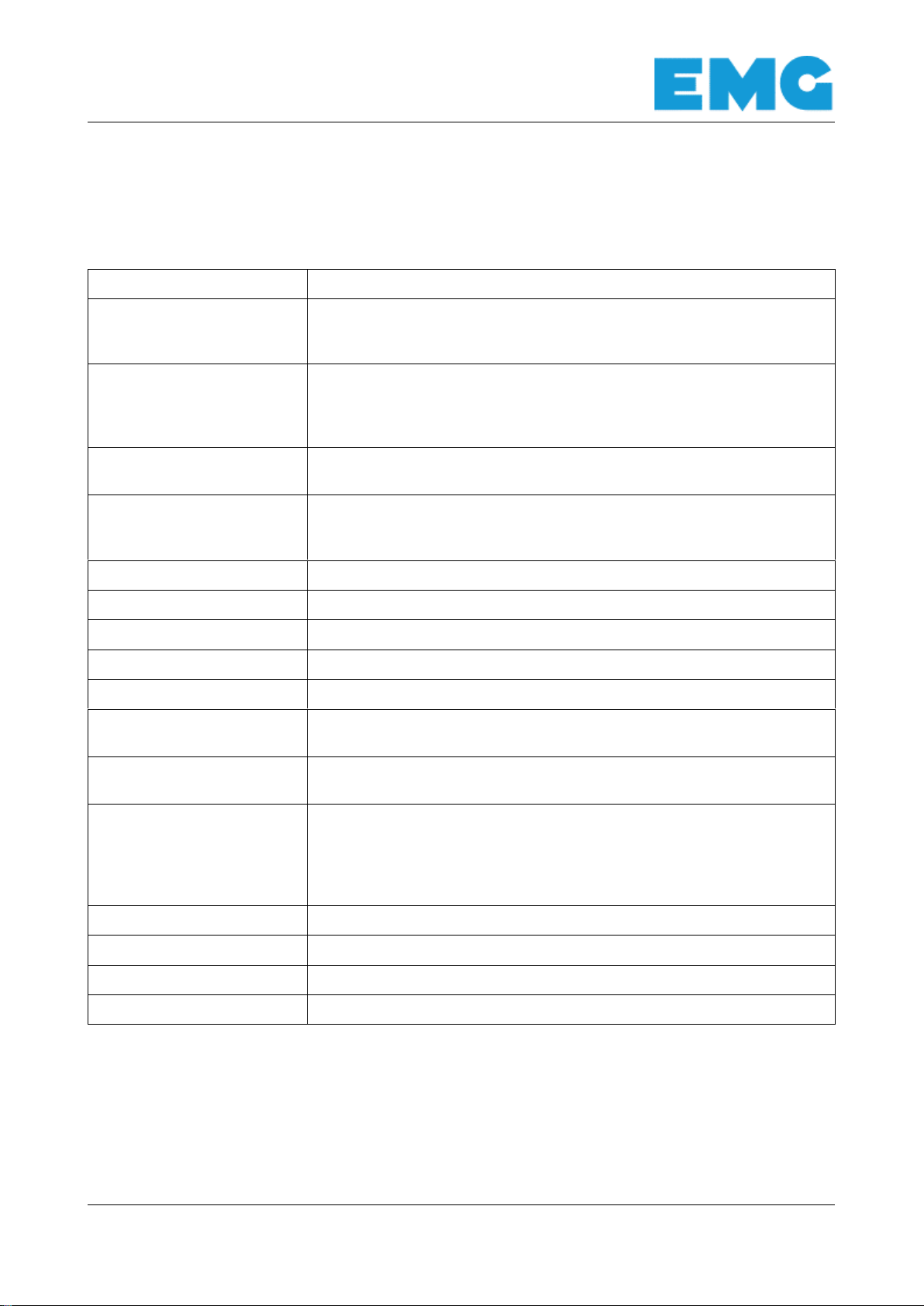

Table of contents

1General remarks......................................................................................... 6

1.1 Information about these Assembly Instructions ............................................................. 6

1.2 Manufacturer........................................................................................................................ 6

1.3 Validity.................................................................................................................................. 7

1.4 Additional applicable documents...................................................................................... 7

1.5 Formal information about these Assembly Instructions ................................................ 7

1.6 Typographical conventions ............................................................................................... 8

1.7 Structure of warnings......................................................................................................... 9

1.8 Definitions and abbreviations............................................................................................ 10

2Safety.......................................................................................................... 11

2.1 Use as intended................................................................................................................... 11

2.2 Improper use........................................................................................................................ 12

2.3 Qualification of personnel.................................................................................................. 12

2.3.1 Trained personnel ................................................................................................................. 13

2.3.2 Trained electrician................................................................................................................. 13

2.3.3 Maintenance personnel......................................................................................................... 14

2.3.4 Responsible personnel.......................................................................................................... 15

2.4 Personal protective equipment.......................................................................................... 16

2.5 Electrical operating equipment.......................................................................................... 16

2.6 Operating materials and supplies ..................................................................................... 17

2.7 Alterations............................................................................................................................ 17

2.8 Spare and wear parts.......................................................................................................... 17

3Technical data............................................................................................ 18

3.1 Type designations and type codes ................................................................................... 18

3.2 Information on the rating plate .......................................................................................... 19

3.3 Key data ............................................................................................................................... 20

3.4 Dimensions.......................................................................................................................... 22

3.4.1 Type Ed 23/5......................................................................................................................... 22

3.4.2 Type Ed 30/5......................................................................................................................... 24

3.4.3 Types Ed 50/6, Ed 80/6, Ed 50/12, Ed 80/12........................................................................ 25

3.4.4 Types Ed121, Ed185, Ed201, Ed301, Ed350, Ed450, Ed630, Ed500.................................. 28

3.5 Airborne noise emission .................................................................................................... 35

3.6 Operating conditions.......................................................................................................... 35

3.6.1 Ambient temperature............................................................................................................. 35

3.6.2 Humidity ................................................................................................................................ 36

3.6.3 Aggressive environmental conditions ................................................................................... 36

3.6.4 Voltage and frequency tolerances......................................................................................... 36