a set

temperature range of 93-99°C.

• Install the provided TPR valve at Point 4, as indicated above.

• Ensure that the TPR valve is insulated with a minimum 13mm

closed-cell insulation to minimise heat loss.

• The TPR should be positioned in a way that the drain line always

points downward, and the discharge point remains open to the

atmosphere.

• When connecting a discharge pipe to the pressure relief valve,

make sure it runs continuously downward and is placed in a frost-

free environment. Do not connect any pressure relief device to the

condensate drain pipe, as water may drip from the pressure relief

device's discharge pipe. This pipe should always be left open to

the atmosphere. Additionally, regularly operate the pressure relief

device to remove lime deposits and confirm it is not blocked.

1 Cold water supply outlet (G 3/4" female thread)

2 Hot water outlet (G 3/4" female thread)

3 Condensing drainage Elbow*

4 P&T Relief Valve* (G 1/2" female) (850k Pa)

5 Electrical cable

6 Tempering valve (high performance recommended)

7 Expansion control valve (ECV)

8 Pressure reduction valve (500k Pa)

9 Non-return/Isolation valve

10 Isolation switch (hardwired into 10 amp circuit)

* Supplied with system

Other manuals for EE-HWS-A1-220

1

This manual suits for next models

17

Table of contents

Other Emerald Heat Pump manuals

Popular Heat Pump manuals by other brands

Ariston

Ariston NIMBUS PLUS S NET manual

Goodman

Goodman SSZ 16 SEER Technical manual

Whirlpool

Whirlpool WHP43 installation instructions

Bryant

Bryant 541D Installation, operation and maintenance instructions

ElectroHeat

ElectroHeat ECO-V 5 Installation and operation manual

Daikin

Daikin Altherma 3 R F User reference guide